Content Menu

● Understanding Aluminum Extrusion

● The Role of Aluminum Extruded Heat Sinks

>> Key Features of Aluminum Extruded Heat Sinks:

● Applications of Aluminum Extrusion in Electronics

● Advantages of Using Aluminum Extrusions for Electronic Enclosures

>> Benefits of Aluminum Extruded Enclosures:

● Customization Capabilities

● Thermal Management Strategies with Aluminum Extrusion

>> 1. Optimizing Heat Sink Design

>> 2. Integrating Heat Pipes

>> 3. Surface Treatments

● Case Studies: Successful Implementations

● Future Trends in Aluminum Extrusion Technology

>> 1. Advanced Alloys

>> 2. Automation in Manufacturing

>> 3. Sustainability Practices

● Conclusion

● FAQ

>> 1. What is aluminum extrusion?

>> 2. Why is aluminum preferred over copper for heat sinks?

>> 3. How do aluminum extruded heat sinks work?

>> 4. Can aluminum extrusions be customized?

>> 5. Are aluminum enclosures effective at protecting electronic components?

● Citations:

In today's fast-paced technological landscape, electronic devices are becoming increasingly powerful while simultaneously shrinking in size. This evolution has led to a significant challenge: effective thermal management. As components generate more heat, the need for efficient cooling solutions has never been more critical. One of the most effective and widely adopted methods for addressing this issue is aluminum extrusion, particularly in the form of heat sinks and electronic enclosures. This article delves into how aluminum extrusion can significantly enhance the cooling of electronic devices.

Understanding Aluminum Extrusion

Aluminum extrusion is a manufacturing process that involves forcing aluminum through a die to create specific shapes and profiles. This process allows for the creation of complex geometries that are highly effective in dissipating heat. The characteristics of aluminum, such as its excellent thermal conductivity, lightweight nature, and corrosion resistance, make it an ideal material for cooling applications.

Benefits of Aluminum Extrusion:

- High Thermal Conductivity: Aluminum has superior thermal conductivity compared to many other materials, allowing it to efficiently transfer heat away from electronic components.

- Lightweight and Strong: The low density of aluminum makes it an excellent choice for portable devices where weight is a concern.

- Design Flexibility: The extrusion process allows for intricate designs that can be customized to meet specific thermal management needs.

- Cost-Effectiveness: Aluminum is generally less expensive than other metals like copper, making it a more economical choice for mass production.

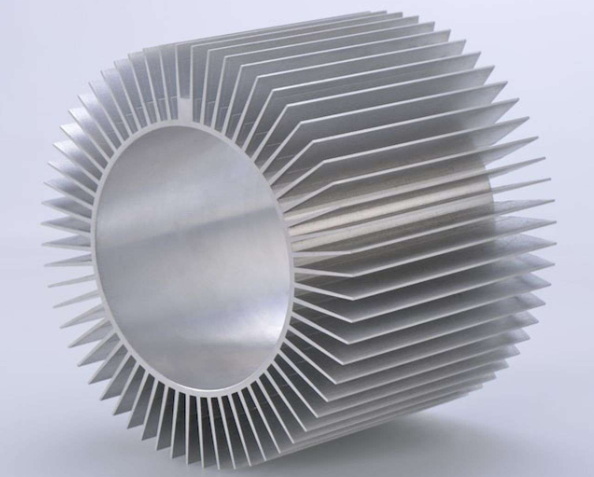

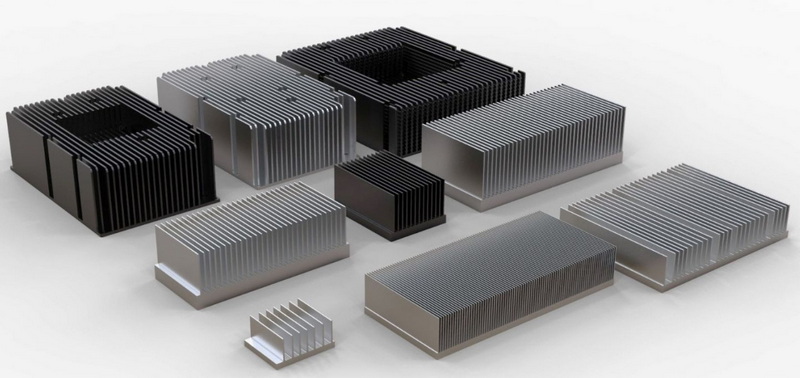

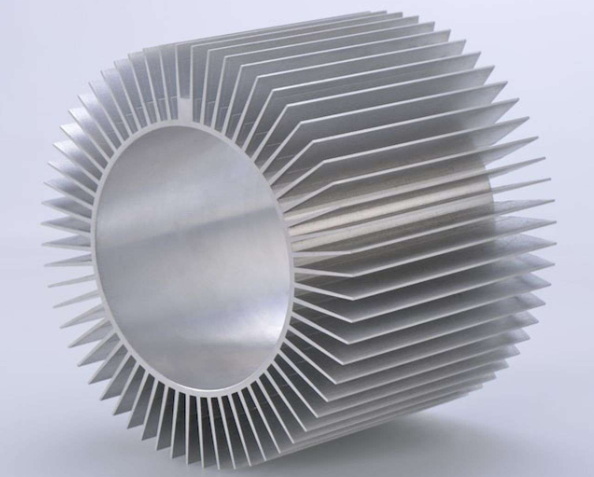

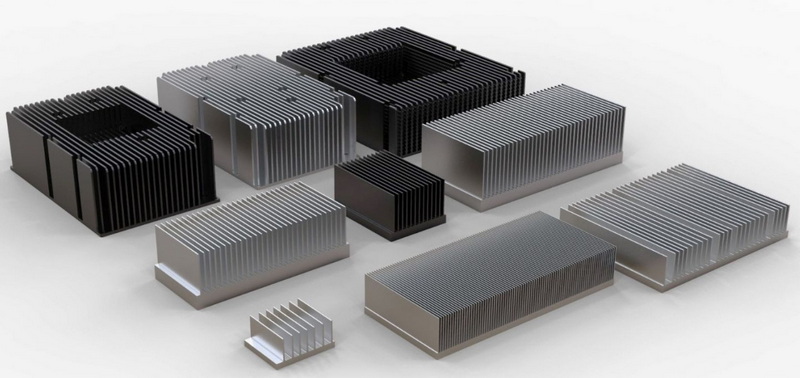

The Role of Aluminum Extruded Heat Sinks

Heat sinks are essential components in electronic devices, designed to absorb and dissipate heat generated by high-performance components such as CPUs and GPUs. Aluminum extruded heat sinks are particularly effective due to their design and material properties.

Key Features of Aluminum Extruded Heat Sinks:

- Increased Surface Area: The extrusion process enables the creation of fins and other structures that increase the surface area available for heat dissipation, enhancing cooling efficiency.

- Passive Cooling Solutions: Unlike active cooling systems that require fans or pumps, aluminum heat sinks operate passively, relying on natural convection to dissipate heat. This results in quieter operation and reduced energy consumption.

- Custom Profiles: Manufacturers can create custom profiles tailored to specific applications, ensuring optimal thermal performance based on device requirements.

Applications of Aluminum Extrusion in Electronics

Aluminum extrusion plays a vital role in various electronic applications where effective cooling is paramount. Here are some common uses:

- Consumer Electronics: In devices like laptops and smartphones, aluminum extruded heat sinks help manage heat from processors and graphics cards, ensuring optimal performance without overheating.

- LED Lighting: LED fixtures often use aluminum extrusions as heat sinks to maintain performance and extend lifespan by preventing overheating.

- Telecommunications Equipment: Routers and switches benefit from aluminum extruded enclosures that provide both protection and effective thermal management.

- Automotive Electronics: With the increasing integration of electronics in vehicles, aluminum extrusions are used to cool components like ECUs (Electronic Control Units) and infotainment systems.

Advantages of Using Aluminum Extrusions for Electronic Enclosures

In addition to heat sinks, aluminum extrusions are also widely used for creating electronic enclosures. These enclosures provide protection for sensitive components while facilitating effective cooling.

Benefits of Aluminum Extruded Enclosures:

- Enhanced Heat Dissipation: Compared to plastic enclosures, aluminum offers superior thermal management capabilities, allowing heat generated by internal components to escape efficiently.

- Durability and Protection: Aluminum enclosures provide robust protection against environmental factors such as moisture and dust, ensuring the longevity of electronic devices.

- Easy Installation: Many extruded aluminum enclosures come with features like card guides for easy installation of printed circuit boards (PCBs), streamlining assembly processes.

Customization Capabilities

One of the standout features of aluminum extrusion is its ability to be customized extensively. Manufacturers can design profiles that meet specific dimensions, shapes, and thermal requirements. This flexibility ensures that each application can have a tailored solution that maximizes cooling efficiency while minimizing costs.

Thermal Management Strategies with Aluminum Extrusion

To fully leverage the benefits of aluminum extrusion in cooling electronic devices, several thermal management strategies can be employed:

1. Optimizing Heat Sink Design

The design of aluminum extruded heat sinks can be optimized through computational fluid dynamics (CFD) simulations. These simulations help engineers understand airflow patterns around the heat sink and adjust the design accordingly. By increasing the number or height of fins or altering their spacing, manufacturers can significantly improve heat dissipation rates.

2. Integrating Heat Pipes

For applications requiring even more efficient cooling solutions, integrating heat pipes with aluminum extrusions can enhance thermal performance further. Heat pipes utilize phase change principles to transfer heat away from critical components rapidly. When combined with an aluminum extruded structure, they can create highly effective thermal management systems suitable for high-performance applications.

3. Surface Treatments

Applying surface treatments such as anodizing or powder coating can improve the thermal performance of aluminum extrusions by increasing their emissivity—how effectively they radiate heat away from surfaces. Anodized surfaces also provide additional corrosion resistance, extending the lifespan of electronic enclosures and heat sinks.

Case Studies: Successful Implementations

Several industries have successfully implemented aluminum extrusion solutions for cooling electronic devices:

- Consumer Electronics Industry: Major smartphone manufacturers have adopted aluminum extruded frames not only for structural integrity but also for their ability to dissipate heat effectively during intensive tasks like gaming or video streaming.

- LED Lighting Solutions: Companies producing LED lighting systems have utilized custom-designed aluminum extrusions as both housing and heat sinks. This dual functionality enhances both aesthetics and performance while reducing overall weight.

- Automotive Sector: In electric vehicles (EVs), where battery management is crucial, manufacturers have turned to aluminum extrusion for battery enclosures that allow efficient cooling while maintaining structural integrity under varying conditions.

Future Trends in Aluminum Extrusion Technology

As technology progresses, several trends are emerging within the realm of aluminum extrusion that could further enhance its role in cooling electronic devices:

1. Advanced Alloys

The development of new aluminum alloys with improved thermal conductivity properties could lead to even more efficient cooling solutions. These advanced materials may also offer better mechanical properties at elevated temperatures, making them suitable for high-performance applications.

2. Automation in Manufacturing

The integration of automation technologies in the extrusion process could streamline production lines, reduce costs, and improve precision in creating complex profiles tailored for specific applications.

3. Sustainability Practices

With an increasing focus on sustainability within manufacturing processes, companies are exploring ways to recycle scrap material generated during extrusion processes effectively. This not only reduces waste but also lowers production costs associated with raw materials.

Conclusion

Aluminum extrusion has emerged as a critical technology in the realm of electronic device cooling solutions. Its combination of high thermal conductivity, lightweight properties, design flexibility, and cost-effectiveness makes it an ideal choice for both heat sinks and electronic enclosures. As technology continues to advance and devices become more compact yet powerful, the role of aluminum extrusions in managing heat will only grow more significant. By leveraging these advantages, manufacturers can ensure their products operate reliably while extending component lifespans and enhancing overall performance.

FAQ

1. What is aluminum extrusion?

Aluminum extrusion is a manufacturing process where aluminum is forced through a die to create specific shapes or profiles suitable for various applications such as heat sinks or enclosures.

2. Why is aluminum preferred over copper for heat sinks?

While copper has better thermal conductivity than aluminum, it is heavier and more expensive. Aluminum's lightweight nature combined with its good thermal properties makes it a more practical choice for many applications.

3. How do aluminum extruded heat sinks work?

Aluminum extruded heat sinks work by absorbing heat from electronic components and dissipating it into the surrounding air through increased surface area created by fins or other designs.

4. Can aluminum extrusions be customized?

Yes, one of the main advantages of aluminum extrusion is its ability to be customized into various shapes and sizes to meet specific thermal management needs for different devices.

5. Are aluminum enclosures effective at protecting electronic components?

Yes, aluminum enclosures provide robust protection against environmental factors such as moisture and dust while also facilitating effective thermal management through their excellent conductivity properties.

Citations:

[1] https://proleantech.com/advantages-of-aluminium-extruded-heat-sink-solutions-in-modern-electronics/

[2] https://www.hydro.com/profiles/aluminum-heat-sink

[3] https://www.budind.com/nema-ip-rated-boxes-extruded-aluminum/?load=true

[4] https://kimsen.vn/heat-sink-applications-of-aluminum-extrusions:-cooling-solutions-for-electronic-devices-ne132.html

[5] https://www.tensilemillcnc.com/blog/12-major-benefits-of-aluminum-extrusions

[6] https://www.budind.com/series/general-use-boxes/ext-series-extruded-aluminum-enclosures/

[7] https://www.otalum.com/the-role-of-aluminum-heatsink-extrusion-profiles-in-electronics.html

[8] https://www.linkedin.com/pulse/custom-aluminum-extrusion-heat-sinks-enhanced-thermal-doman-agtor-dd8lc

[9] https://pioneerthermal.com/the-complete-guide-to-aluminum-heat-sink-extrusion-benefits-uses/

[10] https://www.linkedin.com/pulse/benefits-using-aluminum-extruded-heat-sink-solutions-eason-sjhm-3iroc