Content Menu

● Understanding Aluminum Extrusion

>> Key Benefits of Aluminum Extrusion

● The Role of Aluminum Extrusion Feet

● Applications of Aluminum Extrusion Feet

● How Aluminum Extrusion Feet Improve Durability

>> 1. Material Strength

>> 2. Corrosion Resistance

>> 3. Impact Resistance

>> 4. Thermal Stability

● Conclusion

● FAQ

>> 1. What are aluminum extrusion feet made from?

>> 2. Can aluminum extrusion feet be adjusted?

>> 3. Are aluminum extrusion feet suitable for outdoor use?

>> 4. How do I install aluminum extrusion feet?

>> 5. What industries commonly use aluminum extrusion feet?

● Citations:

Aluminum extrusion feet are essential components that enhance the durability and functionality of various designs across multiple industries. Their unique properties, combined with the benefits of aluminum extrusion, make them a preferred choice for engineers and designers aiming to create robust and long-lasting products. This article will explore how aluminum extrusion feet can significantly improve the durability of your design, delve into their applications, and address common questions regarding their use.

Understanding Aluminum Extrusion

Aluminum extrusion is a manufacturing process that involves shaping aluminum alloy into a desired cross-sectional profile. This process begins with heating an aluminum billet until it becomes malleable, after which it is forced through a die to create specific shapes. The result is a lightweight yet strong material that can be used in various applications, from architectural components to industrial machinery.

Key Benefits of Aluminum Extrusion

- Strength and Durability: Aluminum extrusions are known for their high strength-to-weight ratio, making them ideal for structures that require both lightweight and robust characteristics.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which helps resist corrosion, especially in harsh environments.

- Design Flexibility: The extrusion process allows for complex shapes and designs that can be tailored to specific applications.

- Cost-Effectiveness: Aluminum extrusion is a cost-effective manufacturing method due to its efficiency and minimal waste production.

The Role of Aluminum Extrusion Feet

Aluminum extrusion feet serve as the foundational support for various structures made from aluminum profiles. They play a crucial role in enhancing the stability and durability of designs by providing:

- Enhanced Stability: By distributing weight evenly across the base of the structure, aluminum extrusion feet prevent wobbling and tipping, ensuring that the design remains stable under load.

- Vibration Dampening: These feet can absorb vibrations, reducing wear on both the supporting structure and any equipment mounted on it.

- Height Adjustment: Many aluminum extrusion feet come with adjustable features, allowing for precise leveling of structures on uneven surfaces.

Applications of Aluminum Extrusion Feet

Aluminum extrusion feet are versatile components used in numerous applications:

- Furniture: In modern furniture design, aluminum feet provide stability while maintaining an aesthetic appeal. They can be found in tables, chairs, and shelving units.

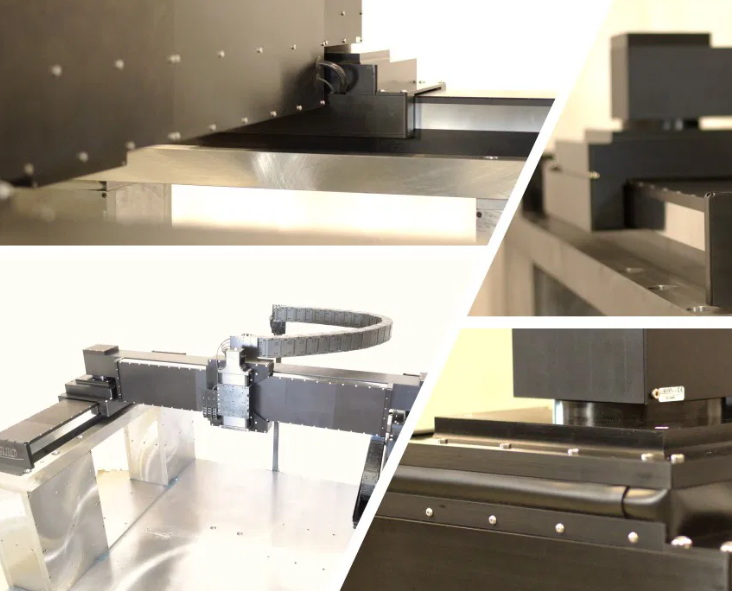

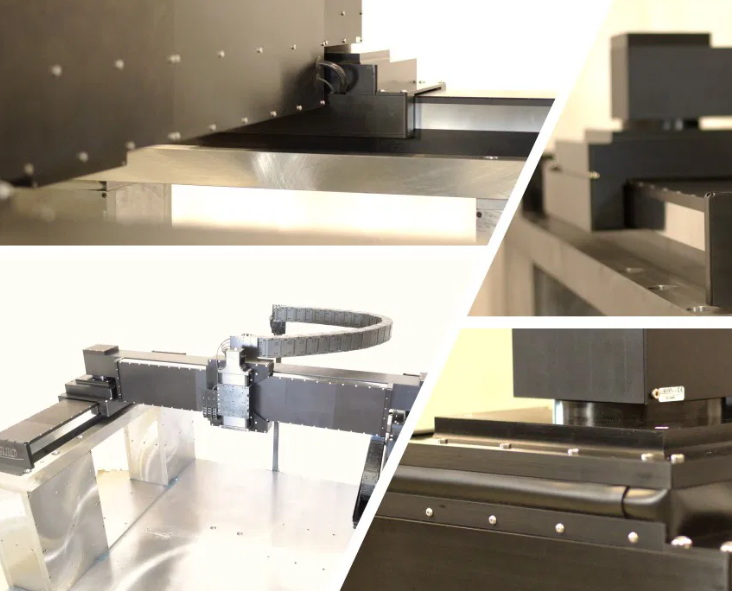

- Industrial Equipment: Many industrial machines utilize aluminum extrusion feet to ensure stability during operation, particularly in environments where vibrations are prevalent.

- Architectural Structures: In construction, aluminum feet are used to support railings, awnings, and other architectural features that require robust support without adding excessive weight.

How Aluminum Extrusion Feet Improve Durability

The integration of aluminum extrusion feet into your design can lead to enhanced durability through several mechanisms:

1. Material Strength

Aluminum is inherently strong yet lightweight. When used as feet for extruded structures, it provides a solid foundation that can withstand significant loads without bending or breaking. This strength is particularly important in high-traffic areas or where heavy equipment is involved.

2. Corrosion Resistance

The corrosion-resistant properties of aluminum mean that even in outdoor or damp environments, the feet will not degrade over time. This longevity reduces the need for frequent replacements or repairs, ultimately lowering maintenance costs.

3. Impact Resistance

Aluminum extrusion feet can absorb impacts better than many other materials. This characteristic is vital in applications where accidental bumps or drops may occur, ensuring that the overall structure remains intact and functional.

4. Thermal Stability

Aluminum has excellent thermal conductivity properties. This means that it can manage temperature fluctuations without warping or compromising structural integrity. In environments subject to temperature changes, aluminum extrusion feet help maintain stability and performance.

Conclusion

Incorporating aluminum extrusion feet into your design enhances durability through their strength, corrosion resistance, impact absorption capabilities, and thermal stability. Whether you're designing furniture, industrial equipment, or architectural structures, these components offer significant advantages that contribute to long-lasting performance and reliability. By choosing aluminum extrusion feet for your projects, you ensure a stable foundation that withstands the test of time while also benefiting from the versatility and cost-effectiveness inherent in aluminum extrusions.

FAQ

1. What are aluminum extrusion feet made from?

Aluminum extrusion feet are typically made from high-quality aluminum alloys designed for strength and durability.

2. Can aluminum extrusion feet be adjusted?

Yes! Many aluminum extrusion feet feature adjustable heights to accommodate uneven surfaces and ensure stability.

3. Are aluminum extrusion feet suitable for outdoor use?

Absolutely! Their corrosion-resistant properties make them ideal for outdoor applications where exposure to moisture is a concern.

4. How do I install aluminum extrusion feet?

Installation usually involves securing them to the base of your structure using screws or bolts compatible with the specific profile design.

5. What industries commonly use aluminum extrusion feet?

Industries such as furniture manufacturing, construction, automotive, and aerospace frequently utilize aluminum extrusion feet due to their strength and versatility.

Citations:

[1] https://www.otalum.com/the-unmatched-strength-and-durability-of-extruded-aluminum-handrails.html

[2] https://americandouglasmetals.com/2024/05/19/understanding-the-aluminum-extrusion-process/

[3] https://www.tensilemillcnc.com/blog/12-major-benefits-of-aluminum-extrusions

[4] https://in.misumi-ec.com/vona2/mech/M1500000000/M1501000000/M1501140000/

[5] https://www.youtube.com/watch?v=P8BWQBP4Vhk

[6] https://www.psiextrusions.com/blog/the-aluminum-extrusion-process/

[7] https://leadrp.net/pt/blog/a-complete-guide-to-aluminum-extrusion/

[8] https://www.pennex.com/press/the-steps-of-aluminum-extrusion

[9] https://www.youtube.com/watch?v=gJIChIs4g6A

[10] https://www.wileymetal.com/five-common-applications-of-aluminum-extrusion/