Content Menu

● Understanding 80/20 Aluminum Extrusion Profiles

>> Key Features of 80/20 Aluminum Extrusions

● Benefits of Using 80/20 Aluminum Extrusion Profiles in DIY Projects

>> Flexibility in Design

>> Cost-Effectiveness

>> Enhanced Aesthetics

>> Improved Structural Integrity

>> Easy Integration with Other Materials

● Applications of 80/20 Aluminum Extrusion Profiles

>> Furniture Design

>> Robotics and Automation

>> Workstations and Tool Racks

>> Display Stands and Exhibits

>> Home Improvement Projects

● Tips for Working with 80/20 Aluminum Extrusion Profiles

>> Plan Your Design

>> Use the Right Tools

>> Take Advantage of Accessories

>> Experiment with Different Configurations

>> Keep Safety in Mind

● Conclusion

● Frequently Asked Questions

>> 1. What are 80/20 aluminum extrusion profiles?

>> 2. What are the advantages of using aluminum extrusion profiles in DIY projects?

>> 3. Can I use aluminum extrusion profiles for outdoor projects?

>> 4. What tools do I need to work with aluminum extrusion profiles?

>> 5. How do I ensure the stability of my projects using aluminum extrusion profiles?

In the world of DIY projects, versatility and adaptability are key. Whether you are building furniture, creating custom frames, or designing intricate mechanical systems, having the right materials can make all the difference. One such material that has gained immense popularity among DIY enthusiasts and professionals alike is the 80/20 aluminum extrusion profile. This article explores how these profiles can enhance your DIY projects, providing insights into their benefits, applications, and tips for effective use.

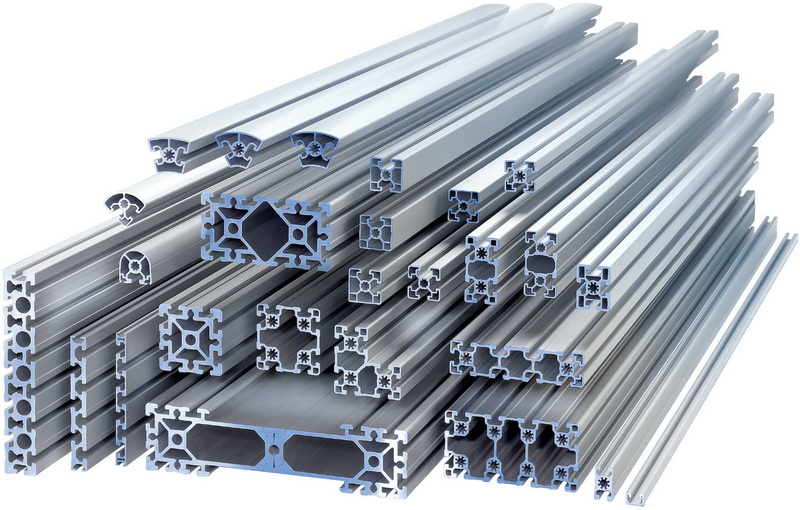

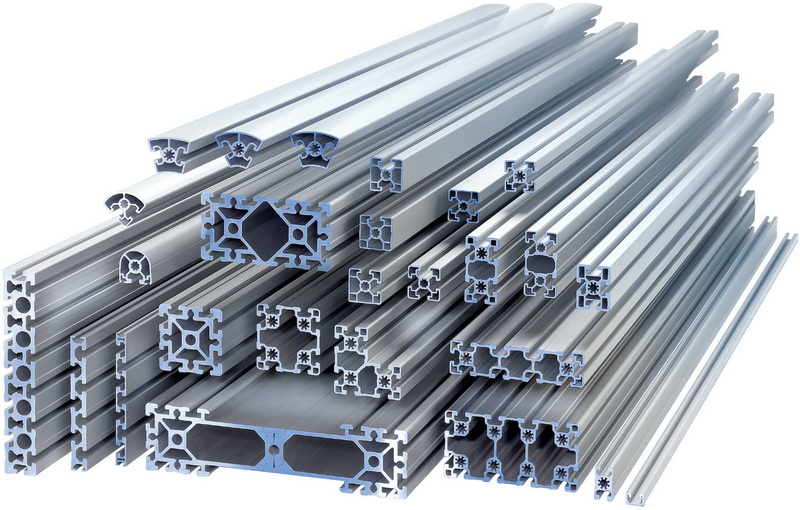

Understanding 80/20 Aluminum Extrusion Profiles

80/20 aluminum extrusion profiles are structural components made from high-quality aluminum. They feature a unique T-slot design that allows for easy assembly and disassembly without the need for specialized tools. This modularity makes them ideal for a wide range of applications, from simple furniture to complex machinery.

Key Features of 80/20 Aluminum Extrusions

1. Modularity: The T-slot design allows for endless configurations, making it easy to adapt your project as needed.

2. Lightweight yet Strong: Aluminum is known for its strength-to-weight ratio, making these profiles both durable and easy to handle.

3. Corrosion Resistance: Aluminum naturally resists corrosion, ensuring that your projects last longer, even in challenging environments.

4. Ease of Assembly: With simple connectors and fasteners, you can quickly assemble and disassemble your projects without the need for welding or heavy machinery.

Benefits of Using 80/20 Aluminum Extrusion Profiles in DIY Projects

Flexibility in Design

One of the most significant advantages of using 80/20 aluminum extrusion profiles is their flexibility. You can create anything from a simple shelf to a complex robotic arm. The ability to easily modify your design as you go allows for creativity and innovation. This flexibility is particularly beneficial for those who enjoy experimenting with different configurations and designs, as it encourages a trial-and-error approach without the fear of wasting materials.

Cost-Effectiveness

While the initial investment in aluminum extrusion profiles may seem higher than traditional materials, the long-term savings are substantial. The durability and reusability of these profiles mean you can repurpose them for future projects, reducing waste and costs over time. Additionally, the ease of assembly can save you time and labor costs, making it a smart investment for both hobbyists and professionals.

Enhanced Aesthetics

Aluminum has a modern and sleek appearance that can enhance the overall look of your project. Whether you are building furniture or creating a display stand, the clean lines of aluminum extrusion profiles can add a professional touch. This aesthetic appeal is particularly important for projects that will be displayed in public or used in professional settings, as it reflects a level of craftsmanship and attention to detail.

Improved Structural Integrity

The strength of aluminum extrusion profiles allows for the construction of robust structures that can support significant weight. This is particularly important for projects that require stability, such as workbenches or shelving units. The ability to create strong, stable designs means you can confidently use these profiles in a variety of applications, knowing they will hold up under pressure.

Easy Integration with Other Materials

80/20 aluminum extrusion profiles can be easily integrated with other materials, such as wood, plastic, or glass. This versatility allows you to create hybrid designs that leverage the strengths of multiple materials. For example, combining aluminum with wood can create a warm, inviting look while maintaining the structural benefits of aluminum.

Applications of 80/20 Aluminum Extrusion Profiles

Furniture Design

DIY furniture projects are among the most popular uses for aluminum extrusion profiles. From tables and chairs to shelving units, the modular nature of these profiles allows for endless design possibilities. You can create custom furniture that fits your space perfectly, whether you need a compact desk for a small apartment or a large conference table for a meeting room.

Robotics and Automation

In the field of robotics, 80/20 aluminum extrusion profiles are often used to build frames for robotic arms, mobile platforms, and other automated systems. Their strength and lightweight nature make them ideal for applications where precision and mobility are crucial. The ability to easily modify and expand these structures allows engineers and hobbyists to innovate and improve their designs continuously.

Workstations and Tool Racks

Creating a custom workstation or tool rack is another excellent application for aluminum extrusion profiles. You can design a workspace that meets your specific needs, incorporating shelves, drawers, and tool holders for maximum efficiency. This customization can lead to a more organized and productive workspace, allowing you to focus on your projects without the distraction of clutter.

Display Stands and Exhibits

For those involved in marketing or exhibitions, aluminum extrusion profiles can be used to create eye-catching display stands. Their sleek design and structural integrity make them perfect for showcasing products at trade shows or retail environments. The ability to create custom displays that can be easily assembled and disassembled is a significant advantage for businesses that frequently change their marketing setups.

Home Improvement Projects

From building custom cabinets to creating unique lighting fixtures, the possibilities for home improvement projects using 80/20 aluminum extrusion profiles are virtually limitless. Their adaptability allows you to tackle a wide range of projects with ease. Whether you are renovating a room or building a new addition, these profiles can help you achieve your vision.

Tips for Working with 80/20 Aluminum Extrusion Profiles

Plan Your Design

Before you start cutting and assembling, take the time to plan your design thoroughly. Sketch out your project and determine the dimensions and materials you will need. This will save you time and materials in the long run. A well-thought-out plan can also help you identify potential challenges before you begin, allowing you to address them proactively.

Use the Right Tools

While aluminum extrusion profiles are easy to work with, having the right tools is essential. A miter saw, drill, and basic hand tools will help you achieve clean cuts and secure connections. Investing in quality tools can make a significant difference in the quality of your finished project.

Take Advantage of Accessories

80/20 offers a wide range of accessories, including brackets, connectors, and fasteners. Utilizing these accessories can enhance the stability and functionality of your projects. Accessories can also simplify the assembly process, making it easier to achieve a professional-looking result.

Experiment with Different Configurations

Don't be afraid to experiment with different configurations and designs. The modular nature of aluminum extrusion profiles allows you to try out various setups until you find the one that works best for your project. This experimentation can lead to innovative solutions and unique designs that set your projects apart.

Keep Safety in Mind

Always prioritize safety when working with tools and materials. Wear appropriate safety gear, such as goggles and gloves, and ensure your workspace is organized and free of hazards. Taking safety precautions can prevent accidents and injuries, allowing you to focus on your work.

Conclusion

80/20 aluminum extrusion profiles are a game-changer for DIY enthusiasts and professionals alike. Their versatility, strength, and ease of use make them an ideal choice for a wide range of projects. Whether you are building furniture, creating custom workspaces, or designing complex mechanical systems, these profiles can enhance your projects in countless ways.

By understanding the benefits and applications of 80/20 aluminum extrusion profiles, you can unlock new possibilities in your DIY endeavors. So gather your materials, plan your design, and start creating!

Frequently Asked Questions

1. What are 80/20 aluminum extrusion profiles?

80/20 aluminum extrusion profiles are structural components made from aluminum, featuring a T-slot design that allows for easy assembly and modification.

2. What are the advantages of using aluminum extrusion profiles in DIY projects?

The advantages include flexibility in design, cost-effectiveness, enhanced aesthetics, improved structural integrity, and easy integration with other materials.

3. Can I use aluminum extrusion profiles for outdoor projects?

Yes, aluminum is naturally resistant to corrosion, making it suitable for outdoor applications. However, consider using additional protective coatings for extended exposure to harsh environments.

4. What tools do I need to work with aluminum extrusion profiles?

Basic tools include a miter saw, drill, and hand tools. Specialized tools like T-slot nuts and connectors can also be beneficial.

5. How do I ensure the stability of my projects using aluminum extrusion profiles?

Use appropriate connectors and fasteners, and consider the weight distribution of your design. Planning and testing different configurations can also help ensure stability.