Content Menu

● Understanding Aluminum Extrusion

● The Aluminum Extrusion Process

>> Material Selection

>> Billet Preparation

>> Extrusion Process

>> Cooling and Cutting

>> Surface Treatment

>> Quality Control

>> Assembly and Fabrication

>> Final Inspection and Packaging

● Applications of Aluminum Extrusion Panels

● Advantages of Aluminum Extrusion Panels

● Future Trends in Aluminum Extrusion

● Conclusion

● Frequently Asked Questions

>> 1. What is the main advantage of using aluminum extrusion panels?

>> 2. How does the extrusion process work?

>> 3. What types of surface treatments are available for aluminum panels?

>> 4. Can aluminum extrusion panels be recycled?

>> 5. What industries commonly use aluminum extrusion panels?

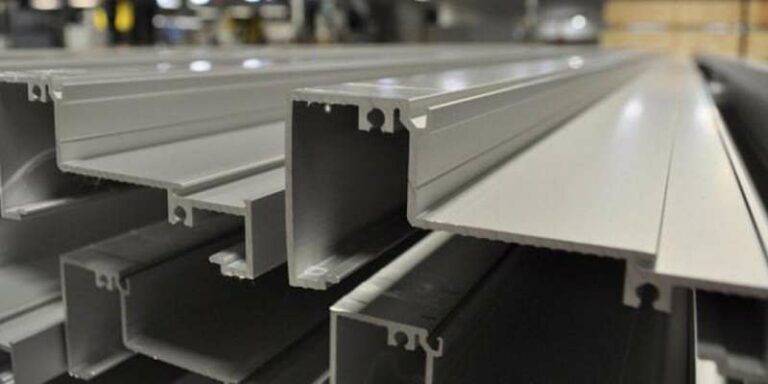

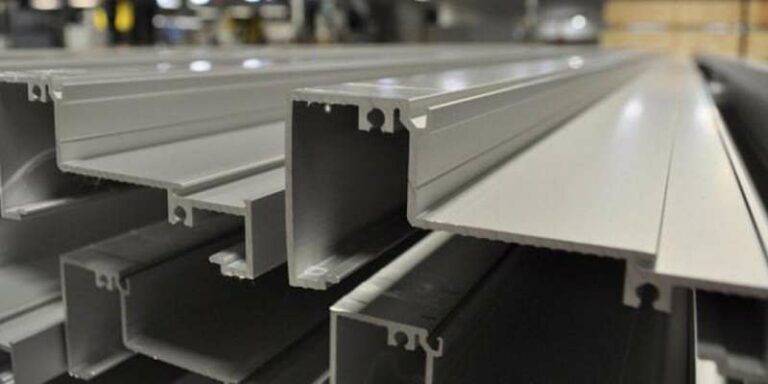

Aluminum extrusion panels are widely used in various industries due to their lightweight, durability, and versatility. The manufacturing process of these panels involves several steps, from the initial design to the final product. This article will explore the intricate process of how aluminum extrusion panels are manufactured and processed, providing insights into the technology and techniques involved.

Understanding Aluminum Extrusion

Aluminum extrusion is a process that involves shaping aluminum alloy into a desired cross-sectional profile. This is achieved by forcing the aluminum through a die, which gives it the desired shape. The process is highly efficient and allows for the production of complex shapes that can be used in a variety of applications, including construction, automotive, and aerospace industries.

The Aluminum Extrusion Process

Material Selection

The first step in the manufacturing of aluminum extrusion panels is selecting the appropriate aluminum alloy. Different alloys have different properties, such as strength, corrosion resistance, and workability. Common alloys used in extrusion include 6061 and 6063, which are known for their excellent mechanical properties and corrosion resistance. The choice of alloy can significantly impact the performance and durability of the final product.

Billet Preparation

Once the alloy is selected, it is formed into a billet, which is a solid piece of aluminum that will be heated and extruded. The billets are typically heated to a temperature of around 400 to 500 degrees Celsius to make them malleable. This heating process is crucial, as it allows the aluminum to flow easily through the die, ensuring a smooth extrusion process.

Extrusion Process

The heated billet is placed in a container and pushed through a die using a hydraulic press. The die is a specially designed tool that shapes the aluminum into the desired profile. As the aluminum is extruded, it cools and hardens, retaining the shape of the die. The extrusion process can produce a wide variety of shapes, including solid, hollow, and complex profiles, making it a versatile manufacturing method.

Cooling and Cutting

After the extrusion process, the newly formed aluminum profile is cooled, typically using air or water. This cooling process is essential to ensure that the aluminum retains its shape and properties. Once cooled, the extruded aluminum is cut into manageable lengths for further processing. The cutting process can be done using saws or shears, depending on the desired length and profile of the aluminum panels.

Surface Treatment

The extruded panels often undergo surface treatments to enhance their appearance and protect against corrosion. Common treatments include anodizing, painting, and powder coating. Anodizing involves creating a protective oxide layer on the surface, which increases corrosion resistance and allows for dyeing in various colors. Powder coating provides a durable finish that can be customized in various colors and textures, making it an attractive option for architectural applications.

Quality Control

Throughout the manufacturing process, quality control measures are implemented to ensure that the aluminum extrusion panels meet industry standards. This includes checking for dimensional accuracy, surface finish, and mechanical properties. Quality control is critical, as it ensures that the final product performs as expected and meets the specifications required by customers.

Assembly and Fabrication

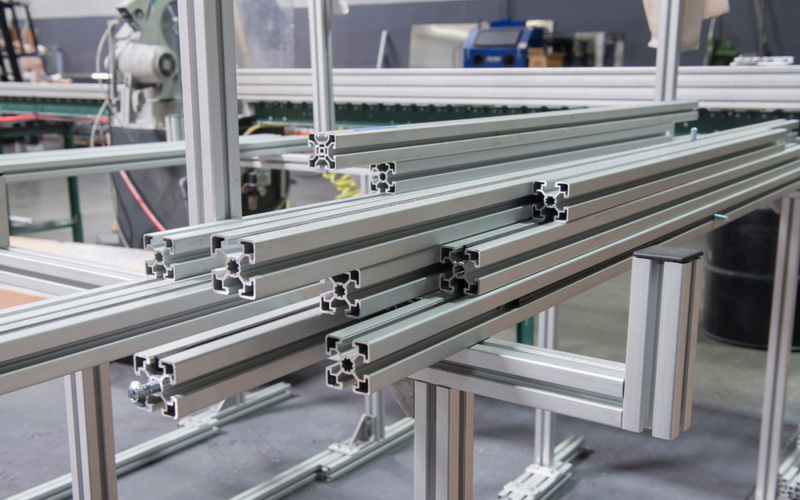

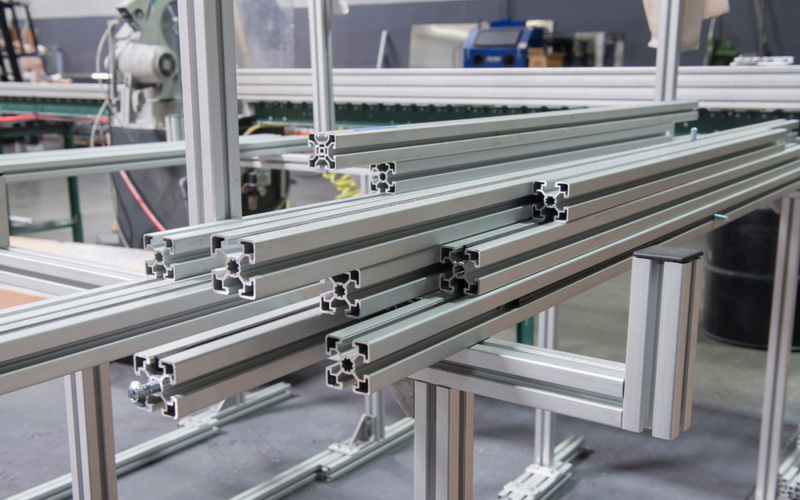

After passing quality control, the aluminum extrusion panels can be assembled into larger structures or fabricated into specific components. This may involve cutting, drilling, or welding the panels to create the final product. The versatility of aluminum extrusion allows for easy integration with other materials, making it a popular choice in various applications.

Final Inspection and Packaging

The final step in the manufacturing process is a thorough inspection of the finished panels. Once approved, the panels are packaged for shipment to customers or distributors. Proper packaging is essential to protect the panels during transportation and ensure they arrive at their destination in excellent condition.

Applications of Aluminum Extrusion Panels

Aluminum extrusion panels are used in a wide range of applications due to their unique properties. Some common uses include:

- Construction: Aluminum panels are used in building facades, window frames, and roofing systems due to their lightweight and corrosion-resistant nature. They provide aesthetic appeal and structural integrity, making them a preferred choice for modern architecture.

- Automotive: The automotive industry utilizes aluminum extrusion panels for lightweight structural components, improving fuel efficiency and performance. The use of aluminum in vehicles helps reduce overall weight, which can lead to better fuel economy and lower emissions.

- Aerospace: In aerospace applications, aluminum panels are used for aircraft structures, providing strength without adding excessive weight. The aerospace industry demands materials that can withstand extreme conditions while remaining lightweight, making aluminum an ideal choice.

- Furniture: Aluminum extrusion panels are also popular in furniture design, offering modern aesthetics and durability. Designers appreciate the flexibility of aluminum, allowing for innovative and functional furniture solutions.

- Electronics: Aluminum extrusion panels are used in the manufacturing of electronic enclosures and heat sinks. Their excellent thermal conductivity helps dissipate heat, ensuring the longevity and performance of electronic devices.

Advantages of Aluminum Extrusion Panels

The popularity of aluminum extrusion panels can be attributed to several advantages:

- Lightweight: Aluminum is significantly lighter than steel, making it easier to handle and transport. This lightweight nature reduces shipping costs and simplifies installation.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, making it resistant to corrosion and suitable for outdoor applications. This property extends the lifespan of aluminum products, reducing maintenance costs.

- Versatility: The extrusion process allows for the creation of complex shapes and profiles, making aluminum panels suitable for a wide range of applications. This versatility enables manufacturers to meet specific design requirements.

- Sustainability: Aluminum is recyclable, making it an environmentally friendly choice for manufacturers and consumers alike. The recycling process requires only a fraction of the energy needed to produce new aluminum, contributing to a more sustainable future.

- Aesthetic Appeal: Aluminum extrusion panels can be finished in various ways, including anodizing and powder coating, allowing for a wide range of colors and textures. This aesthetic flexibility makes aluminum a popular choice in architectural applications.

Future Trends in Aluminum Extrusion

As technology continues to advance, the aluminum extrusion industry is expected to evolve. Some future trends include:

- Increased Automation: The use of automation in the extrusion process can enhance efficiency and reduce labor costs. Automated systems can monitor and control various aspects of production, ensuring consistent quality.

- Advanced Alloys: Research into new aluminum alloys with improved properties is ongoing. These advanced materials may offer enhanced strength, corrosion resistance, and thermal conductivity, expanding the range of applications for aluminum extrusion panels.

- Sustainable Practices: The industry is likely to see a greater emphasis on sustainability, with manufacturers adopting eco-friendly practices and materials. This includes using recycled aluminum and reducing waste during the manufacturing process.

- Customization: As customer demands for unique designs increase, manufacturers will need to offer more customization options. This may involve developing new extrusion techniques or investing in advanced machining capabilities.

Conclusion

The manufacturing and processing of aluminum extrusion panels involve a series of intricate steps, from material selection to final inspection. The versatility and advantages of aluminum make it a popular choice across various industries. As technology continues to advance, the processes involved in aluminum extrusion will likely become even more efficient, further enhancing the appeal of aluminum panels in the market.

Frequently Asked Questions

1. What is the main advantage of using aluminum extrusion panels?

- The main advantage is their lightweight nature combined with high strength and corrosion resistance, making them ideal for various applications.

2. How does the extrusion process work?

- The extrusion process involves heating aluminum billets and forcing them through a die to create a specific shape or profile.

3. What types of surface treatments are available for aluminum panels?

- Common surface treatments include anodizing, painting, and powder coating, which enhance durability and aesthetics.

4. Can aluminum extrusion panels be recycled?

- Yes, aluminum is highly recyclable, making it an environmentally friendly material choice.

5. What industries commonly use aluminum extrusion panels?

- Industries such as construction, automotive, aerospace, and furniture design frequently utilize aluminum extrusion panels.