Content Menu

● Introduction to the Ender 3 Pro Extruder

>> Limitations of the Stock Plastic Extruder

● Benefits of Upgrading to an Aluminum Extruder

>> Additional Benefits for Specific Filaments

● How to Upgrade to an Aluminum Extruder

>> Additional Considerations

● Real-World Experiences with Aluminum Extruders

>> Community Feedback

● Conclusion

● Frequently Asked Questions

>> 1. Does the Ender 3 Pro Have an Aluminum Extruder by Default?

>> 2. What Are the Benefits of Upgrading to an Aluminum Extruder?

>> 3. How Do I Upgrade My Ender 3 Pro with an Aluminum Extruder?

>> 4. Is Upgrading to an Aluminum Extruder Worth It?

>> 5. What Tools Are Required for the Upgrade?

● Citations:

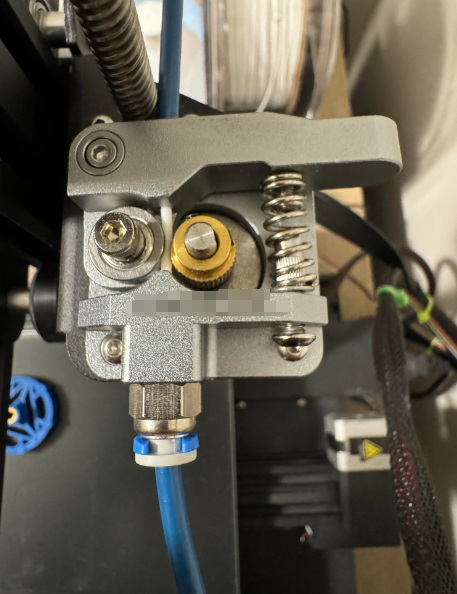

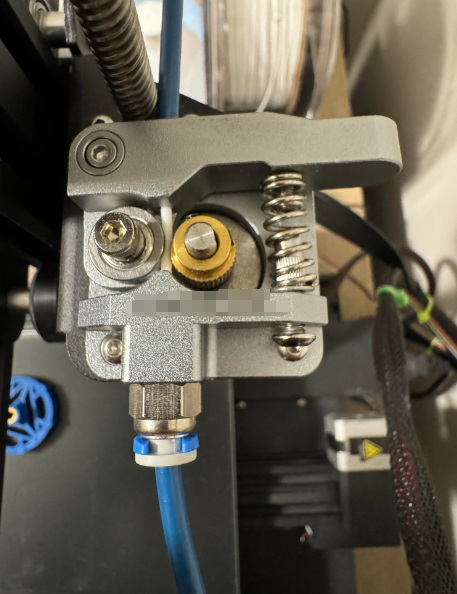

The Creality Ender 3 Pro is a highly popular and affordable 3D printer known for its reliability and versatility. One common question among 3D printing enthusiasts is whether the Ender 3 Pro comes equipped with an aluminum extruder. In this article, we will explore the extruder system of the Ender 3 Pro, discuss the benefits of aluminum extruders, and provide insights on upgrading your printer's extruder.

Introduction to the Ender 3 Pro Extruder

By default, the Ender 3 Pro does not come with an aluminum extruder. Instead, it is equipped with a plastic extruder assembly. This plastic extruder is functional and can produce good quality prints, but it has some limitations that can affect print quality and overall reliability.

Limitations of the Stock Plastic Extruder

1. Durability Issues: Plastic extruders are prone to wear and tear. The constant stress of filament feeding can cause the plastic to degrade over time, leading to cracks, deformation, and eventual failure.

2. Inconsistent Filament Feeding: The flexibility of plastic can result in inconsistent filament feeding, leading to under-extrusion, especially with flexible filaments.

3. Heat Sensitivity: Plastic is not an ideal material for dissipating heat. This can cause the filament to soften or melt prematurely, leading to clogs and print imperfections.

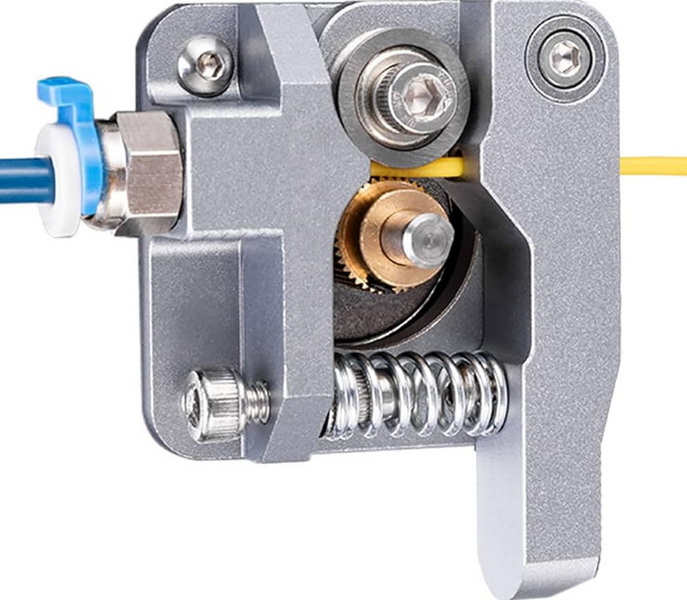

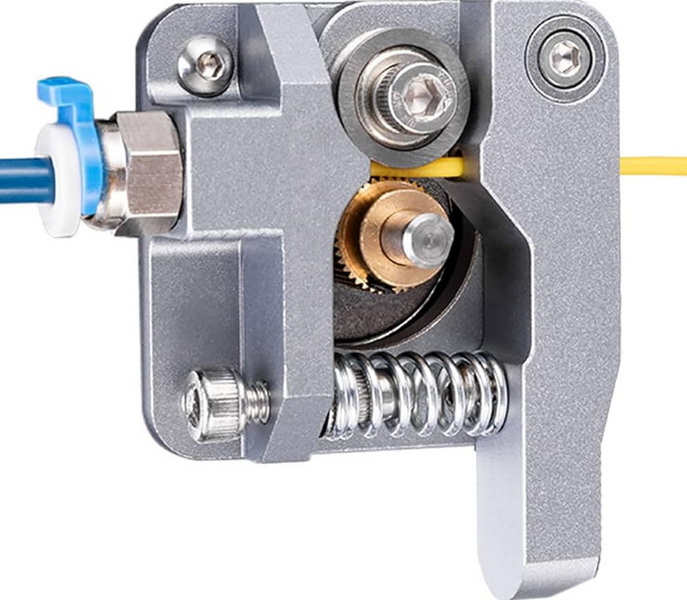

Benefits of Upgrading to an Aluminum Extruder

Upgrading to an aluminum extruder offers several advantages that address the limitations of the stock plastic extruder:

- Increased Durability: Aluminum is much more resistant to wear and tear than plastic. An aluminum extruder can withstand the constant stress of filament feeding without degrading, ensuring long-term reliability.

- Improved Consistency: The rigid metal construction of an aluminum extruder ensures more consistent filament feeding. This results in more accurate and uniform extrusion, leading to better print quality with fewer imperfections.

- Better Heat Dissipation: Aluminum conducts heat more efficiently than plastic. This helps dissipate heat away from the motor and filament, reducing the risk of heat-related issues such as softening or clogging.

- Longer Lifespan: An aluminum extruder is likely to last much longer than its plastic counterpart. Its robust construction and resistance to wear make it a worthwhile investment for users who print frequently or require high levels of reliability.

Additional Benefits for Specific Filaments

Aluminum extruders are particularly beneficial when printing with flexible filaments like TPU or Flex. The increased rigidity and consistent pressure provided by an aluminum extruder help maintain a stable filament feed, which is crucial for achieving high-quality prints with these materials.

How to Upgrade to an Aluminum Extruder

Upgrading your Ender 3 Pro with an aluminum extruder is a relatively straightforward process. Here's a step-by-step guide:

1. Purchase an Aluminum Extruder Upgrade Kit: Ensure the kit is compatible with the Ender 3 Pro. Kits like the Creality Aluminum Extruder Upgrade Kit are popular choices due to their compatibility with various Creality models[4][5].

2. Unload Filament and Turn Off the Printer: Remove any filament from the current extruder and power off the printer.

3. Remove the Old Extruder Assembly:

- Unscrew the Bowden tube coupling.

- Remove the screw attaching the lever arm.

- Remove the spring retaining screw.

- Remove the three screws holding the extruder to the motor.

4. Install the New Aluminum Extruder:

- Attach the new extruder gear to the motor shaft.

- Mount the aluminum extruder housing to the motor.

- Install the spring and lever arm.

- Reattach the Bowden tube.

For a visual guide, you can refer to online tutorials or videos that demonstrate the installation process in detail.

Additional Considerations

- Compatibility: Ensure the aluminum extruder you choose is specifically compatible with the Ender 3 Pro. Some extruders are designed for specific versions or have slight variations that may affect compatibility[1][3].

- Installation Complexity: While not overly complex, the installation process requires some technical skill. If you're not comfortable with disassembling and reassembling printer components, consider seeking assistance from someone with experience[1][3].

- Cost: Aluminum extruders are more expensive than plastic ones. However, the investment is often worthwhile due to the improved performance and longevity[1][3].

- Maintenance: While more durable, aluminum extruders still require regular maintenance for optimal performance. This includes cleaning the extruder gear and ensuring proper tension on the lever arm[1].

- Warranty: Modifying your printer may affect its warranty. Check with the seller or manufacturer about their specific warranty policies regarding upgrades[1][3].

Real-World Experiences with Aluminum Extruders

Many users in the 3D printing community have reported significant improvements in print quality and reliability after upgrading to an aluminum extruder. These upgrades are particularly noted for reducing issues like stringing and oozing, which can be common with plastic extruders. Additionally, users often report better performance with flexible filaments, which are notoriously difficult to print with standard plastic extruders.

Community Feedback

Feedback from the community highlights the importance of proper installation and maintenance to ensure the longevity and performance of the aluminum extruder. Regular cleaning and inspection are crucial to maintaining optimal performance and preventing wear-related issues.

Conclusion

In conclusion, the Ender 3 Pro does not come with an aluminum extruder by default. However, upgrading to one can significantly enhance your 3D printing experience by offering increased durability, improved consistency, better heat dissipation, and a longer lifespan. While the upgrade process requires some technical skill and investment, it is generally worthwhile for frequent users seeking high-quality prints.

Frequently Asked Questions

1. Does the Ender 3 Pro Have an Aluminum Extruder by Default?

No, the Ender 3 Pro does not come with an aluminum extruder by default. It is equipped with a plastic extruder assembly.

2. What Are the Benefits of Upgrading to an Aluminum Extruder?

Upgrading to an aluminum extruder offers increased durability, improved consistency in filament feeding, better heat dissipation, and a longer lifespan compared to plastic extruders.

3. How Do I Upgrade My Ender 3 Pro with an Aluminum Extruder?

To upgrade, purchase a compatible aluminum extruder kit, unload filament, remove the old extruder assembly, and install the new one following the manufacturer's instructions or online guides.

4. Is Upgrading to an Aluminum Extruder Worth It?

Yes, upgrading is often worthwhile for frequent users seeking improved print quality and reliability. However, it requires some technical skill and additional cost.

5. What Tools Are Required for the Upgrade?

Common tools needed include hex wrenches (2.5mm, 2mm), screwdrivers, and possibly a cable holder for managing cables.

Citations:

[1] https://www.yjing-extrusion.com/is-the-ender-3-pro-aluminum-extruder-worth-the-upgrade.html

[2] https://www.yjing-extrusion.com/what-are-the-steps-to-install-an-aluminum-extruder-on-your-ender-3.html

[3] https://www.yjing-extrusion.com/can-you-use-an-aluminum-extruder-on-ender-3.html

[4] https://www.bastelgarage.ch/creality-aluminum-extruder-upgrade-kit-gray

[5] https://www.3dea.co.nz/shop/product/creality-red-metal-extruder-upgrade-kit/

[6] https://www.youtube.com/watch?v=BUFC9YDIiLg

[7] https://community.element14.com/members-area/personalblogs/b/nico-tewinkel-s-blog/posts/ender-3-pro-broken-extruder-arm

[8] https://www.youtube.com/watch?v=k6eDBkc1mDg

[9] https://www.youtube.com/watch?v=nCb_94RTXCU

[10] https://www.3djake.com/creality-3d-printers-spare-parts/metal-extruder-upgrade-kit

[11] https://www.youtube.com/watch?v=pVFlGRmqNxI

[12] https://www.crealityexperts.com/creality-extruder-guide

[13] https://www.reddit.com/r/3Dprinting/comments/lbtobl/what_is_the_benefit_of_a_metal_extruder_for_an/

[14] https://www.youtube.com/watch?v=UtemZqFJ5rY

[15] https://www.yjing-extrusion.com/is-the-upgraded-aluminum-extruder-v2-worth-the-investment-for-better-print-quality.html

[16] https://www.reddit.com/r/ender3v2/comments/v6mmkl/getting_ready_to_add_an_all_metal_extruder/

[17] https://www.youtube.com/watch?v=uyFGLYJZfrM

[18] https://www.youtube.com/watch?v=zJRxRVN3p3Y

[19] https://images-na.ssl-images-amazon.com/images/I/A1RtrhQ8ZOL.pdf

[20] https://www.instructables.com/How-to-Setup-Creality-Ender-3-3d-Printer/