Content Menu

● Introduction to the Ender 3 Extruder System

● Limitations of the Stock Plastic Extruder

● Benefits of Upgrading to an Aluminum Extruder

● Factors to Consider When Upgrading

● Impact on Print Quality

● Alternative Extruder Options

● Maintaining Your Aluminum Extruder

● Community Insights and Reviews

● Conclusion

● FAQ

>> 1. Will upgrading to an aluminum extruder void my Ender 3 warranty?

>> 2. How often should I maintain my aluminum extruder?

>> 3. Can an aluminum extruder improve printing with flexible filaments?

>> 4. Is the aluminum extruder upgrade compatible with all Ender 3 models?

>> 5. What are the signs that my extruder needs to be replaced?

● Citations:

The Creality Ender 3 is a popular and affordable 3D printer, well-regarded by hobbyists and professionals alike. Known for its versatility and ease of modification, the Ender 3 offers a wide range of upgrade options to enhance its performance and reliability. One of the most common and impactful upgrades is replacing the stock plastic extruder with an aluminum extruder. This article delves into the benefits of using an aluminum extruder on the Ender 3, the installation process, factors to consider, and frequently asked questions to provide a comprehensive understanding of this upgrade.

Introduction to the Ender 3 Extruder System

The extruder is a critical component of any 3D printer, responsible for feeding filament consistently to the hot end, where it is melted and deposited onto the print bed. The stock Ender 3 comes with a plastic extruder assembly, which, while functional, has certain limitations. These limitations can affect print quality, consistency, and the lifespan of the printer[1].

Limitations of the Stock Plastic Extruder

1. Durability: Plastic extruders are prone to wear and tear. The constant friction and stress from feeding filament can cause the plastic to degrade over time, leading to cracks and breakages[1].

2. Consistency: The flexibility of plastic can result in inconsistent filament feeding. This can manifest as under-extrusion or over-extrusion, affecting the dimensional accuracy and surface finish of prints[1].

3. Heat Sensitivity: Plastic is more susceptible to heat-related issues. In environments with higher ambient temperatures or during prolonged use, the plastic extruder can soften, leading to deformation and feeding problems[1].

4. Lifespan: Due to the above factors, plastic extruders typically have a shorter lifespan compared to their aluminum counterparts. Regular inspection and maintenance can help extend their life, but eventual replacement is often necessary[1].

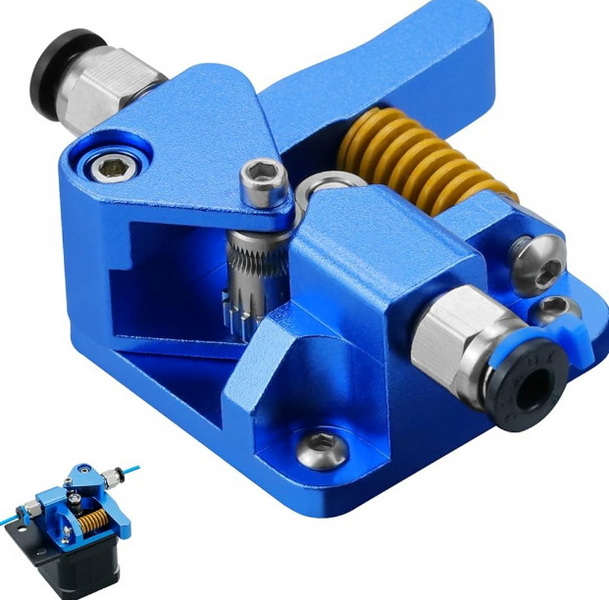

Benefits of Upgrading to an Aluminum Extruder

Upgrading to an aluminum extruder offers several advantages that can significantly improve the 3D printing experience with an Ender 3.

1. Increased Durability: Aluminum is much more resistant to wear and tear than plastic. An aluminum extruder can withstand the constant stress of filament feeding without degrading, ensuring long-term reliability[1].

2. Improved Consistency: The rigid metal construction of an aluminum extruder ensures more consistent filament feeding. This results in more accurate and uniform extrusion, leading to better print quality with fewer imperfections[1].

3. Better Heat Dissipation: Aluminum conducts heat more efficiently than plastic. This helps dissipate heat away from the motor and filament, reducing the risk of heat-related issues such as softening or clogging[1].

4. Longer Lifespan: An aluminum extruder is likely to last much longer than its plastic counterpart. Its robust construction and resistance to wear make it a worthwhile investment for users who print frequently or require high levels of reliability[1].

Factors to Consider When Upgrading

While upgrading to an aluminum extruder is generally beneficial, there are several factors to consider to ensure a successful upgrade:

1. Compatibility: Ensure the aluminum extruder you choose is specifically compatible with the Ender 3 model. Some extruders are designed for specific versions or have slight variations that may affect compatibility[1].

2. Installation Complexity: While the installation process is relatively simple, it requires some basic technical skills. If you're not comfortable with disassembling and reassembling printer components, consider seeking assistance from someone with experience[1].

3. Cost: Aluminum extruders are more expensive than plastic ones. However, the investment is often worthwhile due to the improved performance and longevity[1].

4. Maintenance: While more durable, aluminum extruders still require regular maintenance for optimal performance. This includes cleaning the extruder gear and ensuring proper tension on the lever arm[1].

5. Warranty: Modifying your printer may affect its warranty. Check with the seller or manufacturer about their specific warranty policies regarding upgrades[1].

Impact on Print Quality

Upgrading to an aluminum extruder can significantly improve print quality. Users often report:

- More consistent extrusion[1]

- Reduced stringing and oozing[1]

- Better overall print finish[1]

However, it's important to note that the extruder is just one component of the 3D printer. For optimal results, you may need to adjust your slicer settings and perform proper calibration after the upgrade[1].

Alternative Extruder Options

While aluminum extruders are a popular upgrade, other options are available, each with its own set of advantages and disadvantages.

1. Dual-Gear Extruders: These extruders use two gears to grip the filament, providing more reliable feeding and reducing the risk of slipping. Dual-gear extruders are particularly useful for flexible filaments like TPU[3].

2. Direct Drive Extruders: In a direct drive system, the extruder is mounted directly above the hot end, reducing the distance the filament needs to travel. This setup improves responsiveness and is better suited for flexible filaments[3].

3. Titan Extruders: Known for their compact design and high torque, Titan extruders offer excellent performance in a small package. They are compatible with a wide range of filaments and are relatively easy to install.

Maintaining Your Aluminum Extruder

Proper maintenance is essential to ensure the longevity and performance of your aluminum extruder. Here are some tips:

1. Regular Cleaning: Periodically clean the extruder gear to remove any accumulated debris or filament residue. Use a brush or compressed air to dislodge any particles[9].

2. Check Tension: Ensure the tension on the extruder arm is properly adjusted. Too little tension can cause the filament to slip, while too much tension can deform the filament.

3. Inspect for Wear: Regularly inspect the extruder for any signs of wear or damage. Replace any worn parts promptly to prevent further issues[9].

4. Lubricate Moving Parts: Apply a small amount of lubricant to the moving parts of the extruder to keep them running smoothly. Use a lubricant specifically designed for 3D printer components.

Community Insights and Reviews

Many users in the 3D printing community have shared their experiences with aluminum extruder upgrades on the Ender 3. Here are some common insights:

- Positive Feedback: Most users report noticeable improvements in print quality and reliability after upgrading to an aluminum extruder[1].

- Installation Tips: Many users recommend watching video tutorials and reading online guides before attempting the installation.

- Calibration Advice: Users often advise recalibrating the printer settings after the upgrade to optimize performance.

- Brand Recommendations: Some popular brands for aluminum extruder upgrades include Creality, BIGTREETECH, and Winsinn.

Conclusion

Upgrading to an aluminum extruder on your Ender 3 is a worthwhile investment for improving print quality, consistency, and the overall lifespan of your 3D printer. While the stock plastic extruder is functional, it has limitations that can affect performance over time. An aluminum extruder offers increased durability, better filament feeding, and improved heat dissipation, making it a popular and effective upgrade. By following the step-by-step installation guide and considering the factors discussed in this article, you can successfully upgrade your Ender 3 and enjoy enhanced 3D printing capabilities.

FAQ

1. Will upgrading to an aluminum extruder void my Ender 3 warranty?

Modifying your printer may affect its warranty. It's best to check with the seller or manufacturer about their specific warranty policies regarding upgrades[1].

2. How often should I maintain my aluminum extruder?

Regular maintenance, including cleaning and inspection, should be performed every 1-3 months, depending on usage. More frequent maintenance may be required if you print frequently or use abrasive filaments[1].

3. Can an aluminum extruder improve printing with flexible filaments?

Yes, an aluminum extruder can improve printing with flexible filaments by providing more consistent and reliable filament feeding. However, for optimal results, consider using a dual-gear or direct drive extruder specifically designed for flexible filaments[3].

4. Is the aluminum extruder upgrade compatible with all Ender 3 models?

Most aluminum extruder upgrades are compatible with various Creality models, including the Ender 3, Ender 3 Pro, and Ender 3 V2. However, always check the compatibility before purchasing[1].

5. What are the signs that my extruder needs to be replaced?

Signs that your extruder may need to be replaced include inconsistent filament feeding, frequent clogs, visible cracks or damage to the extruder body, and a noticeable decline in print quality[9].

Citations:

[1] https://www.yjing-extrusion.com/does-ender-3-pro-have-an-aluminum-extruder.html

[2] https://images-na.ssl-images-amazon.com/images/I/A1RtrhQ8ZOL.pdf

[3] https://www.pcfactory.cl/producto/29748-creality-impresora-3d-ender-3

[4] https://www.reddit.com/r/3Dprinting/comments/10eyd2e/aluminum_extrusion_dimensions/

[5] https://www.youtube.com/watch?v=zJRxRVN3p3Y

[6] https://www.creality.com/products/creality-ender-3-v3-ke

[7] https://www.youtube.com/watch?v=UtemZqFJ5rY

[8] https://www.crealityexperts.com/creality-extruder-upgrade-instructions

[9] https://la3dpr.com