Content Menu

● Understanding Aluminum Extrusions

● Applications of 20 x 40 Aluminum Extrusions

● Customization Options

>> 1. Length and Size Adjustments

>> 2. Surface Finishing

>> 3. Machining and Fabrication

>> 4. Color Options

● The Manufacturing Process

● Benefits of Customization

● Conclusion

● Related Questions

>> 1. What are the typical costs associated with customizing 20 x 40 aluminum extrusions?

>> 2. How do different surface finishes impact the longevity of 20 x 40 aluminum extrusions in various environments?

>> 3. What are some innovative applications of customized 20 x 40 aluminum extrusions in the construction industry?

>> 4. Can 20 x 40 aluminum extrusions be used in outdoor applications?

>> 5. What design considerations should be taken into account when customizing aluminum extrusions?

Aluminum extrusions are a vital component in various industries, providing lightweight yet durable solutions for structural and aesthetic applications. Among the many sizes available, the 20 x 40 aluminum extrusion profile stands out due to its versatility and adaptability. This article explores the customization of 20 x 40 aluminum extrusions, detailing their applications, manufacturing processes, design considerations, and the benefits of tailoring these profiles to meet specific needs.

Understanding Aluminum Extrusions

Aluminum extrusion is a process that involves forcing aluminum alloy through a die to create a specific cross-sectional shape. This method allows for the production of complex shapes that can be used in a wide range of applications, from construction to automotive parts. The 20 x 40 aluminum extrusion profile is particularly popular due to its robust structure and ease of integration into various systems.

Applications of 20 x 40 Aluminum Extrusions

The 20 x 40 aluminum extrusion is used in numerous applications, including:

- Frameworks for Machinery: The strength and lightweight nature of aluminum make it ideal for constructing frames for machinery and equipment.

- Workstations and Benches: Many industries utilize these extrusions to create customizable workstations that can be adjusted to fit specific tasks.

- Display Racks: Retail environments often use aluminum extrusions to build display racks that are both functional and visually appealing.

- Automotive Components: The automotive industry benefits from the lightweight properties of aluminum, using these extrusions in various parts to enhance fuel efficiency.

Customization Options

Customizing 20 x 40 aluminum extrusions can significantly enhance their functionality and aesthetic appeal. Here are some common customization options:

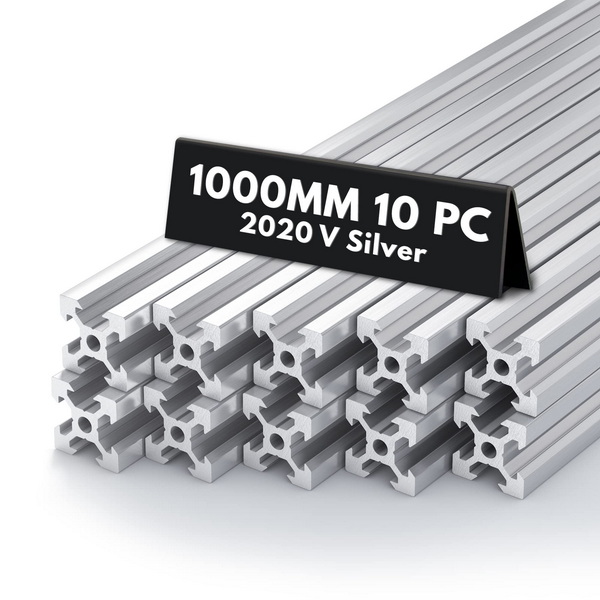

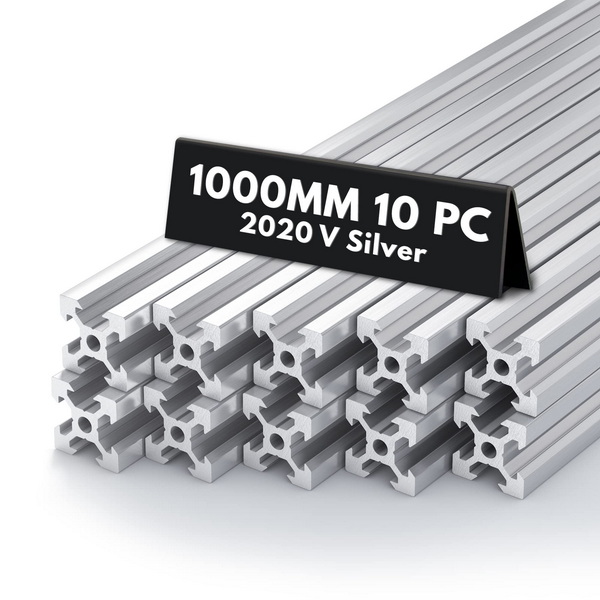

1. Length and Size Adjustments

One of the primary advantages of aluminum extrusions is the ability to cut them to specific lengths. This flexibility allows manufacturers to create components that fit perfectly within their intended applications.

2. Surface Finishing

Aluminum extrusions can be treated with various surface finishes, such as anodizing, powder coating, or painting. These finishes not only improve the appearance of the extrusions but also enhance their resistance to corrosion and wear.

3. Machining and Fabrication

Further customization can be achieved through machining processes, such as drilling, milling, or tapping. These processes allow for the addition of features like holes for fasteners or grooves for sliding components.

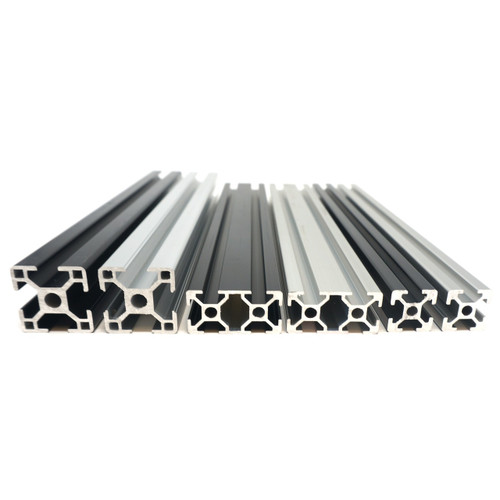

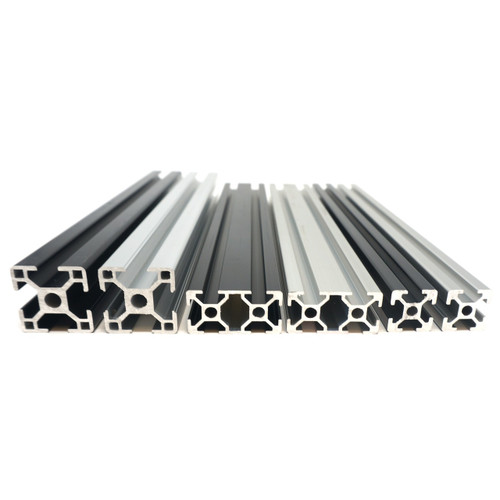

4. Color Options

Custom colors can be applied to aluminum extrusions, allowing businesses to align their products with branding or aesthetic preferences. This is particularly important in consumer-facing applications, such as retail displays.

The Manufacturing Process

The manufacturing process for customizing 20 x 40 aluminum extrusions typically involves several key steps:

1. Design and Prototyping: The first step is to create a design that meets the specific needs of the application. This may involve CAD software to visualize the final product.

2. Die Creation: Once the design is finalized, a die is created. This die is essential for shaping the aluminum during the extrusion process.

3. Extrusion: The aluminum alloy is heated and then forced through the die to create the desired shape. This process can be done at various temperatures depending on the alloy used.

4. Cooling and Cutting: After extrusion, the profiles are cooled and cut to the specified lengths.

5. Finishing: Finally, any surface treatments or machining processes are applied to complete the customization.

Benefits of Customization

Customizing 20 x 40 aluminum extrusions offers several benefits:

- Enhanced Functionality: Tailoring the extrusions to specific needs ensures that they perform optimally in their intended applications.

- Cost-Effectiveness: Custom solutions can reduce waste and improve efficiency, ultimately saving costs in production and assembly.

- Aesthetic Appeal: Customized finishes and colors can enhance the visual appeal of products, making them more attractive to consumers.

Conclusion

The ability to customize 20 x 40 aluminum extrusions opens up a world of possibilities for various industries. By understanding the applications, customization options, and manufacturing processes, businesses can leverage these profiles to create innovative solutions that meet their specific needs.

Related Questions

1. What are the typical costs associated with customizing 20 x 40 aluminum extrusions?

The costs of customizing 20 x 40 aluminum extrusions can vary widely based on factors such as the complexity of the design, the type of surface finish, and the quantity ordered. Generally, larger orders can reduce the per-unit cost, while intricate designs may increase manufacturing expenses.

2. How do different surface finishes impact the longevity of 20 x 40 aluminum extrusions in various environments?

Surface finishes play a crucial role in the longevity of aluminum extrusions. Anodizing, for example, provides a protective layer that enhances corrosion resistance, making it suitable for outdoor applications. Powder coating offers a durable finish that can withstand harsh conditions, while painting may require more maintenance over time.

3. What are some innovative applications of customized 20 x 40 aluminum extrusions in the construction industry?

In the construction industry, customized 20 x 40 aluminum extrusions are used for creating modular building systems, curtain walls, and structural supports. Their lightweight nature allows for easier handling and installation, while their strength ensures safety and durability.

4. Can 20 x 40 aluminum extrusions be used in outdoor applications?

Yes, 20 x 40 aluminum extrusions are suitable for outdoor applications, especially when treated with appropriate surface finishes like anodizing or powder coating. These treatments enhance their resistance to weathering and corrosion.

5. What design considerations should be taken into account when customizing aluminum extrusions?

When customizing aluminum extrusions, it is essential to consider factors such as load-bearing requirements, environmental conditions, and compatibility with other components. Additionally, the intended aesthetic and functionality should guide the design process to ensure optimal performance.