Content Menu

● Introduction to Krauss Maffei Extrusion Systems

>> Key Features of Krauss Maffei HDPE Extrusion Systems

● Application of Automatic Centering System to Other Materials

>> Materials Compatible with Krauss Maffei Extrusion Systems

● Benefits of Using Automatic Centering for Various Materials

● Technical Innovations in Krauss Maffei Systems

>> Role of Digital Technologies

● Case Studies and Applications

>> PureCycle Recycling Process

● Future Developments and Trends

● Extrusion Line Components and Automation

>> Automation Components

● Conclusion

● FAQ

>> 1. What is the primary benefit of using automatic centering in HDPE pipe production?

>> 2. Can KraussMaffei's extrusion systems handle multi-layer pipes?

>> 3. How does the QuickSwitch technology enhance production flexibility?

>> 4. What materials can be processed using KraussMaffei's extrusion systems?

>> 5. What is the role of the C7 control system in KraussMaffei extrusion lines?

● Citations:

KraussMaffei is renowned for its innovative solutions in the field of plastic extrusion, particularly with its HDPE (High-Density Polyethylene) extrusion systems. One of the key features of these systems is the automatic centering technology, which ensures precise alignment and quality in the production of HDPE pipes. However, the question arises whether this technology can be applied to other materials beyond HDPE.

Introduction to Krauss Maffei Extrusion Systems

KraussMaffei offers a comprehensive range of extrusion systems designed to cater to various applications, including pipe extrusion, profile extrusion, and sheet extrusion. Their systems are engineered to handle a wide array of materials, from PVC and PE to PP and more complex composites. The modular design of their extruders and downstream components allows for flexibility and customization to meet specific production needs.

Key Features of Krauss Maffei HDPE Extrusion Systems

1. Automatic Centering Technology: This feature ensures that the pipe is perfectly centered throughout the extrusion process, reducing ovality and enhancing overall pipe quality. The precision achieved through this technology is crucial for maintaining the structural integrity of pipes, especially in applications where high pressure and durability are required.

2. QuickSwitch Technology: Allows for rapid changes in pipe dimensions without the need for retooling, significantly increasing production flexibility and efficiency. This capability is particularly beneficial in environments where product diversification is essential.

3. C7 Control System: Offers comprehensive control over the extrusion line, integrating all units for optimal product quality and process reliability. The system ensures that all production parameters are monitored and adjusted in real-time, ensuring consistent output quality.

Application of Automatic Centering System to Other Materials

While KraussMaffei's automatic centering system is primarily designed for HDPE, its versatility allows it to be adapted for use with other materials. This is due to the modular design of their extrusion systems, which can be tailored to specific material requirements.

Materials Compatible with Krauss Maffei Extrusion Systems

1. PVC (Polyvinyl Chloride): Often used for pipes and profiles, PVC requires precise temperature control and can benefit from automatic centering for improved quality. PVC is widely used in construction and plumbing due to its durability and resistance to corrosion. KraussMaffei's 36D twin-screw extruders are well-suited for producing U-PVC, M-PVC, and foamcore PVC pipes[8].

2. PP (Polypropylene): Used in a variety of applications, PP can be processed using similar extrusion techniques as HDPE, making it suitable for automatic centering systems. PP is valued for its lightweight and chemical resistance properties. KraussMaffei has also been involved in recycling PP through collaborations like the PureCycle process[9].

3. Multi-layer Pipes: These pipes, which combine different materials like PE-X and PE-RT, can also benefit from precise centering to ensure uniform layer distribution. Multi-layer pipes are used in applications requiring enhanced thermal stability and durability. KraussMaffei's pipeheads are designed to handle multi-layer production efficiently[5].

Benefits of Using Automatic Centering for Various Materials

1. Improved Quality: Automatic centering ensures that pipes are produced with minimal ovality, enhancing their structural integrity and performance. This is particularly important for pipes used in high-pressure applications or those exposed to harsh environmental conditions.

2. Increased Efficiency: By reducing the need for manual adjustments and minimizing waste, production efficiency is significantly improved. The automation of centering processes allows for continuous production without interruptions, leading to higher output rates.

3. Flexibility: The ability to adapt the system for different materials allows manufacturers to diversify their product offerings without significant additional investment. This flexibility is crucial in a competitive market where product variety can be a key differentiator.

Technical Innovations in Krauss Maffei Systems

KraussMaffei has been at the forefront of technological innovation in extrusion technology. Their systems incorporate advanced automation and control technologies, ensuring high-quality output and efficient production processes. The use of digital technologies, such as sensors and production monitoring software, further enhances the performance of their extrusion lines by providing real-time data and insights into production processes.

Role of Digital Technologies

Digital technologies play a crucial role in optimizing production processes. By integrating sensors and monitoring software, manufacturers can achieve better control over production parameters, reduce energy consumption, and improve product quality. These technologies also enable predictive maintenance, reducing downtime and increasing overall system reliability.

Case Studies and Applications

KraussMaffei's extrusion systems have been successfully applied in various industries, including construction, automotive, and consumer goods. Their technology has been instrumental in developing innovative products such as coextruded pipes and highly filled pipes, which offer enhanced performance characteristics.

PureCycle Recycling Process

KraussMaffei has collaborated with PureCycle to develop a groundbreaking recycling process for polypropylene. This process involves the use of twin-screw extruders to melt and purify PP carpet scraps, resulting in ultra-pure PP pellets that can be reused in various applications. This collaboration highlights KraussMaffei's commitment to sustainability and innovation in plastics processing[9].

Future Developments and Trends

As the plastics industry continues to evolve, there is a growing emphasis on sustainability and efficiency. KraussMaffei is poised to play a significant role in this evolution by developing technologies that not only improve production processes but also contribute to environmental sustainability. Their focus on digitalization and automation will be key in meeting future demands for high-quality, eco-friendly products.

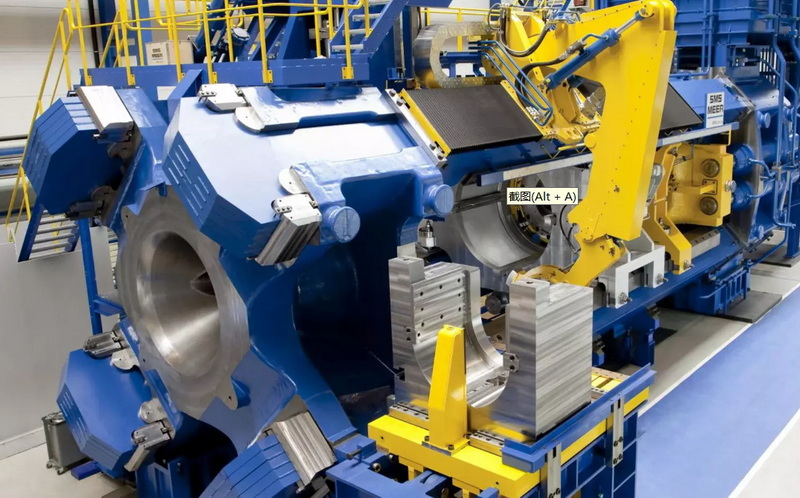

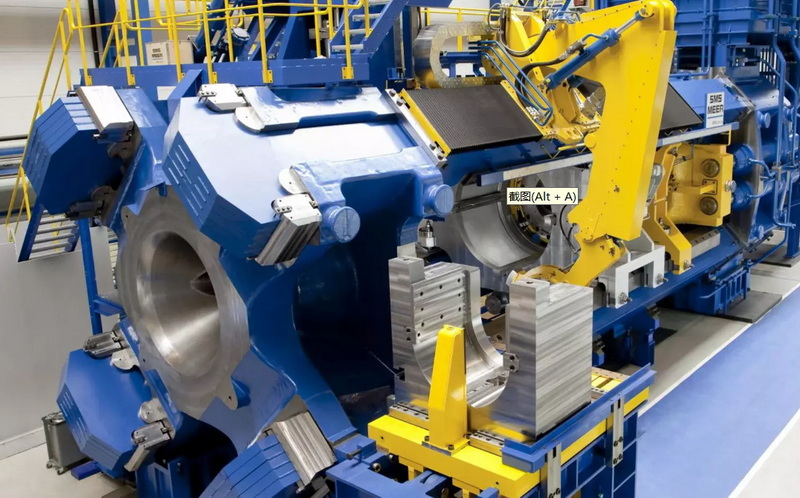

Extrusion Line Components and Automation

KraussMaffei's extrusion lines are equipped with a range of components designed to enhance production efficiency and product quality. These include vacuum tanks, spray tanks, haul-offs, cutting units, and socket forming machines. All these components are engineered for optimal interoperability, ensuring seamless integration into the production line[1].

Automation Components

Automation components, such as seal ring insertion robots and pipe hoist and rotating units, further enhance the efficiency and safety of the production process. These components are designed for maximum operational safety and ease of use, allowing for quick setup and minimal downtime[1].

Conclusion

KraussMaffei's HDPE extrusion automatic centering system is highly versatile and can be effectively used for other materials such as PVC, PP, and multi-layer pipes. The modular design of their systems allows for easy adaptation to different material requirements, making them a valuable asset for manufacturers seeking to optimize production across a range of materials.

FAQ

1. What is the primary benefit of using automatic centering in HDPE pipe production?

The primary benefit is improved pipe quality through reduced ovality and enhanced structural integrity.

2. Can KraussMaffei's extrusion systems handle multi-layer pipes?

Yes, KraussMaffei systems are capable of producing multi-layer pipes, such as PE-X and PE-RT, with precise layer distribution.

3. How does the QuickSwitch technology enhance production flexibility?

QuickSwitch allows for rapid changes in pipe dimensions without retooling, significantly increasing production flexibility and efficiency.

4. What materials can be processed using KraussMaffei's extrusion systems?

KraussMaffei systems can process a wide range of materials, including HDPE, PVC, PP, and multi-layer composites.

5. What is the role of the C7 control system in KraussMaffei extrusion lines?

The C7 control system provides comprehensive control over the extrusion line, integrating all units for optimal product quality and process reliability.

Citations:

[1] https://www.kraussmaffei.com/media/download/cms/media/ext/rohrextrusion/ext-br-rohrextrusionsanlagen-en.pdf

[2] https://press.kraussmaffei.com/en/news/continuous-tube-die-centering-for-precise-wall-thickness-with-maximum-material-savings

[3] https://www.plasticportal.eu/articles/wide-selection-of-kraussmaffei-technologies-on-competence-forum-5108

[4] https://www.kraussmaffei.com/media/download/cms/media/imm/kraussmaffei/downloads/imm-br-lrx-lrx-s-en.pdf

[5] https://www.kraussmaffei.com/media/download/cms/media/ext/downloads/ext-br-po-pipe-en.pdf

[6] https://1plastcompany.com/pvc-pipe-extrusion-lines-kraussmaffei-kmd

[7] https://www.kraussmaffei.com/media/datastore/cms/media/ext/downloads/ext-br-rohrextrusionsanlagen-en.pdf

[8] https://www.kraussmaffei.com/en/our-products/pvc-pipe-extrusion

[9] https://www.ptonline.com/news/kraussmaffei-to-provide-extrusion-technologies-for-purecycle

[10] https://www.kraussmaffei.com/en/our-technologies/extrusion-technology

[11] https://headland.nz/kraussmaffei-delivers-cutting-edge-flexible-pipe-extrusion-lines-with-adjustable-dimensions/

[12] https://www.plasticsnews.com/news/encoma-enters-hdpe-pipe-market-using-kraussmaffeis-quickswitch

[13] https://www.kraussmaffei.com

[14] https://pdf.directindustry.com/pdf/kraussmaffei/extruders-extrusion-lines-made-china/20428-556113.html

[15] https://www.kraussmaffei.com/en/our-products/extrusion-heads

[16] https://polymaker.com/introducing-our-partner-krauss-maffei-and-its-innovations-in-additive-manufacturing-the-powerprint-system/

[17] https://www.plasticsmachinerymanufacturing.com/compounding/article/21279459/kraussmaffei-corp-kraussmaffei-dcim-setup-combines-compounding-injection-molding

[18] https://www.plasticsmachinerymanufacturing.com/injection-molding/article/21238751/patent-report-kraussmaffei-plasticizing-unit-simplifies-nozzle-center-adjustment

[19] https://www.linkedin.com/posts/dr-thomas-unger-0b3843183_kraussmaffei-extrusion-innovation-activity-7300923684481826821-Ocf2

[20] https://en.kunststoffe.de/a/specialistarticle/pipe-extrusion-through-thick-and-thin-2817170