Content Menu

● Introduction

● Understanding 80/20 Aluminum Extrusions

● Customization Options

>> Profile Selection

>> Length and Cut Options

>> Machining Services

>> Accessories and Fasteners

>> Surface Finishing

● Benefits of Customizing 80/20 Aluminum Extrusions

>> Flexibility

>> Cost-Effectiveness

>> Enhanced Performance

>> Aesthetic Appeal

>> Simplified Assembly

● Applications of Customized 80/20 Aluminum Extrusions

>> Industrial Automation

>> Robotics

>> Workstations

>> DIY Projects

>> Display and Exhibit Structures

● Conclusion

● Frequently Asked Questions

>> 1. What types of projects can benefit from 80/20 aluminum extrusions?

>> 2. Can I order custom lengths for aluminum extrusions?

>> 3. Are machining services available for 80/20 aluminum extrusions?

>> 4. How can I ensure my custom design is cost-effective?

>> 5. What finishing options are available for aluminum extrusions?

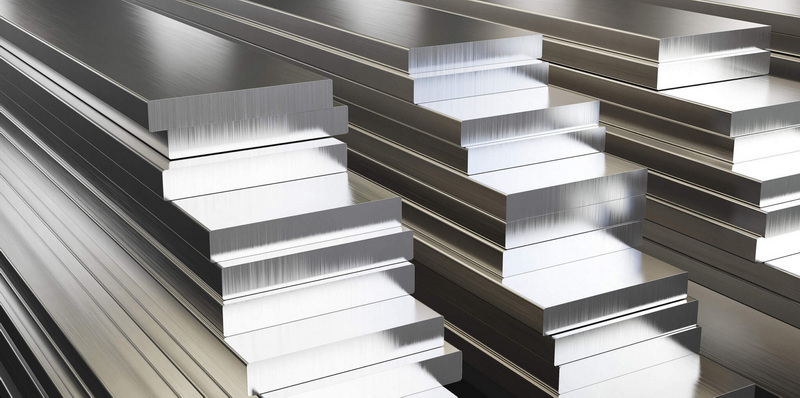

Introduction

In the world of engineering and design, the ability to customize materials to meet specific project requirements is crucial. One of the most versatile materials available today is the 80/20 aluminum extrusion. Known for its strength, lightweight properties, and adaptability, 80/20 aluminum extrusions are widely used in various applications, from industrial automation to DIY projects. This article explores the customization options available for 80/20 aluminum extrusions, how they can be tailored to meet unique project needs, and the benefits of using this material in your designs.

Understanding 80/20 Aluminum Extrusions

80/20 aluminum extrusions are T-slot profiles made from high-quality aluminum. The "80/20" designation refers to the dimensions of the profile, which is 80mm wide and 20mm tall. These extrusions feature a unique T-slot design that allows for easy assembly and disassembly, making them ideal for modular construction. The versatility of 80/20 aluminum extrusions means they can be used in a wide range of applications, including:

- Machine Frames: Providing a sturdy structure for various machinery.

- Workstations: Creating ergonomic and efficient workspaces.

- Safety Guards: Designing protective barriers around equipment.

- Conveyor Systems: Building frameworks for material handling systems.

Customization Options

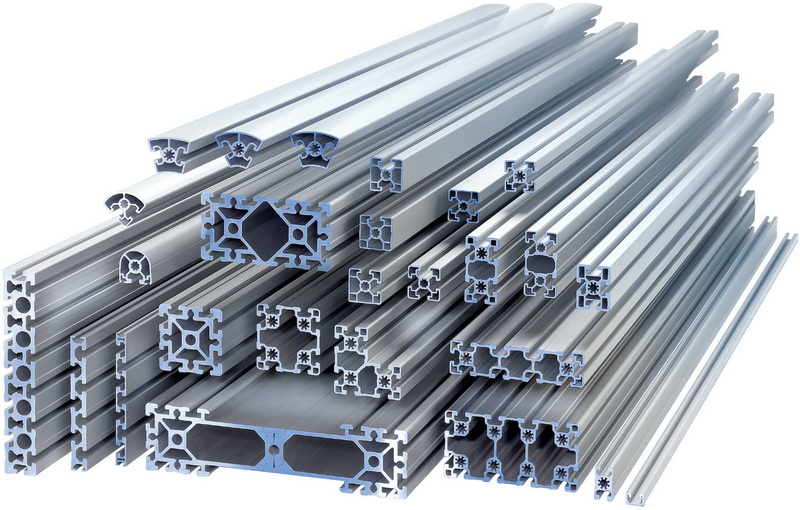

Profile Selection

The first step in customizing 80/20 aluminum extrusions is selecting the appropriate profile. 80/20 offers a wide variety of profiles, each designed for specific applications. Depending on your project requirements, you can choose from different sizes, shapes, and configurations. For instance, if you need a lightweight structure, you might opt for a smaller profile, while a larger profile may be necessary for heavy-duty applications.

Length and Cut Options

80/20 aluminum extrusions can be cut to any length, allowing for precise customization. Whether you need short pieces for a compact project or long sections for extensive frameworks, the ability to specify lengths ensures that you can create a design that fits your exact specifications. Many suppliers offer cutting services, so you can receive your extrusions ready to assemble.

Machining Services

For projects that require more than just standard cuts, machining services are available. This can include drilling holes, tapping threads, or creating custom shapes. Machining allows for the integration of specific features into the extrusions, such as mounting points or channels for wiring. This level of customization is particularly beneficial for complex projects where standard profiles may not suffice.

Accessories and Fasteners

To enhance the functionality of your 80/20 aluminum extrusions, a wide range of accessories and fasteners are available. These include brackets, connectors, and end caps that facilitate assembly and provide additional support. Customizing your project with the right accessories can improve stability and make your design more efficient.

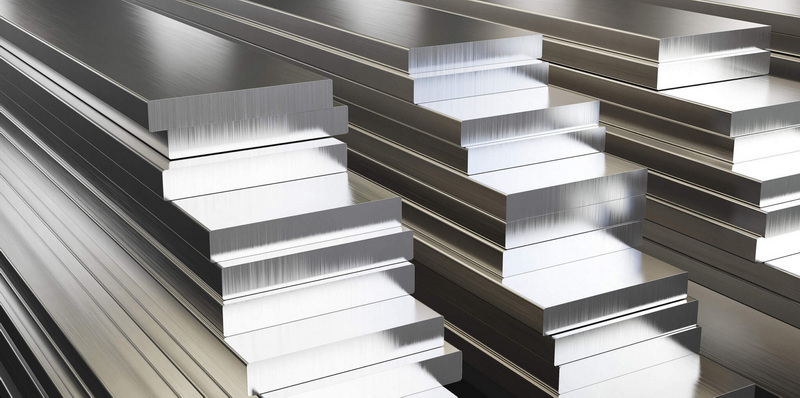

Surface Finishing

Another aspect of customization is surface finishing. While 80/20 aluminum extrusions typically come with a natural finish, you can opt for anodizing or powder coating to enhance durability and aesthetics. Anodizing provides a protective layer that increases corrosion resistance, while powder coating allows for a variety of colors and textures, making your project visually appealing.

Benefits of Customizing 80/20 Aluminum Extrusions

Flexibility

The modular nature of 80/20 aluminum extrusions allows for easy reconfiguration. If your project requirements change, you can modify your design without starting from scratch. This flexibility is particularly valuable in dynamic environments where needs may evolve over time.

Cost-Effectiveness

Customizing 80/20 aluminum extrusions can be cost-effective in the long run. By tailoring the materials to your specific needs, you can reduce waste and avoid the costs associated with over-engineering. Additionally, the durability of aluminum means that your structures will have a longer lifespan, further saving on replacement costs.

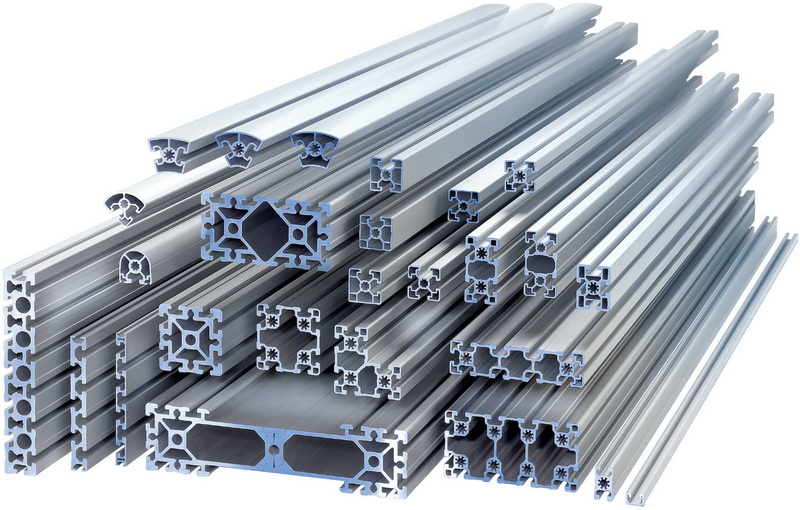

Enhanced Performance

Custom designs can lead to improved performance. By selecting the right profiles, lengths, and accessories, you can create structures that are optimized for their intended use. This can result in better load distribution, increased stability, and enhanced functionality.

Aesthetic Appeal

With options for surface finishing and color customization, you can create visually appealing designs that align with your brand or project theme. This is particularly important for projects that will be visible to clients or the public.

Simplified Assembly

The T-slot design of 80/20 aluminum extrusions simplifies the assembly process. With the right accessories, you can quickly and easily put together complex structures without the need for specialized tools or extensive training.

Applications of Customized 80/20 Aluminum Extrusions

Industrial Automation

In industrial settings, customized 80/20 aluminum extrusions are often used to create machine frames, conveyor systems, and safety guards. The ability to tailor these structures to specific machinery and workflows enhances efficiency and safety. For example, a custom conveyor system can be designed to fit the exact dimensions of a production line, ensuring smooth operation and minimizing downtime.

Robotics

Robotics applications benefit from the lightweight yet strong properties of aluminum extrusions. Custom designs can accommodate various robotic components, ensuring that the structure supports the necessary movements and functions. This is particularly important in applications where precision and stability are critical, such as in robotic arms or automated assembly lines.

Workstations

Custom workstations can be designed using 80/20 aluminum extrusions to create ergonomic and efficient environments. By tailoring the height, layout, and accessories, you can optimize the workspace for specific tasks. This can lead to increased productivity and reduced strain on workers, as they can work in a setup that is comfortable and suited to their needs.

DIY Projects

For hobbyists and DIY enthusiasts, 80/20 aluminum extrusions offer endless possibilities. Whether building a custom shelving unit, a model, or a unique piece of furniture, the ability to customize allows for creativity and innovation. The modular nature of the extrusions means that projects can be easily modified or expanded as needed.

Display and Exhibit Structures

In retail and exhibition settings, customized aluminum extrusions can be used to create eye-catching displays. The modular nature allows for easy reconfiguration, making it simple to adapt to different products or layouts. This flexibility is essential for businesses that frequently change their displays to showcase new products or promotions.

Conclusion

Customizing 80/20 aluminum extrusions for unique project requirements is not only possible but also highly beneficial. With a wide range of profiles, machining options, accessories, and finishing techniques available, you can create structures that meet your specific needs while enhancing performance and aesthetics. Whether you are working on industrial automation, robotics, or DIY projects, the versatility of 80/20 aluminum extrusions makes them an excellent choice for any application.

Frequently Asked Questions

1. What types of projects can benefit from 80/20 aluminum extrusions?

80/20 aluminum extrusions are suitable for a variety of projects, including industrial automation, robotics, workstations, DIY projects, and display structures.

2. Can I order custom lengths for aluminum extrusions?

Yes, most suppliers offer cutting services, allowing you to order aluminum extrusions in custom lengths to fit your project specifications.

3. Are machining services available for 80/20 aluminum extrusions?

Yes, machining services such as drilling, tapping, and custom shaping are available to enhance the functionality of your aluminum extrusions.

4. How can I ensure my custom design is cost-effective?

By carefully selecting the right profiles, lengths, and accessories, you can minimize waste and avoid over-engineering, leading to a more cost-effective design.

5. What finishing options are available for aluminum extrusions?

Common finishing options include anodizing for corrosion resistance and powder coating for color and texture customization.