Content Menu

● Understanding Aluminum Extrusions

● Benefits of Using 1 x 3 Aluminum Extrusion

● Customization Options for 1 x 3 Aluminum Extrusions

>> Cutting and Length Adjustment

>> Drilling and Machining

>> Surface Treatments

>> Joining Techniques

>> Adding Accessories

● Applications of 1 x 3 Aluminum Extrusions

>> Frameworks and Structures

>> Automotive and Aerospace

>> Furniture Design

>> Industrial Applications

>> Signage and Displays

● The Customization Process

>> Design and Planning

>> Material Selection

>> Fabrication

>> Surface Treatment

>> Assembly and Installation

● Conclusion

● Frequently Asked Questions

>> What is the maximum length for a 1 x 3 aluminum extrusion?

>> Can I order custom lengths for 1 x 3 aluminum extrusions?

>> What types of surface treatments are available for aluminum extrusions?

>> Is it possible to weld 1 x 3 aluminum extrusions?

>> How do I determine the right aluminum alloy for my project?

Understanding Aluminum Extrusions

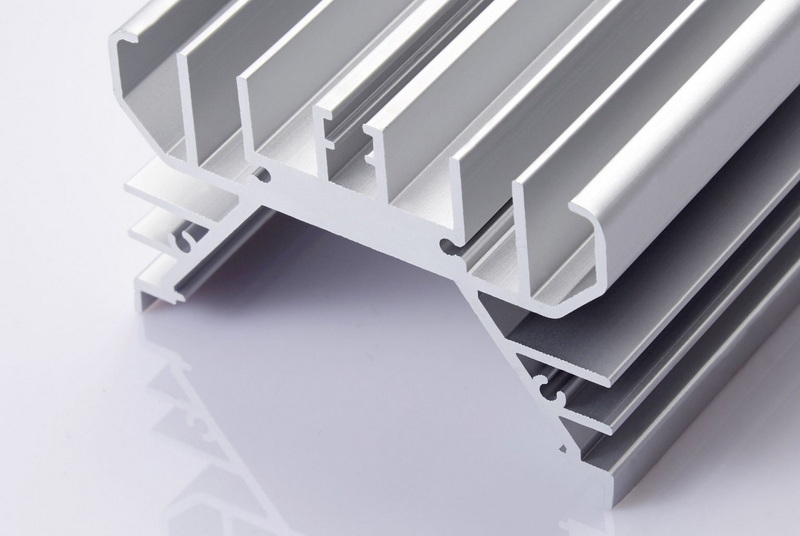

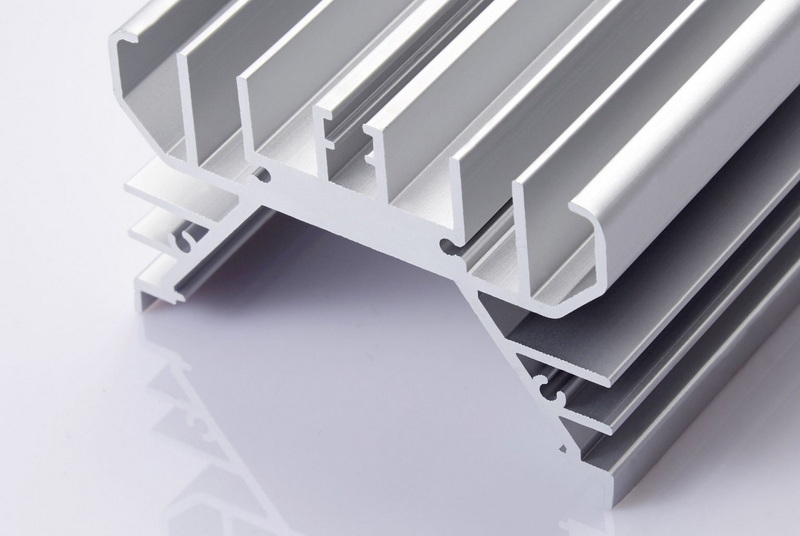

Aluminum extrusion is a manufacturing process that involves shaping aluminum alloy by forcing it through a die. This process allows for the creation of complex cross-sectional shapes that can be used in a variety of applications. The 1 x 3 aluminum extrusion refers to a specific profile that measures one inch in width and three inches in height. This size is particularly popular due to its balance of strength and lightweight properties.

Aluminum extrusions are made from various alloys, each offering different mechanical properties. The most common alloys used in extrusions include 6061 and 6063, which are known for their excellent corrosion resistance and good mechanical properties. The choice of alloy can significantly impact the performance of the final product, making it essential to select the right one for your specific application.

Benefits of Using 1 x 3 Aluminum Extrusion

1. Lightweight and Strong: Aluminum is known for its high strength-to-weight ratio, making it an ideal choice for applications where weight is a concern without compromising structural integrity. This property is particularly beneficial in industries such as aerospace and automotive, where reducing weight can lead to improved fuel efficiency.

2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which helps resist corrosion. This property is especially beneficial in outdoor or humid environments, where other materials may degrade over time. The corrosion resistance of aluminum extrusions makes them suitable for applications in marine environments, chemical processing, and more.

3. Ease of Fabrication: Aluminum extrusions can be easily cut, drilled, and machined, allowing for quick modifications and customizations. This ease of fabrication means that manufacturers can respond rapidly to changing design requirements, making aluminum extrusions a flexible choice for many projects.

4. Aesthetic Appeal: The sleek appearance of aluminum extrusions can enhance the visual appeal of products and structures. With various surface finishes available, including anodizing and powder coating, aluminum extrusions can be tailored to fit the aesthetic needs of any project.

5. Sustainability: Aluminum is recyclable, making it an environmentally friendly choice for manufacturers and consumers alike. The recycling process for aluminum requires only a fraction of the energy needed to produce new aluminum, contributing to a more sustainable manufacturing cycle.

Customization Options for 1 x 3 Aluminum Extrusions

Customizing 1 x 3 aluminum extrusions can involve several processes, depending on the specific requirements of the project. Here are some common customization options:

Cutting and Length Adjustment

One of the simplest forms of customization is cutting the extrusion to the desired length. This can be done using standard cutting tools, and it allows for precise adjustments to fit specific applications. Many suppliers offer cutting services, enabling customers to receive extrusions that are ready for assembly.

Drilling and Machining

Drilling holes or machining specific features into the extrusion can enhance its functionality. This is particularly useful for creating mounting points, channels for wiring, or other features that may be required for assembly. CNC machining can be employed for high precision, ensuring that the finished product meets exact specifications.

Surface Treatments

Aluminum extrusions can undergo various surface treatments to improve their appearance and durability. Common treatments include anodizing, powder coating, and painting. Anodizing enhances corrosion resistance and can add color, while powder coating provides a durable finish that can withstand harsh environments. These treatments not only protect the aluminum but also allow for creative design options.

Joining Techniques

Customizing 1 x 3 aluminum extrusions often involves joining multiple pieces together. Techniques such as welding, riveting, or using mechanical fasteners can create strong connections between sections, allowing for more complex structures. The choice of joining technique will depend on the specific application and the desired strength of the final assembly.

Adding Accessories

Incorporating accessories such as brackets, connectors, and end caps can enhance the functionality of the extrusion. These components can be designed to fit seamlessly with the 1 x 3 profile, providing additional support or attachment points. Custom accessories can be manufactured to meet specific project requirements, further expanding the versatility of aluminum extrusions.

Applications of 1 x 3 Aluminum Extrusions

The versatility of 1 x 3 aluminum extrusions makes them suitable for a wide range of applications, including:

Frameworks and Structures

1 x 3 aluminum extrusions are commonly used in the construction of frameworks for various structures, including shelving units, display cases, and workstations. Their strength and lightweight nature make them ideal for supporting loads without adding excessive weight. In industrial settings, these extrusions can be used to create modular systems that can be easily reconfigured as needs change.

Automotive and Aerospace

In the automotive and aerospace industries, aluminum extrusions are used for components that require a combination of strength and weight savings. The 1 x 3 profile can be found in structural components, brackets, and support frames. The ability to customize these extrusions allows manufacturers to optimize designs for performance and efficiency.

Furniture Design

Custom furniture often incorporates aluminum extrusions for their modern aesthetic and durability. Designers can create unique pieces that are both functional and visually appealing by utilizing 1 x 3 aluminum profiles. The lightweight nature of aluminum also makes it easier to move and rearrange furniture, adding to its practicality.

Industrial Applications

In industrial settings, 1 x 3 aluminum extrusions are used for machine frames, conveyor systems, and safety guards. Their ability to be customized for specific needs makes them a popular choice in manufacturing environments. The extrusions can be designed to accommodate various components, such as motors and sensors, enhancing the overall functionality of the equipment.

Signage and Displays

Aluminum extrusions are often used in the creation of signage and display systems. The 1 x 3 profile can be easily integrated into various designs, providing a sturdy framework for holding graphics and information. Customization options allow for the incorporation of lighting and other features, making displays more engaging and effective.

The Customization Process

Customizing 1 x 3 aluminum extrusions typically involves several steps:

Design and Planning

Before any physical work begins, it's essential to have a clear design and plan for the customization. This may involve creating detailed drawings or CAD models to visualize the final product. Collaborating with engineers and designers can help ensure that the final design meets all functional and aesthetic requirements.

Material Selection

Choosing the right aluminum alloy is crucial for ensuring the extrusion meets the required strength and durability standards. Different alloys offer varying properties, so selecting the appropriate one for the intended application is essential. Factors such as weight, corrosion resistance, and mechanical properties should be considered during this stage.

Fabrication

Once the design is finalized and materials are selected, the fabrication process can begin. This includes cutting, drilling, and machining the aluminum extrusions according to the specifications. Advanced manufacturing techniques, such as CNC machining, can be employed to achieve high precision and repeatability.

Surface Treatment

After fabrication, surface treatments can be applied to enhance the appearance and performance of the extrusions. This step may involve anodizing, powder coating, or painting, depending on the desired finish. Proper surface treatment not only improves aesthetics but also extends the lifespan of the aluminum by providing additional protection against environmental factors.

Assembly and Installation

Finally, the customized aluminum extrusions can be assembled into the final product or structure. This may involve joining multiple pieces together and adding any necessary accessories or components. Proper assembly techniques are crucial to ensure the structural integrity and functionality of the final product.

Conclusion

Customizing 1 x 3 aluminum extrusions offers a wealth of possibilities for various applications. Their lightweight, strong, and corrosion-resistant properties make them an ideal choice for many industries. By understanding the customization options and processes involved, manufacturers and designers can create tailored solutions that meet specific needs. The ability to adapt aluminum extrusions to fit unique requirements not only enhances functionality but also allows for innovative designs that can set products apart in the marketplace.

Frequently Asked Questions

What is the maximum length for a 1 x 3 aluminum extrusion?

The maximum length can vary depending on the supplier, but standard lengths are typically available in 12-foot sections.

Can I order custom lengths for 1 x 3 aluminum extrusions?

Yes, most suppliers offer the option to order custom lengths based on your project requirements.

What types of surface treatments are available for aluminum extrusions?

Common surface treatments include anodizing, powder coating, and painting, each offering different benefits in terms of appearance and durability.

Is it possible to weld 1 x 3 aluminum extrusions?

Yes, aluminum extrusions can be welded, but it requires specific techniques and equipment to ensure a strong bond.

How do I determine the right aluminum alloy for my project?

The choice of aluminum alloy depends on the specific requirements of your project, including strength, weight, and corrosion resistance. Consulting with a supplier or engineer can help you make the best choice.