Content Menu

● Introduction to Extrusion Equipment

>> Types of Extrusion Equipment

● Factors Influencing Efficiency

>> 1. Maintenance and Setup

>> 2. Energy Efficiency

>> 3. Operational Monitoring

>> 4. Safety Protocols

>> 5. Material Supply Chain

● Operating Extrusion Equipment All Weekend

>> 1. Pre-Weekend Preparation

>> 2. Continuous Monitoring

>> 3. Energy Efficiency Measures

>> 4. Staff Management

● Advanced Technologies in Extrusion

>> 1. Predictive Maintenance

>> 2. Automation and Robotics

>> 3. Real-Time Monitoring

● Challenges and Solutions

>> 1. Equipment Wear and Tear

>> 2. Energy Costs

>> 3. Supply Chain Disruptions

● Conclusion

● FAQs

>> 1. What are the key factors for efficient extrusion equipment operation?

>> 2. How can energy efficiency be improved in extrusion operations?

>> 3. What safety measures should be taken during extrusion operations?

>> 4. Can extrusion equipment operate continuously without human intervention?

>> 5. How does maintenance impact the efficiency of extrusion equipment?

● Citations:

Extrusion equipment is a crucial component in various manufacturing processes, including plastics, metals, and food production. The efficiency of these machines is vital for maintaining continuous production, especially during extended periods such as weekends. In this article, we will explore whether extrusion equipment can operate efficiently all weekend and discuss factors that influence its performance.

Introduction to Extrusion Equipment

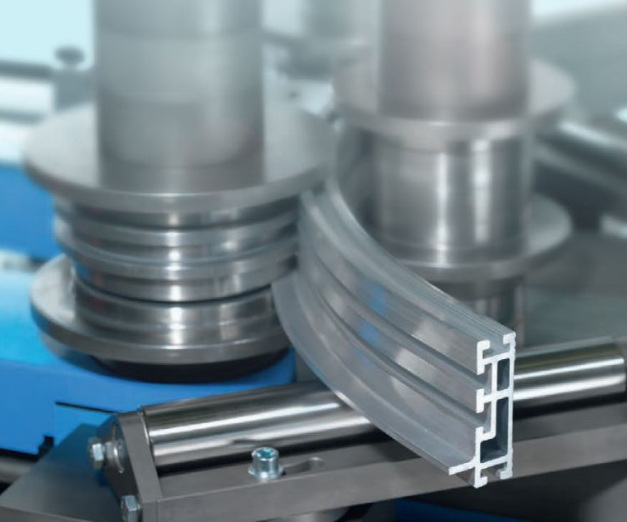

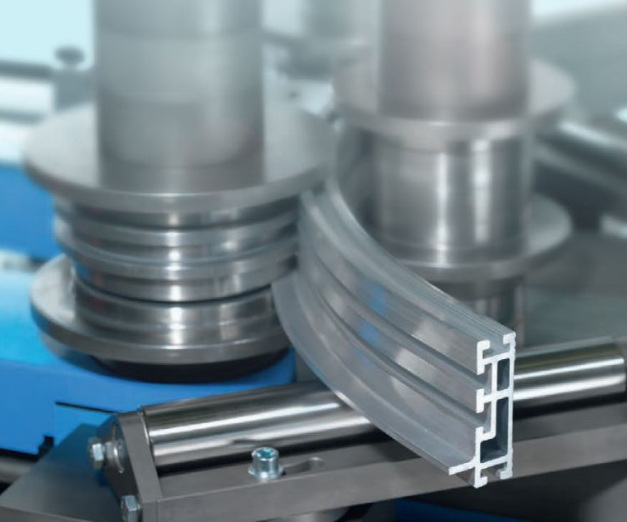

Extrusion equipment is designed to shape materials by forcing them through a die under pressure. This process is widely used in industries like plastics, where it produces pipes, profiles, and packaging materials, and in metals, where it creates rods, tubes, and profiles.

Types of Extrusion Equipment

1. Plastic Extrusion Machines: These are used to produce a variety of plastic products, including PVC pipes, HDPE pipes, and plastic films. They typically consist of a single or twin screw extruder, a die, and a haul-off system.

2. Metal Extrusion Machines: These machines are used to produce metal profiles and tubes. They involve hot or cold extrusion processes, depending on the material and desired properties.

Factors Influencing Efficiency

Several factors determine whether extrusion equipment can operate efficiently all weekend:

1. Maintenance and Setup

Proper maintenance is crucial for efficient operation. This includes regular cleaning, lubrication, and minor repairs. The setup time for extrusion machines can be lengthy, affecting production efficiency if not managed well. Regular checks on the machinery's components, such as the screws and barrels, ensure that they are in good condition and functioning optimally.

2. Energy Efficiency

Modernizing extrusion equipment to improve energy efficiency can enhance overall performance. Techniques include optimizing screw design, using advanced temperature control systems, and recovering energy from cooling systems. Energy-efficient operations not only reduce costs but also contribute to a more sustainable manufacturing process.

3. Operational Monitoring

Continuous monitoring of the extrusion process ensures that materials are shaped correctly and to specification. Adjusting controls in real-time helps maintain quality and consistency. This can be achieved through both manual checks and automated systems that provide real-time data on machine performance.

4. Safety Protocols

Adhering to strict safety standards is essential for preventing accidents and ensuring continuous production. This includes wearing protective gear and following proper machine operation procedures. Regular safety training for operators is also vital to ensure they are aware of potential hazards and know how to respond.

5. Material Supply Chain

A steady supply of raw materials is crucial for maintaining continuous production. Disruptions in the supply chain can lead to downtime, affecting efficiency. Therefore, it is important to have a reliable supplier and maintain a sufficient inventory of materials.

Operating Extrusion Equipment All Weekend

To operate extrusion equipment efficiently all weekend, several strategies can be employed:

1. Pre-Weekend Preparation

- Maintenance Checks: Ensure all machinery is well-maintained before the weekend.

- Material Supply: Stock up on raw materials to avoid supply chain disruptions.

- Staff Training: Ensure operators are trained to handle any issues that may arise.

2. Continuous Monitoring

- Remote Monitoring: Implement remote monitoring systems to track machine performance and address issues promptly.

- Automated Systems: Use automated systems for tasks like temperature control and material feeding.

3. Energy Efficiency Measures

- Optimize Energy Use: Implement energy-saving technologies to reduce consumption.

- Sustainable Practices: Adopt sustainable practices to minimize environmental impact.

4. Staff Management

- Shift Scheduling: Ensure adequate staffing levels throughout the weekend.

- Emergency Procedures: Have clear emergency procedures in place for unexpected issues.

Advanced Technologies in Extrusion

The integration of advanced technologies, such as Industry 4.0 solutions, can significantly enhance the efficiency of extrusion equipment. These technologies include:

1. Predictive Maintenance

Predictive maintenance uses sensors and data analytics to predict when maintenance is needed, reducing downtime and improving overall efficiency.

2. Automation and Robotics

Automating tasks with robotics can improve precision and speed, reducing human error and increasing productivity.

3. Real-Time Monitoring

Real-time monitoring systems provide instant feedback on machine performance, allowing for quick adjustments to maintain optimal conditions.

Challenges and Solutions

Despite the potential for efficient operation, there are challenges to consider:

1. Equipment Wear and Tear

Continuous operation can lead to increased wear and tear on machinery. Regular maintenance and replacement of worn parts are essential to mitigate this issue.

2. Energy Costs

High energy consumption can be a challenge. Implementing energy-efficient technologies and optimizing production schedules can help manage costs.

3. Supply Chain Disruptions

Supply chain issues can halt production. Building strong relationships with suppliers and maintaining a diverse supply chain can help mitigate these risks.

Conclusion

Extrusion equipment can indeed operate efficiently all weekend if proper maintenance, operational monitoring, and safety protocols are in place. Implementing energy-efficient technologies and ensuring a steady supply of raw materials are also crucial. By adopting these strategies, manufacturers can maximize productivity while minimizing downtime.

FAQs

1. What are the key factors for efficient extrusion equipment operation?

Efficient operation of extrusion equipment depends on regular maintenance, proper setup, continuous monitoring, and adherence to safety protocols. Additionally, optimizing energy efficiency and ensuring a steady supply of raw materials are important.

2. How can energy efficiency be improved in extrusion operations?

Improving energy efficiency involves modernizing equipment with advanced temperature control systems, optimizing screw designs, and recovering energy from cooling systems. These measures can significantly reduce energy consumption.

3. What safety measures should be taken during extrusion operations?

Safety measures include wearing protective gear, following proper machine operation procedures, and ensuring electrical safety by grounding machinery and covering terminals. Regular safety checks are also essential.

4. Can extrusion equipment operate continuously without human intervention?

While automation can handle many tasks, continuous human monitoring is still necessary to address unexpected issues and ensure quality control. Remote monitoring systems can help track performance but may not replace human oversight entirely.

5. How does maintenance impact the efficiency of extrusion equipment?

Regular maintenance is crucial for maintaining efficiency. It prevents breakdowns, reduces downtime, and ensures that the equipment operates at optimal levels. Neglecting maintenance can lead to significant losses in productivity and quality.

Citations:

[1] https://www.e3s-conferences.org/articles/e3sconf/pdf/2018/48/e3sconf_icenis18_05003.pdf

[2] https://www.rssinc.com/blog/what-is-an-extrusion-machine-operator/

[3] https://www.linkedin.com/pulse/ways-maximise-energy-efficiency-extrusion-operation-richard-brookes

[4] https://www.alamy.com/stock-photo/extrusion-machine.html

[5] https://www.youtube.com/watch?v=Rf5DQR5qXxU

[6] https://www.ptonline.com/articles/how-to-get-peak-performance-efficiency-out-of-your-extrusion-line---part-i

[7] https://www.plasticstoday.com/extrusion-pipe-profile/extrusion-basics-safe-at-home-and-at-work

[8] https://www.youtube.com/watch?v=Y75IQksBb0M

[9] https://coperion.com/en/news-media/newsletter/2021/plastics-in-focus-edition-042021/energy-efficiency-in-extrusion

[10] https://www.youtube.com/watch?v=WaB-dsB1Kfk

[11] https://www.umac-recyclingmachines.com/en/plastic-extrusion-equipment/

[12] https://www.goodfishgroup.com/plastic-extrusion-company

[13] https://www.pearltechinc.com/2025/02/13/extrusion-equipment-blown-film-efficiency/

[14] https://www.grandviewresearch.com/industry-analysis/extrusion-machinery-market-report

[15] https://firstratemold.com/introduction-to-equipment-of-extrusion/

[16] https://www.linkedin.com/pulse/how-use-plastic-extruder-maintain-it%E4%B8%89-jessie-zhai

[17] https://www.baumueller.com/en/industries/plastics-machines/extrusion-machines

[18] https://jobs.veolia.com/en/job/hopkins/extrusion-machine-operator-i-night-shift/3091/22147260480

[19] https://www.goodfishgroup.com/what-can-be-made-using-plastic-extrusion

[20] https://www.indeed.com/cmp/Genpak/reviews?fcountry=ALL&fjobtitle=Extrusion+Operator