Content Menu

● Introduction to Aluminum Extrusion

● Understanding Aluminum Extrusion Techniques

● Custom Aluminum Profiles: Tailoring Solutions for Every Need

● Automotive Aluminum Applications: Driving Innovation on the Road

● Anodizing And Fabrication Services: Enhancing Aluminum's Potential

● Industrial Aluminum Solutions: Powering Progress Across Sectors

● Architectural Aluminum Extrusions: Building the Future

● High-Quality Aluminum Products: The Foundation of Success

● Precision Aluminum Manufacturing: The Art of Exactitude

● Innovative Extrusion Technology: Pushing the Boundaries

● Sustainable Aluminum Solutions: A Greener Future

● Conclusion: The Future of Aluminum Extrusion

● Frequently Asked Questions

>> Q1: What are the main advantages of using aluminum extrusions?

>> Q2: How does the aluminum extrusion process work?

>> Q3: What industries benefit most from aluminum extrusions?

>> Q4: How does aluminum extrusion contribute to sustainability?

>> Q5: What are some emerging trends in aluminum extrusion technology?

Introduction to Aluminum Extrusion

In the world of manufacturing and construction, few materials have made as significant an impact as aluminum. Its versatility, strength, and lightweight properties have made it a go-to choice for countless applications. At the forefront of this aluminum revolution stands the process of extrusion, a technique that has transformed the way we shape and utilize this remarkable metal. In this comprehensive exploration, we'll delve into the world of aluminum extrusion, with a special focus on industry leaders like Can Art Aluminum Extrusion.

Understanding Aluminum Extrusion Techniques

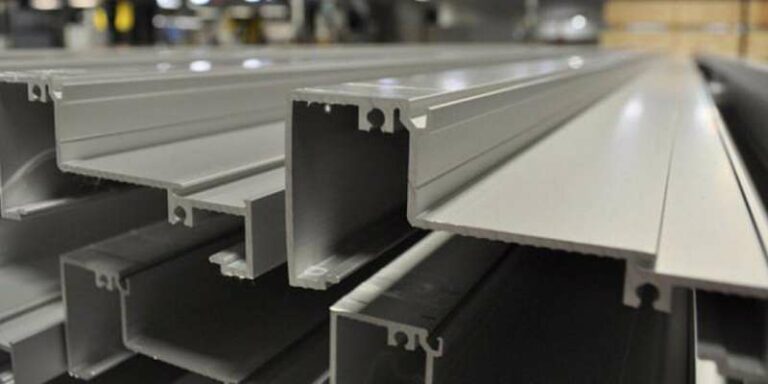

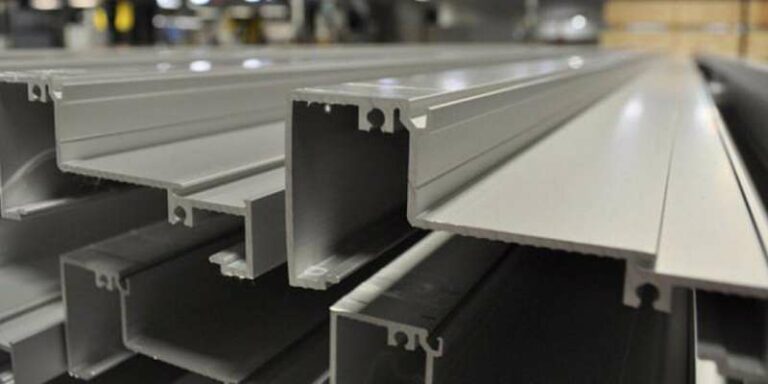

Aluminum extrusion is a process that involves forcing heated aluminum through a die to create specific shapes and profiles. This technique allows for the creation of complex and precise forms that would be difficult or impossible to achieve through other manufacturing methods. The process begins with heating aluminum billets to a temperature where the metal becomes malleable but not molten. These heated billets are then pushed through a die using hydraulic rams, emerging on the other side in the desired shape.

The versatility of this process allows for the creation of both standard and custom aluminum profiles, catering to a wide range of industries and applications. From simple shapes like tubes and bars to complex cross-sections for specialized uses, aluminum extrusion offers unparalleled flexibility in design and production.

Custom Aluminum Profiles: Tailoring Solutions for Every Need

One of the most significant advantages of aluminum extrusion is the ability to create custom profiles. This capability allows manufacturers to design and produce aluminum components that perfectly match their specific requirements. Whether it's a unique shape for an architectural facade or a precisely engineered part for an automotive application, custom aluminum profiles offer a level of customization that few other manufacturing processes can match.

Companies like Can Art Aluminum Extrusion specialize in producing these custom profiles, working closely with clients to understand their needs and translate them into tangible, high-quality aluminum products. This collaborative approach ensures that each extrusion is optimized for its intended use, whether it's for strength, weight reduction, or aesthetic appeal.

Automotive Aluminum Applications: Driving Innovation on the Road

The automotive industry has been one of the biggest beneficiaries of advancements in aluminum extrusion technology. As automakers strive to create vehicles that are lighter, more fuel-efficient, and safer, aluminum has become an increasingly important material in car manufacturing.

Extruded aluminum components are used in various parts of modern vehicles, including:

1. Structural components for improved crash performance

2. Body panels for weight reduction

3. Heat exchangers for efficient cooling systems

4. Interior trim and decorative elements

The use of aluminum in automotive applications not only contributes to improved fuel efficiency but also enhances vehicle performance and durability. As the automotive industry continues to evolve, with a growing focus on electric and hybrid vehicles, the demand for lightweight, high-strength aluminum components is expected to increase even further.

Anodizing And Fabrication Services: Enhancing Aluminum's Potential

While the extrusion process itself is crucial, the finishing touches often make the difference between a good product and an exceptional one. Anodizing is a key process in enhancing the properties of extruded aluminum. This electrochemical process creates a durable, corrosion-resistant oxide layer on the surface of the aluminum, which can also be dyed to achieve various colors and finishes.

Fabrication services further expand the possibilities of extruded aluminum profiles. These services can include:

- Cutting and machining

- Drilling and tapping

- Welding and assembly

- Surface finishing and painting

By offering comprehensive anodizing and fabrication services, companies like Can Art Aluminum Extrusion provide end-to-end solutions for their clients, ensuring that the final product meets exact specifications and quality standards.

Industrial Aluminum Solutions: Powering Progress Across Sectors

The applications of aluminum extrusions in industrial settings are vast and varied. From heavy machinery to delicate electronic components, extruded aluminum finds its way into countless industrial applications. Some key areas include:

1. Manufacturing equipment and machinery

2. Conveyor systems and material handling

3. Electrical enclosures and heat sinks

4. Renewable energy systems, such as solar panel frames

The strength-to-weight ratio of aluminum makes it an ideal choice for many industrial applications where durability and efficiency are paramount. Its excellent thermal and electrical conductivity also make it a preferred material for applications involving heat management or electrical systems.

Architectural Aluminum Extrusions: Building the Future

In the world of architecture and construction, aluminum extrusions have revolutionized the way we design and build structures. From sleek skyscrapers to energy-efficient homes, extruded aluminum profiles play a crucial role in modern architecture. Some common applications include:

- Window and door frames

- Curtain wall systems

- Railings and balustrades

- Decorative facades and cladding

The versatility of extruded aluminum allows architects and designers to push the boundaries of what's possible in building design. Its ability to be formed into complex shapes while maintaining structural integrity opens up new possibilities for creative and functional architectural elements.

High-Quality Aluminum Products: The Foundation of Success

At the heart of every successful aluminum extrusion company is a commitment to producing high-quality products. This commitment involves several key factors:

1. Superior raw materials: Using high-grade aluminum alloys ensures the final product meets or exceeds industry standards.

2. Advanced extrusion technology: State-of-the-art equipment and processes result in more precise and consistent extrusions.

3. Rigorous quality control: Implementing strict quality assurance measures at every stage of production.

4. Continuous innovation: Investing in research and development to improve products and processes.

Companies like Can Art Aluminum Extrusion have built their reputation on delivering high-quality aluminum products that meet the exacting standards of their clients across various industries.

Precision Aluminum Manufacturing: The Art of Exactitude

In many applications, particularly in industries like aerospace and electronics, precision is not just desirable – it's essential. Precision aluminum manufacturing involves creating extrusions with extremely tight tolerances and consistent quality. This level of precision requires:

- Advanced die design and manufacturing

- Highly controlled extrusion processes

- Sophisticated measurement and quality control systems

- Skilled operators and engineers

The ability to produce precise aluminum components opens up new possibilities in product design and functionality, allowing for the creation of complex, high-performance parts that meet the most demanding specifications.

Innovative Extrusion Technology: Pushing the Boundaries

The field of aluminum extrusion is constantly evolving, with new technologies and techniques emerging to improve efficiency, quality, and capabilities. Some of the latest innovations in extrusion technology include:

1. Computer-aided die design and simulation

2. Advanced process control systems

3. Improved billet heating and cooling techniques

4. Enhanced surface finishing technologies

These innovations allow for the production of more complex profiles, faster production speeds, and improved overall quality. Companies at the forefront of these technological advancements, like Can Art Aluminum Extrusion, are able to offer their clients cutting-edge solutions that push the boundaries of what's possible with aluminum extrusion.

Sustainable Aluminum Solutions: A Greener Future

In an era of increasing environmental awareness, the aluminum industry has made significant strides in sustainability. Aluminum is inherently recyclable, with the ability to be melted down and reused indefinitely without losing its properties. This characteristic makes it an excellent choice for environmentally conscious manufacturers and consumers.

Sustainable practices in aluminum extrusion include:

- Using recycled aluminum in production

- Implementing energy-efficient extrusion processes

- Minimizing waste through precise material usage

- Developing products that contribute to energy efficiency in their end-use applications

By focusing on sustainable aluminum solutions, companies not only reduce their environmental impact but also meet the growing demand for eco-friendly products across various industries.

Conclusion: The Future of Aluminum Extrusion

As we look to the future, the role of aluminum extrusion in shaping our world continues to grow. From the cars we drive to the buildings we live and work in, extruded aluminum profiles play a crucial role in countless aspects of modern life. Companies like Can Art Aluminum Extrusion are at the forefront of this industry, driving innovation, quality, and sustainability.

The ongoing development of new alloys, extrusion techniques, and applications ensures that the field of aluminum extrusion will remain dynamic and essential for years to come. As we face global challenges such as climate change and resource scarcity, the versatility, recyclability, and efficiency of aluminum extrusions will undoubtedly play a significant role in creating solutions for a sustainable future.

Frequently Asked Questions

Q1: What are the main advantages of using aluminum extrusions?

A1: The main advantages of aluminum extrusions include their lightweight nature, strength, corrosion resistance, design flexibility, and recyclability. These properties make them ideal for a wide range of applications across various industries, from automotive and aerospace to construction and consumer goods.

Q2: How does the aluminum extrusion process work?

A2: The aluminum extrusion process involves heating aluminum billets and forcing them through a die using hydraulic pressure. The aluminum takes the shape of the die as it's pushed through, creating a profile that can be cut to desired lengths. This process allows for the creation of complex shapes and profiles that would be difficult or impossible to achieve through other manufacturing methods.

Q3: What industries benefit most from aluminum extrusions?

A3: While aluminum extrusions are used across many sectors, the industries that benefit most include automotive, construction, aerospace, electronics, and renewable energy. These industries leverage the unique properties of extruded aluminum to create lightweight, strong, and efficient components for their products.

Q4: How does aluminum extrusion contribute to sustainability?

A4: Aluminum extrusion contributes to sustainability in several ways. Firstly, aluminum is 100% recyclable and can be recycled indefinitely without losing its properties. Additionally, the extrusion process itself is relatively energy-efficient compared to other metal forming processes. Extruded aluminum products often contribute to energy efficiency in their end-use applications, such as in lightweight vehicles or energy-efficient building systems.

Q5: What are some emerging trends in aluminum extrusion technology?

A5: Emerging trends in aluminum extrusion technology include the development of new high-strength aluminum alloys, advancements in die design and manufacturing, improved process control systems for greater precision, and the integration of AI and machine learning for optimized production. There's also a growing focus on developing extrusion techniques for more complex and larger profiles to meet evolving industry needs.