Content Menu

● Understanding Aluminum Extrusion

● The Role of CNC Routers in Aluminum Machining

● Can CNC Routers Handle Complex Designs?

● Applications of Aluminum Extrusion CNC Routers

>> Aerospace Industry

>> Automotive Industry

>> Construction Industry

>> Electronics Industry

>> Furniture Design

● Challenges in Machining Complex Designs

● Innovations in Aluminum Extrusion CNC Routers

● Conclusion

● FAQs

>> 1. What types of designs can an aluminum extrusion CNC router handle?

>> 2. How does the machining process differ for aluminum compared to other materials?

>> 3. What software is commonly used for programming CNC routers?

>> 4. Are there limitations on the size of parts that can be machined?

>> 5. How do I maintain an aluminum extrusion CNC router?

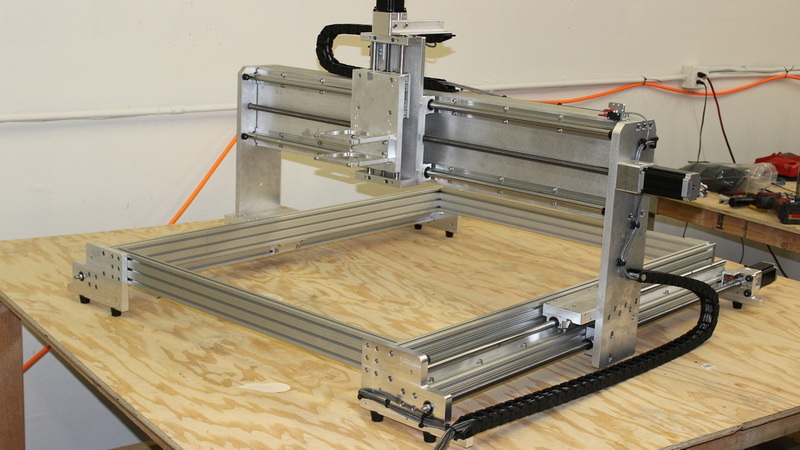

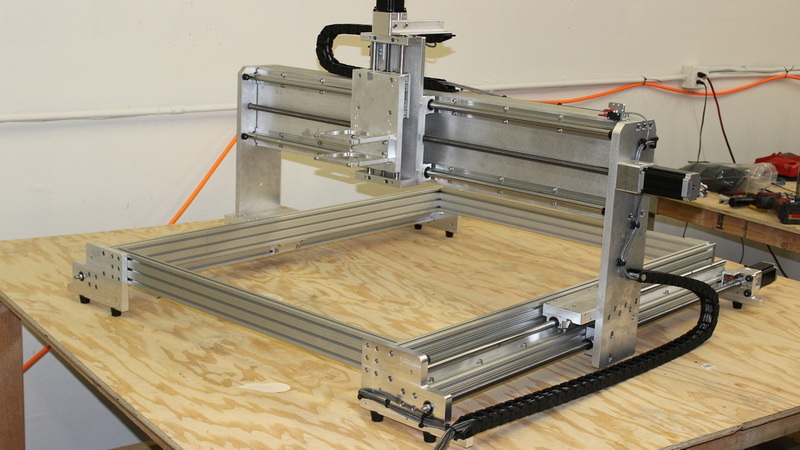

Aluminum extrusion CNC routers have revolutionized the manufacturing landscape, enabling the creation of intricate and complex designs with unparalleled precision. This article delves into the capabilities of aluminum extrusion CNC routers, exploring their advantages, applications, and the technology that empowers them. We will also address common questions regarding their functionality and effectiveness in handling complex designs.

Understanding Aluminum Extrusion

What is Aluminum Extrusion?

Aluminum extrusion is a manufacturing process that involves shaping aluminum alloys by forcing them through a die to create specific cross-sectional profiles. This method is widely used due to aluminum's lightweight, strength, and resistance to corrosion. Common applications include structural components in construction, automotive parts, and various industrial applications.

Key Benefits of Aluminum Extrusion:

- Lightweight yet strong

- Excellent corrosion resistance

- Versatile in design possibilities

- Cost-effective for large-scale production

The Role of CNC Routers in Aluminum Machining

What is a CNC Router?

A CNC (Computer Numerical Control) router is a machine that automates the routing process using computer programming. These machines can cut, carve, and engrave materials with high precision, making them ideal for complex designs.

Advantages of Using CNC Routers for Aluminum Extrusion:

- Precision: CNC routers can achieve tolerances as tight as 0.1mm, ensuring that every piece meets exact specifications.

- Versatility: They can handle various materials beyond aluminum, including plastics and composites.

- Efficiency: CNC routers reduce production time by allowing multiple operations to be performed in one setup.

Can CNC Routers Handle Complex Designs?

Complex Design Capabilities

Yes, aluminum extrusion CNC routers are specifically designed to handle complex designs. Their advanced software and hardware capabilities enable them to execute intricate patterns and shapes that would be challenging or impossible with traditional machining methods.

Factors Contributing to Complexity Handling:

- Multi-Axis Machining: Many modern CNC routers feature multi-axis capabilities (such as 5-axis machining), allowing for more complex geometries and angles.

- Advanced Tooling: The ability to switch between different tools automatically enhances the router's versatility in handling various tasks without manual intervention.

- Software Integration: CAD/CAM software integration allows designers to create intricate designs digitally, which the CNC router can then execute with precision.

Applications of Aluminum Extrusion CNC Routers

Industries Benefiting from CNC Machining

1. Aerospace: Precision components for aircraft structures.

2. Automotive: Lightweight parts that improve fuel efficiency.

3. Construction: Structural elements like window frames and supports.

4. Electronics: Custom enclosures for devices.

5. Furniture Design: Unique shapes for modern furniture pieces.

Aerospace Industry

In the aerospace sector, where weight reduction is crucial for improving fuel efficiency, aluminum extrusion CNC routers are invaluable. They produce complex components such as brackets, frames, and fittings that meet stringent safety standards while minimizing weight. The ability to create intricate designs allows manufacturers to optimize aerodynamics and enhance performance.

Automotive Industry

The automotive industry also benefits significantly from aluminum extrusion CNC routers. With the push towards lighter vehicles for better fuel efficiency and lower emissions, manufacturers use these machines to create parts like chassis components, engine blocks, and body panels. The precision offered by CNC routers ensures that these critical parts fit perfectly during assembly.

Construction Industry

In construction, aluminum extrusions are used extensively for window frames, door frames, and other structural elements. The ability to create custom profiles means architects can design unique buildings with aesthetic appeal while maintaining structural integrity. CNC routers allow for rapid prototyping and production of these components.

Electronics Industry

In electronics manufacturing, custom enclosures are often required to protect sensitive components from environmental factors. Aluminum extrusion CNC routers can create these enclosures with precise dimensions and intricate designs that accommodate various electronic parts while ensuring adequate ventilation and heat dissipation.

Furniture Design

The furniture industry has also embraced aluminum extrusion CNC routers for creating modern furniture pieces with unique shapes and designs. Designers can experiment with complex forms that enhance both aesthetics and functionality, resulting in innovative products that stand out in the market.

Challenges in Machining Complex Designs

While aluminum extrusion CNC routers are adept at handling complex designs, there are challenges involved:

- Material Properties: The machinability of aluminum can vary based on its alloy composition, which may affect cutting speeds and tool wear.

- Tooling Costs: High-quality tooling is essential for maintaining precision during complex cuts, which can increase initial setup costs.

- Programming Complexity: Designing intricate patterns requires skilled operators who are proficient in CAD/CAM software.

Addressing Challenges:

To mitigate these challenges, manufacturers often invest in training programs for their operators to ensure they are well-versed in both the machinery and software used in the design process. Additionally, selecting the right alloy for specific applications can greatly enhance machinability while reducing costs associated with tooling wear.

Innovations in Aluminum Extrusion CNC Routers

The field of aluminum extrusion machining is continually evolving with technological advancements. Recent innovations include:

- Automation: Many modern CNC routers incorporate automation features such as robotic arms for loading and unloading materials, which increases efficiency and reduces labor costs.

- IoT Integration: Internet of Things (IoT) technology allows machines to communicate data regarding performance metrics and maintenance needs, enabling predictive maintenance strategies that minimize downtime.

- Advanced Sensors: Sensors integrated into machines monitor cutting conditions in real-time, adjusting parameters automatically to optimize performance based on material characteristics.

These innovations not only enhance productivity but also improve the overall quality of the finished products.

Conclusion

In summary, aluminum extrusion CNC routers are highly capable machines that excel at handling complex designs across various industries. Their precision, versatility, and efficiency make them invaluable tools in modern manufacturing processes. As technology continues to advance, we can expect even greater capabilities from these machines, further enhancing their role in producing intricate aluminum components.

With their ability to integrate advanced software systems and automation technologies, aluminum extrusion CNC routers will continue to push the boundaries of what is possible in design and manufacturing. As industries seek greater customization and innovation in their products, these machines will play a crucial role in meeting those demands while maintaining high standards of quality and efficiency.

FAQs

1. What types of designs can an aluminum extrusion CNC router handle?

Aluminum extrusion CNC routers can handle a wide range of designs from simple shapes to highly intricate patterns and geometries thanks to their multi-axis capabilities and advanced tooling systems.

2. How does the machining process differ for aluminum compared to other materials?

Aluminum machining often requires different feed rates and cutting tools compared to harder materials like steel due to its unique properties such as softness and thermal conductivity.

3. What software is commonly used for programming CNC routers?

Common software includes CAD (Computer-Aided Design) software for creating designs and CAM (Computer-Aided Manufacturing) software for generating the tool paths necessary for machining processes.

4. Are there limitations on the size of parts that can be machined?

Yes, there are size limitations based on the specific model of the CNC router; however, many machines are designed with large work envelopes to accommodate substantial extrusions.

5. How do I maintain an aluminum extrusion CNC router?

Regular maintenance includes checking tool wear, ensuring proper lubrication of moving parts, calibrating machine settings, and keeping the workspace clean from debris.