Content Menu

● Understanding Aluminum Extrusions

>> Benefits of Using Aluminum Extrusions

● Applications of Aluminum Extrusions in Furniture Design

>> 1. Tables and Desks

>> 2. Chairs and Seating

>> 3. Shelving Units

>> 4. Cabinets and Storage Solutions

>> 5. Outdoor Furniture

● Designing with Aluminum Extrusions

>> 1. Choosing the Right Profile

>> 2. Finishing Options

>> 3. Joining Techniques

>> 4. Incorporating Other Materials

● Innovative Design Ideas Using Aluminum Extrusions

>> 1. Modular Furniture Systems

>> 2. Multi-Functional Pieces

>> 3. Artistic Expressions

>> 4. Sustainable Design Practices

>> 5. Customization for Branding

● Conclusion

● Frequently Asked Questions

>> 1. What are the advantages of using aluminum extrusions in furniture design?

>> 2. Can aluminum extrusions be used for outdoor furniture?

>> 3. How do I choose the right aluminum profile for my project?

>> 4. What finishing options are available for aluminum extrusions?

>> 5. Can aluminum extrusions be combined with other materials?

Understanding Aluminum Extrusions

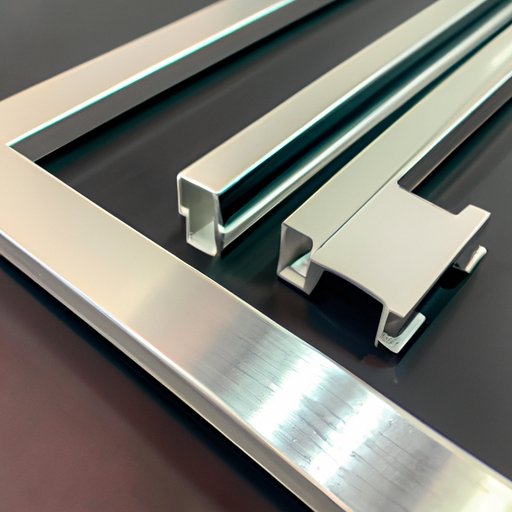

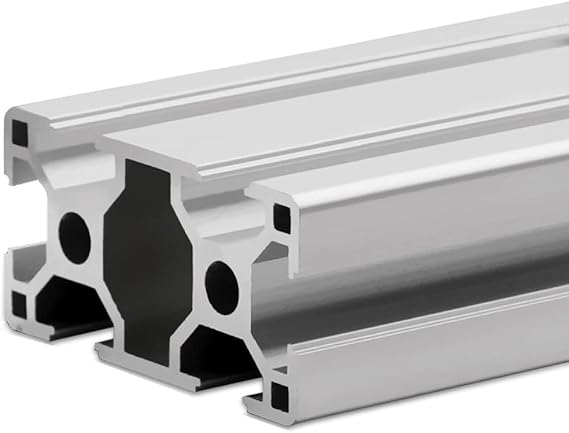

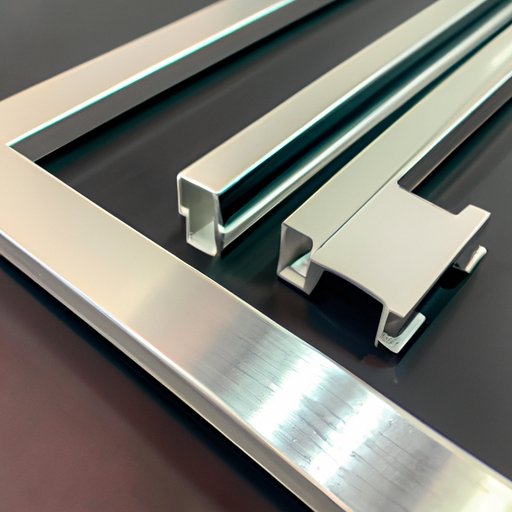

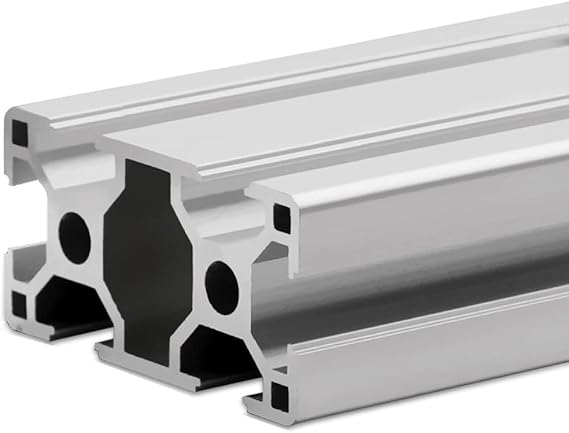

Aluminum extrusion is a manufacturing process that involves shaping aluminum alloy into a desired cross-sectional profile. This is achieved by forcing the aluminum through a die, which creates a specific shape. The resulting extrusions can be cut to length and finished in various ways, making them suitable for a wide range of applications.

Benefits of Using Aluminum Extrusions

1. Lightweight and Durable: Aluminum is significantly lighter than other metals, such as steel, yet it offers excellent strength and durability. This makes it an ideal choice for furniture that needs to be both sturdy and easy to move.

2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer that prevents corrosion. This property makes aluminum extrusions suitable for both indoor and outdoor furniture designs.

3. Design Flexibility: The extrusion process allows for a wide variety of shapes and sizes, enabling designers to create unique and innovative furniture pieces. Custom profiles can be developed to meet specific design requirements.

4. Sustainability: Aluminum is a recyclable material, making it an environmentally friendly choice for furniture design. Using recycled aluminum can further reduce the environmental impact of furniture production.

5. Aesthetic Appeal: Aluminum extrusions can be finished in various ways, including anodizing, powder coating, and painting. This allows for a wide range of colors and textures, enhancing the visual appeal of custom furniture.

Applications of Aluminum Extrusions in Furniture Design

1. Tables and Desks

Aluminum extrusions can be used to create modern and minimalist tables and desks. The clean lines and sleek appearance of aluminum make it an excellent choice for contemporary office furniture. Designers can create custom legs and frames that provide both stability and style.

2. Chairs and Seating

Aluminum extrusions can be used to construct lightweight and durable chairs. The material's strength allows for innovative designs that can support various seating styles, from lounge chairs to dining chairs. Custom extrusions can be designed to create unique backrests and armrests.

3. Shelving Units

Custom shelving units made from aluminum extrusions offer a modern and industrial look. The lightweight nature of aluminum allows for easy installation and rearrangement. Designers can create modular shelving systems that can be adapted to different spaces and needs.

4. Cabinets and Storage Solutions

Aluminum extrusions can be used to create stylish cabinets and storage solutions. The material's strength allows for larger designs without compromising stability. Custom extrusions can be used for cabinet frames, doors, and drawer slides.

5. Outdoor Furniture

Aluminum's corrosion resistance makes it an excellent choice for outdoor furniture. Custom designs can be created for patio sets, loungers, and garden furniture. The lightweight nature of aluminum also makes it easy to move and rearrange outdoor spaces.

Designing with Aluminum Extrusions

When designing custom furniture with aluminum extrusions, there are several factors to consider:

1. Choosing the Right Profile

Selecting the appropriate aluminum profile is crucial for the success of your design. Consider the intended use of the furniture, the weight it needs to support, and the overall aesthetic you want to achieve. Custom profiles can be created to meet specific design needs.

2. Finishing Options

Aluminum extrusions can be finished in various ways to enhance their appearance and durability. Anodizing provides a protective layer and can add color, while powder coating offers a wide range of color options and textures. Consider the finish that best suits your design vision.

3. Joining Techniques

There are several methods for joining aluminum extrusions, including welding, mechanical fasteners, and adhesive bonding. The choice of joining technique will depend on the design requirements and the intended use of the furniture.

4. Incorporating Other Materials

Aluminum extrusions can be combined with other materials, such as wood, glass, or fabric, to create unique and functional furniture pieces. Consider how different materials can complement each other in your design.

Innovative Design Ideas Using Aluminum Extrusions

1. Modular Furniture Systems

One of the most exciting applications of aluminum extrusions in furniture design is the creation of modular furniture systems. These systems allow users to customize their furniture according to their needs. For example, a modular sofa can be rearranged into different configurations, adapting to various spaces and occasions. The use of aluminum extrusions in these designs ensures that the furniture remains lightweight yet sturdy, making it easy to move and reconfigure.

2. Multi-Functional Pieces

Aluminum extrusions can also be used to create multi-functional furniture. For instance, a coffee table can be designed with hidden storage compartments or extendable surfaces. This versatility is particularly appealing in smaller living spaces where maximizing functionality is essential. The sleek design of aluminum extrusions complements modern aesthetics while providing practical solutions.

3. Artistic Expressions

Designers are increasingly using aluminum extrusions as a medium for artistic expression. By experimenting with different shapes, colors, and finishes, they can create statement pieces that serve as focal points in a room. Sculptural furniture made from aluminum extrusions can blend art and functionality, making them ideal for galleries, showrooms, or contemporary homes.

4. Sustainable Design Practices

As sustainability becomes a priority in furniture design, aluminum extrusions offer an eco-friendly option. Designers can utilize recycled aluminum to create new furniture pieces, reducing waste and energy consumption. Additionally, the durability of aluminum means that furniture made from this material can last for many years, further minimizing environmental impact.

5. Customization for Branding

Businesses can leverage aluminum extrusions to create customized furniture that reflects their brand identity. For example, a café might use aluminum extrusions to design unique tables and chairs that align with their branding. The ability to customize shapes, colors, and finishes allows businesses to create a cohesive look that enhances their overall aesthetic.

Conclusion

Aluminum extrusions offer a versatile and innovative solution for custom furniture design. Their lightweight nature, durability, and aesthetic appeal make them an excellent choice for a wide range of applications. By understanding the benefits and design possibilities of aluminum extrusions, designers can create unique and functional furniture pieces that stand out in any space.

Frequently Asked Questions

1. What are the advantages of using aluminum extrusions in furniture design?

Aluminum extrusions are lightweight, durable, corrosion-resistant, and offer design flexibility. They can be finished in various ways to enhance their aesthetic appeal.

2. Can aluminum extrusions be used for outdoor furniture?

Yes, aluminum's corrosion resistance makes it an excellent choice for outdoor furniture, allowing for stylish and functional designs.

3. How do I choose the right aluminum profile for my project?

Consider the intended use, weight requirements, and overall aesthetic when selecting an aluminum profile. Custom profiles can be created to meet specific needs.

4. What finishing options are available for aluminum extrusions?

Aluminum extrusions can be anodized, powder-coated, or painted to achieve different colors and textures, enhancing their appearance and durability.

5. Can aluminum extrusions be combined with other materials?

Yes, aluminum extrusions can be combined with materials like wood, glass, or fabric to create unique and functional furniture designs.