Content Menu

● Understanding Aluminum Extrusion

>> Benefits of Aluminum Extrusions

● Customization Options for 40x80 Aluminum Extrusions

>> Length Adjustments

>> Surface Finishing

>> Custom Holes and Slots

>> Special Shapes and Profiles

>> Integrated Features

● Applications of 40x80 Aluminum Extrusions

>> Structural Frameworks

>> Automotive Components

>> Furniture and Fixtures

>> Transportation and Logistics

>> Signage and Displays

● The Customization Process

● Conclusion

● Frequently Asked Questions

>> 1. What is the maximum length for a customized 40x80 aluminum extrusion?

>> 2. Can I order a small quantity of customized aluminum extrusions?

>> 3. How long does it take to produce customized aluminum extrusions?

>> 4. Are there any design limitations for custom aluminum extrusions?

>> 5. What types of finishes are available for aluminum extrusions?

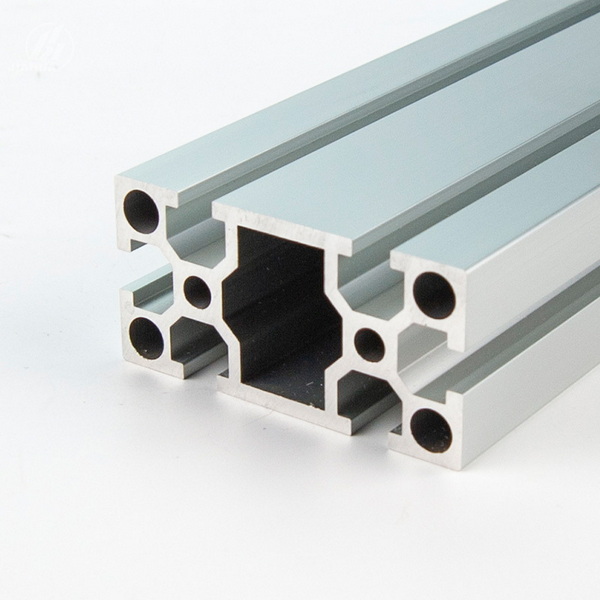

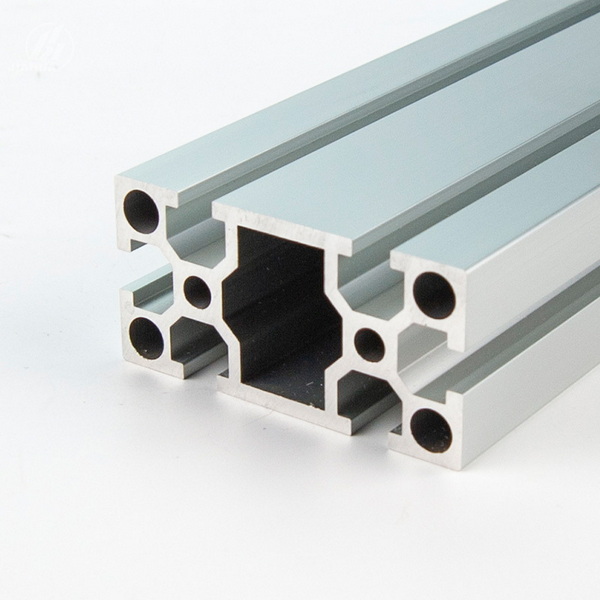

Aluminum extrusions have become a cornerstone in various industries due to their versatility, strength, and lightweight properties. Among the many sizes available, the 40x80 aluminum extrusion stands out for its unique dimensions and adaptability. This article explores the customization options available for 40x80 aluminum extrusions, their applications, and the benefits of tailoring these profiles to meet specific needs.

Understanding Aluminum Extrusion

Aluminum extrusion is a manufacturing process that involves forcing aluminum alloy through a die to create a specific cross-sectional shape. This process allows for the production of complex shapes that can be used in a wide range of applications, from structural components to decorative elements. The 40x80 aluminum extrusion refers to a profile that measures 40mm in width and 80mm in height, making it suitable for various structural and framing applications.

Benefits of Aluminum Extrusions

1. Lightweight: Aluminum is significantly lighter than steel, making it easier to handle and transport.

2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which helps resist corrosion, making it ideal for outdoor applications.

3. Strength: Despite its lightweight nature, aluminum is strong and can support substantial loads, especially when used in structural applications.

4. Versatility: Aluminum extrusions can be easily customized to meet specific design requirements, including length, shape, and surface finish.

Customization Options for 40x80 Aluminum Extrusions

Customization is one of the key advantages of using aluminum extrusions. The 40x80 profile can be tailored in several ways to meet specific project requirements:

Length Adjustments

One of the most straightforward customization options is adjusting the length of the extrusion. Manufacturers can cut the 40x80 aluminum extrusion to the exact length required for a project, minimizing waste and ensuring a perfect fit. This flexibility is particularly beneficial in projects where space constraints are a concern, allowing for precise installations without the need for additional modifications.

Surface Finishing

The surface finish of aluminum extrusions can significantly impact their appearance and performance. Common finishing options include:

- Anodizing: This process enhances corrosion resistance and can add color to the extrusion. Anodized finishes are popular in architectural applications where aesthetics are important.

- Powder Coating: A durable finish that provides a wide range of color options and additional protection against wear and tear. Powder coating is often used in furniture and consumer products to enhance visual appeal.

- Mill Finish: The natural finish of the aluminum after extrusion, which can be left as is for a more industrial look. This finish is often chosen for applications where the raw aluminum appearance is desired.

Custom Holes and Slots

To facilitate assembly and integration with other components, custom holes and slots can be added to the 40x80 aluminum extrusion. This customization allows for easy attachment of brackets, fasteners, and other hardware, making it ideal for modular construction. The ability to incorporate specific hole patterns can streamline the assembly process, reducing installation time and labor costs.

Special Shapes and Profiles

While the standard 40x80 profile is versatile, some projects may require unique shapes. Manufacturers can create custom dies to produce specialized profiles that meet specific design criteria. This flexibility is particularly beneficial in industries such as automotive, aerospace, and construction, where unique design requirements are common.

Integrated Features

For advanced applications, extrusions can be designed with integrated features such as channels for wiring, grooves for sliding mechanisms, or even thermal breaks for improved insulation. These integrated features can streamline assembly and enhance the functionality of the final product. For example, a 40x80 extrusion with integrated wiring channels can simplify the installation of electrical components in machinery or lighting fixtures.

Applications of 40x80 Aluminum Extrusions

The versatility of 40x80 aluminum extrusions makes them suitable for a wide range of applications, including:

Structural Frameworks

In construction and manufacturing, 40x80 aluminum extrusions are often used to create structural frameworks for machinery, workstations, and assembly lines. Their strength and lightweight nature make them ideal for supporting heavy loads while remaining easy to handle. The ability to customize lengths and integrate features allows for the creation of tailored solutions that meet specific operational needs.

Automotive Components

The automotive industry utilizes aluminum extrusions for various components, including chassis, frames, and body panels. The 40x80 profile can be customized to meet the specific requirements of different vehicle models, contributing to weight reduction and improved fuel efficiency. As manufacturers strive to meet stricter fuel economy standards, the use of lightweight materials like aluminum is becoming increasingly important.

Furniture and Fixtures

Aluminum extrusions are increasingly used in furniture design, particularly for modern and industrial styles. The 40x80 profile can be used to create sturdy tables, shelving units, and display fixtures, offering both aesthetic appeal and functionality. The ability to customize colors and finishes allows designers to create unique pieces that fit specific interior design themes.

Transportation and Logistics

In the transportation sector, 40x80 aluminum extrusions are used to build lightweight and durable structures for trailers, shipping containers, and cargo handling equipment. Their resistance to corrosion makes them ideal for use in harsh environments. Customization options, such as integrated features for securing cargo, enhance the functionality of these extrusions in logistics applications.

Signage and Displays

The retail and advertising industries often use aluminum extrusions for signage and display systems. The 40x80 profile can be customized to create eye-catching displays that are both lightweight and durable. The ability to incorporate lighting elements or digital displays into the extrusion design can further enhance the visibility and impact of promotional materials.

The Customization Process

The process of customizing 40x80 aluminum extrusions typically involves several steps:

1. Consultation: Clients discuss their specific needs with manufacturers, including dimensions, finishes, and any additional features required. This initial step is crucial for understanding the project scope and ensuring that all requirements are captured.

2. Design and Prototyping: Manufacturers create detailed designs and prototypes to ensure the extrusion meets the client's specifications. This phase may involve CAD modeling and 3D printing to visualize the final product before production.

3. Production: Once the design is approved, the extrusion is produced using the appropriate die and finishing processes. Advanced manufacturing techniques ensure that the extrusions are produced efficiently and to high-quality standards.

4. Quality Control: The finished product undergoes rigorous quality checks to ensure it meets industry standards and client expectations. This step is essential for maintaining the integrity and performance of the extrusions in their intended applications.

5. Delivery: Customized extrusions are packaged and delivered to the client for installation. Timely delivery is critical, especially in industries where project timelines are tight.

Conclusion

The ability to customize 40x80 aluminum extrusions makes them an invaluable resource across various industries. From structural applications to decorative elements, these extrusions can be tailored to meet specific needs, enhancing their functionality and aesthetic appeal. As industries continue to evolve, the demand for customized aluminum solutions will only grow, making it essential for manufacturers to offer flexible and innovative options.

Frequently Asked Questions

1. What is the maximum length for a customized 40x80 aluminum extrusion?

The maximum length can vary by manufacturer, but typically, extrusions can be produced in lengths up to 6 meters or more, depending on the equipment used.

2. Can I order a small quantity of customized aluminum extrusions?

Yes, many manufacturers accept small orders, but minimum order quantities may apply depending on the customization required.

3. How long does it take to produce customized aluminum extrusions?

Production time can vary based on complexity and order volume, but it generally takes a few weeks from design approval to delivery.

4. Are there any design limitations for custom aluminum extrusions?

While there are some limitations based on the extrusion process, most designs can be accommodated. It's best to consult with the manufacturer for specific requirements.

5. What types of finishes are available for aluminum extrusions?

Common finishes include anodizing, powder coating, and mill finish. Custom colors and textures can also be requested.