Content Menu

● Understanding Aluminum Extrusion

● Benefits of Using 20mm Aluminum Extrusion Outdoors

● Common Outdoor Applications for 20mm Aluminum Extrusion

>> 1. Garden Structures

>> 2. Outdoor Furniture

>> 3. Canopies and Awnings

>> 4. Fencing and Railings

>> 5. Greenhouses

● Considerations for Outdoor Use

>> 1. Environmental Factors

>> 2. Thermal Expansion

>> 3. Fasteners and Connectors

>> 4. Maintenance

>> 5. Design Considerations

● Conclusion

● Frequently Asked Questions

>> 1. Can 20mm aluminum extrusion be used for outdoor furniture?

>> 2. How do I maintain aluminum extrusion used outdoors?

>> 3. Is aluminum extrusion suitable for coastal environments?

>> 4. Can I paint or anodize aluminum extrusion?

>> 5. What are the load-bearing capabilities of 20mm aluminum extrusion?

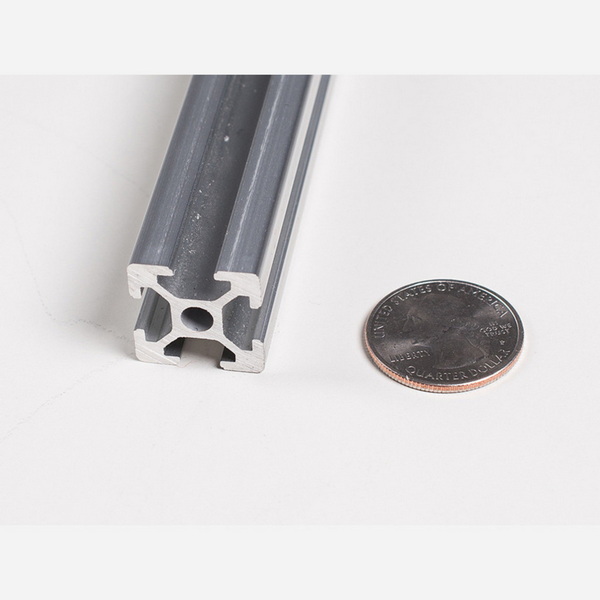

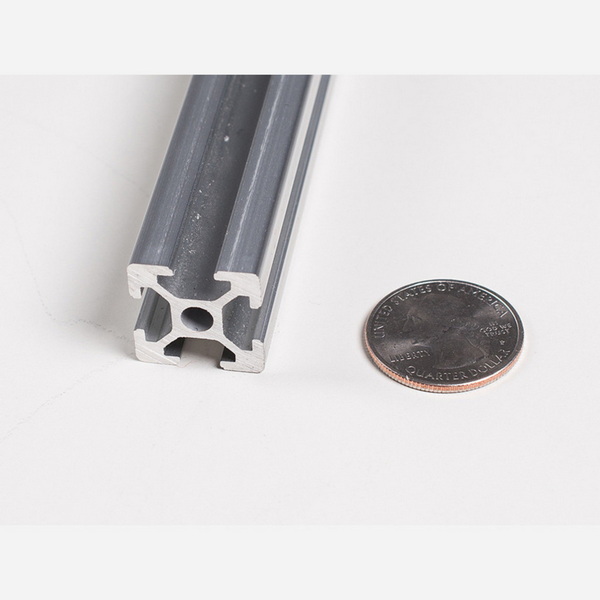

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. This process is widely used in various industries due to its versatility, strength, and lightweight properties. One specific size that has gained popularity is the 20mm aluminum extrusion. This article will explore the various aspects of using 20mm aluminum extrusion for outdoor applications, including its benefits, potential uses, and considerations for outdoor environments.

Understanding Aluminum Extrusion

Aluminum extrusion involves forcing heated aluminum through a die to create a specific shape. The resulting profiles can be solid, hollow, or complex shapes, making them suitable for a wide range of applications. The 20mm size refers to the width of the extrusion, which is a common dimension used in various structural and architectural applications.

Benefits of Using 20mm Aluminum Extrusion Outdoors

1. Corrosion Resistance: One of the most significant advantages of aluminum is its natural resistance to corrosion. When exposed to the elements, aluminum forms a protective oxide layer that prevents further oxidation. This property makes 20mm aluminum extrusion an excellent choice for outdoor applications, where exposure to moisture and varying weather conditions can lead to deterioration in other materials.

2. Lightweight: Aluminum is significantly lighter than steel and other metals, making it easier to handle and install. This lightweight nature allows for more straightforward transportation and assembly, especially in outdoor settings where heavy lifting equipment may not be available.

3. Strength and Durability: Despite its lightweight nature, aluminum is incredibly strong. The structural integrity of 20mm aluminum extrusion can support various loads, making it suitable for outdoor structures such as canopies, frames, and supports.

4. Versatility: The versatility of aluminum extrusion allows for a wide range of designs and applications. Whether you need a simple frame for a garden trellis or a complex structure for a patio cover, 20mm aluminum extrusion can be customized to meet your specific needs.

5. Aesthetic Appeal: Aluminum can be finished in various ways, including anodizing, powder coating, and painting. This allows for a wide range of colors and finishes, making it easy to match the aesthetic of outdoor spaces.

Common Outdoor Applications for 20mm Aluminum Extrusion

1. Garden Structures

20mm aluminum extrusion is often used in the construction of garden structures such as trellises, arbors, and raised garden beds. Its lightweight nature makes it easy to assemble, while its strength ensures that it can support climbing plants and withstand outdoor conditions. The ability to customize the design allows gardeners to create unique structures that enhance the beauty of their gardens.

2. Outdoor Furniture

Aluminum extrusion is a popular choice for outdoor furniture due to its durability and resistance to rust. Tables, chairs, and benches made from 20mm aluminum extrusion can withstand the elements while providing a stylish and modern look to outdoor spaces. Additionally, the lightweight nature of aluminum makes it easy to rearrange furniture as needed, allowing for flexibility in outdoor layouts.

3. Canopies and Awnings

Using 20mm aluminum extrusion for canopies and awnings provides a sturdy framework that can support various types of coverings, such as fabric or polycarbonate panels. This application is particularly beneficial for patios, decks, and outdoor dining areas, providing shade and protection from the elements. The ability to customize the size and shape of the canopy allows homeowners to create functional outdoor spaces that can be enjoyed year-round.

4. Fencing and Railings

Aluminum extrusion can be used to create attractive and durable fencing and railing systems. The 20mm size is ideal for constructing strong posts and rails that can withstand wind and weather while maintaining a sleek appearance. This application is particularly popular in residential settings, where homeowners seek to enhance their outdoor aesthetics while ensuring safety and security.

5. Greenhouses

For gardening enthusiasts, 20mm aluminum extrusion is an excellent choice for building greenhouses. Its lightweight and corrosion-resistant properties make it suitable for creating a structure that can support glass or polycarbonate panels, allowing for optimal sunlight while protecting plants from harsh weather. The modular nature of aluminum extrusion allows for easy expansion or modification of greenhouse designs as gardening needs change.

Considerations for Outdoor Use

While 20mm aluminum extrusion offers many benefits for outdoor applications, there are several considerations to keep in mind:

1. Environmental Factors

When using aluminum extrusion outdoors, consider the environmental factors that may affect its performance. For instance, areas with high salt content in the air, such as coastal regions, may require additional protective coatings to prevent corrosion. Additionally, UV exposure can affect the longevity of certain finishes, so selecting the right coating is essential for maintaining the appearance and durability of the extrusion.

2. Thermal Expansion

Aluminum expands and contracts with temperature changes. When designing structures using 20mm aluminum extrusion, it is essential to account for thermal expansion to prevent warping or structural issues over time. Proper spacing and the use of flexible connectors can help accommodate these changes, ensuring the integrity of the structure remains intact.

3. Fasteners and Connectors

Using the right fasteners and connectors is crucial for ensuring the structural integrity of outdoor applications. Stainless steel or coated fasteners are recommended to prevent corrosion when in contact with aluminum. Additionally, using compatible connectors designed for aluminum extrusion can enhance the overall strength and stability of the assembly.

4. Maintenance

While aluminum is low-maintenance, periodic cleaning is recommended to remove dirt and debris that can accumulate over time. This will help maintain its appearance and performance. Regular inspections for any signs of wear or damage can also prolong the life of outdoor structures made from aluminum extrusion.

5. Design Considerations

When designing outdoor structures with 20mm aluminum extrusion, consider factors such as load-bearing requirements, wind resistance, and aesthetic preferences. Collaborating with a professional designer or engineer can help ensure that your project meets all necessary specifications. Additionally, considering the overall layout and functionality of the space can lead to more effective and enjoyable outdoor environments.

Conclusion

In conclusion, 20mm aluminum extrusion is an excellent choice for various outdoor applications due to its lightweight, strength, and corrosion resistance. From garden structures to outdoor furniture, the versatility of aluminum extrusion allows for creative and functional designs that can withstand the elements. By considering environmental factors, thermal expansion, and proper maintenance, you can ensure that your outdoor projects using 20mm aluminum extrusion will be durable and aesthetically pleasing for years to come.

Frequently Asked Questions

1. Can 20mm aluminum extrusion be used for outdoor furniture?

Yes, 20mm aluminum extrusion is an excellent choice for outdoor furniture due to its lightweight, strength, and resistance to rust and corrosion. It can withstand various weather conditions while maintaining its structural integrity.

2. How do I maintain aluminum extrusion used outdoors?

Periodic cleaning with mild soap and water is recommended to remove dirt and debris. Avoid using harsh chemicals that could damage the finish. Regular inspections for wear and tear can also help prolong the life of the aluminum structures.

3. Is aluminum extrusion suitable for coastal environments?

Yes, aluminum has natural corrosion resistance, but additional protective coatings may be necessary in areas with high salt content in the air. This will help prevent corrosion and maintain the appearance of the aluminum.

4. Can I paint or anodize aluminum extrusion?

Yes, aluminum can be painted or anodized to achieve various colors and finishes, enhancing its aesthetic appeal for outdoor applications. Anodizing also provides an additional layer of protection against corrosion.

5. What are the load-bearing capabilities of 20mm aluminum extrusion?

The load-bearing capabilities depend on the specific design and application. It is advisable to consult with a structural engineer for precise calculations based on your project requirements, ensuring that the design meets safety standards and functional needs.