Content Menu

● Introduction

● What Are 2020 Aluminum Extrusions?

>> Key Features of 2020 Aluminum Extrusions

● Benefits of Using 2020 Aluminum Extrusion Connectors in Robotics

>> Versatility

>> Enhanced Structural Integrity

>> Customization

>> Cost-Effectiveness

>> Compatibility with Other Components

● Applications of 2020 Aluminum Extrusion Connectors in Robotics

>> Robotic Arms

>> Mobile Robots

>> CNC Machines

>> Robotics Competitions

>> Prototyping

● How to Use 2020 Aluminum Extrusion Connectors in Robotics Projects

>> Step 1: Design Your Structure

>> Step 2: Gather Materials

>> Step 3: Assemble the Frame

>> Step 4: Integrate Components

>> Step 5: Test and Iterate

● Conclusion

● Frequently Asked Questions

>> 1. What are the advantages of using aluminum extrusions in robotics?

>> 2. Can I use 2020 aluminum extrusions for outdoor robotics projects?

>> 3. How do I cut 2020 aluminum extrusions?

>> 4. Are 2020 aluminum extrusion connectors compatible with other extrusion sizes?

>> 5. What tools do I need to assemble a structure using 2020 aluminum extrusions?

Introduction

In the rapidly evolving field of robotics, the choice of materials and components plays a crucial role in the design and functionality of robotic systems. Among the various materials available, aluminum extrusions, particularly the 2020 series, have gained significant popularity due to their versatility, strength, and ease of use. This article explores the application of 2020 aluminum extrusion connectors in robotics projects, discussing their benefits, practical uses, and how they can enhance the design and performance of robotic systems.

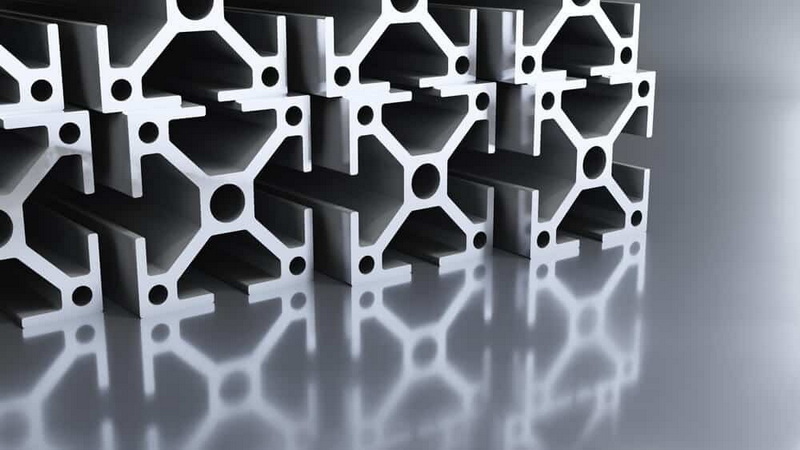

What Are 2020 Aluminum Extrusions?

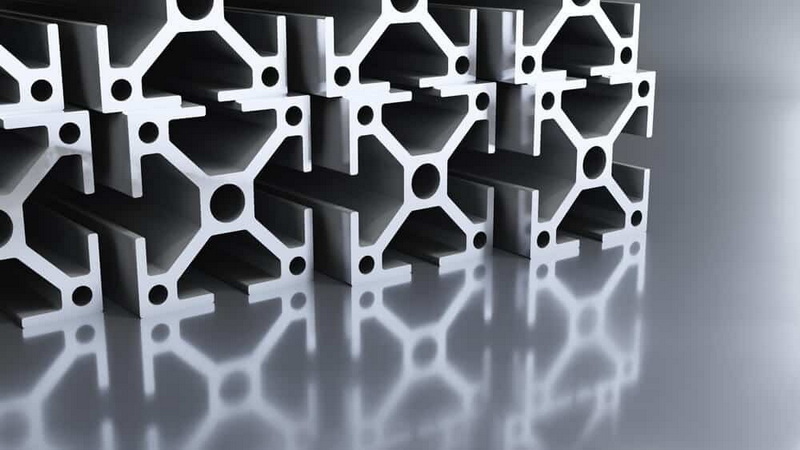

2020 aluminum extrusions are profiles with a cross-section measuring 20mm x 20mm. They are part of a modular framing system that allows for easy assembly and disassembly of structures. The T-slot design of these extrusions enables the attachment of various connectors, brackets, and accessories, making them ideal for building frames, enclosures, and other structures in robotics.

Key Features of 2020 Aluminum Extrusions

1. Lightweight and Strong: Aluminum is known for its excellent strength-to-weight ratio, making it an ideal choice for robotics where weight is a critical factor.

2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which helps prevent corrosion, ensuring longevity in various environments.

3. Modularity: The T-slot design allows for easy customization and modification of structures, enabling engineers to adapt their designs as needed.

4. Ease of Assembly: With the right connectors and tools, 2020 aluminum extrusions can be assembled quickly and efficiently, reducing project timelines.

Benefits of Using 2020 Aluminum Extrusion Connectors in Robotics

Versatility

2020 aluminum extrusion connectors come in various shapes and sizes, allowing for a wide range of applications in robotics. Whether you are building a simple robotic arm or a complex mobile robot, these connectors can accommodate different design requirements. Their adaptability makes them suitable for both hobbyist projects and professional applications.

Enhanced Structural Integrity

Using connectors specifically designed for 2020 aluminum extrusions ensures that the joints are strong and stable. This is particularly important in robotics, where movement and load-bearing capabilities are essential. Properly connected frames can withstand the stresses of operation without compromising performance. The structural integrity provided by these connectors is vital for maintaining the functionality and reliability of robotic systems.

Customization

Robotics projects often require unique designs tailored to specific tasks. The modular nature of 2020 aluminum extrusions and their connectors allows engineers to create custom solutions that meet their project needs. This flexibility is invaluable in a field where innovation is key. Engineers can easily modify existing designs or create entirely new structures without starting from scratch.

Cost-Effectiveness

While high-quality materials can be expensive, 2020 aluminum extrusions offer a cost-effective solution for building robotic structures. Their durability and ease of assembly can lead to lower overall project costs, as they reduce the need for specialized tools and extensive labor. Additionally, the ability to reuse connectors and extrusions in different projects further enhances their cost-effectiveness.

Compatibility with Other Components

2020 aluminum extrusion connectors are designed to work seamlessly with a variety of other components, such as motors, sensors, and control systems. This compatibility simplifies the integration of different technologies into a single robotic system. Engineers can easily incorporate various components into their designs, enhancing the overall functionality of the robot.

Applications of 2020 Aluminum Extrusion Connectors in Robotics

Robotic Arms

One of the most common applications of 2020 aluminum extrusions in robotics is in the construction of robotic arms. These arms require precise movements and stability, which can be achieved using the right connectors and brackets. The modular design allows for easy adjustments and upgrades as technology evolves. Robotic arms built with 2020 aluminum extrusions can be used in various industries, including manufacturing, healthcare, and research.

Mobile Robots

Mobile robots, such as autonomous vehicles and drones, benefit from the lightweight and strong properties of 2020 aluminum extrusions. The connectors can be used to create robust frames that support various sensors and navigation systems, ensuring reliable operation in diverse environments. The ability to quickly modify the frame design allows for rapid prototyping and testing of new ideas.

CNC Machines

CNC (Computer Numerical Control) machines often utilize 2020 aluminum extrusions for their frames. The precision and stability provided by these connectors are essential for maintaining accuracy during machining processes. The use of aluminum extrusions in CNC machines allows for easy adjustments and modifications, making it easier to adapt to different machining tasks.

Robotics Competitions

In robotics competitions, teams often need to build and modify their robots quickly. The ease of assembly and disassembly of 2020 aluminum extrusions allows teams to make rapid changes to their designs, giving them a competitive edge. The modular nature of these connectors enables teams to experiment with different configurations and improve their designs based on performance feedback.

Prototyping

For engineers and hobbyists, 2020 aluminum extrusions are an excellent choice for prototyping new robotic designs. The ability to quickly assemble and modify structures makes it easier to test ideas and iterate on designs. Prototyping with aluminum extrusions allows for rapid development cycles, enabling engineers to bring their concepts to life more efficiently.

How to Use 2020 Aluminum Extrusion Connectors in Robotics Projects

Step 1: Design Your Structure

Before you begin assembling your robotic structure, it's essential to have a clear design. Use CAD software to create a detailed plan that includes dimensions, connector types, and the overall layout of your robot. A well-thought-out design will help streamline the assembly process and ensure that all components fit together correctly.

Step 2: Gather Materials

Collect all necessary materials, including 2020 aluminum extrusions, connectors, screws, and any additional components required for your project. Ensure that you have the right tools for assembly, such as an Allen wrench and a screwdriver. Having all materials on hand before starting will help prevent delays during the assembly process.

Step 3: Assemble the Frame

Start by cutting the aluminum extrusions to the desired lengths. Use the connectors to join the pieces together, ensuring that each joint is secure. Pay attention to the alignment of the extrusions to maintain structural integrity. A well-assembled frame will provide a solid foundation for the rest of the robotic system.

Step 4: Integrate Components

Once the frame is assembled, integrate other components such as motors, sensors, and control systems. Use additional connectors and brackets as needed to secure these components in place. Proper integration of components is crucial for ensuring that the robot functions as intended.

Step 5: Test and Iterate

After assembling your robot, conduct tests to ensure that it operates as intended. Make any necessary adjustments to the design or components based on the results of your tests. The modular nature of 2020 aluminum extrusions allows for easy modifications. Iterative testing and refinement are key to achieving optimal performance in robotic systems.

Conclusion

2020 aluminum extrusion connectors are an invaluable resource in the field of robotics. Their versatility, strength, and ease of use make them ideal for a wide range of applications, from robotic arms to mobile robots. By leveraging the benefits of these connectors, engineers and hobbyists can create innovative robotic solutions that meet their specific needs.

As robotics technology continues to evolve, the importance of adaptable and reliable materials like 2020 aluminum extrusions will only grow. Whether you are a seasoned engineer or a newcomer to the field, incorporating these connectors into your projects can enhance your designs and improve overall performance.

Frequently Asked Questions

1. What are the advantages of using aluminum extrusions in robotics?

Aluminum extrusions offer a lightweight, strong, and corrosion-resistant option for building robotic structures. Their modular design allows for easy assembly and customization, making them ideal for various applications.

2. Can I use 2020 aluminum extrusions for outdoor robotics projects?

Yes, 2020 aluminum extrusions are suitable for outdoor projects due to their corrosion resistance. However, consider additional protective coatings for enhanced durability in harsh environments.

3. How do I cut 2020 aluminum extrusions?

You can cut 2020 aluminum extrusions using a miter saw or a band saw with a fine-toothed blade. Ensure you measure accurately and wear safety gear while cutting.

4. Are 2020 aluminum extrusion connectors compatible with other extrusion sizes?

While 2020 aluminum extrusion connectors are specifically designed for 20mm x 20mm profiles, some connectors may be compatible with other sizes. Always check the specifications before purchasing.

5. What tools do I need to assemble a structure using 2020 aluminum extrusions?

Basic tools required include an Allen wrench, screwdriver, and possibly a saw for cutting the extrusions. Additional tools may be needed depending on the complexity of your design.