Content Menu

● Understanding Aluminum Extrusions

● Why Choose 1.5 Inch Aluminum Extrusions?

● Popular DIY Projects Using 1.5 Inch Aluminum Extrusions

>> Furniture Construction

>> Workbenches and Tool Racks

>> DIY Shelving Units

>> Greenhouses and Garden Structures

>> Robotics and Automation Projects

● Tips for Working with 1.5 Inch Aluminum Extrusions

● Advanced Applications of 1.5 Inch Aluminum Extrusions

>> Custom Displays and Signage

>> Home Automation Frames

>> Art and Sculpture

● Conclusion

● Frequently Asked Questions

>> 1. What tools do I need to work with 1.5 inch aluminum extrusions?

>> 2. Can I paint aluminum extrusions?

>> 3. Are 1.5 inch aluminum extrusions strong enough for heavy loads?

>> 4. How do I cut aluminum extrusions accurately?

>> 5. Can I use 1.5 inch aluminum extrusions for outdoor projects?

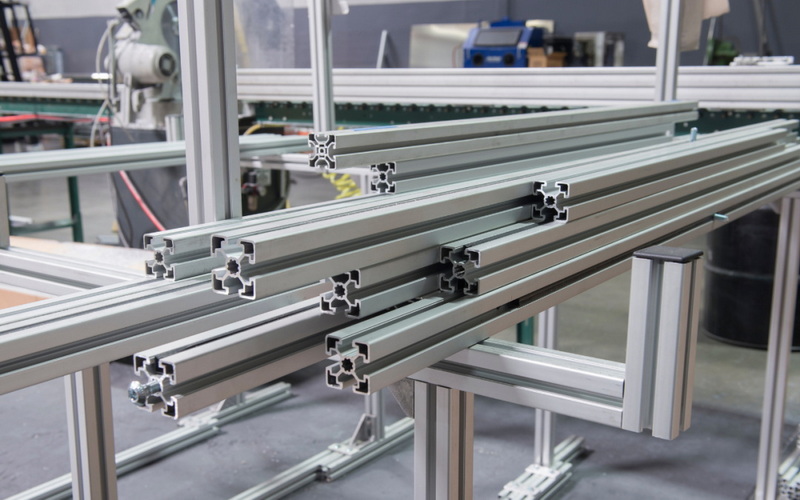

Aluminum extrusions have become increasingly popular in the DIY community due to their versatility, strength, and lightweight properties. Among the various sizes available, 1.5 inch aluminum extrusions stand out as a favored choice for many projects. This article will explore the numerous ways you can utilize 1.5 inch aluminum extrusions in your DIY endeavors, providing insights, tips, and inspiration for your next project.

Understanding Aluminum Extrusions

Aluminum extrusion is a process that involves shaping aluminum alloy into a desired cross-sectional profile. This is achieved by forcing heated aluminum through a die, resulting in long lengths of material that can be cut to size. The benefits of using aluminum extrusions include:

- Lightweight: Aluminum is significantly lighter than steel, making it easier to handle and transport.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which helps prevent rust and corrosion.

- Strength: Despite its lightweight nature, aluminum is strong and can support substantial loads.

- Versatility: Aluminum extrusions can be used in a wide range of applications, from structural frameworks to decorative elements.

Why Choose 1.5 Inch Aluminum Extrusions?

1.5 inch aluminum extrusions are particularly popular for DIY projects due to their ideal size for various applications. They provide a good balance between strength and weight, making them suitable for both small and large projects. Here are some reasons to consider using 1.5 inch aluminum extrusions:

- Ease of Use: The size is manageable for most DIY enthusiasts, allowing for easy cutting and assembly.

- Compatibility: Many accessories and connectors are available for 1.5 inch extrusions, making it easy to create complex structures.

- Aesthetic Appeal: Aluminum has a modern look that can enhance the visual appeal of your projects.

Popular DIY Projects Using 1.5 Inch Aluminum Extrusions

Furniture Construction

One of the most popular uses for 1.5 inch aluminum extrusions is in furniture design. You can create custom tables, chairs, and shelving units that are both functional and stylish. The lightweight nature of aluminum makes it easy to move furniture around, while its strength ensures durability.

Example Project: A simple coffee table can be constructed using 1.5 inch aluminum extrusions for the frame, paired with a glass or wooden top. This combination creates a modern look that fits well in any living space.

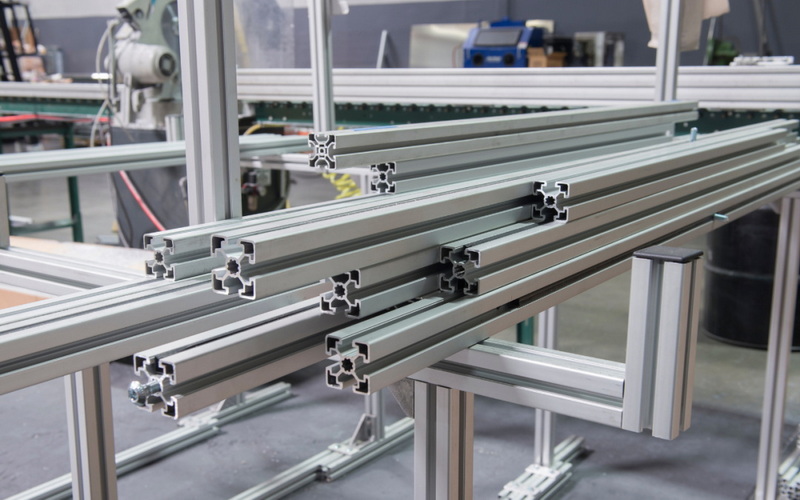

Workbenches and Tool Racks

For those who enjoy woodworking or other crafts, building a sturdy workbench is essential. 1.5 inch aluminum extrusions can be used to create a robust frame that can support heavy tools and materials. Additionally, you can design tool racks that keep your workspace organized and efficient.

Example Project: A workbench with adjustable height can be built using 1.5 inch extrusions, allowing you to customize it to your preferred working position. This flexibility can enhance comfort and productivity during long crafting sessions.

DIY Shelving Units

Creating custom shelving units is another excellent way to utilize 1.5 inch aluminum extrusions. You can design shelves that fit perfectly in your space, whether it's for a garage, office, or living room. The sleek look of aluminum adds a modern touch to any room.

Example Project: A modular shelving system can be constructed using 1.5 inch extrusions, allowing you to adjust the height and spacing of the shelves as needed. This adaptability makes it easy to accommodate different items, from books to decorative pieces.

Greenhouses and Garden Structures

If you're a gardening enthusiast, consider using 1.5 inch aluminum extrusions to build a greenhouse or garden structure. The lightweight yet sturdy nature of aluminum makes it an ideal material for supporting glass panels or plastic sheeting.

Example Project: A small greenhouse frame can be constructed using 1.5 inch extrusions, providing a controlled environment for your plants. This structure can help extend your growing season and protect your plants from harsh weather conditions.

Robotics and Automation Projects

For tech enthusiasts, 1.5 inch aluminum extrusions are perfect for building frames for robots or automation systems. Their strength and lightweight properties allow for the construction of complex structures that can support motors, sensors, and other components.

Example Project: A robotic arm can be built using 1.5 inch extrusions, providing a stable base for movement and functionality. This project can be a great way to learn about robotics while creating something practical.

Tips for Working with 1.5 Inch Aluminum Extrusions

1. Cutting: Use a miter saw or band saw with a fine-toothed blade to achieve clean cuts. Always wear safety goggles when cutting aluminum to protect your eyes from metal shavings.

2. Joining: Consider using T-nuts and bolts for easy assembly and disassembly. This allows for flexibility in your designs and makes it easier to modify your projects as needed.

3. Finishing: If desired, you can anodize or paint your aluminum extrusions to match your project's aesthetic. Anodizing not only enhances the appearance but also increases corrosion resistance.

4. Planning: Before starting your project, sketch out your design and make a list of materials needed. This will help streamline the building process and ensure you have everything on hand.

5. Safety First: Always prioritize safety when working with tools and materials. Use gloves when handling sharp edges and ensure your workspace is clean and organized to prevent accidents.

Advanced Applications of 1.5 Inch Aluminum Extrusions

Custom Displays and Signage

1.5 inch aluminum extrusions can also be used to create custom displays and signage for businesses or events. Their sleek design and durability make them an excellent choice for both indoor and outdoor applications.

Example Project: A trade show display can be constructed using 1.5 inch extrusions, allowing for easy assembly and disassembly. This portability is ideal for businesses that attend multiple events throughout the year.

Home Automation Frames

As smart home technology continues to grow, many DIY enthusiasts are looking for ways to integrate these systems into their homes. 1.5 inch aluminum extrusions can be used to create frames for home automation devices, such as smart lighting or security systems.

Example Project: A frame for mounting smart home sensors can be built using 1.5 inch extrusions, providing a clean and organized look while ensuring the devices are securely positioned.

Art and Sculpture

Artists can also benefit from using 1.5 inch aluminum extrusions in their work. The material can be shaped and assembled to create unique sculptures or installations that are both lightweight and visually striking.

Example Project: An abstract sculpture can be constructed using 1.5 inch extrusions, allowing for creative expression while utilizing a durable material that can withstand outdoor conditions.

Conclusion

1.5 inch aluminum extrusions are an excellent choice for a wide range of DIY projects. Their versatility, strength, and lightweight properties make them suitable for everything from furniture to robotics. With the right tools and a bit of creativity, you can create stunning and functional pieces that enhance your living space or workshop.

Frequently Asked Questions

1. What tools do I need to work with 1.5 inch aluminum extrusions?

- Basic tools include a miter saw, drill, and various hand tools. T-nuts and bolts are also essential for assembly.

2. Can I paint aluminum extrusions?

- Yes, aluminum can be painted. It's recommended to use a primer designed for metal surfaces for the best results.

3. Are 1.5 inch aluminum extrusions strong enough for heavy loads?

- Yes, 1.5 inch aluminum extrusions are strong and can support substantial loads, making them suitable for various applications.

4. How do I cut aluminum extrusions accurately?

- Use a miter saw with a fine-toothed blade for clean cuts. Always measure twice before cutting to ensure accuracy.

5. Can I use 1.5 inch aluminum extrusions for outdoor projects?

- Yes, aluminum is corrosion-resistant, making it suitable for outdoor use. However, consider using protective coatings for added durability.