Content Menu

● Understanding Aluminum Extrusion

>> Why Choose Aluminum Extrusion?

● The Aluminum Extrusion Market in Mexico

>> Key Suppliers of Aluminum Extrusions in Mexico

● Evaluating Reliability of Suppliers

● Challenges and Opportunities

● Trends Influencing the Market

● The Role of Technology

● Case Studies of Success

● Navigating Import Regulations

● Ensuring Quality and Standards

● Future Outlook

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What is aluminum extrusion?

>> 2. Why is Mexico a good location for sourcing aluminum extrusions?

>> 3. How do I choose the right aluminum extruder supplier?

>> 4. What industries commonly use aluminum extrusions?

>> 5. Are there sustainability practices followed by Mexican suppliers?

● Citations:

The aluminum extrusion industry in Mexico is rapidly evolving, with a growing number of suppliers offering high-quality products and services. This article explores the landscape of aluminum extruder suppliers in Mexico, highlighting key players, their capabilities, and what to look for when selecting a reliable supplier.

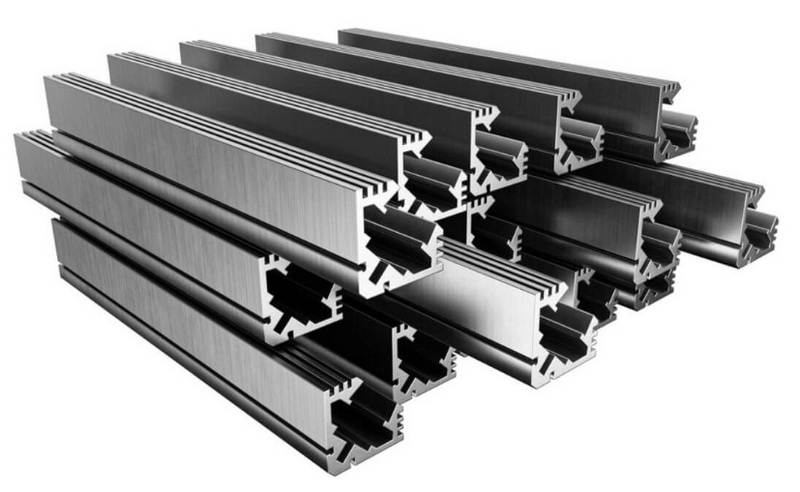

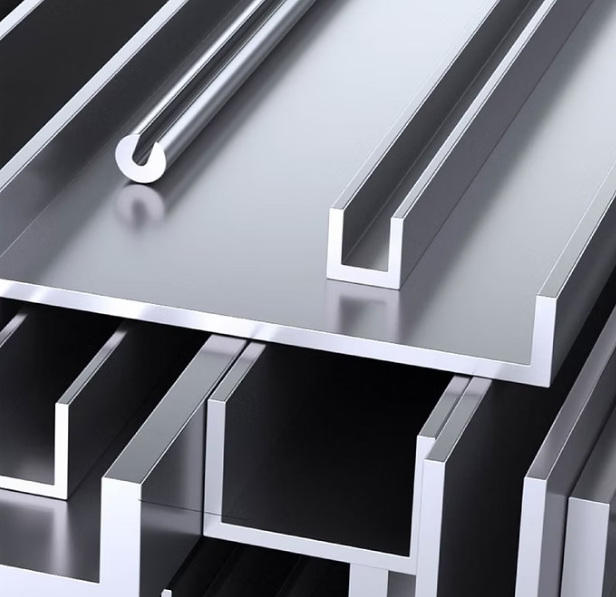

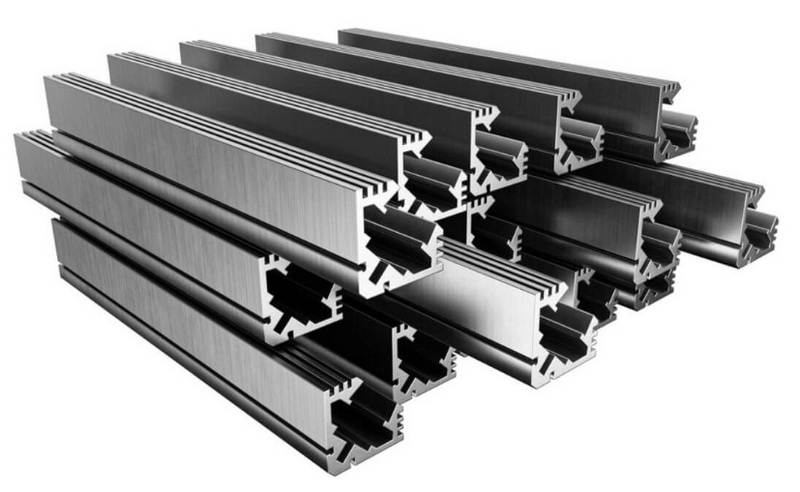

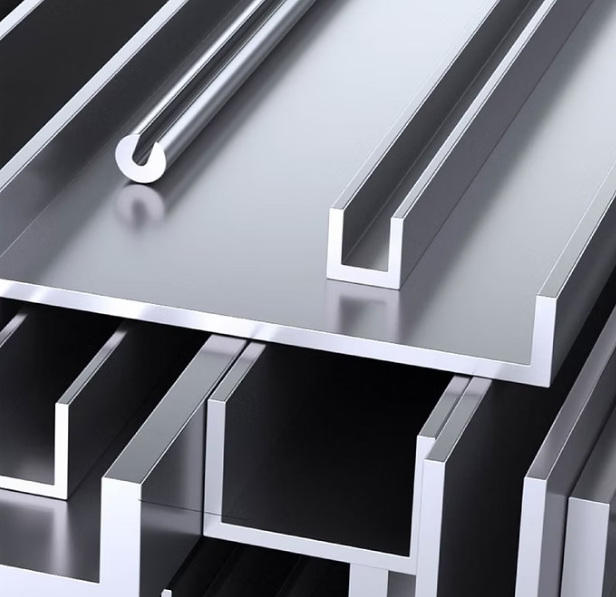

Understanding Aluminum Extrusion

Aluminum extrusion is a process used to create objects of a fixed cross-sectional profile by pushing or drawing aluminum through a die. This technique is widely used in various industries, including automotive, construction, and electronics, due to aluminum's lightweight, durability, and corrosion resistance[5].

Why Choose Aluminum Extrusion?

- Versatility: Aluminum can be extruded into complex shapes and sizes[5].

- Lightweight: Aluminum's low density makes it ideal for applications where weight savings are critical[5].

- Corrosion Resistance: Aluminum naturally forms a protective oxide coating that helps prevent rust[5].

- Recyclability: Aluminum can be recycled without losing its properties, making it an environmentally friendly choice[5].

The Aluminum Extrusion Market in Mexico

Mexico has become a significant player in the global aluminum extrusion market[3]. The country benefits from a robust manufacturing base, proximity to the United States, and favorable trade agreements such as the USMCA (United States-Mexico-Canada Agreement)[1]. However, the Mexican automotive industry faces a shortage of local Tier 2 suppliers, particularly in aluminum processes like extrusion, casting, and forging[2].

Key Suppliers of Aluminum Extrusions in Mexico

1. CUPRUM S.A. de C.V.

- The largest aluminum extrusion manufacturer in Mexico and Latin America[3].

- Offers a wide range of products for architectural and industrial applications[3].

- Operates multiple extrusion divisions across major cities like Monterrey and Guadalajara[3].

2. ABC Aluminum

- Known for high-quality aluminum extrusions with over 30 years of experience[5].

- Provides customized solutions to meet specific customer needs[5].

- Invests heavily in technology to enhance production efficiency[5]. ABC Aluminum recently expanded its facility near Monterrey, investing $5 million in new extrusion presses to increase capacity by 30% to meet growing demand from automotive clients requiring lightweight components for electric vehicles[5].

3. Valsa

- Specializes in value-added aluminum profiles with extensive finishing options[5].

- Committed to quality through multiple certifications and sustainable practices[5].

- Focuses on sectors like construction and transportation[5]. Valsa has implemented a closed-loop recycling system within their operations, recycling scrap material generated during production back into usable feedstock, reducing waste and lowering raw material costs[5].

4. Aluminext

- Offers custom-designed aluminum parts and profiles for various applications.

- Provides precision machining services alongside extrusion.

5. Marvol Metal Solutions

- Supplies aluminum extrusions for diverse industries including window manufacturing and hurricane protection.

- Emphasizes competitive pricing and timely deliveries.

Several other key players operate in the Mexico aluminum industry, including Alyex, Indalum, ALFA Metal, Alumeta, Flex N Gate LLC, Norsk Hydro ASA, Mexico Aluminium Co. L.L.C., Fagor Ederlan, Hindalco Industries Ltd., Hal Aluminum Mexico S.A. De C.V., Trefinasa de Mexico S.A. de C.V., and ARZYZ, S.A. DE C.V[6].

Evaluating Reliability of Suppliers

When searching for reliable aluminum extruder suppliers in Mexico, consider the following factors:

- Experience: Look for companies with a proven track record in the industry.

- Quality Certifications: Suppliers should have relevant quality certifications (e.g., ISO 9001) that ensure adherence to international standards[5].

- Technology and Equipment: Advanced machinery can significantly affect the quality and efficiency of production[4].

- Customer Service: Evaluate their responsiveness and willingness to provide customized solutions[5].

- Market Presence: A well-established supplier is likely to have better resources and reliability.

Challenges and Opportunities

Despite the growing market, the aluminum extrusion industry in Mexico faces certain challenges:

- Tariffs and Trade: New tariffs on aluminum imports imposed by Mexico are affecting the supply chain, trade flows, and premiums[7]. These duties could potentially increase costs for Mexican aluminum processors who rely on offshore suppliers[1].

- Supplier Shortages: The Mexican automotive sector faces a shortage of local Tier 2 suppliers in aluminum processes like extrusion, casting, and forging[2].

- Competition: The industry faces competition from imports, with Vietnam, China, and the United States being the leading suppliers of aluminum extrusions to Mexico[8].

However, there are also significant opportunities:

- Growing Demand: The Mexican aluminum market is set to grow from $3.86 billion in 2023 to $6.07 billion by 2030, driven by rising demand in packaging and consumer goods industries[6].

- USMCA Benefits: The USMCA agreement provides opportunities for regional integration and increased trade within North America[1].

- Sustainability Initiatives: The increasing focus on sustainable practices and recycling offers a competitive advantage for companies that adopt eco-friendly production methods[5].

Trends Influencing the Market

Several trends are shaping the aluminum extrusion market in Mexico:

- Sustainability Initiatives: Companies are increasingly focusing on eco-friendly practices, including recycling programs and energy-efficient production methods[5].

- Technological Advancements: Automation and advanced manufacturing technologies are enhancing production capabilities[4].

- Global Demand: The demand for aluminum extrusions is rising globally, driven by sectors like automotive and renewable energy[6].

- Higher Strength Alloys: The development of higher strength 6000 series aluminum alloys, particularly for automotive applications, is gaining traction[4].

- AI Integration: Artificial intelligence is being incorporated into the extrusion process for predictive maintenance, die design, and process optimization[4].

The Role of Technology

Technological advancements play a crucial role in enhancing the efficiency and quality of aluminum extrusions. Innovations such as rapid extrusion profile inspection using Computerized Topology (CAT) X-ray scanning eliminate time-consuming sample preparation and improve quality control[4]. Rapid quench systems with multiple nozzles and adjustable flow valves ensure uniform cooling, reducing deformations and improving product quality[4].

Case Studies of Success

- ABC Aluminum's Expansion Strategy: ABC Aluminum expanded its facility near Monterrey by investing $5 million into new extrusion presses that increase their capacity by 30% to meet growing demand from automotive clients who require lightweight components for electric vehicles[5].

- Valsa's Sustainable Initiatives: Valsa has implemented a closed-loop recycling system within their operations that recycles scrap material generated during production back into usable feedstock, reducing waste and lowering raw material costs[5].

- Simax's Innovative Products: Simax developed a new line of thermal break profiles that improve energy efficiency in buildings by collaborating with architects and builders early in the design process[5].

Navigating Import Regulations

Starting an aluminum extrusion import business in Mexico requires careful planning and understanding of import procedures[8]. It is essential to establish a company, register it, and obtain an Import Export Code (IEC) from the Directorate General of Foreign Trade (DGFT)[8]. Compliance with the Government of Mexico's Foreign Trade Policy (FTP) is crucial, and consulting with professionals familiar with specific regulations for aluminum extrusion is advisable[8].

Ensuring Quality and Standards

Mexican manufacturers comply with international quality standards such as ISO 9001 and ASTM standards, ensuring product reliability across various applications[5]. These certifications are essential for maintaining competitiveness and meeting customer expectations.

Future Outlook

The future of the aluminum extrusion market in Mexico looks promising, with increased demand for lightweight materials, advancements in manufacturing technologies, and a focus on sustainability practices[5]. Collaboration between manufacturers and end-users during product development will drive innovation and growth in the sector[5].

Conclusion

In conclusion, Mexico hosts a variety of reliable aluminum extruder suppliers capable of meeting diverse industry needs. Companies like CUPRUM, ABC Aluminum, Valsa, Aluminext, and Marvol Metal Solutions exemplify the quality and service available within this market[3][5]. When selecting a supplier, it's essential to consider their experience, certifications, technology capabilities, customer service quality, and overall market presence to ensure you choose a partner that aligns with your business goals. While challenges such as tariffs and supplier shortages exist, the growing demand and increasing focus on sustainability and technology offer significant opportunities for growth in the aluminum extrusion industry in Mexico[2][5][7].

Frequently Asked Questions (FAQ)

1. What is aluminum extrusion?

Aluminum extrusion is a manufacturing process where aluminum is pushed through a die to create specific shapes or profiles used in various applications[5].

2. Why is Mexico a good location for sourcing aluminum extrusions?

Mexico offers competitive pricing, proximity to major markets like the U.S., skilled labor, and favorable trade agreements that enhance supply chain efficiency[1][5].

3. How do I choose the right aluminum extruder supplier?

Consider factors such as experience, quality certifications, technological capabilities, customer service reputation, and market presence when evaluating potential suppliers[5].

4. What industries commonly use aluminum extrusions?

Industries such as automotive, construction, aerospace, electronics, and consumer goods frequently utilize aluminum extrusions due to their versatility and strength-to-weight ratio[5][6].

5. Are there sustainability practices followed by Mexican suppliers?

Many suppliers in Mexico are adopting sustainable practices such as recycling programs and energy-efficient manufacturing processes to minimize environmental impact[5].

Citations:

[1] https://eccomelt.com/the-new-mexican-duties/

[2] https://mexicobusiness.news/automotive/news/mexicos-auto-sector-faces-tier-2-supplier-shortfall

[3] https://www.presezziextrusiongroup.com/case-history.html

[4] https://profileprecisionextrusions.com/the-evolution-of-aluminum-extrusions-emerging-trends-and-technologies/

[5] https://www.yjing-extrusion.com/how-does-aluminum-extrusion-in-mexico-compare-to-other-locations.html

[6] https://www.nextmsc.com/report/mexico-aluminium-market

[7] https://www.fastmarkets.com/insights/mexican-tariffs-affecting-aluminium-supply-chain-and-premiums/

[8] https://www.volza.com/p/aluminum-extrusion/import/import-in-mexico/

[9] https://www.news.market.us/aluminum-extrusion-market-news/

[10] https://taberextrusions.com/not-just-a-new-years-resolution-aluminum-extrusion-sustainability/

[11] https://ensun.io/search/aluminum-extrusion/mexico

[12] https://www.spglobal.com/commodity-insights/en/news-research/latest-news/metals/051324-us-extruders-warn-of-consequences-from-mexicos-aluminum-tariff-reversal

[13] https://ensun.io/search/extrusion/mexico

[14] https://www.fortune-alu.com/info-detail/future-trends-in-aluminum-extrusion

[15] https://www.alcircle.com/news/sustainability-in-aluminium-top-10-green-initiatives-in-the-extrusion-segment-96387

[16] https://www.grandviewresearch.com/horizon/outlook/aluminum-extrusion-market/mexico

[17] https://www.alcircle.com/news/canalum-stands-firm-defending-mexico-s-aluminium-integrity-amidst-us-allegations-107993

[18] https://www.trade.gov/preliminary-determination-cvd-investigations-aluminum-extrusions-china-indonesia-mexico-and-turkey

[19] https://www.alcircle.com/news/tech-trends-driving-the-aluminium-extrusion-industry-111131

[20] https://abc-aluminum.com/innovative-aluminum-companies-in-mexico/