Content Menu

● Introduction to Pipe Extrusion

>> Key Components of Pipe Extrusion Machines

● Affordable Pipe Extrusion Equipment Options

>> 1. Single-Screw Extruders

>> 2. Conical Twin-Screw Extruders

>> 3. Used or Refurbished Equipment

>> 4. DIY or Custom-Built Solutions

>> 5. Modular Systems

● Factors Influencing the Cost of Pipe Extrusion Equipment

● Benefits of Affordable Pipe Extrusion Equipment

● Market Trends and Future Developments

>> Emerging Technologies

● Case Studies

● Challenges and Solutions

● Conclusion

● FAQs

>> 1. What is the difference between single-screw and twin-screw extruders?

>> 2. How does the die design affect pipe quality?

>> 3. What factors influence the cost of a pipe extrusion machine?

>> 4. Can cheap pipe extrusion equipment produce high-quality pipes?

>> 5. How do I choose the right cheap pipe extrusion equipment price for my needs?

Pipe extrusion is a crucial process in the manufacturing of plastic pipes, which are widely used in various industries such as water supply, drainage, and gas distribution. The cost of pipe extrusion equipment can be a significant barrier for small-scale manufacturers or startups. However, there are several low-cost options available that can help reduce the initial investment while maintaining production efficiency. In this article, we will explore these affordable options, discuss their features, and provide insights into how they can benefit businesses.

Introduction to Pipe Extrusion

Pipe extrusion involves transforming raw plastic materials into continuous lengths of pipe. This process is highly automated, ensuring consistent quality and high production rates. The key components of a pipe extrusion line include the extruder, die, cooling system, haul-off, and cutting machine.

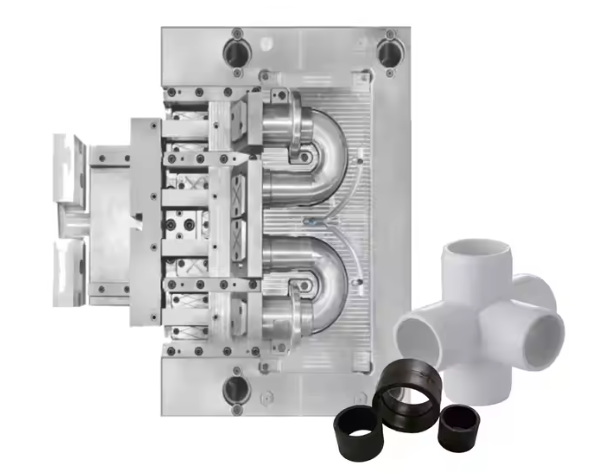

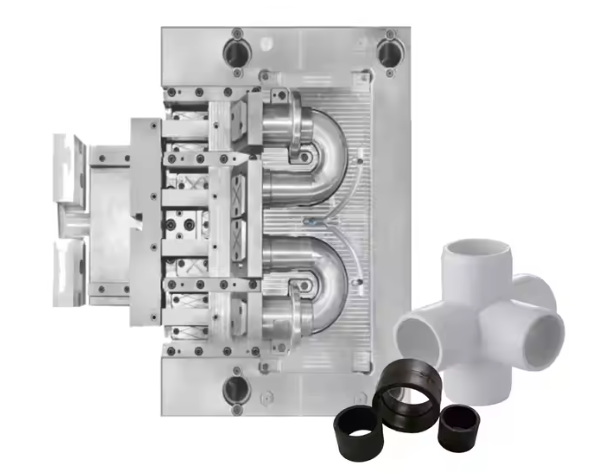

Key Components of Pipe Extrusion Machines

1. Extruder: This is the heart of the pipe extrusion line. It melts and mixes the plastic material, preparing it for extrusion. Extruders can be single-screw or twin-screw, with twin-screw offering better mixing and output for complex materials.

2. Die: Determines the pipe's dimensions and surface finish. A well-designed die ensures consistent dimensions and smooth surfaces.

3. Cooling System: Essential for dimensional stability. Common systems include water baths or air cooling.

4. Haul-off and Cutting Machine: These components pull the pipe through the cooling system and cut it to the desired length.

Affordable Pipe Extrusion Equipment Options

1. Single-Screw Extruders

Single-screw extruders are simpler and less expensive than twin-screw models, making them a cost-effective choice for less demanding applications. They are suitable for producing pipes from materials like PE and PVC. Single-screw extruders are ideal for small-scale production or when working with materials that do not require extensive mixing.

2. Conical Twin-Screw Extruders

Conical twin-screw extruders are more advanced and offer better mixing capabilities. They are ideal for producing PVC and CPVC pipes with minimal rejection rates. Companies like SMT offer affordable conical twin-screw extruders with advanced features such as adjustable screw speeds and precise temperature control. These machines are suitable for medium to large-scale production where consistent quality is crucial.

3. Used or Refurbished Equipment

Another cost-effective option is purchasing used or refurbished pipe extrusion equipment. This can significantly reduce the initial investment while still providing reliable performance. However, it's crucial to ensure the equipment is thoroughly inspected and certified before purchase. Used equipment can be sourced from reputable suppliers or through online marketplaces.

4. DIY or Custom-Built Solutions

For those with limited budgets, building a DIY extruder can be a viable option. While it requires technical expertise, it can be a cheap pipe extrusion equipment solution. Murray Gans' DIY PVC extruder is an example of such a project. DIY solutions allow for customization based on specific needs but may lack the efficiency and reliability of commercial equipment.

5. Modular Systems

Some manufacturers offer modular pipe extrusion systems that can be expanded or modified as needed. These systems allow businesses to start with a basic setup and add components as production demands increase. Modular systems are flexible and can be more cost-effective in the long run.、

Factors Influencing the Cost of Pipe Extrusion Equipment

The cost of pipe extrusion equipment is influenced by several factors:

- Capacity and Automation Level: Higher capacity and automation increase costs but improve efficiency and quality.

- Extruder Type: Twin-screw extruders are more expensive than single-screw models due to their superior mixing capabilities.

- Material Processing Capabilities: Machines capable of handling a variety of materials, including recycled materials, are generally more expensive.

- Brand Reputation and Quality: Equipment from reputable brands tends to be more expensive but offers better durability and performance.

Benefits of Affordable Pipe Extrusion Equipment

1. Reduced Initial Investment: Lower costs allow more businesses to enter the market.

2. Increased Efficiency: Even affordable equipment can offer high production rates and consistent quality.

3. Flexibility: Many affordable options allow for easy changes in pipe size and material, adapting to market demands.

4. Environmental Benefits: Using recycled materials in affordable equipment can reduce waste and support sustainable manufacturing practices.

Market Trends and Future Developments

The pipe extrusion industry is evolving with advancements in technology and materials. There is a growing demand for pipes made from sustainable materials and for equipment that can efficiently process these materials. Companies are investing in research and development to create more efficient and environmentally friendly pipe extrusion solutions.

Emerging Technologies

1. Advanced Materials: The use of bioplastics and recycled materials is becoming more prevalent. Equipment capable of processing these materials is in high demand.

2. Automation and IoT Integration: Modern pipe extrusion lines are increasingly automated, with integration of IoT technologies to monitor and optimize production processes.

3. Energy Efficiency: There is a focus on developing equipment that consumes less energy while maintaining or improving production efficiency.

Case Studies

Several companies have successfully implemented affordable pipe extrusion solutions to enhance their production capabilities. For instance, a small manufacturer in Asia started with a single-screw extruder and gradually upgraded to a twin-screw model as demand increased. This approach allowed them to manage costs while expanding their market share.

Challenges and Solutions

Despite the benefits, affordable pipe extrusion equipment also presents challenges such as maintenance costs and potential quality issues. Regular maintenance and quality control measures can mitigate these risks. Additionally, partnering with suppliers who offer comprehensive after-sales support can ensure that any issues are addressed promptly.

Conclusion

While high-end pipe extrusion equipment can be costly, there are several affordable options available that can meet the needs of small-scale manufacturers. Single-screw extruders, conical twin-screw extruders, used equipment, DIY solutions, and modular systems are all viable alternatives. Understanding the specific requirements of your production and selecting the right equipment can help reduce costs without compromising on quality.

FAQs

1. What is the difference between single-screw and twin-screw extruders?

Single-screw extruders are simpler and less expensive, suitable for less demanding applications. Twin-screw extruders offer superior mixing and output, ideal for complex materials or high-volume production.

2. How does the die design affect pipe quality?

The die determines the pipe's dimensions and surface finish. Precise die design ensures consistent dimensions, smooth surfaces, and avoids defects like variations in wall thickness.

3. What factors influence the cost of a pipe extrusion machine?

Cost is influenced by capacity, automation level, extruder type, material processing capabilities, and included features. Larger, more automated machines with advanced features are more expensive.

4. Can cheap pipe extrusion equipment produce high-quality pipes?

Yes, affordable equipment can produce high-quality pipes if properly maintained and operated. However, the quality may vary depending on the specific machine and material used.

5. How do I choose the right cheap pipe extrusion equipment price for my needs?

Consider your production requirements, material types, and budget. Compare prices from different manufacturers and ensure the equipment meets your specific needs and standards.