Content Menu

● Introduction to Rubber Extrusion Equipment

>> Types of Rubber Extrusion Equipment

● Applications of Rubber Extrusion Equipment

● Discounts on Bulk Orders

>> China Rubber Extrusion Equipment Quotes

● Market Trends and Future Outlook

>> Technological Advancements

>> Sustainability Initiatives

● Conclusion

● Frequently Asked Questions

>> 1. What Types of Rubber Materials Can Be Used in Extrusion?

>> 2. How Do I Choose the Right Rubber Extruder Machine?

>> 3. Are Discounts Available for Bulk Orders of Rubber Extrusion Equipment?

>> 4. What Are the Key Components of a Rubber Extruder Machine?

>> 5. How Does the Vulcanization Process Affect Extruded Rubber Products?

The demand for rubber extrusion equipment in China has been on the rise due to its versatility and efficiency in producing a wide range of rubber products. These machines are crucial for manufacturing industries, especially those involved in automotive, construction, and consumer goods. One of the key factors that influence purchasing decisions is the availability of discounts on bulk orders. In this article, we will delve into the world of China rubber extrusion equipment, exploring the types of machinery available, their applications, and whether discounts are offered for bulk purchases.

Introduction to Rubber Extrusion Equipment

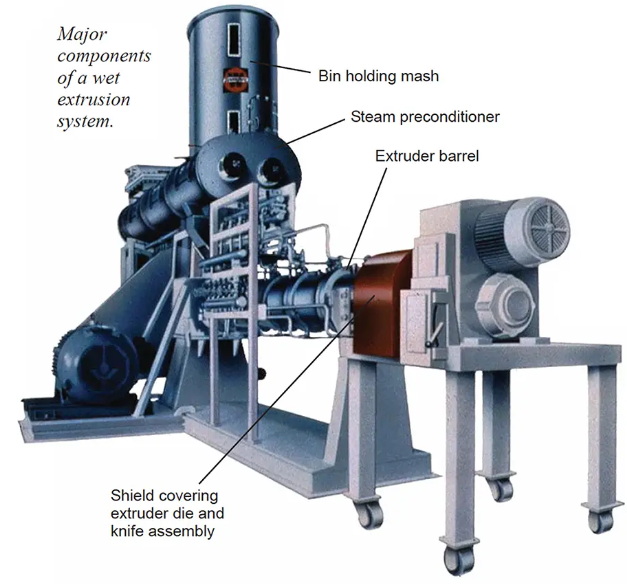

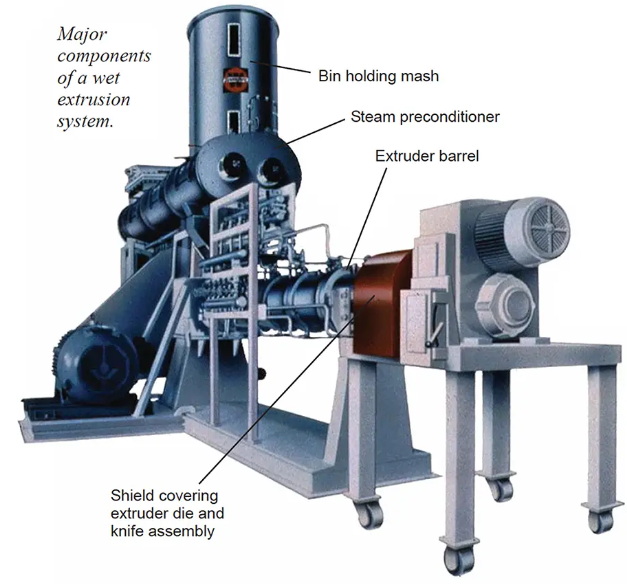

Rubber extrusion equipment is designed to process rubber materials into various shapes and profiles. The process involves feeding raw rubber into the extruder, where it is heated and mixed by a screw or screws, and then forced through a die to achieve the desired shape. This continuous process allows for the mass production of parts with precise dimensions and uniformity.

Types of Rubber Extrusion Equipment

1. Hot Feed Rubber Extruders: These machines are commonly used for producing tire treads, rubber pipes, and inner tubes. They are efficient for high-volume production due to their ability to continuously process rubber without the need for preheating the material. Hot feed extruders are favored in industries where speed and consistency are paramount.

2. Cold Feed Rubber Extruders: Unlike hot feed extruders, cold feed machines require preheating of the rubber before it is fed into the extruder. They are suitable for producing complex profiles and are often used in industries requiring precise control over the extrusion process. Cold feed extruders offer flexibility in handling different types of rubber compounds.

3. Silicone Rubber Extruders: These machines are specialized for processing silicone rubber, which is used in applications requiring high temperature resistance and flexibility. Silicone extrusions are common in industries such as aerospace and automotive, where durability and performance under extreme conditions are critical.

Applications of Rubber Extrusion Equipment

Rubber extrusion equipment is versatile and can be used in various industries:

- Automotive Industry: For producing seals, gaskets, and other components essential for vehicle assembly. The automotive sector benefits significantly from the precision and consistency offered by rubber extrusion machinery.

- Construction Industry: For manufacturing rubber profiles used in sealing and insulation. These profiles help in maintaining structural integrity and energy efficiency in buildings.

- Consumer Goods: For creating rubber parts used in household appliances and toys. The consumer goods sector relies on rubber extrusion for producing components that require flexibility and durability.

Discounts on Bulk Orders

When purchasing China rubber extrusion equipment, suppliers often offer discounts for bulk orders. These discounts can significantly reduce the overall cost per unit, making large-scale production more economical. Here are some factors to consider when negotiating discounts:

- Supplier Reputation: Working with reputable suppliers can ensure better quality equipment and more reliable discounts. Reputable suppliers typically have a history of delivering high-performance machinery and honoring their commitments.

- Customization Options: Some suppliers may offer customization options for bulk orders, which can enhance the machinery's efficiency and suitability for specific production needs. Customization can include modifications to the extruder's design, material handling systems, or control systems.

- Payment Terms: Negotiating favorable payment terms can also impact the overall cost-effectiveness of the purchase. Flexible payment options can help manage cash flow and reduce financial strain on the business.

China Rubber Extrusion Equipment Quotes

When seeking quotes for China rubber extrusion equipment, it's essential to compare prices from different suppliers. Here are some examples of prices and their corresponding machinery:

- Qingdao Junlin Machinery Co., Ltd.: Offers rubber extrusion machinery starting from US$ 141.72-283.44 per set. This range is suitable for small to medium-sized operations looking to expand their production capabilities.

- Qingdao Boria Machinery Manufacturing Co., Ltd.: Provides EPDM rubber hose production lines priced between US$ 8900-9000 per set. These lines are ideal for industries requiring high-quality rubber hoses for various applications.

- Zhejiang Baina Rubber and Plastic Equipment Co., Ltd.: Offers high-end rubber extrusion machinery priced at US$ 42000 per piece. This premium equipment is designed for large-scale production facilities seeking advanced technology and high efficiency.

Market Trends and Future Outlook

The market for rubber extrusion equipment is expected to grow due to increasing demand from emerging industries. Technological advancements in machinery design and material science are also driving innovation in this sector. As manufacturers look to improve efficiency and reduce costs, the demand for high-quality rubber extrusion equipment will continue to rise.

Technological Advancements

Recent advancements in rubber extrusion technology include the development of more efficient heating systems, improved screw designs, and advanced control systems. These innovations enhance the precision and speed of the extrusion process, allowing for more complex profiles and better product quality.

Sustainability Initiatives

There is a growing focus on sustainability in the rubber extrusion industry. Manufacturers are exploring the use of recycled materials and developing processes that minimize waste and energy consumption. This shift towards sustainability is expected to influence future trends in rubber extrusion equipment design and operation.

Conclusion

In conclusion, purchasing China rubber extrusion equipment in bulk can indeed offer significant discounts, making it a cost-effective option for large-scale production needs. Understanding the types of machinery available and their applications is crucial for selecting the right equipment for your business. Additionally, negotiating with suppliers can lead to better deals, especially when considering customization options and payment terms.

Frequently Asked Questions

1. What Types of Rubber Materials Can Be Used in Extrusion?

Rubber extrusion can use a wide range of natural and synthetic rubber compounds, including nitrile, SBR, EPDM, and silicone. The choice of material depends on the specific application requirements, such as temperature resistance or chemical exposure.

2. How Do I Choose the Right Rubber Extruder Machine?

Choosing the right rubber extruder involves considering factors like production capacity, material type, and desired product shape. It's also important to evaluate the supplier's reputation and after-sales service.

3. Are Discounts Available for Bulk Orders of Rubber Extrusion Equipment?

Yes, discounts are often available for bulk orders. Suppliers may offer price reductions or customization options for large purchases, which can enhance the machinery's efficiency and suitability for specific production needs.

4. What Are the Key Components of a Rubber Extruder Machine?

The key components of a rubber extruder machine include the drive system, barrel, transporting unit (screw or ram), and the head which holds the die. These components work together to heat, mix, and shape the rubber into the desired profile.

5. How Does the Vulcanization Process Affect Extruded Rubber Products?

Vulcanization is a critical step in rubber extrusion as it stabilizes the geometry and mechanical properties of the extruded product. This process involves heating the rubber under pressure to cross-link the molecules, enhancing its durability and resistance to deformation.