Content Menu

● Introduction to Polymer Extrusion

>> How Polymer Extrusion Works

● Industries Benefiting from Polymer Extrusion Equipment

>> 1. Construction Industry

>> 2. Automotive Industry

>> 3. Medical Industry

>> 4. Consumer Goods Industry

>> 5. Electronics Industry

● Benefits of Polymer Extrusion Equipment

● Challenges and Opportunities

● Future Trends in Polymer Extrusion

>> Integration with Emerging Technologies

>> Sustainability Initiatives

● Case Studies: Successful Applications of Polymer Extrusion

● Conclusion

● FAQ

>> 1. What is Polymer Extrusion?

>> 2. Which Industries Use Polymer Extrusion?

>> 3. What Are the Benefits of Polymer Extrusion Equipment?

>> 4. How Does Polymer Extrusion Contribute to Sustainability?

>> 5. What Future Trends Are Emerging in Polymer Extrusion?

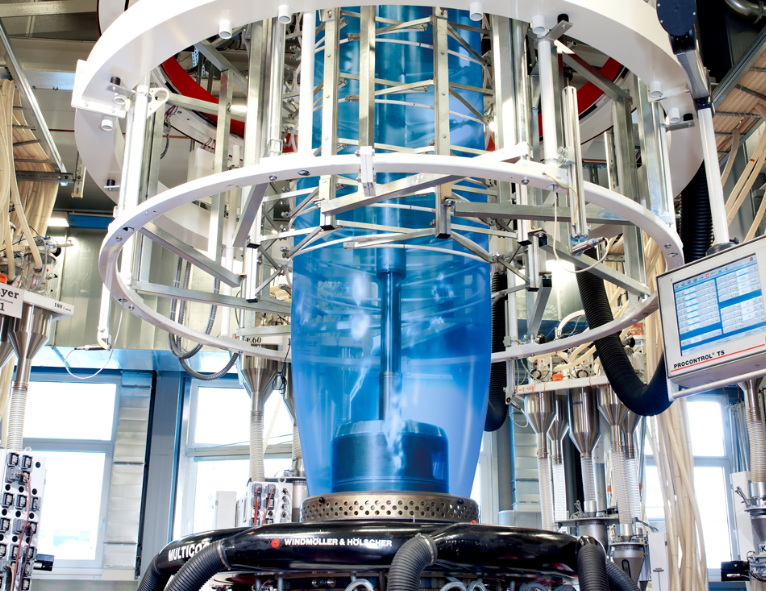

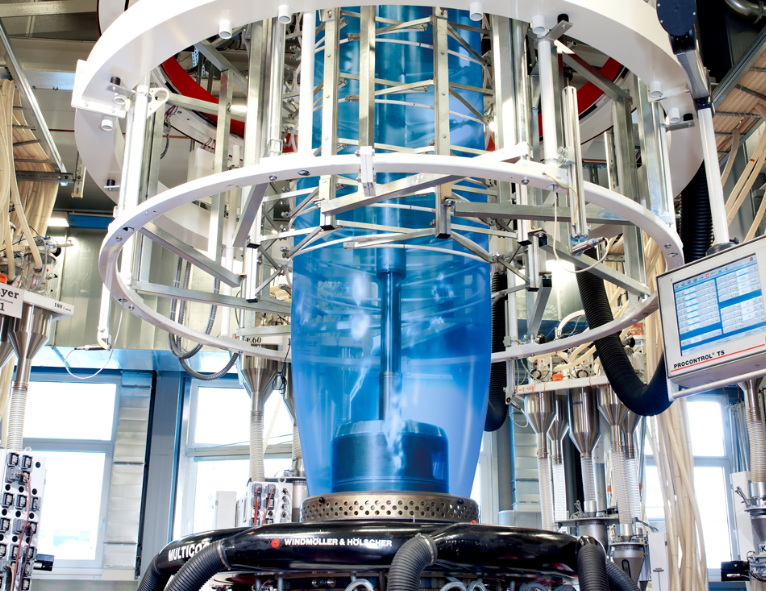

Polymer extrusion equipment plays a pivotal role in modern manufacturing, offering versatility, precision, and cost-effectiveness across various industries. This technology enables the production of a wide range of products, from simple packaging materials to complex medical devices. In this article, we will explore the industries that benefit most from polymer extrusion equipment and delve into the applications and advantages of this technology.

Introduction to Polymer Extrusion

Polymer extrusion is a process where thermoplastic materials are melted and formed into continuous profiles. This process involves feeding raw plastic materials into an extruder, where they are heated and melted, then forced through a die to create the desired shape. The resulting products can range from simple tubes and pipes to complex profiles used in construction and automotive parts.

How Polymer Extrusion Works

The extrusion process begins with material preparation, where raw plastic materials are fed into a hopper. The plastic is then melted by heat and mechanical shearing as it moves through the extruder's barrel. Once molten, the plastic is pushed through a die, which shapes it into the desired form. The extruded product is then cooled and solidified, often using water baths or cooling rolls.

Polymer extrusion equipment is designed to handle a variety of materials, including PVC, PE, PP, and ABS, each with its own unique properties and applications. For instance, PVC is commonly used for pipes and window frames due to its durability and resistance to moisture, while PE is often used in packaging due to its flexibility and cost-effectiveness.

Industries Benefiting from Polymer Extrusion Equipment

1. Construction Industry

In the construction sector, polymer extrusion equipment is used to produce materials like window frames, weatherstripping, siding, and insulation. These products offer durability, resistance to moisture, and energy efficiency, making them ideal for building applications. Extruded plastics can also be formulated to meet specific building codes and standards, ensuring safety and compliance.

For example, extruded vinyl siding is popular for its low maintenance and ability to withstand harsh weather conditions. Similarly, extruded plastic window frames provide excellent thermal insulation, reducing energy costs and enhancing building comfort.

2. Automotive Industry

The automotive industry utilizes polymer extrusion for parts such as door seals, weatherstripping, wire harnesses, and interior components. These parts are lightweight, durable, and resistant to weather conditions, contributing to vehicle performance and fuel efficiency. The use of extruded plastics also helps in reducing vehicle weight, which is crucial for improving fuel economy and reducing emissions.

In addition, extruded plastics are used in automotive applications where high heat resistance is required, such as in engine components and electrical systems. This ensures reliability and safety under demanding operating conditions.

3. Medical Industry

In the medical field, polymer extrusion equipment is used to produce tubing for IV lines, catheters, and other healthcare equipment. The precision and control over material properties ensure biocompatibility and meet strict health and safety standards. Extruded medical tubing must be sterile, flexible, and resistant to chemicals, making it suitable for a variety of medical procedures.

The use of polymer extrusion in medical devices also allows for customization, enabling the creation of specialized tubing with specific properties tailored to different medical applications.

4. Consumer Goods Industry

Consumer goods, including packaging materials, household appliances, and electronics, benefit from polymer extrusion. This technology allows for the production of unique shapes and designs that enhance product functionality and aesthetics. For instance, extruded plastic packaging materials are used in food wrapping, bottles, and containers due to their flexibility and barrier properties.

In household appliances, extruded plastics are used for components like handles, knobs, and casings, providing durability and resistance to wear and tear. The versatility of extrusion also enables the creation of complex designs that improve user experience and product appeal.

5. Electronics Industry

In the electronics sector, polymer extrusion equipment is used for wire and cable insulation, protective casings, and electronic enclosures. These plastics must be heat-resistant, flexible, and durable to ensure component safety and performance. Extruded plastics in electronics also help in reducing electromagnetic interference (EMI), which is critical for maintaining signal integrity.

The use of extruded plastics in electronic devices also supports miniaturization, allowing for the creation of smaller, more compact components that are essential for modern electronic devices.

Benefits of Polymer Extrusion Equipment

Polymer extrusion equipment offers several benefits, including:

- Material Efficiency: The ability to produce continuous lengths of product reduces waste and optimizes material usage. This is particularly important in industries where material costs are high or where sustainability is a priority.

- Precision and Versatility: Extrusion allows for precise control over product dimensions and shapes, enabling the creation of complex profiles. This versatility is crucial for meeting the diverse needs of different industries.

- Cost-Effectiveness: High-volume production capabilities make extrusion a cost-effective manufacturing method. It allows companies to produce large quantities of products at lower costs compared to other manufacturing processes.

Challenges and Opportunities

Despite its advantages, polymer extrusion faces challenges related to sustainability and environmental impact. The use of non-biodegradable plastics has raised concerns about waste management and pollution. However, advancements in polymer extrusion technology are addressing these issues by promoting the use of recycled materials and biodegradable plastics.

Moreover, the integration of polymer extrusion with emerging technologies like 3D printing and Industry 4.0 offers new opportunities for innovation. These technologies can enhance production efficiency, improve product design, and expand the range of applications for extruded plastics.

For instance, automation in polymer extrusion will improve production consistency and reduce labor costs. Sustainability efforts will focus on using recycled materials and developing biodegradable plastics, which will help reduce plastic waste and mitigate environmental concerns.

Additionally, the integration with Industry 4.0 technologies will enable real-time monitoring and optimization of production processes, further enhancing efficiency and product quality.

Future Trends in Polymer Extrusion

The future of polymer extrusion is marked by advancements in automation, sustainability, and integration with emerging technologies. These trends aim to enhance efficiency, reduce environmental impact, and expand the range of applications for extruded plastics.

For instance, advancements in material science are leading to the development of new polymers with enhanced properties, such as improved thermal resistance and biodegradability. This will open up new applications in industries where these properties are critical.

Moreover, the use of artificial intelligence (AI) and machine learning (ML) in polymer extrusion will enable predictive maintenance and quality control, reducing downtime and improving product consistency.

Integration with Emerging Technologies

The integration of polymer extrusion with technologies like 3D printing and robotics is also expected to play a significant role in the future. This integration will allow for the creation of complex geometries and customized products that cannot be produced using traditional extrusion methods alone.

For example, combining extrusion with 3D printing can enable the rapid prototyping of extruded parts, speeding up the development process and reducing costs associated with tooling and testing.

Sustainability Initiatives

Sustainability initiatives in polymer extrusion are gaining momentum, with a focus on reducing waste and promoting the use of eco-friendly materials. This includes the development of bioplastics, which are derived from renewable resources and can biodegrade more easily than traditional plastics.

Additionally, efforts to increase recycling rates and use recycled plastics in extrusion processes are underway. This not only reduces waste but also conserves natural resources by reusing existing materials.

Case Studies: Successful Applications of Polymer Extrusion

Several companies have successfully leveraged polymer extrusion to innovate and improve their products. For instance, in the automotive sector, companies have used extruded plastics to create lightweight yet durable components, contributing to improved fuel efficiency and reduced emissions.

In the medical field, polymer extrusion has enabled the production of specialized tubing and devices that meet stringent safety standards, enhancing patient care and outcomes.

These case studies highlight the versatility and potential of polymer extrusion in driving innovation and efficiency across various industries.

Conclusion

Polymer extrusion equipment is a vital tool across multiple industries, providing solutions that are both innovative and cost-effective. Its versatility and precision make it indispensable for manufacturing complex and durable products. As technology continues to evolve, the applications of polymer extrusion will expand, contributing to advancements in sustainability and efficiency.

FAQ

1. What is Polymer Extrusion?

- Polymer extrusion is a process where thermoplastic materials are melted and formed into continuous profiles. It involves feeding raw plastic into an extruder, heating it, and then forcing it through a die to create the desired shape.

2. Which Industries Use Polymer Extrusion?

- Polymer extrusion is used in various industries, including construction, automotive, medical, consumer goods, and electronics. Each industry benefits from the unique properties and versatility of extruded plastics.

3. What Are the Benefits of Polymer Extrusion Equipment?

- The benefits include material efficiency, precision, versatility, and cost-effectiveness. Extrusion allows for high-volume production with minimal waste, making it a preferred method for many manufacturers.

4. How Does Polymer Extrusion Contribute to Sustainability?

- Polymer extrusion contributes to sustainability by enabling the use of recycled materials and promoting the development of biodegradable plastics. Additionally, it supports energy-efficient manufacturing processes.

5. What Future Trends Are Emerging in Polymer Extrusion?

- Emerging trends include increased automation, the use of sustainable materials, and integration with technologies like 3D printing and Industry 4.0. These advancements aim to enhance efficiency, reduce environmental impact, and expand application possibilities.