Content Menu

● Introduction

● Understanding 10 Series Aluminum Extrusions

>> Characteristics of 1020 Aluminum

● Key Benefits of 10 Series Aluminum Extrusions

>> Strength and Durability

>> Lightweight Nature

>> Versatility in Applications

>> Cost-Effectiveness

● Applications of 10 Series Aluminum Extrusions

>> Structural Framing

>> Custom Fabrication

>> DIY Projects

● Conclusion

● Frequently Asked Questions

>> 1. What are the main advantages of using 1020 aluminum extrusion in industrial applications?

>> 2. How does 10 series aluminum extrusion compare to other aluminum series?

>> 3. Can 1020 aluminum extrusion be easily welded?

>> 4. What industries commonly use 10 series aluminum extrusions?

>> 5. Are there any limitations to using 1020 aluminum extrusion?

Introduction

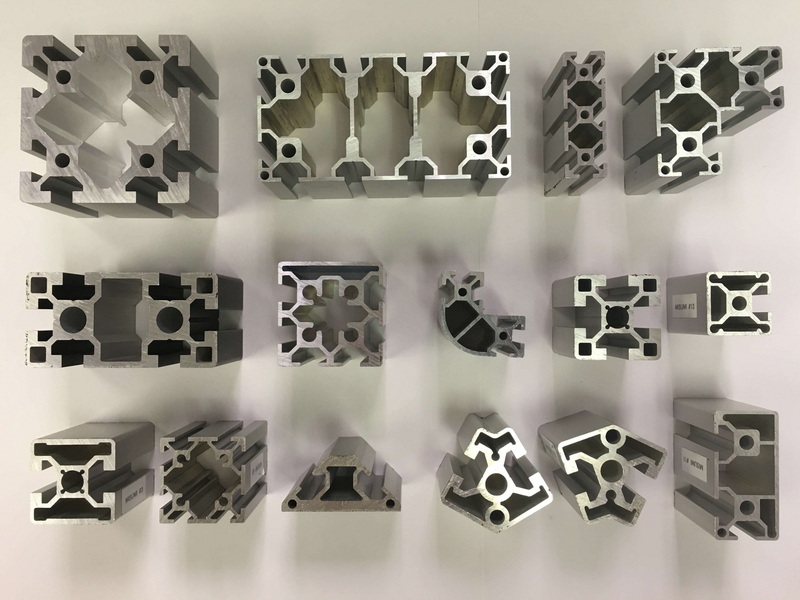

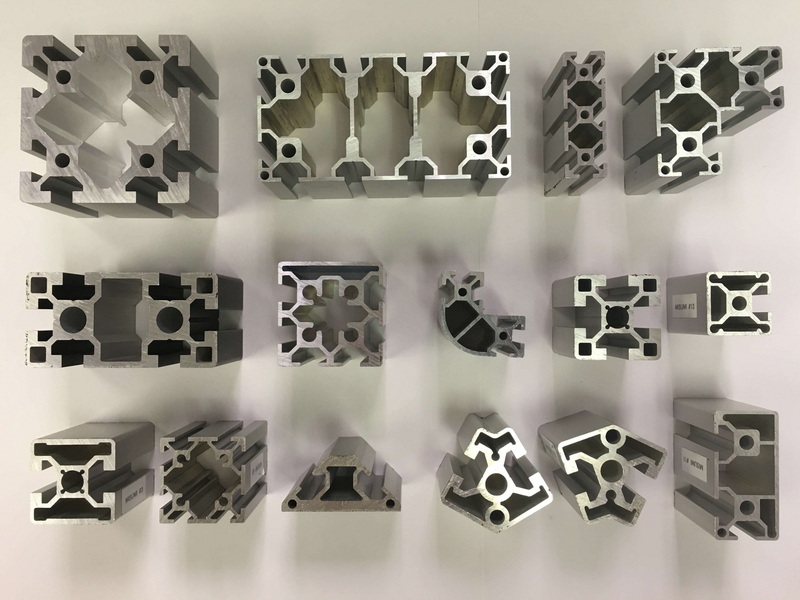

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. Among the various series of aluminum extrusions, the 10 series, particularly the 1020 aluminum extrusion, stands out for its versatility and strength. This article explores the unique properties of 10 series aluminum extrusions, their benefits, and why they are ideal for industrial applications.

Understanding 10 Series Aluminum Extrusions

The 10 series aluminum extrusions are characterized by their specific alloy composition, which typically includes a higher percentage of silicon and magnesium. This composition enhances the material's strength and durability, making it suitable for a wide range of industrial applications. The 1020 aluminum extrusion, in particular, is known for its excellent mechanical properties, including high tensile strength and resistance to corrosion.

Characteristics of 1020 Aluminum

1020 aluminum is a low-strength alloy that is easy to work with and can be easily welded. Its properties include:

- Tensile Strength: The tensile strength of 1020 aluminum is significantly higher than that of many other materials, making it ideal for structural applications.

- Corrosion Resistance: This alloy exhibits excellent resistance to corrosion, which is crucial for industrial environments where exposure to moisture and chemicals is common.

- Lightweight: Despite its strength, 1020 aluminum is lightweight, which reduces the overall weight of structures and components, leading to easier handling and transportation.

Key Benefits of 10 Series Aluminum Extrusions

Strength and Durability

One of the primary reasons why 10 series aluminum extrusions, particularly 1020 aluminum, are favored in industrial applications is their strength and durability. The high tensile strength allows these extrusions to support heavy loads without deforming. This makes them ideal for use in structural applications, such as frames for machinery, supports for equipment, and even in the construction of buildings.

Lightweight Nature

The lightweight nature of 1020 aluminum extrusions is another significant advantage. In industries where weight is a critical factor, such as aerospace and automotive, using lightweight materials can lead to improved fuel efficiency and reduced operational costs. The ability to create strong yet lightweight structures is a hallmark of 10 series aluminum extrusions.

Versatility in Applications

10 series aluminum extrusions are incredibly versatile and can be used in various applications across different industries. Some common uses include:

- Structural Framing: The strength of 1020 aluminum makes it an excellent choice for structural framing in buildings and industrial facilities.

- Custom Fabrication: Manufacturers can easily customize 10 series extrusions to meet specific design requirements, making them suitable for unique applications.

- Machinery Components: The durability and lightweight properties of 1020 aluminum make it ideal for components in machinery, where both strength and weight are critical.

Cost-Effectiveness

When considering materials for industrial applications, cost is always a factor. 10 series aluminum extrusions, particularly 1020 aluminum, offer a cost-effective solution. The combination of strength, lightweight properties, and corrosion resistance means that these extrusions can reduce maintenance costs and extend the lifespan of structures and components.

Applications of 10 Series Aluminum Extrusions

Structural Framing

In construction, 10 series aluminum extrusions are often used for structural framing. Their strength allows them to support significant loads, making them suitable for everything from small buildings to large industrial facilities. The ability to customize the extrusions means that they can be tailored to fit specific architectural designs.

Custom Fabrication

The flexibility of 1020 aluminum extrusions allows for custom fabrication. Manufacturers can create unique profiles that meet the specific needs of their projects. This adaptability is particularly beneficial in industries where standard components may not suffice.

DIY Projects

The popularity of 10 series aluminum extrusions extends beyond industrial applications. Hobbyists and DIY enthusiasts often use 1020 aluminum for various projects, from building custom furniture to creating intricate models. The ease of working with this material makes it a favorite among those looking to create something unique.

Conclusion

In conclusion, 10 series aluminum extrusions, particularly 1020 aluminum, are ideal for industrial use due to their strength, lightweight nature, versatility, and cost-effectiveness. Their unique properties make them suitable for a wide range of applications, from structural framing to custom fabrication. As industries continue to seek materials that offer both performance and efficiency, 10 series aluminum extrusions will undoubtedly remain a top choice.

Frequently Asked Questions

1. What are the main advantages of using 1020 aluminum extrusion in industrial applications?

The main advantages include high tensile strength, lightweight nature, excellent corrosion resistance, and cost-effectiveness, making it suitable for various structural and custom applications.

2. How does 10 series aluminum extrusion compare to other aluminum series?

10 series aluminum extrusions typically offer higher strength and better corrosion resistance compared to other series, making them ideal for demanding industrial environments.

3. Can 1020 aluminum extrusion be easily welded?

Yes, 1020 aluminum is known for its weldability, allowing for easy fabrication and assembly in various applications.

4. What industries commonly use 10 series aluminum extrusions?

Industries such as construction, automotive, aerospace, and manufacturing commonly use 10 series aluminum extrusions for their strength and versatility.

5. Are there any limitations to using 1020 aluminum extrusion?

While 1020 aluminum offers many benefits, it may not be suitable for applications requiring extremely high strength or specialized properties found in other aluminum alloys.