Content Menu

● Introduction to Single Screw Extruders

>> Key Components of a Single Screw Extruder

● Single Screw Extruders in Plastic Processing

>> Advantages in Plastic Processing

● Aluminum Extrusion Process

>> Challenges in Aluminum Extrusion

● Adapting Single Screw Extruders for Aluminum

>> Potential Modifications

● Comparison with Twin Screw Extruders

>> Key Differences

● Applications of Single Screw Extruders

● Future Developments

>> Emerging Technologies

● Conclusion

● Frequently Asked Questions

>> 1. What is a single screw extruder?

>> 2. Can single screw extruders be used for aluminum?

>> 3. What are the key components of a single screw extruder?

>> 4. How does a single screw extruder work?

>> 5. What are the advantages of single screw extruders?

Aluminum extrusion is a widely used process in manufacturing, where aluminum billets are heated and forced through a die to create various profiles. While single screw extruders are more commonly associated with plastic processing, they can also be adapted for use with other materials, including aluminum, under specific conditions. However, traditional single screw extruders are not typically designed for aluminum due to its high melting point and specific processing requirements. In this article, we will explore the concept of single screw extruders, their applications, and how they might be adapted for aluminum processing.

Introduction to Single Screw Extruders

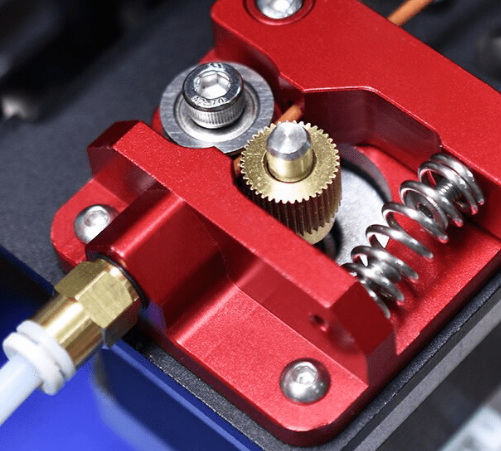

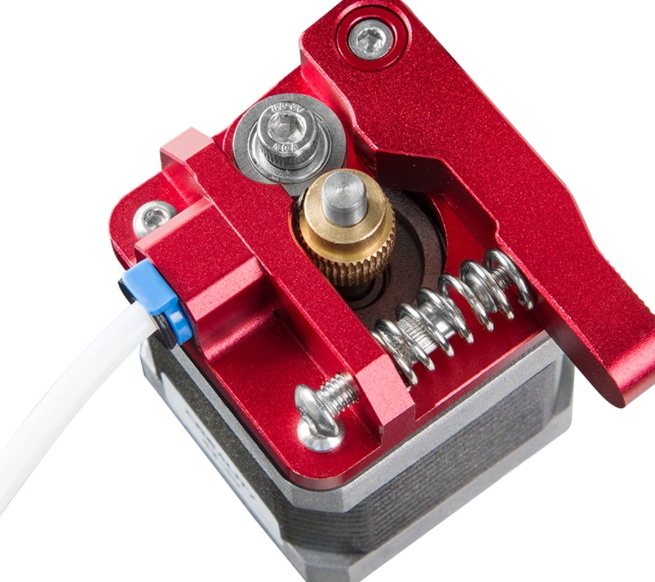

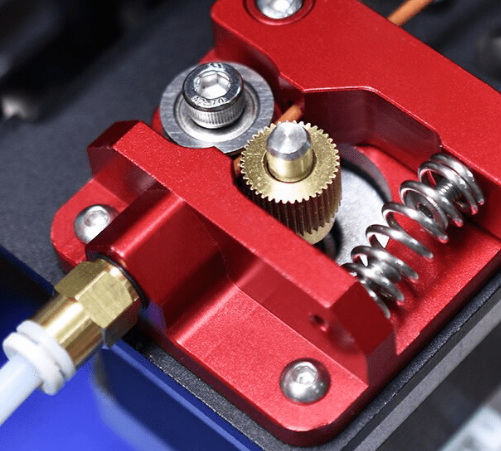

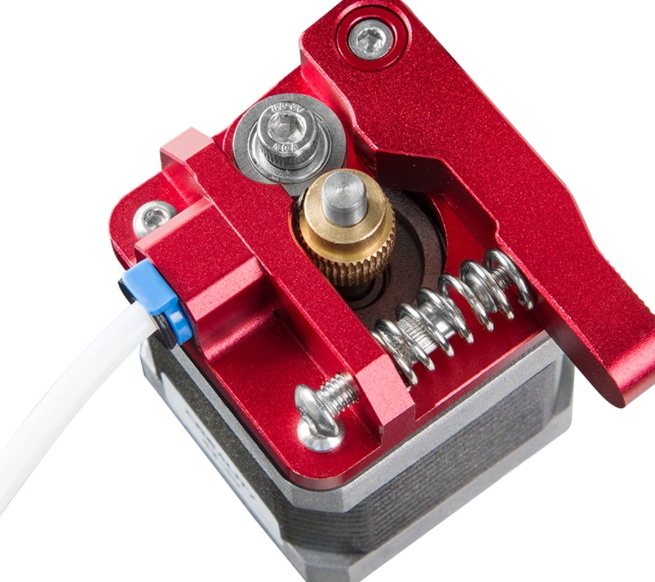

Single screw extruders are machines that use one helical screw to convey, compress, and melt materials. They are widely used in plastic processing due to their simplicity and cost-effectiveness. The basic components of a single screw extruder include a hopper, screw, barrel, die, temperature control system, and drive mechanism.

Key Components of a Single Screw Extruder

- Hopper: Where raw materials are fed into the machine.

- Screw: The core component that mixes, melts, and conveys materials.

- Barrel: A cylindrical housing containing the screw and heating elements.

- Die: Shapes the final product.

- Temperature Control System: Regulates temperature during processing.

- Drive Mechanism: Supplies torque and speed to the screw.

Single Screw Extruders in Plastic Processing

Single screw extruders are extensively used in plastic processing for producing pipes, sheets, and other profiles. They are suitable for materials like PP-R pipes, PE gas pipes, and PEX cross-linked pipes. However, their application in aluminum processing is limited due to aluminum's high melting point and specific processing requirements.

Advantages in Plastic Processing

1. Cost-Effectiveness: Single screw extruders are less expensive compared to twin screw extruders.

2. Simplicity: They have fewer moving parts, making them easier to maintain.

3. Energy Efficiency: While less efficient than twin screw extruders, they are still suitable for many plastic applications.

Aluminum Extrusion Process

Aluminum extrusion involves heating aluminum billets to a high temperature and forcing them through a die to create profiles. This process is typically done using hydraulic presses rather than extruders designed for plastics. The high melting point of aluminum requires specialized equipment capable of achieving and maintaining very high temperatures.

Challenges in Aluminum Extrusion

1. High Melting Point: Aluminum requires temperatures around 500°C to 600°C, which is challenging for standard plastic extruders.

2. Material Properties: Aluminum has different rheological properties than plastics, requiring adjustments in processing conditions.

Adapting Single Screw Extruders for Aluminum

While traditional single screw extruders are not designed for aluminum, there are potential adaptations that could make them suitable for certain aluminum applications. This might involve modifying the heating system to achieve higher temperatures and using specialized dies designed for aluminum profiles.

Potential Modifications

1. Enhanced Heating System: Upgrading the heating elements to achieve higher temperatures.

2. Specialized Dies: Designing dies that can handle the flow characteristics of molten aluminum.

3. Screw Design: Modifying the screw geometry to improve mixing and conveying of aluminum.

Comparison with Twin Screw Extruders

Twin screw extruders offer better mixing, venting, and self-cleaning capabilities compared to single screw extruders. They are more versatile and can handle a wider range of materials, including those with poor thermal stability. However, they are more complex and expensive.

Key Differences

- Mixing Ability: Twin screw extruders provide superior mixing and blending capabilities.

- Material Range: They can process a broader range of materials, including complex polymers.

- Energy Efficiency: Generally more energy-efficient due to better heat transfer and mixing.

Applications of Single Screw Extruders

Single screw extruders are widely used in various industries, including:

- Plastic Pipes and Profiles: For producing PP-R pipes, PE gas pipes, and other plastic profiles.

- Food Processing: In some cases, they are used for processing food materials like pasta or snacks.

- Pharmaceuticals: Used in certain pharmaceutical applications where simple mixing is required.

Future Developments

As technology advances, there may be opportunities to develop single screw extruders that can efficiently process materials like aluminum. This could involve integrating advanced materials and technologies into the design of the extruder.

Emerging Technologies

1. Advanced Materials: Using new materials for the barrel and screw that can withstand high temperatures.

2. Digital Control Systems: Implementing sophisticated control systems to optimize processing conditions.

Conclusion

While single screw extruders are not typically used for aluminum extrusion due to the material's high melting point and specific processing requirements, there are potential adaptations that could make them suitable for certain applications. However, these adaptations would require significant modifications to the heating system and screw design.

Frequently Asked Questions

1. What is a single screw extruder?

A single screw extruder is a machine that uses one helical screw to melt and form materials, commonly used in plastic processing.

2. Can single screw extruders be used for aluminum?

Traditional single screw extruders are not designed for aluminum due to its high melting point. However, potential adaptations could make them suitable for certain applications.

3. What are the key components of a single screw extruder?

The key components include a hopper, screw, barrel, die, temperature control system, and drive mechanism.

4. How does a single screw extruder work?

Raw materials are fed into the hopper, mixed and melted by the screw in the heated barrel, and then shaped by the die.

5. What are the advantages of single screw extruders?

They are simpler and less expensive than twin screw extruders, making them suitable for simpler processes.