Content Menu

● What Is a GIA Aluminum Extrusion Press?

● Components of a GIA Aluminum Extrusion Press

● How Does a GIA Aluminum Extrusion Press Work?

>> 1. Billet Preparation

>> 2. Loading the Billet

>> 3. Extrusion Process

>> 4. Quenching and Cooling

>> 5. Stretching and Cutting

>> 6. Aging and Finishing

● Advanced Features of GIA Aluminum Extrusion Presses

>> Intelligent Control Systems

>> Energy Efficiency

>> Enhanced Safety Features

● Applications of GIA Aluminum Extrusion Presses

>> Automotive Industry

>> Construction and Architecture

>> Electronics and Technology

>> Aerospace and Defense

>> Renewable Energy

● Advantages of GIA Aluminum Extrusion Presses

● Future Trends in Aluminum Extrusion Technology

>> Industry 4.0 Integration

>> Advanced Materials Processing

>> Sustainable Manufacturing

● Conclusion

● FAQs

>> 1. What is an aluminum extrusion press?

>> 2. What makes GIA aluminum extrusion presses unique?

>> 3. What industries benefit from GIA aluminum extrusion presses?

>> 4. How does quenching improve extruded profiles?

>> 5. Can GIA presses handle custom designs?

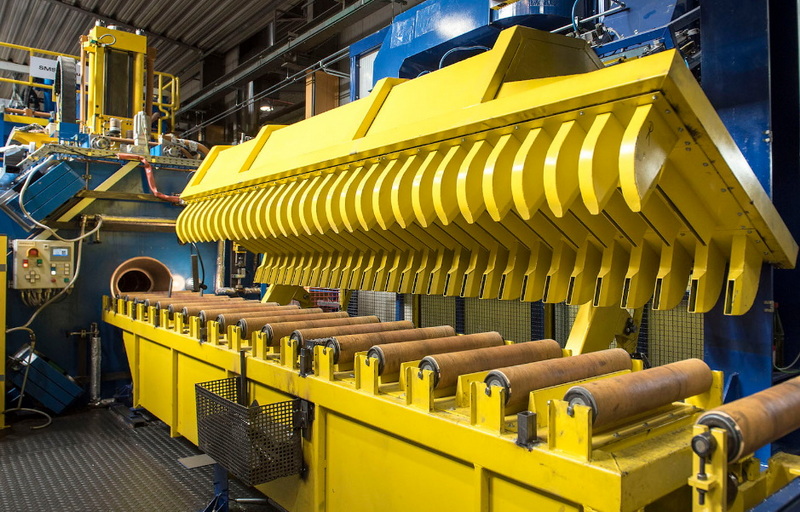

Aluminum extrusion is a transformative manufacturing process that shapes aluminum into specific profiles by forcing it through a die under high pressure. Among the leading technologies in this field is the GIA aluminum extrusion press, a sophisticated machine designed for precision, efficiency, and versatility. This article explores the components, working principles, applications, and advantages of GIA aluminum extrusion presses.

What Is a GIA Aluminum Extrusion Press?

A GIA aluminum extrusion press is an advanced machine used to produce aluminum profiles by extruding preheated aluminum billets through dies. Manufactured by GIA Clecim Press, these presses are renowned for their reliability, stiffness, and ability to handle diverse extrusion processes, including:

- Direct extrusion: The billet and die move in the same direction.

- Indirect extrusion: The die moves toward the stationary billet.

- Combination presses: Capable of both direct and indirect extrusion.

- Seamless hollow extrusion: Using a piercer to create hollow profiles.

These machines also integrate auxiliary systems for billet handling, cooling, quenching, and profile finishing, making them a comprehensive solution for aluminum extrusion.

Components of a GIA Aluminum Extrusion Press

Understanding the key components of a GIA aluminum extrusion press is crucial to appreciating its functionality:

1. Main Cylinder: The powerhouse of the press, generating the force required for extrusion.

2. Container: Houses the billet during the extrusion process.

3. Ram: Pushes the billet through the container and die.

4. Die: Shapes the aluminum into the desired profile.

5. Billet Loader: Automates the process of loading preheated billets into the container.

6. Puller: Guides and pulls the extruded profile as it emerges from the die.

7. Cooling System: Manages temperature control throughout the process.

8. Control System: Monitors and adjusts press parameters for optimal performance.

Each component plays a vital role in ensuring the efficiency and precision of the GIA aluminum extrusion press.

How Does a GIA Aluminum Extrusion Press Work?

The operation of a GIA aluminum extrusion press involves several critical steps:

1. Billet Preparation

The process begins with aluminum billets, which are cylindrical blocks of aluminum alloy. These billets are preheated to temperatures between 400°C and 500°C to achieve malleability without liquefying. The preheating process is crucial as it determines the flow characteristics of the aluminum during extrusion.

2. Loading the Billet

The preheated billet is transferred into the press chamber. Lubricants or release agents are applied to prevent adhesion between the billet and the ram. This step is often automated in modern GIA presses to ensure consistency and reduce human error.

3. Extrusion Process

A hydraulic ram (or stem) applies immense pressure—up to 15,000 tons—pushing the billet into the container. The billet flows through the die opening, taking on its desired cross-sectional shape. The pressure and speed of extrusion are carefully controlled to maintain product quality and dimensional accuracy.

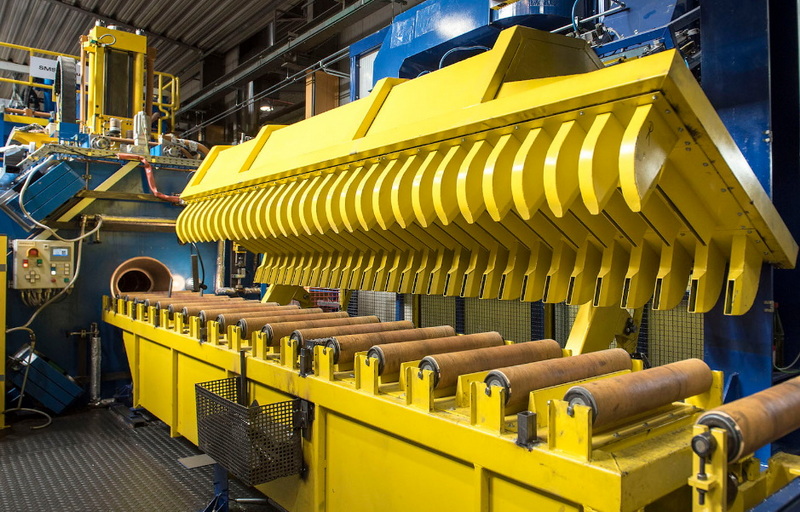

4. Quenching and Cooling

As the extruded profile exits the die, it undergoes quenching using water baths or air fans to cool it evenly. This step ensures structural integrity and prevents deformation. The cooling rate is critical in determining the final properties of the extruded product.

5. Stretching and Cutting

The extruded profile is stretched to eliminate twists or distortions before being cut to specified lengths using precision saws. This step helps achieve the desired straightness and dimensional accuracy of the final product.

6. Aging and Finishing

The profiles are heat-treated to enhance their mechanical properties (e.g., T4 to T6 temper). Surface finishes such as anodizing or powder coating may also be applied to improve aesthetics and durability.

Advanced Features of GIA Aluminum Extrusion Presses

GIA aluminum extrusion presses incorporate several advanced features that set them apart:

Intelligent Control Systems

Modern GIA presses are equipped with sophisticated control systems that utilize artificial intelligence and machine learning algorithms. These systems can:

- Optimize extrusion parameters in real-time

- Predict and prevent potential issues

- Reduce setup times between different profiles

Energy Efficiency

GIA has made significant strides in improving the energy efficiency of their presses:

- Regenerative braking systems that recover energy during deceleration

- Optimized hydraulic systems to reduce power consumption

- Intelligent standby modes that minimize energy use during idle periods

Enhanced Safety Features

Safety is paramount in GIA press design:

- Advanced interlocking systems prevent accidental access to danger zones

- Emergency stop functions are strategically placed for quick response

- Automated systems reduce the need for manual intervention in high-risk areas

Applications of GIA Aluminum Extrusion Presses

GIA aluminum extrusion presses cater to various industries due to their adaptability and precision:

Automotive Industry

In the automotive sector, GIA presses are used to create:

- Lightweight structural components for vehicle frames

- Heat exchangers and radiators

- Trim and decorative elements

Construction and Architecture

The construction industry relies on GIA presses for:

- Window and door frames

- Curtain wall systems

- Structural supports for buildings

Electronics and Technology

In the rapidly evolving tech sector, GIA presses produce:

- Heat sinks for electronic devices

- Casings and enclosures for computers and smartphones

- LED lighting fixtures and housings

Aerospace and Defense

The aerospace industry utilizes GIA presses for:

- Aircraft fuselage components

- Wing spars and ribs

- Satellite structures

Renewable Energy

In the growing renewable energy sector, GIA presses contribute to:

- Solar panel frames and mounting systems

- Wind turbine components

- Geothermal heat exchanger tubes

The versatility of GIA aluminum extrusion presses allows manufacturers to meet the diverse needs of these industries with precision and efficiency.

Advantages of GIA Aluminum Extrusion Presses

1. Versatility: Capable of producing complex shapes with high precision, allowing for innovative design solutions across industries.

2. Efficiency: Integrated systems for billet handling, cooling, and finishing streamline production, reducing cycle times and increasing output.

3. Durability: Designed for long-term use with minimal maintenance, ensuring a reliable production process and reduced downtime.

4. Customization: Supports tailored solutions for specific industrial needs, allowing manufacturers to create unique profiles that meet exact specifications.

5. Quality Control: Advanced monitoring systems ensure consistent product quality, reducing waste and improving customer satisfaction.

6. Scalability: GIA offers a range of press sizes and configurations, allowing businesses to scale their production capabilities as needed.

7. Sustainability: Energy-efficient designs and the use of recyclable aluminum contribute to more sustainable manufacturing practices.

Future Trends in Aluminum Extrusion Technology

As the demand for aluminum extrusions continues to grow, GIA is at the forefront of developing new technologies to meet future challenges:

Industry 4.0 Integration

GIA is working on fully integrating their presses into the Industry 4.0 ecosystem:

- IoT sensors for real-time monitoring and predictive maintenance

- Cloud-based data analytics for process optimization

- Seamless integration with ERP and MES systems

Advanced Materials Processing

Research is underway to expand the capabilities of GIA presses to handle:

- High-strength aluminum alloys for aerospace applications

- Aluminum-matrix composites for enhanced properties

- Multi-material extrusions for specialized applications

Sustainable Manufacturing

GIA is committed to developing more sustainable extrusion processes:

- Closed-loop recycling systems for scrap aluminum

- Reduced energy consumption through advanced heating technologies

- Water-based lubricants to minimize environmental impact

Conclusion

The "GIA aluminum extrusion press" represents cutting-edge technology in aluminum manufacturing. Its robust design, flexibility, and efficiency make it an essential tool for industries requiring high-quality aluminum profiles. By understanding its operation and benefits, manufacturers can leverage this technology for innovative applications across various sectors. As GIA continues to innovate, the future of aluminum extrusion looks promising, with advancements in automation, sustainability, and material science set to further revolutionize the industry.

FAQs

1. What is an aluminum extrusion press?

An aluminum extrusion press is a machine that shapes preheated aluminum billets into specific profiles by forcing them through a die under high pressure.

2. What makes GIA aluminum extrusion presses unique?

GIA presses are known for their reliability, stiffness, and ability to handle complex processes like seamless hollow extrusions and combined direct/indirect extrusions.

3. What industries benefit from GIA aluminum extrusion presses?

Industries such as automotive, construction, aerospace, and electronics use these presses for lightweight yet durable components.

4. How does quenching improve extruded profiles?

Quenching rapidly cools the extruded material to maintain its structural integrity and prevent deformation during processing.

5. Can GIA presses handle custom designs?

Yes, GIA presses can produce custom profiles by utilizing specially designed dies tailored to specific requirements.