Content Menu

● Introduction

● Understanding Aluminum Extrusion

● Key Factors Influencing Pricing

>> Material Costs

>> Complexity of Design

>> Quantity and Scale

>> Finishing Processes

● Market Trends Affecting Prices

● Cost-Saving Strategies

● Conclusion

● Related Questions

>> 1. What are the most common applications of aluminum extrusions?

>> 2. How can I reduce costs when ordering aluminum extrusions?

>> 3. What types of finishing processes are available for aluminum extrusions?

>> 4. How does the price of aluminum fluctuate?

>> 5. What should I consider when selecting an aluminum extrusion supplier?

Introduction

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. This versatile technique is widely used across various industries, including construction, automotive, aerospace, and consumer goods. Understanding the factors that influence aluminum extrusion pricing is crucial for businesses and consumers alike, as it can significantly impact project budgets and overall costs. In this article, we will explore the key elements that affect aluminum extrusion prices, market trends, and strategies for cost savings.

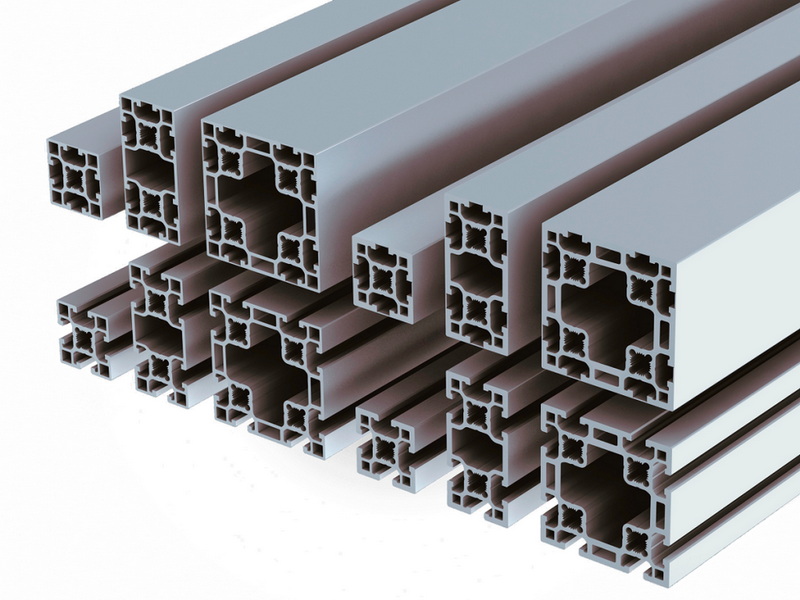

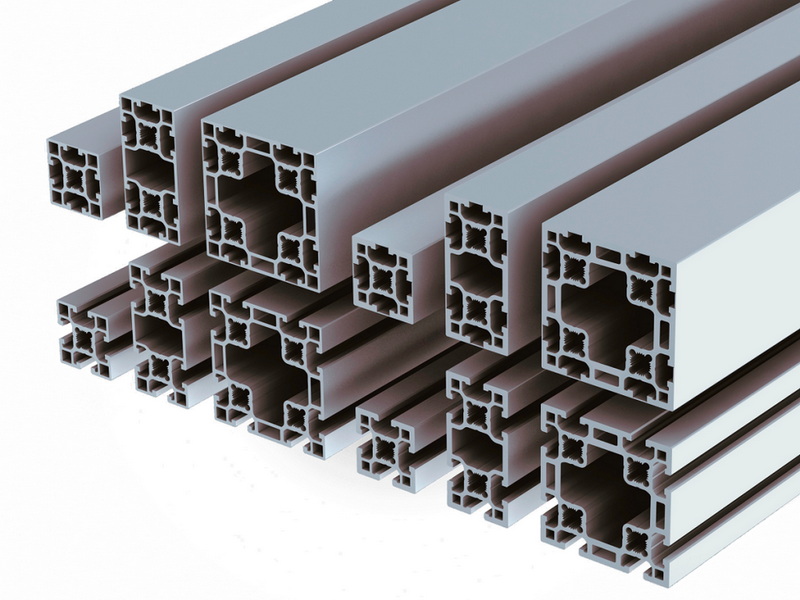

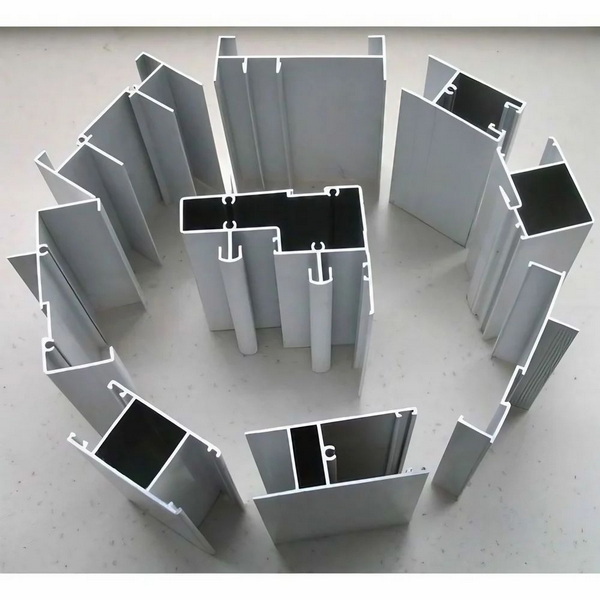

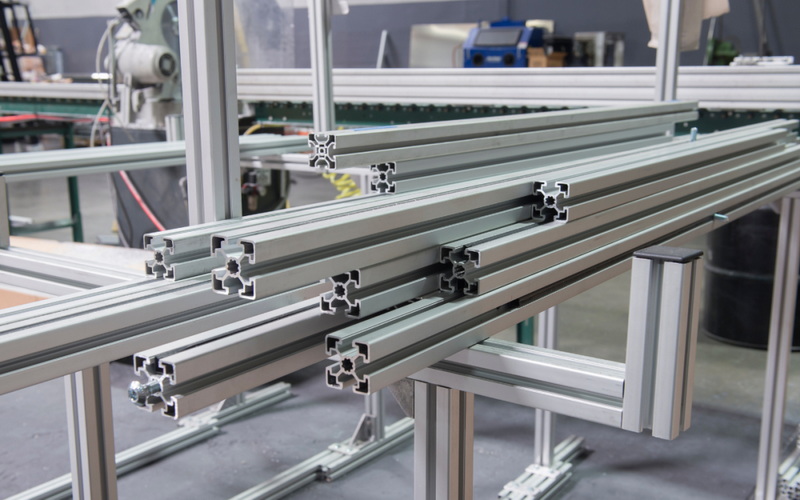

Understanding Aluminum Extrusion

Aluminum extrusion involves forcing heated aluminum alloy through a die to create a specific shape. The process allows for the production of complex profiles with high precision and minimal waste. Aluminum extrusions are lightweight, corrosion-resistant, and can be easily fabricated, making them ideal for a wide range of applications, from structural components to decorative elements.

The benefits of aluminum extrusions include:

- Lightweight: Aluminum is significantly lighter than steel, making it easier to handle and transport.

- Strength: Despite its light weight, aluminum has a high strength-to-weight ratio, making it suitable for structural applications.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which helps prevent corrosion.

- Versatility: The extrusion process allows for a wide variety of shapes and sizes, catering to diverse industry needs.

Key Factors Influencing Pricing

Material Costs

One of the most significant factors affecting aluminum extrusion pricing is the cost of raw materials. The price of aluminum can fluctuate based on various factors, including global supply and demand, production costs, and geopolitical events. When aluminum prices rise, manufacturers often pass these costs onto consumers, leading to higher extrusion prices. Additionally, the specific alloy used can also impact pricing, as some alloys are more expensive due to their unique properties.

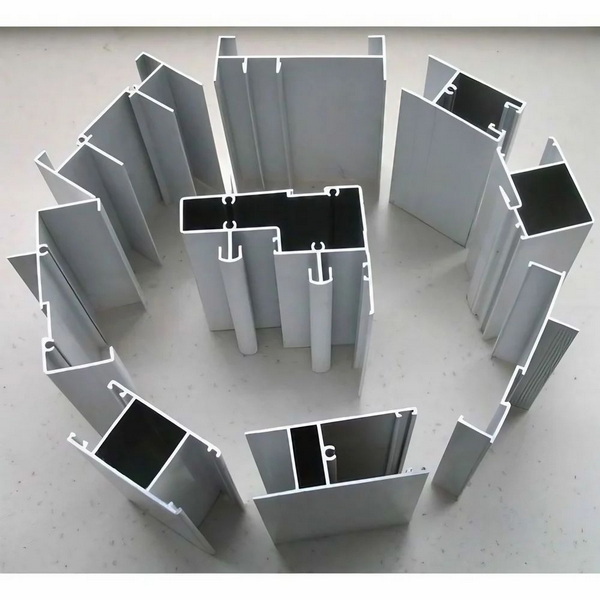

Complexity of Design

The complexity of the extrusion design plays a crucial role in determining the overall cost. More intricate designs require specialized dies and longer production times, which can increase manufacturing costs. For example, a simple, straight profile will generally be less expensive to produce than a complex shape with multiple bends and features. When planning a project, it is essential to consider the design's complexity and how it may affect the final price.

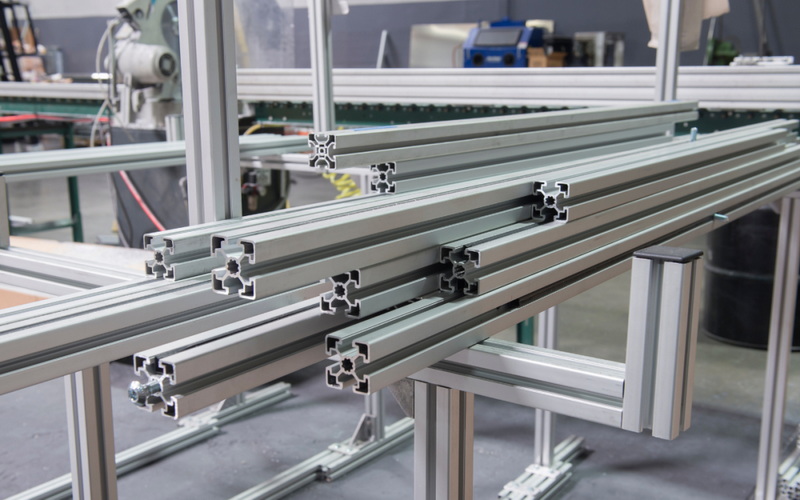

Quantity and Scale

The quantity of aluminum extrusions ordered can significantly influence pricing. Manufacturers often offer bulk discounts for larger orders, which can help reduce the per-unit cost. Conversely, smaller orders may incur higher prices due to the setup costs associated with producing a new die and running a production run. Businesses should evaluate their needs and consider ordering larger quantities when possible to take advantage of cost savings.

Finishing Processes

Aluminum extrusions often require additional finishing processes, such as anodizing, painting, or powder coating, to enhance their appearance and durability. These finishing processes can add to the overall cost of the extrusions. For instance, anodizing involves an electrochemical process that increases corrosion resistance and surface hardness, but it also requires additional time and resources. When budgeting for aluminum extrusions, it is essential to factor in these finishing costs.

Market Trends Affecting Prices

The aluminum extrusion market is influenced by various trends that can impact pricing. One significant trend is the growing demand for lightweight materials in industries such as automotive and aerospace. As manufacturers seek to improve fuel efficiency and reduce emissions, the demand for aluminum extrusions is expected to rise, potentially driving up prices.

Additionally, global supply chain issues can affect aluminum pricing. Events such as natural disasters, trade disputes, or changes in regulations can disrupt the supply of raw materials, leading to price fluctuations. Businesses must stay informed about these trends to make informed decisions regarding their aluminum extrusion needs.

Cost-Saving Strategies

To minimize costs when ordering aluminum extrusions, businesses can implement several strategies:

- Optimize Design: Simplifying the design can reduce manufacturing costs. Consider working with engineers to create efficient designs that minimize complexity while still meeting functional requirements.

- Order in Bulk: Taking advantage of bulk discounts can significantly lower per-unit costs. If possible, plan for future projects and order larger quantities to benefit from these savings.

- Choose the Right Supplier: Research and select suppliers that offer competitive pricing and high-quality products. Building a strong relationship with a reliable supplier can lead to better pricing and service.

- Negotiate Terms: Don't hesitate to negotiate pricing and terms with suppliers. Many manufacturers are willing to work with customers to find mutually beneficial arrangements.

Conclusion

Understanding the factors that influence aluminum extrusion pricing is essential for businesses and consumers looking to make informed decisions. By considering material costs, design complexity, order quantity, and finishing processes, stakeholders can better navigate the aluminum extrusion market. Staying informed about market trends and implementing cost-saving strategies can further enhance the value of aluminum extrusions in various applications.

Related Questions

1. What are the most common applications of aluminum extrusions?

Aluminum extrusions are commonly used in construction, automotive parts, aerospace components, and consumer products. Their lightweight and durable nature makes them ideal for structural applications, framing, and decorative elements.

2. How can I reduce costs when ordering aluminum extrusions?

To reduce costs, consider optimizing your design for simplicity, ordering in bulk to take advantage of discounts, choosing the right supplier, and negotiating terms.

3. What types of finishing processes are available for aluminum extrusions?

Common finishing processes for aluminum extrusions include anodizing, painting, and powder coating. Each process enhances the appearance and durability of the extrusions.

4. How does the price of aluminum fluctuate?

The price of aluminum can fluctuate based on global supply and demand, production costs, and geopolitical events. Staying informed about these factors can help businesses anticipate price changes.

5. What should I consider when selecting an aluminum extrusion supplier?

When selecting a supplier, consider their pricing, quality of products, delivery times, and customer service. Building a strong relationship with a reliable supplier can lead to better pricing and service in the long run.