Content Menu

● Understanding Aluminum Extrusions

● Key Dimensions of 1010 Aluminum Extrusions

>> Profile Shape

>> Wall Thickness

>> Overall Size

>> Length

>> Weight

● Applications of 1010 Aluminum Extrusions

>> Structural Components

>> Automotive Industry

>> Aerospace Applications

>> Manufacturing Equipment

>> Furniture and Fixtures

● Benefits of Using 1010 Aluminum Extrusions

>> Corrosion Resistance

>> Lightweight

>> Versatility

>> Ease of Fabrication

>> Recyclability

● Conclusion

● Frequently Asked Questions

>> 1. What is the difference between 1010 aluminum and other aluminum alloys?

>> 2. Can 1010 aluminum extrusions be customized?

>> 3. What industries commonly use 1010 aluminum extrusions?

>> 4. How do I calculate the weight of a 1010 aluminum extrusion?

>> 5. Are 1010 aluminum extrusions recyclable?

Aluminum extrusions are a vital component in various industries, including construction, automotive, aerospace, and manufacturing. Among the many types of aluminum extrusions, the 1010 aluminum extrusion is particularly popular due to its versatility and strength. This article will explore the key dimensions of 1010 aluminum extrusions, their applications, and the benefits they offer.

Understanding Aluminum Extrusions

Aluminum extrusion is a process that involves shaping aluminum alloy into a desired cross-sectional profile. This is achieved by forcing the aluminum through a die, which gives it the desired shape. The 1010 aluminum alloy is a specific type of aluminum that is known for its excellent corrosion resistance, lightweight nature, and good mechanical properties.

The extrusion process allows for the creation of complex shapes that would be difficult or impossible to achieve with other manufacturing methods. This capability is one of the reasons why aluminum extrusions are so widely used in various applications.

Key Dimensions of 1010 Aluminum Extrusions

When discussing the dimensions of 1010 aluminum extrusions, several factors come into play, including the profile shape, wall thickness, and overall size. Here are some of the key dimensions to consider:

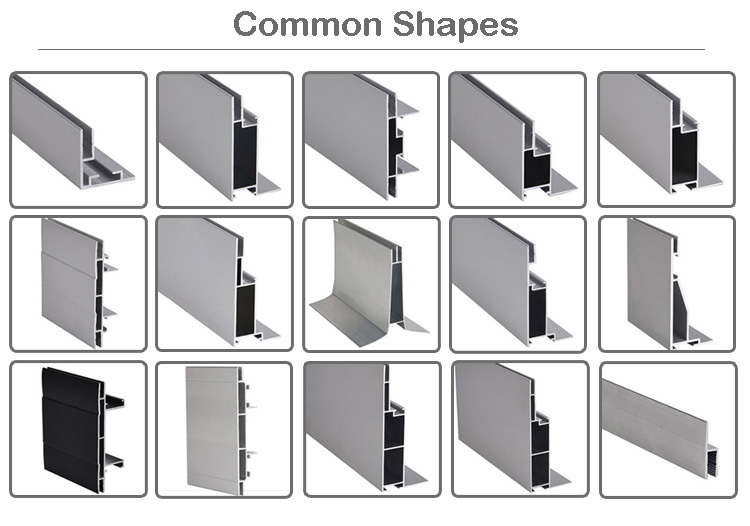

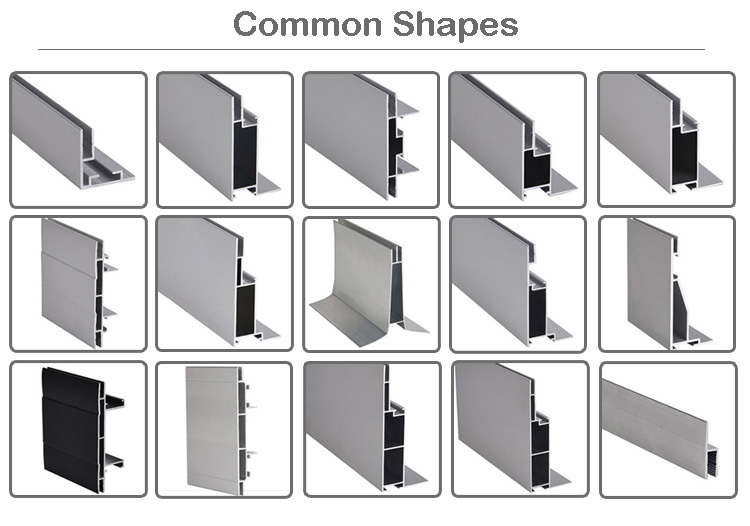

Profile Shape

The shape of the extrusion can vary widely, from simple rectangular shapes to complex designs with multiple features. Common shapes include T-slots, angles, channels, and tubes. Each shape serves different purposes and is chosen based on the specific requirements of the application.

For instance, T-slot extrusions are popular in modular framing systems, allowing for easy assembly and reconfiguration. On the other hand, channel extrusions are often used in applications requiring a strong, lightweight support structure.

Wall Thickness

The wall thickness of the extrusion is crucial for determining its strength and load-bearing capacity. For 1010 aluminum extrusions, wall thickness can range from 1.5 mm to 5 mm, depending on the specific design and application. Thicker walls provide greater strength but may also increase weight.

In applications where weight is a critical factor, such as in aerospace or automotive industries, engineers must carefully balance wall thickness with the need for strength. This consideration ensures that the final product meets performance requirements without unnecessary weight.

Overall Size

The overall dimensions of the extrusion, including length, width, and height, are essential for ensuring compatibility with other components in a system. Standard sizes for 1010 aluminum extrusions typically include profiles that are 1 inch by 1 inch, 2 inches by 2 inches, and larger sizes depending on the application.

Manufacturers often provide a range of standard sizes, but custom sizes can also be produced to meet specific project needs. This flexibility allows designers to create solutions tailored to their unique requirements.

Length

The length of aluminum extrusions can vary significantly based on the manufacturing process and customer requirements. Standard lengths are often available in 12-foot or 20-foot sections, but custom lengths can be produced to meet specific project needs.

When ordering aluminum extrusions, it is essential to consider the length required for the application. Longer lengths may reduce the number of joints needed in a structure, which can enhance overall strength and stability.

Weight

The weight of the extrusion is an important consideration, especially in applications where weight savings are critical. The weight of 1010 aluminum extrusions can be calculated based on the dimensions and wall thickness, allowing engineers to design systems that meet weight specifications.

Understanding the weight of the extrusion is crucial for applications in the automotive and aerospace industries, where every ounce counts. By selecting the appropriate dimensions and wall thickness, manufacturers can optimize the performance of their products.

Applications of 1010 Aluminum Extrusions

The versatility of 1010 aluminum extrusions makes them suitable for a wide range of applications. Here are some common uses:

Structural Components

1010 aluminum extrusions are often used in the construction of frames, supports, and other structural elements due to their strength and lightweight properties. The ability to create custom shapes allows engineers to design structures that meet specific load requirements while minimizing weight.

Automotive Industry

In the automotive sector, aluminum extrusions are used for various components, including chassis, body panels, and interior structures. The lightweight nature of aluminum helps improve fuel efficiency, making it an attractive option for manufacturers looking to enhance vehicle performance.

Aerospace Applications

The aerospace industry relies on aluminum extrusions for aircraft frames, wing structures, and other components where weight reduction is critical. The high strength-to-weight ratio of aluminum makes it an ideal choice for aerospace applications, where every gram saved can lead to significant fuel savings.

Manufacturing Equipment

Many manufacturing processes utilize 1010 aluminum extrusions for machine frames, conveyor systems, and other equipment that requires strength and durability. The ease of fabrication and assembly of aluminum extrusions allows manufacturers to create efficient production systems.

Furniture and Fixtures

Aluminum extrusions are also popular in the design of furniture and fixtures, providing a modern aesthetic while maintaining structural integrity. The versatility of aluminum allows designers to create innovative and functional furniture solutions that meet contemporary design trends.

Benefits of Using 1010 Aluminum Extrusions

There are several advantages to using 1010 aluminum extrusions in various applications:

Corrosion Resistance

Aluminum naturally forms a protective oxide layer, making it highly resistant to corrosion. This property is particularly beneficial in outdoor applications or environments with high humidity. The longevity of aluminum extrusions in harsh conditions reduces maintenance costs and extends the lifespan of structures.

Lightweight

Aluminum is significantly lighter than steel, making it an ideal choice for applications where weight savings are essential. This characteristic is especially important in the automotive and aerospace industries, where reducing weight can lead to improved fuel efficiency and performance.

Versatility

The ability to create custom shapes and sizes allows for a wide range of applications. Manufacturers can design extrusions to meet specific requirements, ensuring optimal performance. This versatility enables engineers to innovate and develop solutions tailored to their unique challenges.

Ease of Fabrication

Aluminum extrusions can be easily cut, drilled, and machined, allowing for quick assembly and modification. This flexibility is advantageous in manufacturing and construction processes, where time and efficiency are critical.

Recyclability

Aluminum is 100% recyclable without losing its properties, making it an environmentally friendly choice. This sustainability aspect is increasingly important in today's manufacturing landscape, as companies seek to reduce their environmental impact.

Conclusion

In summary, 1010 aluminum extrusions are a versatile and valuable material used across various industries. Understanding the key dimensions, including profile shape, wall thickness, overall size, length, and weight, is essential for selecting the right extrusion for specific applications. The benefits of using 1010 aluminum extrusions, such as corrosion resistance, lightweight nature, and ease of fabrication, make them an excellent choice for structural components, automotive parts, aerospace applications, and more.

Frequently Asked Questions

1. What is the difference between 1010 aluminum and other aluminum alloys?

1010 aluminum is known for its excellent corrosion resistance and lightweight properties. Other alloys may offer different mechanical properties, such as increased strength or improved machinability. Each alloy is designed for specific applications, and understanding these differences is crucial for selecting the right material.

2. Can 1010 aluminum extrusions be customized?

Yes, 1010 aluminum extrusions can be customized in terms of shape, size, and wall thickness to meet specific project requirements. Manufacturers often work closely with clients to develop custom solutions that fit their needs.

3. What industries commonly use 1010 aluminum extrusions?

Common industries include construction, automotive, aerospace, manufacturing, and furniture design. The versatility of aluminum extrusions makes them suitable for a wide range of applications across these sectors.

4. How do I calculate the weight of a 1010 aluminum extrusion?

The weight can be calculated using the dimensions and wall thickness of the extrusion, typically using the formula: Weight = Volume x Density (where density for aluminum is approximately 2.7 g/cm³). This calculation helps engineers ensure that their designs meet weight specifications.

5. Are 1010 aluminum extrusions recyclable?

Yes, aluminum is 100% recyclable, making it an environmentally friendly material choice. Recycling aluminum requires significantly less energy than producing new aluminum, contributing to sustainability efforts in manufacturing.