Content Menu

● Introduction

● Understanding 6060 Aluminum Extrusion

● Key Benefits of 6060 Aluminum Extrusion

>> Lightweight and Strong

>> Corrosion Resistance

>> Versatility in Applications

● Manufacturing Process of 6060 Aluminum Extrusions

● Common Applications of 6060 Aluminum Extrusions

● Conclusion

● Related Questions

>> 1. What is the difference between 6060 and 6061 aluminum extrusion?

>> 2. Can 6060 aluminum extrusion be anodized?

>> 3. What are the common applications of 6060 aluminum extrusion?

>> 4. How does the manufacturing process of 6060 aluminum extrusion work?

>> 5. Why is 6060 aluminum extrusion preferred for architectural applications?

Introduction

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. This technique is widely used across various industries due to its versatility, strength, and lightweight properties. Among the many aluminum alloys available, 6060 aluminum extrusion stands out for its unique characteristics and benefits. This article will explore the key advantages of using 6060 aluminum extrusion in your projects, highlighting its applications, manufacturing process, and why it is a preferred choice for engineers and designers alike.

Understanding 6060 Aluminum Extrusion

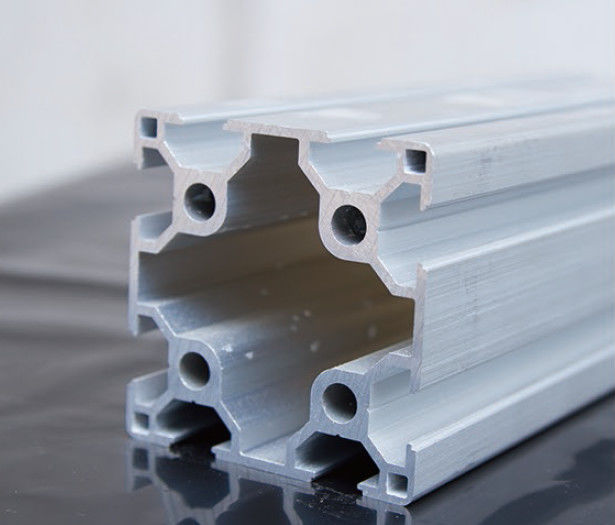

6060 aluminum extrusion is a medium-strength alloy that is primarily used for architectural applications. It is known for its excellent corrosion resistance, good weldability, and ability to be anodized, which enhances its surface properties. The alloy is primarily composed of aluminum, magnesium, and silicon, which contribute to its strength and workability.

One of the key features of 6060 aluminum is its versatility. It can be easily extruded into complex shapes and profiles, making it suitable for a wide range of applications. Compared to other aluminum alloys, such as 6061 and 6063, 6060 offers a balance of strength and formability, making it an ideal choice for various projects.

Key Benefits of 6060 Aluminum Extrusion

Lightweight and Strong

One of the most significant advantages of 6060 aluminum extrusion is its lightweight nature. Aluminum is known for its high strength-to-weight ratio, which means that structures made from 6060 aluminum can be both strong and lightweight. This property is particularly beneficial in applications where weight is a critical factor, such as in the aerospace and automotive industries.

The lightweight nature of 6060 aluminum extrusion allows for easier handling and installation, reducing labor costs and improving efficiency. Additionally, the strength of the material ensures that it can withstand various loads and stresses, making it suitable for structural applications.

Corrosion Resistance

6060 aluminum extrusion exhibits excellent corrosion resistance, which is a crucial factor in many applications. The natural oxide layer that forms on the surface of aluminum provides a protective barrier against environmental factors such as moisture, chemicals, and UV radiation. This property is further enhanced when the aluminum is anodized, creating a thicker and more durable oxide layer.

The corrosion resistance of 6060 aluminum makes it an ideal choice for outdoor applications, such as window frames, railings, and architectural facades. Structures made from 6060 aluminum can maintain their appearance and structural integrity over time, reducing the need for maintenance and replacement.

Versatility in Applications

6060 aluminum extrusion is incredibly versatile and can be used in a wide range of applications. Its ability to be extruded into various shapes and sizes allows designers and engineers to create custom solutions tailored to specific project requirements. Some common applications of 6060 aluminum extrusion include:

- Architectural Elements: 6060 aluminum is often used in the construction of window frames, doors, and curtain walls due to its aesthetic appeal and durability.

- Furniture: The lightweight and strong properties of 6060 aluminum make it a popular choice for modern furniture designs, including tables, chairs, and shelving units.

- Transportation: In the automotive and aerospace industries, 6060 aluminum is used for structural components, frames, and body panels, where weight reduction is essential for fuel efficiency.

- Industrial Applications: 6060 aluminum extrusion is commonly used in manufacturing equipment, machinery frames, and conveyor systems due to its strength and resistance to wear.

Manufacturing Process of 6060 Aluminum Extrusions

The manufacturing process of 6060 aluminum extrusion involves several key steps, ensuring that the final product meets the desired specifications and quality standards. The process begins with the selection of high-quality aluminum billets, which are heated to a specific temperature to make them malleable.

Once the billets are heated, they are placed in an extrusion press, where a hydraulic ram forces the aluminum through a die. The die determines the shape and profile of the extruded aluminum. After the extrusion process, the aluminum profiles are cooled and cut to the required lengths.

An important aspect of the manufacturing process is the quality control measures in place to ensure that the extrusions meet the necessary standards. This includes checking for dimensional accuracy, surface finish, and mechanical properties. The precision in manufacturing is crucial for achieving high-quality outcomes, especially in applications where tolerances are critical.

Common Applications of 6060 Aluminum Extrusions

6060 aluminum extrusion is widely used in various industries due to its unique properties. Here are some detailed examples of products made from 6060 aluminum:

- Window Frames: The lightweight and corrosion-resistant nature of 6060 aluminum makes it an ideal choice for window frames. These frames can be anodized to enhance their appearance and durability, providing a modern look to buildings while ensuring long-lasting performance.

- Furniture: Many contemporary furniture designs incorporate 6060 aluminum extrusion for its sleek appearance and strength. Tables, chairs, and shelving units made from this material are not only aesthetically pleasing but also durable and easy to maintain.

- Structural Components: In construction, 6060 aluminum is often used for structural components such as beams, columns, and trusses. Its strength and lightweight properties allow for efficient designs that can support significant loads while minimizing material usage.

- Signage and Displays: The versatility of 6060 aluminum extrusion makes it a popular choice for signage and display systems. Its ability to be easily fabricated into custom shapes allows for creative designs that can attract attention and convey messages effectively.

- Transportation: In the automotive industry, 6060 aluminum is used for various components, including frames, body panels, and structural elements. The lightweight nature of the material contributes to improved fuel efficiency and performance.

Conclusion

In conclusion, 6060 aluminum extrusion offers numerous benefits that make it an excellent choice for a wide range of projects. Its lightweight and strong properties, combined with excellent corrosion resistance and versatility in applications, make it a preferred material for engineers and designers. The manufacturing process ensures high-quality outcomes, allowing for custom solutions tailored to specific needs.

As industries continue to seek lightweight and durable materials, 6060 aluminum extrusion will remain a vital component in various applications, from architecture to transportation. By understanding the advantages of this material, you can make informed decisions for your projects, ensuring both performance and aesthetic appeal.

Related Questions

1. What is the difference between 6060 and 6061 aluminum extrusion?

6060 aluminum extrusion is primarily used for architectural applications and offers good corrosion resistance and formability. In contrast, 6061 aluminum extrusion is a higher-strength alloy that is often used in structural applications. While 6060 is more versatile for complex shapes, 6061 is preferred for applications requiring higher strength.

2. Can 6060 aluminum extrusion be anodized?

Yes, 6060 aluminum extrusion can be anodized. Anodizing enhances the corrosion resistance and surface finish of the aluminum, making it suitable for outdoor applications and improving its aesthetic appeal.

3. What are the common applications of 6060 aluminum extrusion?

Common applications of 6060 aluminum extrusion include window frames, furniture, structural components in construction, signage, and transportation parts. Its versatility allows it to be used in various industries.

4. How does the manufacturing process of 6060 aluminum extrusion work?

The manufacturing process involves heating aluminum billets, extruding them through a die to create the desired shape, and then cooling and cutting the extrusions to length. Quality control measures ensure that the final product meets specifications.

5. Why is 6060 aluminum extrusion preferred for architectural applications?

6060 aluminum extrusion is preferred for architectural applications due to its lightweight nature, excellent corrosion resistance, and ability to be easily fabricated into complex shapes. Its aesthetic appeal and durability make it ideal for modern building designs.