Content Menu

● Introduction to Sheet Extrusion Machinery

>> Typical Applications

● The Importance of Customization in Sheet Extrusion

● Key Components That Can Be Customized

>> 1. Extruder Design

>> 2. Die Head and Die Design

>> 3. Cooling and Calendering Systems

>> 4. Cutting, Trimming, and Winding Units

>> 5. Control and Automation Systems

>> 6. Material Handling and Feeding

● Customization for Industry-Specific Applications

>> Packaging Industry

>> Construction

>> Automotive

>> Medical Technology

>> Electronics and Signage

● Technologies Enabling Custom Sheet Extrusion

>> Modular Machine Design

>> Advanced Screw and Barrel Engineering

>> Precision Control Systems

>> Co-Extrusion and Multi-Layer Technology

>> In-Line Quality Monitoring

>> Energy-Efficient Heating and Cooling

● The Process of Customizing Sheet Extrusion Machinery

● Advantages of Custom Sheet Extrusion Machinery

● Challenges and Considerations in Customization

● Future Trends in Sheet Extrusion Customization

● Conclusion

● FAQ

>> 1. What components of sheet extrusion machinery can be customized?

>> 2. How does customization improve the quality of extruded sheets?

>> 3. Is it possible to customize sheet extrusion machinery for small or research-scale production?

>> 4. What industries benefit most from custom sheet extrusion machinery?

>> 5. How do I start the process of customizing a sheet extrusion line?

● Citations:

Sheet extrusion machinery is at the heart of modern manufacturing, enabling the production of plastic sheets used in a vast array of industries—from packaging and automotive to construction, electronics, and medical technology. As industries diversify and product requirements become increasingly specialized, the demand for customized sheet extrusion machinery has grown exponentially. This article explores the full scope of customization in sheet extrusion machinery, examining why it matters, how it is achieved, what technologies are involved, and the benefits it brings to manufacturers across sectors.

Introduction to Sheet Extrusion Machinery

Sheet extrusion machinery, also known as plastic sheet extruders, is designed to transform raw thermoplastic materials—typically in the form of pellets—into continuous sheets of specific thickness and width[6][13]. The extrusion process involves feeding the plastic into a hopper, melting and mixing it in a heated barrel with a rotating screw, and then forcing the molten material through a flat die to form a sheet. The sheet is then cooled, trimmed, and either wound into rolls or stacked as flat sheets[6][13].

Typical Applications

- Packaging (food, electronics, pharmaceuticals)

- Construction (panels, insulation)

- Automotive (trim parts, lightweight components)

- Furniture and interior design

- Medical technology (sterilizable, biocompatible sheets)

- Advertising (billboards, displays)[2][13]

The Importance of Customization in Sheet Extrusion

As industries evolve, the need for plastic sheets with highly specific properties—such as unique thickness, width, color, multi-layer construction, or enhanced mechanical or chemical resistance—has become critical. Off-the-shelf sheet extrusion machinery may not always meet these specialized requirements, making customization essential[3][4][16].

Customization in sheet extrusion machinery allows manufacturers to:

- Produce sheets with precise dimensions and properties

- Integrate advanced features like multi-layer co-extrusion or in-line lamination

- Handle unique or challenging materials

- Achieve higher efficiency and lower waste for specific production runs

- Adapt to rapid changes in market demand or regulatory standards[3][9][16]

Key Components That Can Be Customized

Customizing a sheet extrusion line involves tailoring various components and subsystems to meet the precise needs of an application. Below are the primary elements that can be adapted:

1. Extruder Design

- Screw Type and Configuration: Single-screw or twin-screw extruders can be chosen based on material complexity and mixing requirements. Twin-screw extruders excel at blending additives and colorants, and are ideal for materials requiring high homogeneity[6][10][4].

- Screw Geometry: The length-to-diameter ratio, pitch, and flight depth can be customized for optimal melting, mixing, and conveying of specific polymers.

2. Die Head and Die Design

- Die Width and Gap: The die determines the sheet's width and thickness; custom dies allow for precise control over these dimensions[4][15].

- Multi-Layer Co-Extrusion: Dies can be designed for co-extrusion, enabling the production of sheets with multiple functional layers—such as barrier layers, UV protection, or decorative surfaces[2][9][15].

3. Cooling and Calendering Systems

- Chill Rollers: The number, diameter, and surface finish of chill rollers can be specified to achieve the desired cooling rate and surface quality[13][11].

- Temperature Control: Advanced, multi-zone temperature control ensures uniform cooling and prevents warping, especially for thick or specialty sheets[5][11].

4. Cutting, Trimming, and Winding Units

- Edge Trimmers and Cutters: Customizable for specific sheet widths and cutting patterns, including automated length control[13][15].

- Winding or Stacking: Machinery can be configured for roll winding or flat stacking, depending on downstream processing needs[13].

5. Control and Automation Systems

- PLC and HMI: Customizable control systems with user-friendly interfaces allow for real-time monitoring, recipe management, and process optimization[4][5][12].

- Remote Monitoring: Integration with Industry 4.0 solutions for remote diagnostics and data analysis[5][14].

6. Material Handling and Feeding

- Dehumidification and Drying: Essential for hygroscopic materials; systems can be tailored for specific throughput and material types[15].

- Additive Dosing: Precision feeders for colorants, UV stabilizers, or flame retardants[2][9].

Customization for Industry-Specific Applications

Customization is not a one-size-fits-all process. Different industries have unique requirements, and sheet extrusion machinery can be tailored to address these needs:

Packaging Industry

- High-speed lines for thin, flexible sheets

- Multi-layer co-extrusion for barrier properties (e.g., food packaging)

- In-line lamination and printing integration[2][9]

Construction

- Thick, rigid sheets for wall panels or insulation

- Enhanced weather resistance and fire retardancy

- Custom surface textures or colors[2][5][15]

Automotive

- Lightweight, impact-resistant sheets for interior and exterior parts

- High transparency or specific color matching

- Integration of recycled materials for sustainability[2][5][9]

Medical Technology

- Biocompatible and sterilizable sheets

- Tight tolerances for thickness and surface quality

- Cleanroom-compatible machinery[2][9]

Electronics and Signage

- Sheets with antistatic or conductive properties

- UV-stable and printable surfaces

- Large-format, high-gloss finishes[2][9]

Technologies Enabling Custom Sheet Extrusion

The ability to customize sheet extrusion machinery is made possible by several technological advancements:

Modular Machine Design

Modern extrusion lines are built with modularity in mind, allowing manufacturers to mix and match components such as extruders, dies, and downstream equipment for specific applications[3][16].

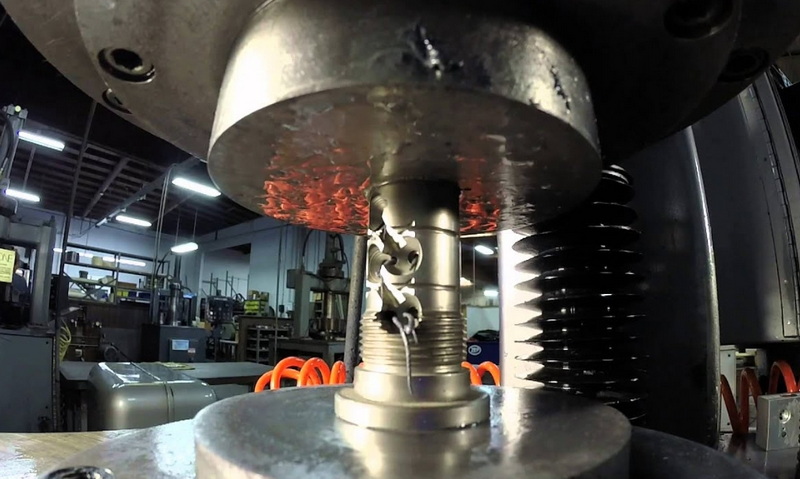

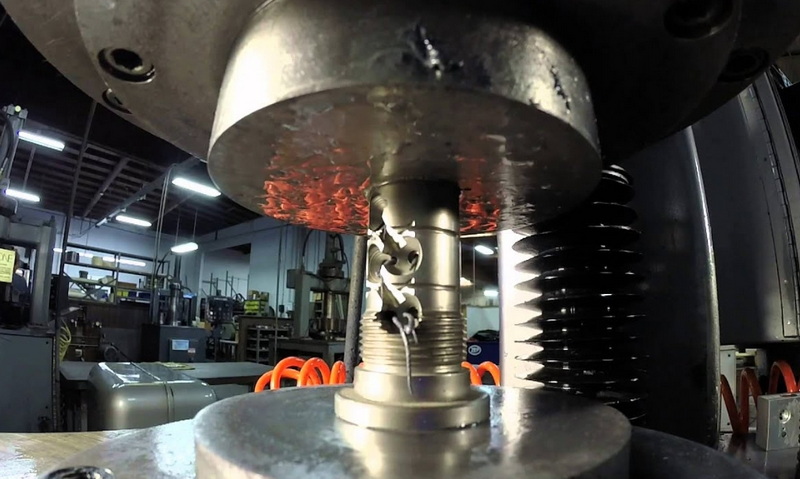

Advanced Screw and Barrel Engineering

Custom screw profiles, including mixing and barrier sections, are engineered for optimal processing of specialty polymers or blends[6][10][4].

Precision Control Systems

PLC-based automation and touch-screen HMIs provide granular control over every parameter—temperature, pressure, screw speed, and more—enabling rapid recipe changes and process optimization[4][5][12].

Co-Extrusion and Multi-Layer Technology

Co-extrusion systems allow for the combination of different materials in a single sheet, imparting properties such as improved barrier performance, strength, or aesthetics[2][9][15].

In-Line Quality Monitoring

Sensors and automated inspection systems monitor thickness, width, and surface quality in real time, ensuring consistent output and reducing waste[8][14].

Energy-Efficient Heating and Cooling

High-efficiency heaters, servo drives, and advanced cooling systems reduce energy consumption and improve product consistency[8][11].

The Process of Customizing Sheet Extrusion Machinery

Customizing a sheet extrusion line typically follows a collaborative, step-by-step process between the manufacturer and the machinery supplier:

1. Needs Assessment

- Detailed analysis of the customer's application, including material types, sheet dimensions, required properties, and production volumes[3][16].

2. Design and Engineering

- Selection and configuration of extruder type, die design, cooling systems, and automation features tailored to the application[4][15][16].

3. Prototyping and Testing

- Pilot runs or small-scale production to validate machine performance and product quality[9].

4. Manufacturing and Assembly

- Building the custom machine or line, often using modular components for flexibility and scalability[3][16].

5. Installation and Commissioning

- On-site setup, integration with existing production lines, and training of operators[4][16].

6. Ongoing Support and Optimization

- Technical support, maintenance, and process optimization services to ensure long-term performance[4][16].

Advantages of Custom Sheet Extrusion Machinery

Customizing sheet extrusion machinery offers a host of benefits:

- Optimized Product Quality: Machines are engineered to produce sheets that meet exact specifications for thickness, width, and material properties[8][9].

- Increased Efficiency: Tailored lines minimize waste, maximize throughput, and reduce changeover times[8][16].

- Greater Flexibility: Ability to switch between products or materials quickly, supporting diverse product portfolios[3][9].

- Cost Savings: Reduced material waste, lower energy consumption, and minimized manual intervention lower operating costs[8][16].

- Enhanced Innovation: Manufacturers can develop new products and respond rapidly to market trends or regulatory changes[3][9][16].

- Sustainability: Custom lines can be designed for recycled or biodegradable materials, supporting green manufacturing initiatives[2][8].

Challenges and Considerations in Customization

While the benefits are significant, customizing sheet extrusion machinery also involves certain challenges:

- Upfront Investment: Custom machines may have higher initial costs compared to standard models.

- Lead Time: Engineering, prototyping, and testing add to the delivery timeline.

- Technical Complexity: Integration with existing lines or advanced features requires skilled engineering and operator training.

- Maintenance: Custom components may require specialized maintenance or spare parts.

Despite these challenges, the long-term gains in efficiency, quality, and flexibility often outweigh the initial hurdles.

Future Trends in Sheet Extrusion Customization

As technology advances, the customization of sheet extrusion machinery is expected to become even more sophisticated:

- Digital Twin and Simulation: Virtual modeling of extrusion lines for rapid prototyping and optimization.

- AI-Driven Process Control: Machine learning algorithms for predictive maintenance and real-time process adjustment.

- Sustainable Materials: Increased use of recycled, biodegradable, or bio-based polymers.

- Integrated Manufacturing: Seamless integration with downstream processes such as thermoforming, printing, or lamination.

The future promises even greater adaptability, efficiency, and sustainability in sheet extrusion.

Conclusion

Sheet extrusion machinery can absolutely be customized for specific applications, and this capability is transforming industries worldwide. From the choice of extruder and die design to advanced control systems and modular downstream equipment, every aspect of a sheet extrusion line can be tailored to meet the precise demands of an application. Customization delivers superior product quality, greater efficiency, and the flexibility to innovate—making it a vital strategy for manufacturers seeking a competitive edge in today's fast-evolving markets.

FAQ

1. What components of sheet extrusion machinery can be customized?

Almost every major component can be customized, including the extruder (screw type and geometry), die head (width, gap, and multi-layer capability), cooling and calendering systems, cutting and winding units, and the control/automation systems. This ensures that the machinery meets the exact requirements of the intended application[4][15][16].

2. How does customization improve the quality of extruded sheets?

Customization allows for precise control over process parameters such as temperature, pressure, and material flow. This results in uniform thickness, consistent surface quality, and the ability to incorporate special features like multi-layer construction or enhanced barrier properties, all tailored to the end-use application[2][9][8].

3. Is it possible to customize sheet extrusion machinery for small or research-scale production?

Yes, many suppliers offer solutions for both high-volume industrial production and small-scale research or pilot runs. Customization at the R&D level enables manufacturers to test new materials or designs before scaling up to full production[9][16].

4. What industries benefit most from custom sheet extrusion machinery?

Industries with specialized requirements—such as packaging, automotive, construction, medical technology, and electronics—benefit greatly from custom sheet extrusion machinery. Customization enables the production of sheets with unique properties, dimensions, or regulatory compliance[2][3][9].

5. How do I start the process of customizing a sheet extrusion line?

Begin by consulting with an experienced sheet extrusion machinery supplier. Provide detailed information about your application, including material types, desired sheet properties, production volumes, and any special features needed. The supplier will then design, prototype, and build a line tailored to your specifications, often involving close collaboration throughout the process[3][4][16].

Citations:

[1] https://diamat.com/technology/plate-production/

[2] https://www.kuhne-mb.de/en/landing-pages/sheet-extrusion

[3] https://www.milacron.com/product-types/extrusion-machines/

[4] https://www.plastic-thermoformingmachine.com/sale-47843468-customized-plastic-extruder-machine-with-high-extrusion-capacity-and-water-cooling-system.html

[5] https://davis-standard.com/extrusion_system/sheet/

[6] https://www.cnchaoxu.com/news-center/what-is-sheet-extrusion-machine

[7] https://www.boyuextruder.com/blog/plastic-extrusion-problems-and-how-to-solve.html

[8] https://www.yjing-extrusion.com/what-are-the-key-benefits-of-using-plastic-sheet-extrusion-equipment.html

[9] https://fabexco.com/custom-sheet-extrusion

[10] https://plasticextrusiontech.net/machines-used-in-the-plastic-extrusion-process/

[11] http://extruder-lines.com/1-plastic-sheet-extrusion-equipment.html

[12] https://www.autoformingmachine.com/single-layer-plastic-extruder-pp-ps-sheet-extrusion-product/

[13] https://www.yjing-extrusion.com/what-is-sheet-extrusion-equipment-and-how-does-it-work.html

[14] https://tsm-controls.com/blog/applications/sheet-extrusion/

[15] https://www.leadertw.com/Plastic-Sheet-Extrusion-Line/ABS-PC-PP-PS-Sheet-Extrusion-Line.html

[16] https://jiantai.io/plastic-sheet-machine/

[17] https://www.ptiextruders.com

[18] https://www.arlingtonmachinery.com/plastic-extruder/pl.c.1047.0/sheet-extrusion-lines/

[19] https://diamat.com/products/diamat-laboratory-custom-machinery/

[20] https://www.gsextruder.com/top-10-plastic-sheet-extrusion-machine-manufacturers-in-2024/

[21] https://www.grahamengineering.com/products-solutions/sheet-extrusion/

[22] https://www.cowellextrusion.com/everything-you-need-to-know-about-sheet-extrusion-a-comprehensive-guide/

[23] https://www.leadertw.com/application/7

[24] https://jwellmachinery.en.made-in-china.com/product/iXjnEKTHYDYc/China-Customized-Fullly-Automatic-Plastic-Film-Plate-Profile-Sheet-Pipe-Extrusion-Machine-Price.html

[25] https://www.moldingmachinetepai.com/resources/plastic-extrusion-machines-introduction-types-application.html

[26] https://tsm-controls.com/blog/applications/sheet-extrusion/

[27] https://www.leadertw.com/Plastic-Sheet-Extrusion-Line/ABS-PC-PP-PS-Sheet-Extrusion-Line.html

[28] https://www.gwellmachine.com/supplier-453738-pet-sheet-extruder-machine

[29] https://mm.made-in-china.com/hot-china-products/Customized_Plastic_Extrusion_Machinery.html

[30] https://www.cnchaoxu.com/news-center/plastic-sheet-extrusion-machine-a-key-equipment-in-the-plastics-industry

[31] https://plastic-extrusionmachines.com/pp-hollow-sheet-extrusion-line/

[32] https://www.jwellfactory.com/sheet-extrusion-machinery/

[33] https://zjgfld.en.made-in-china.com/product/hfvpeTaxRukG/China-High-Quality-Customizable-Plastic-Sheet-Machine-for-Industrial-Extrusion-Processes.html

[34] https://www.cnchaoxu.com/plastic-sheet-extruder-machine/yx-23p-multilayer-plastic-sheet-extruder-machine

[35] https://www.alibaba.com/showroom/polypropylene-sheet-extrusion-machine.html

[36] https://plasticsheetextrusionline.com/features.html

[37] https://plasticsheetextruder.en.made-in-china.com/product/rwfGpNHUgltO/China-Pet-Sheet-Extrusion-Line-with-Customizable-Thickness.html

[38] https://www.seagateplastics.com/frequently-asked-questions/

[39] https://diamat.com/technology/plate-production/

[40] https://www.pexco.com/custom-plastic-extrusion-basics-benefits-and-future-explained/

[41] https://www.won-plus.com/blog/extrusion-technology-related-questions-and-answers_b40

[42] https://www.bausano.com/en/press-and-news/common-problems-in-the-plastic-extrusion-process

[43] https://plasticextrusiontech.net/what-are-the-benefits-of-using-plastic-extrusions-over-other-materials/

[44] https://jjindustriesindia.com/plastic-extrusion-machine-faqs/

[45] https://testbook.com/objective-questions/mcq-on-extrusion--5eea6a0d39140f30f369e2ec

[46] https://www.kaironggroup.com/pet-sheet-production-process-and-common-problems/

[47] https://www.seagateplastics.com/unlock-benefits-plastic-sheet-fabrication/