Content Menu

● Introduction to Automatic Plastic Sheet Extrusion Machines

>> Key Components of Automatic Plastic Sheet Extrusion Machines

● Benefits of Using Automatic Plastic Sheet Extrusion Machines

>> Efficiency and Productivity

>> Cost-Effectiveness

>> Flexibility and Adaptability

>> Environmental Benefits

● Integration with Automation Technologies

● Applications of Automatic Plastic Sheet Extrusion Machines

● Innovations in Plastic Sheet Extrusion Technology

>> Role of Artificial Intelligence

>> Advanced Cooling Systems

● Challenges and Solutions in Plastic Sheet Extrusion

● Future Trends in Automatic Plastic Sheet Extrusion

● Conclusion

● Frequently Asked Questions

>> 1. What are the primary advantages of using an automatic plastic sheet extrusion machine?

>> 2. How does automation enhance the plastic sheet extrusion process?

>> 3. What types of industries benefit from automatic plastic sheet extrusion machines?

>> 4. How do these machines contribute to environmental sustainability?

>> 5. What are some common materials processed by automatic plastic sheet extrusion machines?

● Citations:

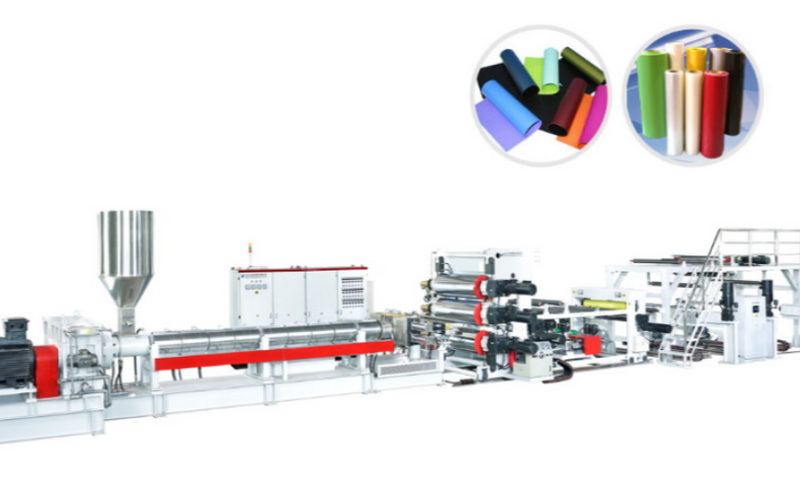

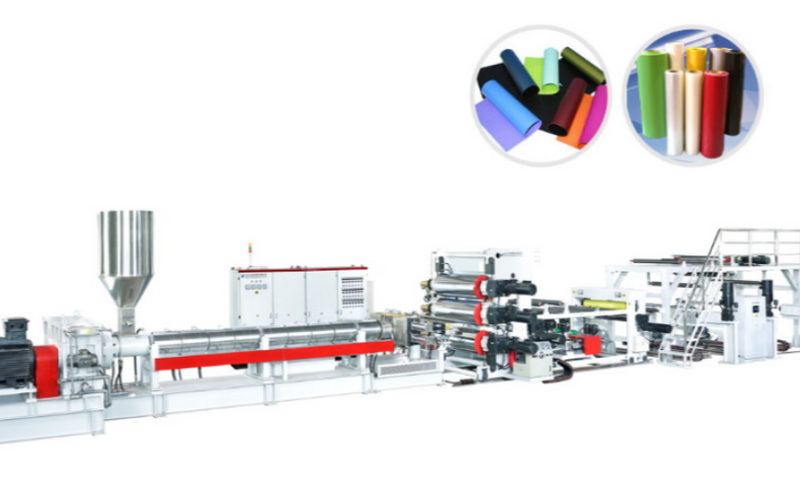

The use of automatic plastic sheet extrusion machines has revolutionized the plastic manufacturing industry by offering numerous benefits that enhance efficiency, quality, and sustainability. These machines are designed to produce high-quality plastic sheets with precise thickness and uniformity, making them ideal for various applications such as packaging, construction, and automotive industries.

Introduction to Automatic Plastic Sheet Extrusion Machines

Automatic plastic sheet extrusion machines operate by melting plastic pellets and forcing them through a die to create a continuous sheet. This process is highly automated, allowing for consistent production with minimal manual intervention. The machines are equipped with advanced control systems that monitor temperature, speed, and pressure to ensure optimal production conditions.

Key Components of Automatic Plastic Sheet Extrusion Machines

1. Extruder: This is the core component where plastic is melted and mixed. It can be a single-screw or twin-screw extruder, each offering different advantages in terms of mixing efficiency and material handling.

2. Die: The die shapes the molten plastic into the desired sheet form. It is crucial for achieving uniform thickness and quality.

3. Cooling System: After extrusion, the sheet passes through a cooling system to solidify it. This can include water baths or air cooling systems.

4. Winding System: The final sheet is wound onto rolls for easy handling and storage.

Benefits of Using Automatic Plastic Sheet Extrusion Machines

Efficiency and Productivity

- High-Speed Production: These machines can produce plastic sheets at high speeds, significantly increasing productivity compared to manual or semi-automatic processes.

- Consistent Quality: The automated process ensures that every sheet produced meets the desired specifications, reducing defects and waste.

Cost-Effectiveness

- Reduced Labor Costs: By automating the production process, the need for manual labor is minimized, leading to cost savings.

- Energy Efficiency: Modern machines are designed to consume less energy, reducing operational costs and environmental impact.

Flexibility and Adaptability

- Material Variety: Automatic plastic sheet extrusion machines can handle a wide range of plastic materials, including PET, PP, PVC, and more.

- Customizable Thickness: The machines allow for easy adjustment of sheet thickness to meet different application requirements.

Environmental Benefits

- Reduced Waste: The ability to recycle excess plastic material minimizes waste and supports sustainable manufacturing practices.

- Longer Product Lifespan: Extruded plastic sheets are durable and long-lasting, reducing the need for frequent replacements.

Integration with Automation Technologies

The integration of automation technologies further enhances the efficiency and quality of the plastic sheet extrusion process. This includes:

- Data Collection and Analysis: Real-time data collection helps optimize production parameters for better quality and efficiency.

- Automated Raw Material Handling: Reduces manual labor and ensures a smooth production flow.

- Quality Control Automation: Instant defect detection using sensors and cameras ensures high-quality products.

- Predictive Maintenance: Minimizes downtime by predicting potential machine failures.

Applications of Automatic Plastic Sheet Extrusion Machines

These machines are widely used in various industries:

- Packaging Industry: For producing plastic films and sheets used in food packaging and other applications.

- Construction Industry: Produces sheets used in roofing and insulation materials.

- Automotive Industry: Creates components like dashboard trim and interior panels.

Innovations in Plastic Sheet Extrusion Technology

Recent advancements in plastic extrusion technology have significantly improved the efficiency and precision of the process. Innovations such as servo-driven extruders and high-efficiency heaters reduce energy consumption while enhancing product consistency and quality[3]. Additionally, co-extrusion techniques allow for the simultaneous extrusion of multiple layers, enabling the creation of complex structures with enhanced functionalities[5].

Role of Artificial Intelligence

Artificial Intelligence (AI) plays a crucial role in optimizing extrusion processes by analyzing data and making real-time adjustments to parameters like temperature and pressure. This ensures optimal performance and reduces material waste[3].

Advanced Cooling Systems

Modern cooling systems are designed to expedite the solidification process, improving the dimensional stability of extruded products while reducing energy consumption[3]. These systems are integral to maintaining high-quality outputs and enhancing production efficiency.

Challenges and Solutions in Plastic Sheet Extrusion

Despite the benefits, plastic sheet extrusion faces challenges such as die swell, temperature control, and equipment maintenance[1]. To address these issues, manufacturers invest in advanced machinery with precise temperature control systems and predictive maintenance technologies to minimize downtime and ensure consistent product quality.

Future Trends in Automatic Plastic Sheet Extrusion

The future of plastic sheet extrusion is poised to be shaped by technological innovations and sustainability initiatives. As demand for high-quality plastic products continues to grow, manufacturers are focusing on integrating more automation and sustainable practices into their production processes. This includes the use of renewable energy sources and recycled materials to reduce environmental impact.

Conclusion

In conclusion, automatic plastic sheet extrusion machines offer a multitude of benefits that make them indispensable in modern plastic manufacturing. Their ability to enhance efficiency, reduce costs, and promote sustainability aligns with the evolving needs of industries seeking high-quality plastic products.

Frequently Asked Questions

1. What are the primary advantages of using an automatic plastic sheet extrusion machine?

The primary advantages include high production efficiency, consistent product quality, reduced labor costs, and the ability to handle a variety of plastic materials.

2. How does automation enhance the plastic sheet extrusion process?

Automation enhances the process by providing real-time quality control, predictive maintenance, and efficient material handling, which together improve product quality and reduce downtime.

3. What types of industries benefit from automatic plastic sheet extrusion machines?

Industries such as packaging, construction, and automotive benefit significantly from these machines due to their need for high-quality, durable plastic sheets.

4. How do these machines contribute to environmental sustainability?

They contribute by minimizing waste through recycling excess plastic material and producing durable products that reduce the need for frequent replacements.

5. What are some common materials processed by automatic plastic sheet extrusion machines?

Common materials include PET, PP, PVC, and ABS, among others, which are used in various applications across different industries.

Citations:

[1] https://jieyatwinscrew.com/blog/everything-you-need-to-know-about-plastic-extrusion-machines/

[2] https://www.summitsystems.co.uk/plastics-automation/extrusion-lines-recycling-plants/extrusion-lines/

[3] https://www.wevolver.com/article/extruding-plastic

[4] https://www.technicmachines.com/sheet-extruder-machine-line/

[5] https://www.seagateplastics.com/shaping-the-future-innovations-in-plastic-extrusion-techniques/

[6] https://www.machinedesign.com/3d-printing-cad/article/55248644/redetec-high-risk-high-reward-investing-in-game-changing-plastics-extrusion-technology

[7] https://www.autoformingmachine.com/news/innovations-in-plastic-film-extrusion-lines-increase-productivity-and-sustainability/

[8] https://plasticsheetextruder.en.made-in-china.com/product/oZITNfPchHAg/China-Advanced-Plastic-Extrusion-Equipment-for-Sheet.html

[9] https://www.jwellmachine.com/analysis-of-plastic-extrusion-technology/

[10] https://plasticsheetextruder.en.made-in-china.com/product/bwTGalUCgIfo/China-Advanced-Pet-Plastic-Sheet-Extrusion-Production-Line-PP-PS-Extruding-Machine.html

[11] https://www.ptonline.com/articles/get-ready-to-be-blown-away-with-new-extrusion-technology

[12] https://jieyatwinscrew.com/blog/sheet-extrusion/

[13] https://www.yeshaengineering.com/sheet-extrusion-line.html

[14] https://www.deskera.com/blog/latest-innovations-in-plastic-manufacturing/

[15] https://plasticextrusiontech.net/what-are-the-benefits-of-using-plastic-extrusions-over-other-materials/

[16] https://www.alibaba.com/showroom/plastic-sheet-extruder-machine.html

[17] https://www.stlongsheng.com/News_dt/1885563825914740736.html

[18] https://www.prm-taiwan.com/blog/advantages-aba-coextrusion-blown-film-machine_411

[19] https://www.market-prospects.com/articles/shang-ta-chia

[20] https://www.plasticextrusion-machine.com/sale-33816267-apet-pet-plastic-sheet-extrusion-machine-thermoforming-sheet-extrusion-line.html