Content Menu

● What is a 720mm 20 Series Aluminum Extruder?

● Key Advantages

● Applications of 720mm 20 Series Aluminum Extruder

● Advantages of Aluminum Extrusion Over Other Materials

● Factors to Consider

● Best Practices for Utilization

● Examples of Successful Projects

● Innovations and Future Trends

● The Role of Software in Design and Implementation

● Maintenance and Longevity

● Conclusion

● FAQ

>> 1. What is the primary advantage of using a 20 series aluminum extrusion?

>> 2. How does the strength-to-weight ratio of 20 series aluminum extrusions benefit projects?

>> 3. In what environments is the corrosion resistance of aluminum extrusions most beneficial?

>> 4. Can 20 series aluminum extrusions be used for heat dissipation?

>> 5. What are some typical applications for 20 series aluminum extrusions?

● Citations:

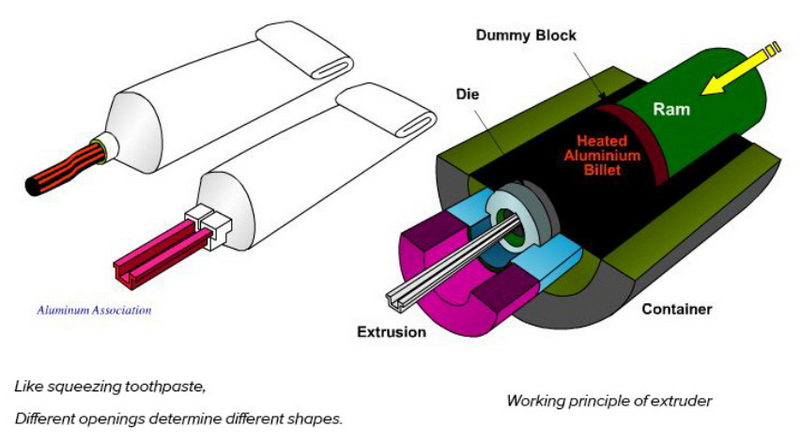

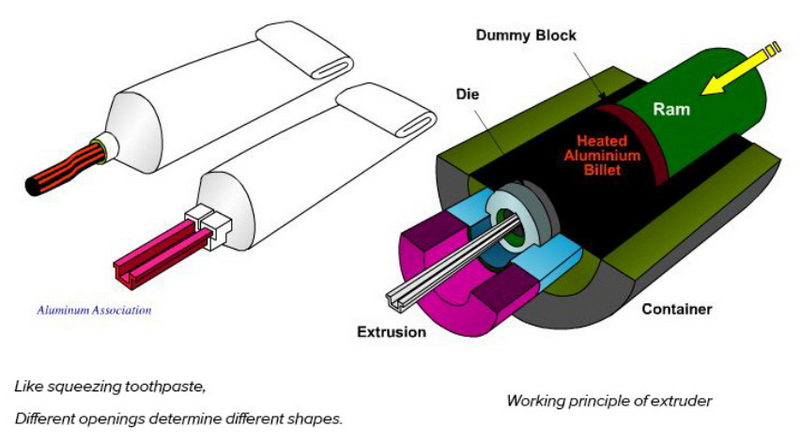

Aluminum extruders are essential tools in manufacturing and DIY projects, offering versatility and precision. Among the various types, the 720mm 20 series aluminum extruder stands out for its unique benefits. This article explores the advantages of using a 720mm 20 series aluminum extruder, its applications, and best practices for utilization.

What is a 720mm 20 Series Aluminum Extruder?

A 720mm 20 series aluminum extruder is a tool used to shape aluminum into specific profiles by forcing the material through a die. The "20 series" refers to the dimensions and compatibility with other 20 series components, making it a modular and versatile option for various projects[2]. The 720mm length provides a substantial working area, suitable for medium to large-scale applications. These extrusions typically have four open T-slots, one on each face, which enables access from any direction and are useful for mounting accessories[6].

Key Advantages

The advantages of using a "720mm 20 series aluminum extruder" are numerous, making it a popular choice for both industrial and DIY applications:

- Modularity: The 20 series aluminum extrusions have standardized dimensions, which allows for easy integration with connectors and accessories, enabling quick and flexible assembly. This modularity is a key benefit, particularly when compared to welded solutions, because it saves time and money[2].

- Strength-to-Weight Ratio: Despite being lightweight (approximately a third of the weight of iron, steel, copper, or brass), these extrusions maintain high strength[4], supporting structures without adding significant weight[2]. The unique combination of high strength and low weight makes them ideal for applications like aerospace, truck trailers, and bridges where load carrying is a key performance factor[4].

- Corrosion Resistance: Aluminum naturally forms a protective oxide coating, making these profiles resistant to corrosion, which is vital for applications in harsh environments[4]. This natural protection can be further enhanced by anodizing or other finishing processes[4].

- Thermal Conductivity: Exhibiting good thermal conductivity, 20 series aluminum profiles are suitable for applications requiring heat dissipation, such as electronic enclosures[4]. Extruded aluminum's flexibility allows designers to optimize heat dissipation in housings and other components[4].

- Customization: Aluminum extrusions offer design freedom, allowing for complex shapes tailored to specific needs[4]. The ability to design a profile to meet specific functional, aesthetic, and manufacturability objectives makes aluminum extrusions a preferred element in many product solutions[4].

- Increased Strength: Products made by aluminum extrusion typically have increased strength and therefore wear resistance[1]. This is because the material is formed under pressure to produce a homogenous structure with no cavities, chips, or pores[1].

- Low Material Loss: The aluminum extrusion process ensures minimal material wastage[1].

- Non-Sparking: Because aluminum is non-sparking, aluminum extrusions are well suited for applications involving explosive materials or taking place in highly flammable environments[4].

- Electrical Conductivity: Pound-for-pound, aluminum is twice as conductive as copper, making extruded aluminum a cost-effective alternative for electrical connectors and bus bar distribution components[4].

- Non-Combustible and Non-Toxic: Aluminum does not burn and even at extremely high temperatures does not produce toxic fumes[4].

Applications of 720mm 20 Series Aluminum Extruder

The "720mm 20 series aluminum extruder" is used across various industries due to its versatility and ease of use[5]:

- CNC Machine Builds: In computer numerical control (CNC) machines, 20 series aluminum extrusions create the structural framework[5]. Their precision and strength allow for developing machines capable of detailed and accurate cutting, milling, or engraving on various materials[5].

- 3D Printers: The construction of 3D printers heavily relies on these extrusions for framing[5]. Their modularity supports the evolving needs of 3D printing technology, facilitating customization and scalability[5].

- Machine Guards: Aluminum extrusion is an extremely important application of the material because the versatility of the t-slotted design allows you to create a guard that will cover everything safely[8]. Depending on what the function of the machine is, you can put panels or mesh inside the t-slots[8]. Add some doors with safety switches if access is needed[8].

- Work Stations: Design ergonomic and efficient workstations for your laboratory, workshop, or manufacturing facility[3].

- Automation and Robotics: Develop custom automation solutions and robotic arms[3]. The 20 series provides the rigidity needed for precise and repeatable movements[3].

- Exhibition Booths: Craft modular and reusable exhibition booths for trade shows and events[3]. The extrusion's adaptability allows for quick setup and teardown[3].

- Retail Displays: Craft eye-catching retail displays that draw customers in[3].

- Aerospace Prototyping: Rapidly prototype aerospace components and structures[3]. The extrusion's lightweight aluminum is ideal for aerospace applications[3].

- Solar Panel Frames: Build durable frames to support solar panels in residential and commercial installations[3].

Advantages of Aluminum Extrusion Over Other Materials

Compared to other materials and processes, aluminum extrusions offer several unique advantages[4]:

- Cost-Effectiveness: Aluminum extrusion is generally a competitive and economical production option, especially when dealing with very complex cross-sections[2][7]. Tooling for aluminum extrusion is relatively inexpensive with generally short lead times, facilitating rapid prototype development, testing, and product launch[4].

- Design Flexibility: Complex shapes can be realized in one-piece extruded aluminum sections without having to rely on mechanical joining[4].

- Sustainability: Aluminum's inherent “green” features of recyclability and sustainability, coupled with its other unique attributes, makes aluminum a versatile material for many applications[4].

- Efficiency: Aluminum extrusions have continuously demonstrated to be superior in performance, reliability, and efficiency for a variety of markets–from consumer durables to transportation and from electronics to building and construction[4].

- Weight: Aluminum is about 1/3 the weight of iron, steel, copper or brass[4]. This makes aluminum extrusions easier to handle, less expensive to ship, and an attractive material for use in applications where weight reduction is a priority, especially in transportation and other applications involving moving parts[4].

- Strength: Aluminum extrusions can be made as strong as needed for most applications and, due to the nature of the extrusion process, the strength can be concentrated where it is really needed by including varying wall thicknesses and internal reinforcement in the profile design[4]. Cold-weather applications are particularly well served by extrusions, as aluminum becomes stronger as temperatures fall[4].

- Corrosion Resistance: Aluminum extrusions offer excellent corrosion resistance because they do not rust, and the aluminum surface is protected by its own naturally occurring oxide layer[4]. This protection can be further enhanced by anodizing or with other finishing processes[4].

- Thermal Conductivity: Based on weight and overall cost, aluminum conducts heat and cold better than other common metals, making aluminum extrusion ideal for applications requiring heat exchangers or heat dissipation[4]. Extruded aluminum's flexibility allows designers to optimize heat dissipation in housings and other components[4].

- Non-Sparking: Because aluminum is non-sparking, aluminum extrusions are well suited for applications involving explosive materials or taking place in highly flammable environments[4].

- Electrical Conductivity: Pound-for-pound, aluminum is twice as conductive as copper, making extruded aluminum a cost-effective alternative for electrical connectors and bus bar distribution components[4].

- Non-Combustible and Non-Toxic: Aluminum does not burn and even at extremely high temperatures does not produce toxic fumes[4].

Factors to Consider

When selecting a *720mm 20 series aluminum extruder*, several factors should be considered to ensure it meets the project's specific requirements:

- Material Grade: Typically made from aluminum grade 6063-T6, known for its strength and corrosion resistance[6].

- Dimensions: Ensure the 20mm x 20mm profile meets the structural requirements of the project[2].

- Compatibility: Verify compatibility with standard 20 series connectors and accessories[2].

- Thermal Properties: Consider thermal conductivity for applications involving heat dissipation[4].

- T-Slots: T-slots are essential for connecting accessories and components[6].

- Finish: Anodized finishes can enhance corrosion resistance and provide a more aesthetically pleasing look[4].

- Load Capacity: Understand the load capacity to ensure the extrusions can handle the intended weight and stress[2].

Best Practices for Utilization

To maximize the benefits of a *720mm 20 series aluminum extruder*, it's important to follow best practices during design, assembly, and maintenance:

- Design Considerations: Plan the structure in CAD software to leverage the geometric features of the extrusions[4].

- Assembly Techniques: Use appropriate connectors and fasteners to ensure secure and stable assembly[2].

- Cutting and Machining: Employ proper cutting tools to achieve precise lengths and angles[1].

- Finishing: Anodizing or applying other finishes can enhance corrosion resistance and aesthetics[4].

- Maintenance: Regularly inspect the extrusions and connections to ensure they remain in good condition.

- Proper Fastening: Choose the right fastening method to ensure the strength and integrity of the frame[2].

- Consider the Environment: Protect the aluminum from harsh chemicals or physical damage[4].

Examples of Successful Projects

Numerous projects have successfully utilized *720mm 20 series aluminum extruders*, demonstrating their versatility and reliability:

- Custom CNC Machines: Many hobbyists and professionals have built custom CNC machines using 20 series extrusions, achieving precise and reliable performance.

- 3D Printer Enclosures: The extrusions have been used to create sturdy and aesthetically pleasing enclosures for 3D printers, improving safety and print quality.

- Ergonomic Workstations: Companies have designed and built ergonomic workstations using 20 series extrusions, enhancing employee comfort and productivity.

- Robotics Projects: Students and engineers have used the extrusions to build robotic arms and automated systems, showcasing the modularity and adaptability of the material.

- Retail Displays: Retailers have created eye-catching displays using 20 series extrusions, attracting customers and showcasing products effectively.

Innovations and Future Trends

The field of aluminum extrusion is continuously evolving, with innovations and trends that promise to further enhance the capabilities and applications of "720mm 20 series aluminum extruders":

- Advanced Materials: Research into new aluminum alloys with improved strength, corrosion resistance, and thermal properties.

- Smart Extrusions: Integration of sensors and electronics directly into the extrusions for monitoring structural health and performance.

- Sustainable Practices: Increased focus on sustainable manufacturing processes and the use of recycled aluminum.

- Customization: Further advancements in customization options, allowing for even more tailored solutions to meet specific project needs.

- Automation: Greater automation in the extrusion process, leading to increased efficiency and reduced costs.

The Role of Software in Design and Implementation

Modern CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software play a crucial role in designing and implementing projects using *720mm 20 series aluminum extruders*. These tools allow engineers and designers to:

- Create Detailed 3D Models: Visualize and refine designs before physical construction.

- Simulate Structural Performance: Analyze stress, strain, and load-bearing capabilities.

- Optimize Material Usage: Minimize waste and reduce costs.

- Generate Manufacturing Instructions: Streamline the fabrication process.

- Collaborate Effectively: Share designs and collaborate with team members.

Maintenance and Longevity

Proper maintenance is essential to ensure the longevity and reliability of structures built with *720mm 20 series aluminum extruders*:

- Regular Inspections: Check for loose connections, corrosion, and physical damage.

- Cleaning: Keep the extrusions clean and free from debris.

- Lubrication: Lubricate moving parts, such as hinges and sliders.

- Tightening Fasteners: Periodically tighten fasteners to maintain structural integrity.

- Replacement: Replace damaged or worn components promptly.

Conclusion

The "720mm 20 series aluminum extruder" is a versatile and indispensable tool for engineers, designers, and DIY enthusiasts. Its modularity, strength, corrosion resistance, and thermal conductivity make it suitable for various applications, from CNC machines to custom workstations[2][4]. The 20 series aluminum extrusions offer design freedom, allowing for complex shapes tailored to specific needs[4]. By understanding its advantages, considering key factors, and following best practices, users can unlock the full potential of this essential component in their projects. Aluminum extrusions offer advantages unmatched by other materials and processes[4]. They are lightweight, strong, corrosion resistant, quick-to-market, sustainable, excellent conductors, noncombustible, nontoxic, and more[4]! They are generally a competitive and economical production option especially when dealing with very complex cross-sections[7].

FAQ

1. What is the primary advantage of using a 20 series aluminum extrusion?

The primary advantage is its modularity, which allows easy integration with standard connectors and accessories for quick and flexible assembly[2].

2. How does the strength-to-weight ratio of 20 series aluminum extrusions benefit projects?

Despite their lightweight nature, these extrusions offer high strength, enabling them to support structures without adding significant weight[4], making them ideal for applications where weight reduction is a priority[2].

3. In what environments is the corrosion resistance of aluminum extrusions most beneficial?

The corrosion resistance is most beneficial in harsh environments where materials are exposed to moisture, chemicals, or other corrosive elements, ensuring longevity and reliability[4].

4. Can 20 series aluminum extrusions be used for heat dissipation?

Yes, their good thermal conductivity makes them suitable for applications requiring heat dissipation, such as electronic enclosures and heat exchangers[4].

5. What are some typical applications for 20 series aluminum extrusions?

Typical applications include CNC machine builds, 3D printer frames, machine guards, custom workstations, automation systems, and retail displays[2][5].

Citations:

[1] https://www.tensilemillcnc.com/blog/12-major-benefits-of-aluminum-extrusions

[2] https://www.zetwerk.com/resources/knowledge-base/aluminum-extrusions/2020-t-slot-aluminum-extrusion/

[3] https://www.makerstore.com.au/product/v-slot-20-x-20mm/

[4] https://aec.org/features-benefits

[5] https://jieyatwinscrew.com/blog/unlock-the-potential-of-20x20-aluminum-extrusion/

[6] https://8020.net/20-2020.html

[7] https://www.impol.com/everything-you-need-to-know-about-aluminum-extrusion/

[8] https://blog.knottsco.com/blog/bid/46509/3-Different-80-20-Aluminum-Extrusion-Applications

[9] https://www.reddit.com/r/simracing/comments/s4tnh8/aluminum_profile_comparison_simlab_to_industrial/

[10] https://www.reddit.com/r/simracing/comments/qq6lya/metric_vs_imperial_extrusion/

[11] https://amcaluminum.ph/common-applications-of-aluminum-extrusion/

[12] https://www.reddit.com/r/VanLife/comments/1ddnw7h/would_20mm_extruded_aluminum_8020_be_good_for/

[13] https://bitfab.parts/blog/what-are-the-sizes-of-aluminum-extrusion-profiles/

[14] https://mx.misumi-ec.com/en/vona2/detail/110302686270/

[15] https://www.chiefdelphi.com/t/t-slot-extruded-aluminum/68172

[16] https://vention.io/parts/20mm-od-round-585mm-aluminum-extrusion-1106

[17] https://8020.net

[18] https://www.youtube.com/watch?v=CwGimohCH8A