Content Menu

● Introduction to Aluminum Extrusion Lines

● Top 10 Aluminum Extrusion Line Manufacturers in China

>> 1. Foshan Yejing Machinery Manufacturing Co., Ltd.

>> 2. Guangdong Fenglu Aluminum Co., Ltd.

>> 3. Zhongwang Group

>> 4. Guangdong Xingfa Aluminium Co., Ltd.

>> 5. Jiahua Aluminium Co., Ltd.

>> 6. Foshan Shenghai Aluminum Co., Ltd.

>> 7. Sinpower China Aluminium

>> 8. Asia Aluminum Factory Co., Ltd.

>> 9. Foshan Jingye Machinery Manufacturing Co., Ltd.

>> 10. Foshan Fengda Machinery Equipment Co., Ltd.

● Industry Trends and Innovations in Aluminum Extrusion

● Challenges and Opportunities

● Future Outlook

● Case Studies of Leading Manufacturers

>> Foshan Yejing Machinery Manufacturing Co., Ltd.

>> Guangdong Fenglu Aluminum Co., Ltd.

>> Zhongwang Group

● Market Impact and Global Reach

● Conclusion

● Frequently Asked Questions

>> Q1: What is an aluminum extrusion line?

>> Q2: What factors should I consider when choosing an aluminum extrusion line manufacturer?

>> Q3: How does the extrusion process impact aluminum profile quality?

>> Q4: Can aluminum extrusion lines be customized for different industries?

>> Q5: What are the latest trends in aluminum extrusion line technology?

Aluminum extrusion technology is at the heart of modern manufacturing, powering industries from construction and transportation to electronics and renewable energy. China, as the world's leading aluminum producer, is home to some of the most advanced and innovative aluminum extrusion line manufacturers. This article explores the top 10 Aluminum Extrusion Line Manufacturers in China, with a special focus on their strengths, innovations, and global impact. We begin with the industry leader, Foshan Yejing Machinery Manufacturing Co., Ltd., and provide a comprehensive overview of each company, including detailed descriptions.

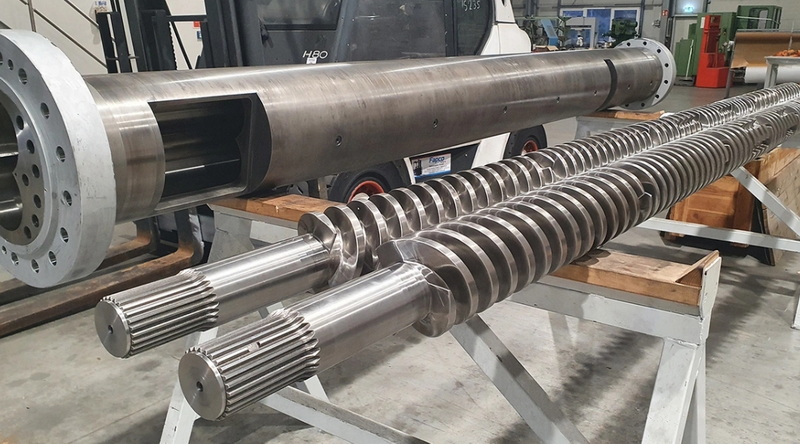

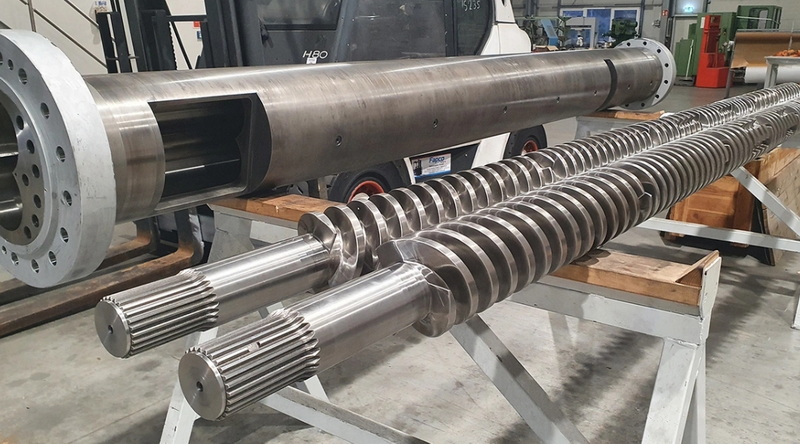

Introduction to Aluminum Extrusion Lines

Aluminum extrusion lines are sophisticated manufacturing systems designed to transform raw aluminum billets into complex profiles used in a wide range of applications. The process involves heating the billet and forcing it through a die to create products with precise cross-sectional shapes. Modern extrusion lines integrate advanced automation, intelligent controls, and high-efficiency cooling and cutting systems, ensuring high productivity and consistent quality.

The aluminum extrusion industry in China has seen rapid growth over the past decades, driven by increasing demand in sectors such as construction, automotive, aerospace, electronics, and renewable energy. Chinese manufacturers have invested heavily in research and development to improve extrusion technology, focusing on energy efficiency, precision, and automation.

Top 10 Aluminum Extrusion Line Manufacturers in China

1. Foshan Yejing Machinery Manufacturing Co., Ltd.

Foshan Yejing Machinery Manufacturing Co., Ltd. is a pioneer in the design and manufacture of aluminum extrusion presses and complete extrusion line solutions. Established in 1990, Yejing has delivered over 3,000 sets of aluminum profile extruders to clients worldwide, earning a reputation for precision, reliability, and innovation. The company's products are exported to more than 30 countries, including Australia, South Korea, Turkey, and Brazil, and are trusted by leading Chinese aluminum profile manufacturers such as Xingfa Aluminum and Nanping Aluminum.

Yejing's extrusion presses feature advanced short-stroke technology and intelligent control systems that optimize energy consumption and improve product quality. The company emphasizes research and development, continuously upgrading its machinery to meet evolving market demands.

2. Guangdong Fenglu Aluminum Co., Ltd.

Guangdong Fenglu Aluminum is renowned for its high-end intelligent manufacturing capabilities. The company operates the largest aluminum extrusion production line in China, with a 20,000-ton capacity, capable of producing lightweight and high-precision profiles for sectors such as 5G communications, aerospace, and high-speed rail.

Fenglu's integrated molding technology and large-scale production lines have positioned it as a key partner for the Chinese aerospace industry and a major player in the global high-end aluminum profile market. The company invests heavily in automation and quality control to ensure consistent product performance.

3. Zhongwang Group

Zhongwang Group is the largest aluminum extrusion manufacturer in Asia and the second largest globally. With a focus on innovation, eco-friendly production, and high-tech aluminum products, Zhongwang provides one-stop services including R&D, die design, alloy smelting, and casting. The company's products are widely used in construction, transportation, and industrial applications.

Zhongwang's commitment to sustainability is evident in its use of recycled aluminum and energy-efficient manufacturing processes. The company also invests in advanced technologies such as 3D printing for die manufacturing and smart factory systems.

4. Guangdong Xingfa Aluminium Co., Ltd.

Founded in 1984, Xingfa Aluminium is a leader in the architectural aluminum industry, specializing in the manufacture, processing, and distribution of aluminum materials and alloys. The company is known for its intelligent production systems and creative product development, making it one of the earliest and most respected aluminum extrusion line manufacturers in China.

Xingfa's product range includes architectural profiles, industrial profiles, and customized solutions for various applications. The company's focus on quality and innovation has earned it numerous certifications and industry awards.

5. Jiahua Aluminium Co., Ltd.

With 28 years of experience, Jiahua Aluminium is a top OEM manufacturer specializing in window, door, curtain wall, kitchen, wardrobe, and industrial aluminum profiles. The company operates 23 extrusion lines with a yearly capacity of 90,000 tons and offers a wide range of surface treatments, including powder coating, anodizing, and wood grain finishes.

Jiahua's commitment to quality and innovation has earned it a strong global reputation. The company also emphasizes environmental responsibility, implementing strict waste management and energy-saving measures.

6. Foshan Shenghai Aluminum Co., Ltd.

Shenghai Aluminum is a leading manufacturer with a focus on high-quality aluminum profiles for construction and industrial applications. The company's advanced extrusion lines and strict quality management have made it a preferred supplier for both domestic and international clients.

Shenghai invests in continuous improvement of its production processes, adopting lean manufacturing principles and advanced quality control systems to ensure product consistency and customer satisfaction.

7. Sinpower China Aluminium

Sinpower China Aluminium is recognized for its innovation and high standards in aluminum extrusion. The company supplies a wide range of profiles for various industries and is known for its efficient production processes and reliable quality.

Sinpower focuses on research and development to enhance extrusion technology and product performance. The company also offers customized solutions to meet specific client requirements.

8. Asia Aluminum Factory Co., Ltd.

Established in 1990, Asia Aluminum is one of the largest aluminum manufacturers in Asia, with an annual production capacity of 500,000 tons. The company utilizes automated mold-making equipment and focuses on high-precision aluminum products, earning recognition as a top brand in China.

Asia Aluminum's investment in automation and precision manufacturing has enabled it to maintain competitive advantages in both domestic and international markets.

9. Foshan Jingye Machinery Manufacturing Co., Ltd.

Jingye Machinery, established in 1992, specializes in the design and manufacture of aluminum extrusion dies, auxiliary equipment, and polyamide insulation strips. With decades of experience, Jingye has become a diversified enterprise group serving both domestic and international markets.

Jingye's expertise in die manufacturing and auxiliary equipment supports the aluminum extrusion industry by providing high-quality components that enhance production efficiency and product quality.

10. Foshan Fengda Machinery Equipment Co., Ltd.

Fengda Machinery is known for its innovative aluminum extrusion line solutions, designed to enhance production efficiency and product quality. The company's equipment covers every stage of the extrusion process, from raw material feeding to cutting, and is suitable for a wide range of profile applications.

Fengda emphasizes customization and precision engineering, working closely with clients to develop tailored extrusion lines that meet specific production needs.

Industry Trends and Innovations in Aluminum Extrusion

The aluminum extrusion industry in China is rapidly evolving, driven by technological advancements and increasing demand for lightweight, durable materials. Manufacturers are investing in automation, artificial intelligence, and smart factory solutions to enhance production efficiency and product quality. Energy efficiency and environmental sustainability are also key focus areas, with companies adopting green manufacturing practices and recycling initiatives.

One notable trend is the integration of Industry 4.0 technologies, including IoT sensors and data analytics, which enable real-time monitoring and predictive maintenance of extrusion lines. This reduces downtime and improves overall equipment effectiveness. Additionally, advancements in die design and alloy development are expanding the range of applications for aluminum profiles, from automotive lightweighting to high-strength aerospace components.

Challenges and Opportunities

Despite the rapid growth, the aluminum extrusion industry faces challenges such as rising raw material costs, trade tensions, and the need for skilled labor. However, these challenges also present opportunities for innovation and collaboration. Manufacturers are exploring new markets, enhancing customization capabilities, and strengthening global partnerships to maintain competitiveness.

Government support through policies and subsidies aimed at promoting advanced manufacturing and environmental protection further bolsters the industry's growth potential.

Future Outlook

The future of aluminum extrusion in China looks promising, with continued emphasis on technological innovation and sustainability. Emerging technologies like additive manufacturing and advanced surface treatments are expected to complement traditional extrusion processes, offering new possibilities for product design and performance.

As global demand for aluminum profiles increases, Chinese manufacturers are poised to lead the market by delivering high-quality, cost-effective solutions tailored to diverse industry needs.

Case Studies of Leading Manufacturers

Foshan Yejing Machinery Manufacturing Co., Ltd.

Yejing's commitment to innovation is exemplified by its development of intelligent extrusion presses that reduce energy consumption by up to 20%. The company's global reach is supported by a comprehensive after-sales service network, ensuring customer satisfaction and long-term partnerships. Yejing also collaborates with research institutions to develop new alloys and extrusion techniques, maintaining its competitive edge.

Guangdong Fenglu Aluminum Co., Ltd.

Fenglu's strategic focus on high-precision profiles for aerospace applications has led to partnerships with major aerospace manufacturers in China. The company's investment in automated quality inspection systems ensures that every profile meets stringent industry standards. Fenglu's ability to produce large-scale, lightweight profiles supports the development of next-generation transportation technologies.

Zhongwang Group

Zhongwang's eco-friendly initiatives include the use of recycled aluminum and solar power in its manufacturing processes. The company's smart factory implementation has increased production efficiency by 15%, reducing waste and operational costs. Zhongwang's diverse product portfolio allows it to serve multiple industries, enhancing its resilience in fluctuating markets.

Market Impact and Global Reach

Chinese aluminum extrusion manufacturers have significantly influenced the global market by offering cost-effective, high-quality products. Their ability to customize solutions for various industries has attracted international clients, expanding China's export footprint. The integration of advanced technologies and sustainable practices positions these manufacturers as leaders in the global aluminum extrusion industry.

The competitive pricing and robust supply chains of Chinese manufacturers have also pressured global competitors to innovate and improve efficiency. This dynamic has accelerated technological advancements and raised industry standards worldwide.

Conclusion

China's aluminum extrusion line manufacturers have established themselves as global leaders through continuous innovation, investment in advanced technology, and commitment to quality. From Foshan Yejing Machinery Manufacturing Co., Ltd. to Fengda Machinery Equipment Co., Ltd., these companies provide comprehensive solutions that meet the diverse needs of industries worldwide. As demand for lightweight, high-performance aluminum profiles grows, Chinese manufacturers are well-positioned to drive the future of aluminum extrusion technology.

Frequently Asked Questions

Q1: What is an aluminum extrusion line?

A1: An aluminum extrusion line is a series of machines and processes that transform raw aluminum billets into shaped profiles by forcing the heated metal through a die. The line typically includes billet heating, extrusion presses, cooling, cutting, and surface treatment equipment.

Q2: What factors should I consider when choosing an aluminum extrusion line manufacturer?

A2: Key factors include the manufacturer's experience, production capacity, technological innovation, quality control systems, after-sales support, and ability to customize solutions for your specific needs.

Q3: How does the extrusion process impact aluminum profile quality?

A3: The quality of aluminum profiles depends on precise temperature control, die design, press capacity, and post-extrusion treatments. Advanced extrusion lines ensure consistent dimensions, strength, and surface finish.

Q4: Can aluminum extrusion lines be customized for different industries?

A4: Yes, leading manufacturers offer customizable extrusion lines tailored to the requirements of industries such as construction, automotive, electronics, and aerospace.

Q5: What are the latest trends in aluminum extrusion line technology?

A5: Recent trends include intelligent automation, energy-efficient designs, integration of quality monitoring systems, and environmentally friendly production processes.