Content Menu

● Market Overview

● Major Aluminum Extruder Manufacturers and Suppliers in South Korea

>> 1. Aluko Group (Hyundai Aluminum)

>>> Key Strengths:

>> 2. ALUS Co., Ltd.

>>> Key Strengths:

>> 3. HIS Systems

>>> Key Strengths:

>> 4. Sunwoo Engineering Co., Ltd.

>>> Key Strengths:

>> 5. SKM Korea

>>> Key Strengths:

● Extrusion Process and Capabilities

>> Machinery and Capacities

>> Alloy and Profile Design

>> Quality Control

● Industry Innovations and Trends

● Applications Across Industries

>> Automotive Industry

>> Construction and Architecture

>> Electronics and Electrical Equipment

>> Renewable Energy

>> Heavy Machinery and Industrial Equipment

● Conclusion

● Frequently Asked Questions (FAQs)

>> 1. What is aluminum extrusion and why is it important for modern industry?

>> 2. How does South Korean competency in aluminum extrusion benefit international OEM customers?

>> 3. Which sectors in South Korea drive demand for aluminum extruded products?

>> 4. Can South Korean aluminum extruder manufacturers provide custom profiles and private-label solutions?

>> 5. What are the major trends in South Korea's aluminum extrusion industry for the next decade?

South Korea stands as a powerhouse in the aluminum extrusion industry, home to several world-renowned aluminum extruder manufacturers and suppliers. With robust growth driven by booming construction, automotive, renewable energy, and electronics sectors, the nation's aluminum extrusion market is projected to continue expanding consistently over the coming years. This article offers a comprehensive exploration of the key companies, their specialties, ongoing innovations, and how South Korea has positioned itself as a leader in aluminum extrusion technology. We will delve deeply into the market dynamics, industry trends, and applications, providing a holistic picture of South Korea's aluminum extrusion landscape.

Market Overview

South Korea's aluminum extrusion market is experiencing robust growth, valued at approximately $1.45 billion in 2024 and projected to reach over $3.38 billion by 2035, at an average compound annual growth rate (CAGR) of around 8%. This expansion is fueled by increasing demand for lightweight, durable, and versatile aluminum parts used in construction, automotive, and green energy sectors. Aluminum extrusions offer a unique balance of strength, machinability, and corrosion resistance, making them the preferred choice for modern infrastructure and next-generation vehicles.

Key market drivers include:

- Accelerated urbanization and large-scale infrastructure investment, increasing demand for aluminum profiles in construction and architectural applications.

- Surge in electric vehicle (EV) and renewable energy component demand, where aluminum extrusions are essential for lightweight and efficient design.

- Emphasis on recyclable and sustainable materials for “green building” initiatives aligns well with aluminum's environmentally friendly lifecycle.

Government policies supporting electric vehicles and green buildings further stimulate market growth, positioning South Korea as a critical player in the global aluminum extrusion supply chain.

Major Aluminum Extruder Manufacturers and Suppliers in South Korea

South Korea hosts several prominent manufacturers and suppliers of aluminum extrusions. These companies provide a wide variety of high-quality products and services, catering to OEMs, wholesalers, and producers worldwide.

1. Aluko Group (Hyundai Aluminum)

Founded in 1956, Aluko Group, often associated with Hyundai Aluminum, is the largest and oldest aluminum processing company in South Korea. Initially established as Dongyang Steel, the company evolved into a diversified industrial giant specializing in aluminum extrusion and processing.

Key Strengths:

- Korea's first aluminum manufacturer and extrusion company with decades of accumulated expertise.

- Diversified business portfolio including aluminum profiles, panels, automotive parts, and battery cases specifically tailored for the growing electric vehicle segment.

- Continuous investment in research and development (R&D), emphasizing sustainability and premium alloy development.

- Integrated production capabilities that include billet casting, extrusion, finishing, and machining in an ISO-certified environment.

- An extensive global network with subsidiaries and manufacturing facilities not only in Korea but also in the United States, Vietnam, and other international locations.

Today, Aluko Group is recognized as a trendsetter in the industry, providing customized solutions for automotive lightweight structures, energy-efficient building materials, and next-generation battery casings.

2. ALUS Co., Ltd.

Established in 1999, ALUS Co., Ltd. has carved a niche as a premium supplier of high-quality alloy billets and precision aluminum extrusions. The company specializes in aluminum formwork and structural profiles mainly serving the construction and industrial sectors.

Key Strengths:

- Annual extrusion capacity reportedly reaching 36,000 metric tons.

- Main focus on 6000 series aluminum alloys, known for their excellent mechanical properties and corrosion resistance.

- The capability to produce “special” alloy billets tailored to specific client requirements, providing flexibility for highly specialized industrial applications.

- Highly automated billet casting and extrusion lines that ensure consistent quality and delivery.

ALUS is widely appreciated for the durability and precision of its aluminum formwork systems, which have become critical enablers for modern construction in Korea and overseas markets.

3. HIS Systems

Founded in 1983, HIS Systems has established itself as the premier specialist in aluminum extrusion dies, molds, and profile manufacturing in South Korea.

Key Strengths:

- The pioneering company in Korea specialized exclusively in the production of extrusion dies, a crucial component ensuring precision and efficiency in extrusion.

- Operates extrusion presses of 1,800 and 2,750-ton capacities with a monthly extrusion capacity exceeding 1,000 tons.

- International OEM relationships sustained over decades due to consistent product quality and timely delivery.

- Expertise in complex aluminum profiles ranging from heat sinks to architectural sections.

HIS Systems is known for its commitment to engineering excellence, offering customized die solutions that meet global standards and enable manufacturers to achieve outstanding product performance.

4. Sunwoo Engineering Co., Ltd.

With roots dating back to 1989, Sunwoo Engineering is a specialist manufacturer of aluminum extrusion press lines and related processing equipment.

Key Strengths:

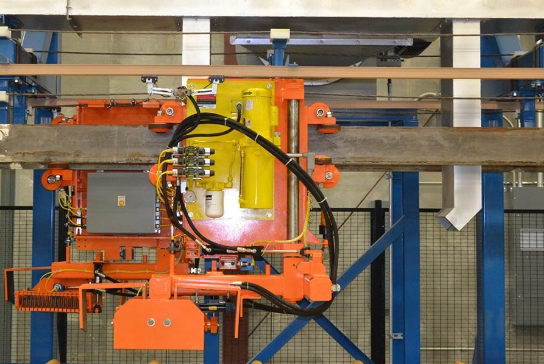

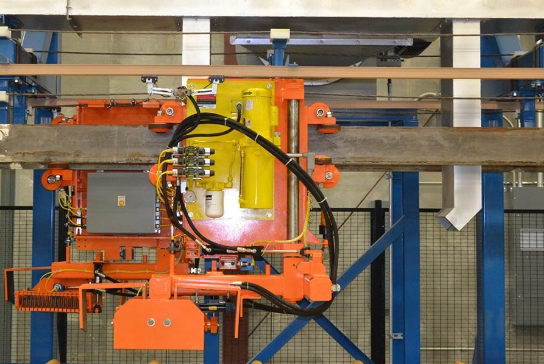

- More than 180 aluminum extrusion press lines delivered globally, including turnkey plants.

- Highly regarded for precision extrusion press machinery, including front-loading short stroke presses and variable-section extrusion technology.

- Extensive aftermarket support and engineering consultation for OEM extrusion plants.

- Strong export record to major markets such as the United States, Japan, China, India, Vietnam, and the European Union.

Sunwoo Engineering's focus on high-efficiency, low-maintenance extrusion machinery has made it a preferred partner for aluminum profile producers seeking to upgrade or establish their extrusion capabilities.

5. SKM Korea

Founded in 1990, SKM Korea has built a solid reputation as a full-scope supplier of aluminum extrusion equipment, focusing on delivering heavy-duty machinery and integrated processing lines.

Key Strengths:

- A record-setting portfolio covering equipment ranging from 1,000 to 8,500 tons of extrusion force.

- Developed advanced technical solutions facilitating high-precision aluminum profile manufacturing.

- Provides turn-key extrusion plants including handling equipment, melting, casting, quenching, and anodizing facilities.

- Acts as an essential industrial partner for large-scale OEMs and heavy industries both domestically and internationally.

SKM Korea's integrated solutions enable aluminum extrusion businesses to achieve consistent product quality and efficient production through automation and advanced process controls.

Extrusion Process and Capabilities

The aluminum extrusion process involves heating aluminum billets to a malleable but solid state and then forcing them through a die with a specific cross-sectional profile. This process yields versatile and complex shapes that can be used directly or further fabricated for diverse industrial applications.

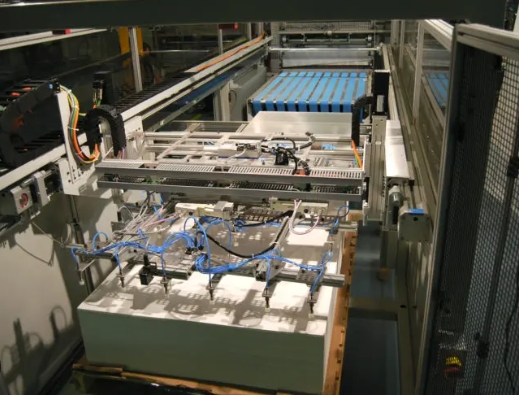

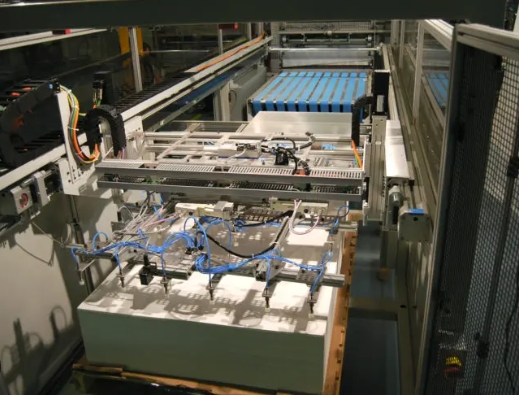

Machinery and Capacities

The extrusion presses used in South Korea vary from small presses of approximately 1,000 tons up to ultra-large presses exceeding 8,500 tons of extrusion force, reflecting the ability to produce everything from delicate profiles to heavy structural sections.

The main manufacturing steps include:

- Billet Casting: Producing high-quality aluminum billets with tailored alloy compositions to meet specific mechanical and physical attributes.

- Extrusion: Pushing the heated billet through the shaped die using hydraulic presses.

- Cooling & Stretching: Controlled cooling followed by stretching to ensure dimensional stability.

- Cutting & Finishing: Profiles are cut to length and may undergo surface treatments such as anodizing or powder coating.

Alloy and Profile Design

South Korean manufacturers offer a broad spectrum of aluminum alloys, with the 6000 series (Aluminum-Magnesium-Silicon) being the most common due to its strength, corrosion resistance, and ease of fabrication. Special alloying is also available to meet unique client specifications involving enhanced thermal conductivity, strength, or corrosion resistance.

Complex profile geometries are achievable due to advanced die-making expertise, including multi-chamber dies and variable cross-section designs that cater to demanding applications like automotive chassis components and intricate architectural elements.

Quality Control

Stringent quality control systems are integral to South Korean aluminum extruder manufacturers. These include inline dimensional inspections, ultrasonic testing, mechanical property verification, and surface quality assessments to ensure adherence to international standards such as ISO and ASTM.

Industry Innovations and Trends

The South Korean aluminum extrusion market continues to evolve with key innovations that reflect global demands and technological progress:

- Electrification and Lightweighting: The automotive sector's shift to electric vehicles increases demand for lightweight aluminum structures and battery enclosures. Manufacturers invest heavily in alloys and extrusion techniques suited to these requirements.

- Green Building Materials: Aluminum extrusions are essential in sustainable construction projects due to their recyclability and energy efficiency. Low-carbon footprint manufacturing processes are increasingly implemented.

- Automation and Smart Manufacturing: Leading extrusion companies adopt Industry 4.0 technologies including robotics, AI-driven process optimization, and digital twins to enhance productivity and consistency.

- Customization and Rapid Prototyping: Flexible manufacturing systems allow for quick adaptation to new designs, enabling OEMs to accelerate product development cycles.

- Integration of Secondary Processes: On-site capabilities for anodizing, powder coating, and machining enable suppliers to provide finished products ready for assembly or direct use.

These trends position South Korea as a global innovation hub for aluminum extrusion technologies, balancing quality, environmental responsibility, and client-specific customization.

Applications Across Industries

South Korean aluminum extruder manufacturers and suppliers cater to a wide range of industries, leveraging aluminum's advantageous properties:

Automotive Industry

Aluminum extrusions enable the production of lightweight vehicle frames, battery trays, heat dissipation systems, and interior/exterior trim components. The shift to electric vehicles (EVs) significantly amplifies demand for bespoke aluminum parts that reduce weight without compromising safety or performance.

Construction and Architecture

Aluminum extrusions form the skeleton of modern architectural designs including curtain walls, window and door frames, roofing, sun-shades, and formwork systems. Their corrosion resistance and design flexibility make them ideal for infrastructure across Korea and global markets.

Electronics and Electrical Equipment

Extrusions serve as heat sinks, housings, and structural elements in various electronic devices due to aluminum's excellent thermal conductivity and electrical properties.

Renewable Energy

Solar panel frames, mounting brackets, and wind turbine components benefit from aluminum's strength-to-weight ratio, durability, and eco-friendliness.

Heavy Machinery and Industrial Equipment

Precision aluminum extrusions are used in tubes, framework, and specialized equipment parts, supporting sectors such as HVAC, medical devices, and industrial automation.

Conclusion

South Korea's aluminum extrusion industry is a dynamic and vital sector, anchored by world-class manufacturers and suppliers such as Aluko Group, ALUS Co., Ltd., HIS Systems, Sunwoo Engineering, and SKM Korea. These companies combine decades of experience, advanced process technology, and strong innovation capabilities to serve a broad range of international OEMs, wholesalers, and manufacturers. With expanding applications across automotive, construction, electronics, and renewable energy, South Korea continues to solidify its position as a global leader in aluminum extrusion manufacturing. The ongoing emphasis on sustainable practices, customization, automation, and alloy innovation ensures the market will maintain healthy growth and technological competitiveness well into the future.

Frequently Asked Questions (FAQs)

1. What is aluminum extrusion and why is it important for modern industry?

Aluminum extrusion is a manufacturing process where heated aluminum billets are forced through dies to create specific cross-sectional profiles. It is essential due to aluminum's lightweight, strength, corrosion resistance, and design versatility, enabling applications from automotive parts to building materials.

2. How does South Korean competency in aluminum extrusion benefit international OEM customers?

South Korean manufacturers offer advanced quality control, state-of-the-art technology, flexible OEM/ODM services, and compliance with global standards. Their technical expertise ensures reliable, customized solutions and consistent product quality.

3. Which sectors in South Korea drive demand for aluminum extruded products?

Key sectors include construction, automotive (especially electric vehicles), renewable energy, electronics, and heavy machinery. Government initiatives promoting green and energy-efficient materials further stimulate demand.

4. Can South Korean aluminum extruder manufacturers provide custom profiles and private-label solutions?

Yes. Leading companies provide comprehensive customization ranging from alloy composition and profile design to finishing and assembly, enabling private-label manufacturing tailored to client specifications.

5. What are the major trends in South Korea's aluminum extrusion industry for the next decade?

Trends include electrification of transport with increased lightweight aluminum use, green building materials, automation and smart manufacturing, greater focus on sustainability, and expanding global market reach.