Content Menu

● Understanding the Aluminum MK8 Extruder

● Compatibility with Different 3D Printers

● Installation Process

● Advantages of Upgrading to an Aluminum MK8 Extruder

● Common Issues with Plastic Extruders

● Comparative Analysis: Aluminum vs. Plastic Extruders

● Filament Types Suitable for Aluminum MK8 Extruders

● Maintenance Tips for Aluminum MK8 Extruders

● Upgrading Your Existing Setup

● User Experiences and Testimonials

● Common Troubleshooting Tips

● Conclusion

● FAQ

>> 1. What types of filaments can I use with an Aluminum MK8 extruder?

>> 2. Do I need any special tools for installation?

>> 3. Is there a significant difference in print quality after upgrading?

>> 4. Can I use an Aluminum MK8 extruder on a dual-extrusion setup?

>> 5. What should I do if my printer is not compatible with an Aluminum MK8 extruder?

● Citations:

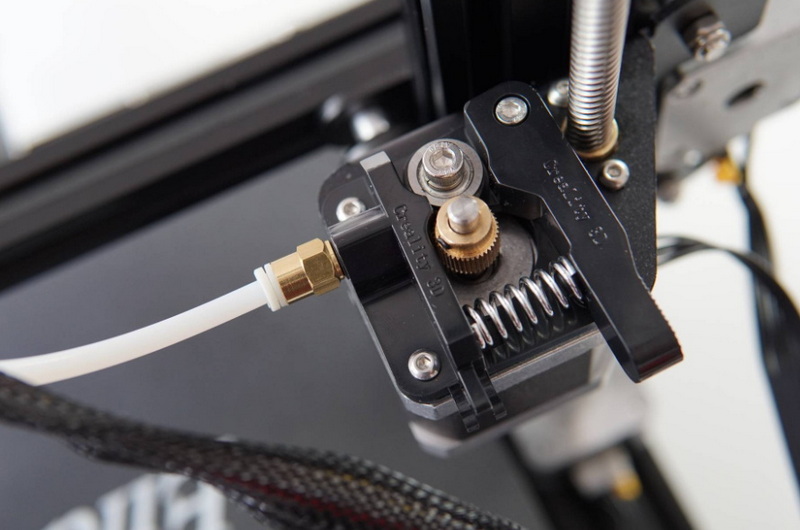

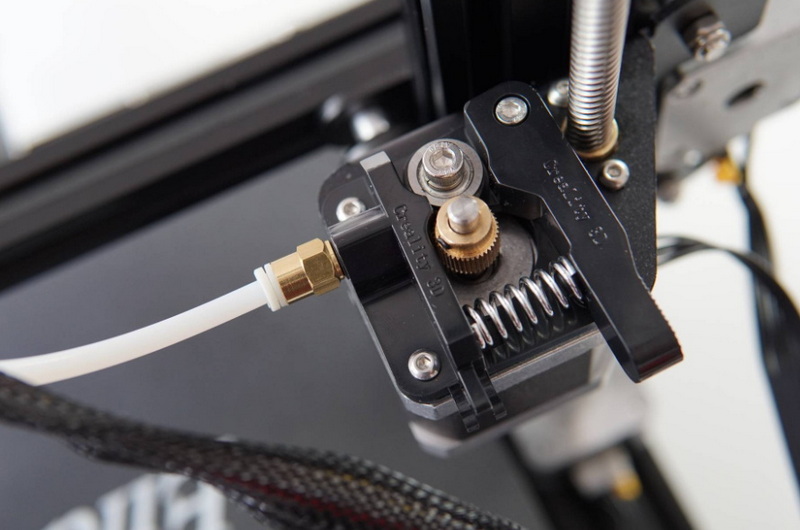

The Aluminum MK8 extruder has gained popularity among 3D printing enthusiasts for its durability and efficiency compared to traditional plastic extruders. However, a common question arises: "Is the Aluminum MK8 extruder compatible with all 3D printers?" This article will delve into the compatibility of the Aluminum MK8 extruder, its features, installation process, and provide a comprehensive FAQ section to address common queries.

Understanding the Aluminum MK8 Extruder

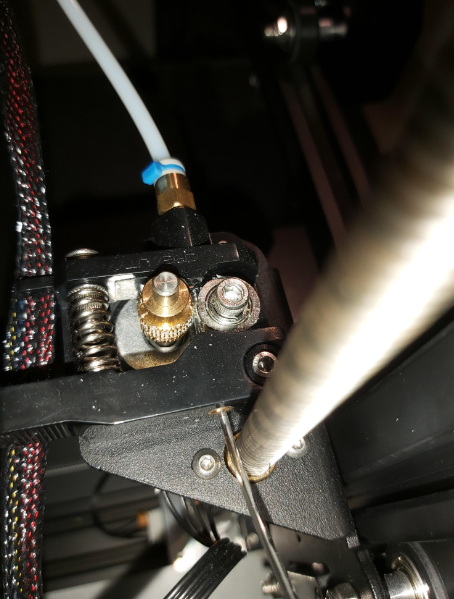

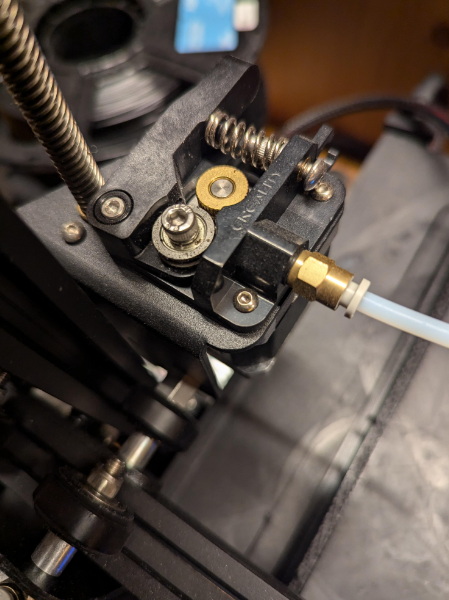

The Aluminum MK8 extruder is designed to handle 1.75mm filament and is commonly used in various 3D printers, particularly those that utilize Bowden or direct drive systems. Its robust aluminum construction offers several advantages:

- Durability: Unlike plastic extruders, aluminum models are less prone to wear and tear.

- Consistent Performance: They provide better pressure control for filament feeding, leading to improved print quality.

- Versatility: Compatible with a range of filament types, including PLA, ABS, PETG, and flexible materials.

Compatibility with Different 3D Printers

While the Aluminum MK8 extruder is designed to fit many popular 3D printer models, it is not universally compatible. Here's a breakdown of its compatibility:

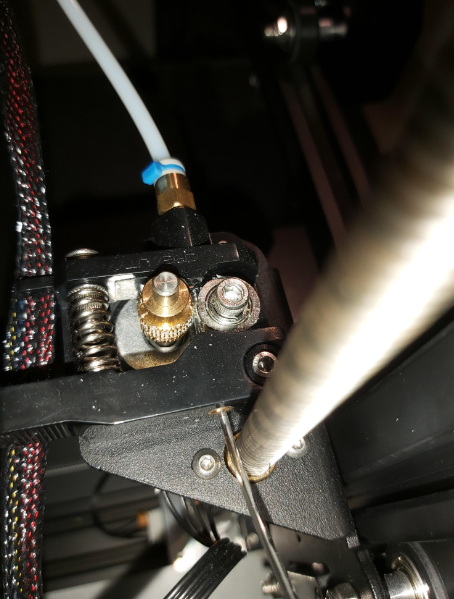

- Creality Printers: The MK8 extruder is widely compatible with Creality models such as the Ender 3 series (Ender 3, Ender 3 Pro, Ender 3 V2), CR-10 series (CR-10, CR-10S), and others. These printers often come with standard mounting options that easily accommodate the MK8 design.

- Other Brands: Many other brands like Anycubic, Tevo, and Monoprice also support the MK8 extruder. However, users should verify specific model compatibility as some printers may require additional adapters or modifications.

- DIY and Custom Builds: For custom-built or DIY printers, the MK8 extruder can generally be adapted as long as the mounting points align correctly. Users may need to create custom brackets or use existing mounts.

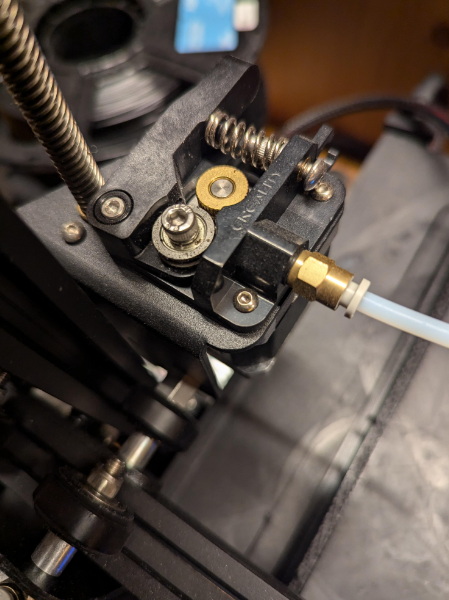

Installation Process

Installing an Aluminum MK8 extruder can significantly enhance your printing experience. Below are the general steps for installation:

1. Gather Required Tools:

- Allen wrenches

- Screwdriver

- Filament cutter

2. Remove the Existing Extruder:

- Power off your printer.

- Carefully detach the old extruder by unscrewing it from its mount.

- Disconnect any wiring connected to the stepper motor.

3. Prepare the New Extruder:

- Assemble your new Aluminum MK8 extruder if it comes in parts.

- Ensure that all screws and components are secure.

4. Install the Extruder:

- Position the new extruder onto the mount.

- Secure it using screws provided in the kit.

- Reconnect any wiring to ensure proper functionality.

5. Calibrate Your Printer:

- After installation, recalibrate your printer settings for optimal performance.

- Adjust extrusion settings in your slicer software to match the new setup.

Advantages of Upgrading to an Aluminum MK8 Extruder

Upgrading to an Aluminum MK8 extruder provides several benefits:

- Improved Filament Handling: The enhanced grip on filament reduces slippage and grinding issues.

- Higher Pressure Application: It allows for better extrusion at higher speeds without compromising quality.

- Long-Term Cost Efficiency: Although initially more expensive than plastic counterparts, aluminum extruders tend to last longer and require fewer replacements.

Common Issues with Plastic Extruders

Plastic extruders often present challenges that can hinder printing performance:

- Wear and Tear: Over time, plastic components can wear down, leading to inconsistent extrusion.

- Heat Sensitivity: Plastic can warp or deform under high temperatures, affecting print quality.

- Limited Filament Compatibility: Many plastic extruders struggle with flexible filaments due to insufficient grip and pressure.

Comparative Analysis: Aluminum vs. Plastic Extruders

To better understand why many users prefer aluminum MK8 extruders over plastic ones, consider this comparison:

| Feature | Aluminum MK8 Extruder | Plastic Extruder |

| Durability | High | Moderate |

| Temperature Resistance | High | Low |

| Print Quality | Excellent | Variable |

| Filament Compatibility | Wide | Limited |

| Maintenance Frequency | Low | High |

Filament Types Suitable for Aluminum MK8 Extruders

The versatility of the Aluminum MK8 extruder allows it to handle various filament types effectively:

- PLA (Polylactic Acid): Easy to print and widely used for general purposes.

- ABS (Acrylonitrile Butadiene Styrene): Requires higher temperatures but offers durability.

- PETG (Polyethylene Terephthalate Glycol): Combines ease of printing with strength and flexibility.

- TPU (Thermoplastic Polyurethane): A flexible filament that benefits from consistent extrusion pressure provided by aluminum designs.

Maintenance Tips for Aluminum MK8 Extruders

To ensure longevity and optimal performance of your Aluminum MK8 extruder, follow these maintenance tips:

- Regular Cleaning: Periodically clean the nozzle and feeding mechanism to prevent clogs.

- Check Tension Settings: Ensure that the tension on the filament drive gear is adjusted correctly for different filament types.

- Lubrication: Apply a small amount of lubricant on moving parts as needed to maintain smooth operation.

Upgrading Your Existing Setup

If you're considering upgrading from a plastic to an aluminum MK8 extruder, here are some steps you can take:

1. Evaluate your current setup: Assess whether your existing printer can accommodate an aluminum upgrade without significant modifications.

2. Research compatibility: Look into specific models that have successfully integrated aluminum MK8 extruders.

3. Purchase a quality kit: Ensure you buy a reliable aluminum kit that includes all necessary components for installation.

4. Follow online guides: Utilize video tutorials or assembly instructions available online for a smooth installation process.

User Experiences and Testimonials

Many users have shared their experiences after upgrading to an Aluminum MK8 extruder:

- One user reported a significant improvement in print quality after switching from a plastic extruder on their Ender 3 Pro. They noted that prints were more consistent and had fewer defects due to better filament control.

- Another user highlighted how they could now print flexible filaments without issues that were common with their previous setup. The increased grip on the filament allowed them to experiment with various materials effectively.

These testimonials underscore the advantages of making this upgrade for both novice and experienced users alike.

Common Troubleshooting Tips

Even with an upgraded aluminum MK8 extruder, users may encounter issues during printing. Here are some common troubleshooting tips:

1. Filament Jamming: If you experience jamming during printing, check if the filament path is clear and ensure that there are no obstructions in the nozzle or feeding mechanism.

2. Inconsistent Extrusion: If extrusion seems inconsistent, verify that your tension settings on the drive gear are properly adjusted; too much tension can crush filaments while too little can lead to slippage.

3. Temperature Settings: Ensure that your temperature settings match those recommended for your specific filament type; incorrect temperatures can lead to poor adhesion or excessive stringing in prints.

4. Calibration Issues: Regularly calibrate your printer after making any changes or upgrades; this helps maintain optimal performance across different materials and setups.

Conclusion

In summary, while the Aluminum MK8 extruder is compatible with many popular 3D printers, it is essential to check specific model requirements before purchase. Its robust design and enhanced performance make it a worthwhile investment for serious hobbyists and professionals alike. By understanding its advantages and proper installation techniques, users can significantly improve their 3D printing experience.

FAQ

1. What types of filaments can I use with an Aluminum MK8 extruder?

You can use various filaments such as PLA, ABS, PETG, TPU (flexible), and more. However, ensure that your printer settings are adjusted accordingly for different materials.

2. Do I need any special tools for installation?

Basic tools like Allen wrenches and screwdrivers are typically sufficient for installation. Some kits may include specific tools needed for assembly.

3. Is there a significant difference in print quality after upgrading?

Yes, many users report improved print quality due to better filament control and consistent extrusion pressure when using an aluminum extruder compared to plastic ones.

4. Can I use an Aluminum MK8 extruder on a dual-extrusion setup?

Yes, you can use two different types of MK8 extruders (e.g., one left-side and one right-side) for dual-extrusion setups as long as they are compatible with your printer's configuration.

5. What should I do if my printer is not compatible with an Aluminum MK8 extruder?

If your printer isn't directly compatible, you may need to modify existing mounts or create custom brackets to fit the aluminum extruder properly.

Citations:

[1] https://www.sunrobotics.in/products/mk8-extruder-right-side

[2] https://www.3djake.com/reviews/creality-3d-printers-spare-parts/metal-extruder-upgrade-kit

[3] https://www.youtube.com/watch?v=zJRxRVN3p3Y

[4] https://reprap.org/wiki/Extruder_assembly

[5] https://www.youtube.com/watch?v=pVFlGRmqNxI

[6] https://www.tinytronics.nl/en/3d-printing/extrusion/hotends-and-extruders/aluminum-mk8-bowden-extruder-right

[7] https://novo3d.in/mk8-extruder/

[8] https://forum.v1e.com/t/problem-with-mk8-extruder/6793

[9] https://www.youtube.com/watch?v=UtemZqFJ5rY

[10] https://zbotic.in/product/left-side-mk8-extruder-aluminum-3d-printer-block/

[11] https://sg.cytron.io/p-upgraded-aluminum-mk8-extruder-for-ender3

[12] https://www.crealityexperts.com/creality-extruder-upgrade-instructions

[13] https://gr33nonline.wordpress.com/2019/05/15/assembly-of-an-mk8/

[14] https://www.crealityexperts.com/creality-extruder-upgrade-instructions

[15] https://www.noon.com/saudi-en/ender-3-v2-metal-extruder-aluminum-mk8-bowden-extruder-with-40-teeth-drive-gear-compatible-with-creality-ender-3-pro-ender-5-pro-ender-5-plus-cr-10-series-3d-printer/Z346331D007C2C4779865Z/p/

[16] https://www.reddit.com/r/ender5plus/comments/n02dbn/reason_to_upgrade_to_an_all_metal_mk8_extruder/

[17] https://www.reddit.com/r/ender3v2/comments/o90cgl/design_flaw_in_mk8_aluminum_metal_extruder/

[18] https://m.geeetech.com/mk8-extruder-aluminum-feeder-kit-for-175mm-filament-for-single-extruder-printer-a10-a20-a30-can-not-fit-a10m-a20m-a30m-a10t-a20t-a30t-p-995.html

[19] https://biqu.equipment/products/3d-printer-parts-mk8-extruder-upgrade-aluminum-alloy-block-bowden-extruder-cr10-1-75mm-filament-extrusion-for-mk8-cr-10-ender-3

[20] https://www.youtube.com/watch?v=UtemZqFJ5rY

[21] https://www.aliexpress.com/i/1005005915695361.html

[22] https://www.youtube.com/watch?v=aKDym_qGLEw

[23] https://gr33nonline.wordpress.com/2019/05/15/assembly-of-an-mk8/

[24] https://robu.in/product/right-side-mk8-extruder-aluminum-3d-printer-block/

[25] https://makersupplies.sg/products/upgraded-mk8-aluminium-extruder-feed-replacement-kit-for-creality-cr-ender

[26] https://www.youtube.com/watch?v=TPyTiZ6-_jM

[27] https://www.thingiverse.com/thing:59129

[28] https://www.youtube.com/watch?v=hKqs-mR0urw

[29] https://www.youtube.com/watch?v=Npuocf_f0jk

[30] https://www.facebook.com/cytrontech/videos/upgrade-aluminum-extruder-for-ender-3-v2/809669046552050/?locale=ar_AR

[31] https://www.geeetech.com/mk8-extruder-aluminum-feeder-kit-for-175mm-filament-p-995.html

[32] https://www.youtube.com/watch?v=6q2xWd40U8g

[33] https://www.aliexpress.com/p/video/detail.html?itemId=1005007144818556