Content Menu

● What Are 2020 V Slot Aluminum Extrusions?

>> Benefits of Using 2020 V Slot Aluminum Extrusions

● Tools and Materials Needed

>> Tools

>> Materials

● Step-by-Step Guide to Customizing Your Setup

>> Step 1: Plan Your Design

>> Step 2: Cut the Aluminum Extrusions

>> Step 3: Assemble the Frame

>> Step 4: Install V Wheels or Linear Bearings

>> Step 5: Add Additional Components

>> Step 6: Final Adjustments

>> Step 7: Finishing Touches

● Tips for Customizing Your Setup

● Conclusion

● Common Questions and Answers

>> 1. What is the weight capacity of 2020 V Slot aluminum extrusions?

>> 2. Can I use 2020 V Slot extrusions for outdoor projects?

>> 3. What tools do I need to cut aluminum extrusions?

>> 4. How do I ensure my setup is stable?

>> 5. Can I combine different sizes of aluminum extrusions?

Customizing your setup with 2020 V Slot aluminum extrusions can be an exciting and rewarding project. Whether you are building a 3D printer frame, a CNC machine, or a custom workstation, V Slot extrusions offer versatility, strength, and ease of assembly. In this article, we will explore the benefits of using 2020 V Slot aluminum extrusions, the tools and materials you will need, and step-by-step instructions on how to customize your setup effectively.

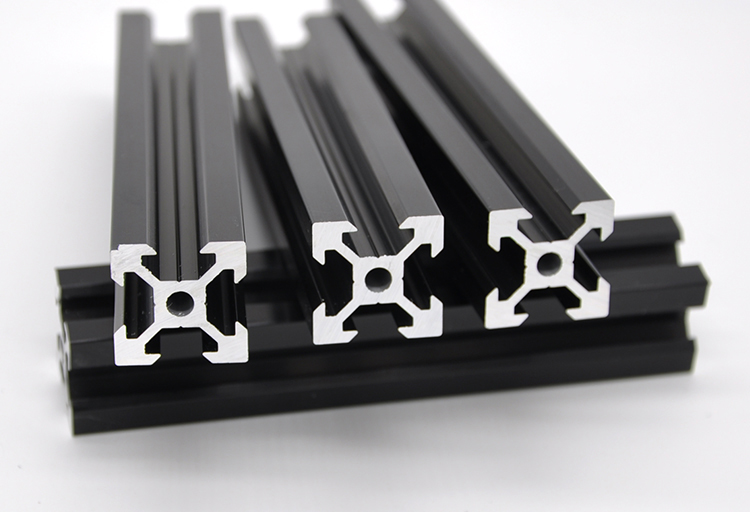

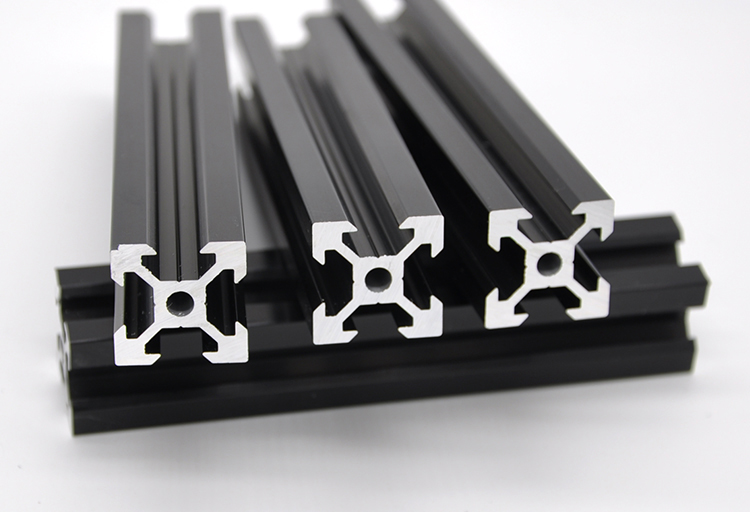

What Are 2020 V Slot Aluminum Extrusions?

2020 V Slot aluminum extrusions are a type of structural framing system made from high-quality aluminum. The "2020" designation refers to the dimensions of the profile, which measures 20mm x 20mm. The "V Slot" refers to the unique V-shaped groove that runs along the length of the extrusion, allowing for smooth linear motion when paired with V wheels or linear bearings.

Benefits of Using 2020 V Slot Aluminum Extrusions

1. Modularity: One of the primary advantages of using V Slot extrusions is their modularity. You can easily add or remove components, making it simple to adapt your setup as your needs change.

2. Strength and Durability: Aluminum is known for its strength-to-weight ratio. V Slot extrusions are robust enough to support heavy loads while remaining lightweight, making them ideal for various applications.

3. Ease of Assembly: The design of V Slot extrusions allows for quick and easy assembly. You can use T-nuts and bolts to connect different pieces without the need for specialized tools.

4. Versatile Applications: Whether you are building a 3D printer, CNC machine, or custom furniture, V Slot extrusions can be used in a wide range of projects.

5. Aesthetic Appeal: The sleek, modern look of aluminum extrusions can enhance the visual appeal of your setup, making it not only functional but also attractive.

Tools and Materials Needed

Before you start customizing your setup, gather the following tools and materials:

Tools

- Aluminum Extrusion Cutter: A miter saw or a hacksaw designed for cutting aluminum.

- Drill: For making holes in the extrusions if needed.

- T-Nuts and Bolts: To connect the extrusions securely.

- Wrenches: For tightening bolts.

- Measuring Tape: To ensure accurate measurements.

- Square: To check for right angles during assembly.

Materials

- 2020 V Slot Aluminum Extrusions: Purchase the lengths you need for your project.

- V Wheels or Linear Bearings: For smooth movement along the V grooves.

- Corner Brackets: To reinforce connections at corners.

- End Caps: To finish the ends of the extrusions and provide a clean look.

Step-by-Step Guide to Customizing Your Setup

Step 1: Plan Your Design

Before cutting any materials, take the time to plan your design. Sketch out your setup, including dimensions and the arrangement of components. Consider the following:

- Purpose: What will your setup be used for? This will influence the design and materials needed.

- Dimensions: Measure the space where your setup will be located to ensure it fits.

- Components: List all the components you will need, including extrusions, wheels, and any additional hardware.

Step 2: Cut the Aluminum Extrusions

Once you have a plan, it's time to cut your aluminum extrusions to the desired lengths. Use an aluminum extrusion cutter for clean cuts. Measure twice and cut once to avoid mistakes.

Step 3: Assemble the Frame

Start assembling the frame of your setup. Use T-nuts and bolts to connect the extrusions at the corners. Make sure to use a square to ensure that all angles are right angles. This will help maintain the structural integrity of your setup.

Step 4: Install V Wheels or Linear Bearings

After the frame is assembled, install the V wheels or linear bearings. These components will allow for smooth movement along the V grooves. Ensure that the wheels are properly aligned to avoid any binding during movement.

Step 5: Add Additional Components

Depending on your project, you may need to add additional components such as shelves, brackets, or other hardware. Use corner brackets for added stability, especially if you are building a larger structure.

Step 6: Final Adjustments

Once everything is assembled, check for any loose connections and tighten all bolts. Make any necessary adjustments to ensure that everything is aligned and functioning correctly.

Step 7: Finishing Touches

Finally, add any finishing touches to your setup. This could include painting the extrusions, adding end caps, or organizing cables for a clean look.

Tips for Customizing Your Setup

- Use CAD Software: Consider using CAD software to design your setup digitally before building. This can help you visualize the final product and make adjustments easily.

- Experiment with Layouts: Don't be afraid to experiment with different layouts. The modular nature of V Slot extrusions allows for easy reconfiguration.

- Keep It Organized: Use cable management solutions to keep your setup tidy and organized. This not only improves aesthetics but also functionality.

Conclusion

Customizing your setup with 2020 V Slot aluminum extrusions is a straightforward process that allows for creativity and flexibility. With the right tools, materials, and a solid plan, you can create a functional and aesthetically pleasing structure tailored to your needs. Whether for a 3D printer, CNC machine, or any other project, V Slot extrusions provide a reliable solution for your building needs.

Common Questions and Answers

1. What is the weight capacity of 2020 V Slot aluminum extrusions?

The weight capacity can vary based on the design and configuration, but generally, 2020 V Slot extrusions can support significant loads when properly assembled.

2. Can I use 2020 V Slot extrusions for outdoor projects?

Yes, but it is recommended to use anodized or powder-coated extrusions to prevent corrosion and damage from the elements.

3. What tools do I need to cut aluminum extrusions?

A miter saw or hacksaw designed for cutting aluminum is ideal. Ensure you have a fine-toothed blade for clean cuts.

4. How do I ensure my setup is stable?

Use corner brackets and ensure all connections are tight. Additionally, consider adding weight to the base if necessary.

5. Can I combine different sizes of aluminum extrusions?

Yes, you can combine different sizes, but ensure that the connections are compatible and that the structure remains stable.