Content Menu

● Introduction

● What Are Aluminum Extrusion Profiles?

● Benefits of Using Aluminum Extrusion Profiles

>> Lightweight Yet Strong Material Properties

>> Design Flexibility and Customization Options

>> Cost-Effectiveness in Manufacturing and Assembly

● Innovative Applications of Aluminum Extrusions

>> Use in Construction

>> Applications in Automotive and Aerospace Industries

>> Role in Electronics and Consumer Products

● Understanding the Aluminum Extrusion Process

● Choosing the Right Custom Aluminum Extrusions

>> Project Requirements

>> Design Considerations

>> Material Selection

>> Supplier Capabilities

>> Cost and Lead Time

● Finding Reliable Aluminum Extrusion Suppliers

>> Tips for Identifying Reputable Suppliers

● Conclusion

● Related Questions

>> 1. What are the advantages of using aluminum extrusions over other materials?

>> 2. How can I ensure the quality of custom aluminum extrusions?

>> 3. What types of finishes are available for aluminum extrusions?

>> 4. Can aluminum extrusions be recycled?

>> 5. How do I determine the right aluminum alloy for my project?

Introduction

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. This process is widely used in various industries due to the material's lightweight, strength, and versatility. When embarking on a project that requires custom aluminum extrusions, understanding how to choose the right profiles is crucial. This article will guide you through the essential factors to consider when selecting custom aluminum extrusions, ensuring that your project is successful and meets all specifications.

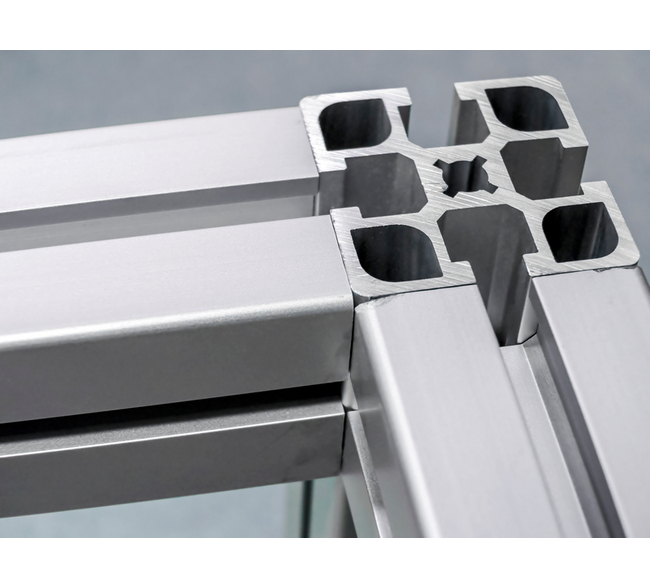

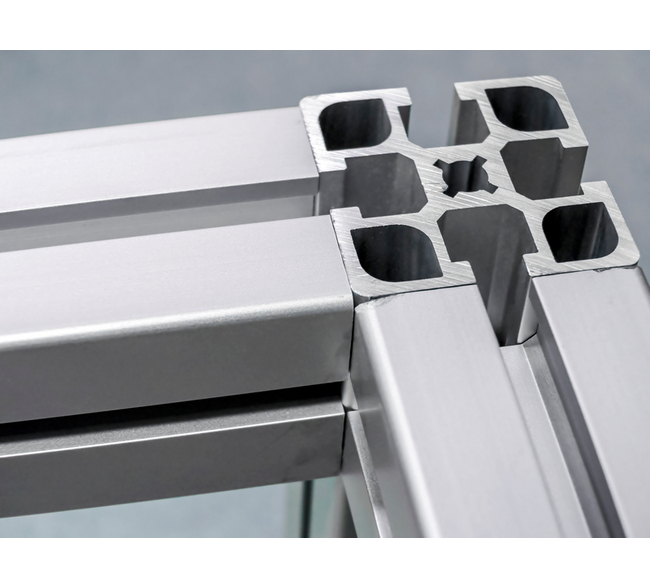

What Are Aluminum Extrusion Profiles?

Aluminum extrusion profiles are created by forcing aluminum alloy through a die, resulting in a specific shape that can be used in various applications. These profiles can be simple or complex, depending on the design requirements. Common shapes include angles, channels, tubes, and custom designs tailored to specific needs.

The versatility of aluminum extrusion profiles allows them to be used in numerous applications, from construction and automotive to electronics and consumer products. The ability to create intricate designs while maintaining structural integrity makes aluminum extrusions a preferred choice for many engineers and designers.

Benefits of Using Aluminum Extrusion Profiles

Lightweight Yet Strong Material Properties

One of the primary advantages of aluminum is its lightweight nature. Aluminum extrusions are significantly lighter than steel or other materials, making them easier to handle and transport. Despite their light weight, aluminum profiles offer excellent strength-to-weight ratios, making them suitable for structural applications where weight savings are critical.

Design Flexibility and Customization Options

Aluminum extrusion allows for a high degree of design flexibility. Manufacturers can create custom profiles that meet specific project requirements, including unique shapes and sizes. This customization capability enables designers to optimize their products for performance, aesthetics, and functionality.

Cost-Effectiveness in Manufacturing and Assembly

Using aluminum extrusions can lead to cost savings in both manufacturing and assembly processes. The extrusion process itself is efficient, allowing for high-volume production with minimal waste. Additionally, the lightweight nature of aluminum reduces shipping costs and simplifies assembly, as fewer fasteners and supports may be required.

Innovative Applications of Aluminum Extrusions

Use in Construction

Aluminum extrusions are widely used in the construction industry. They are commonly found in window frames, curtain walls, and structural components. The durability and corrosion resistance of aluminum make it an ideal choice for outdoor applications, ensuring longevity and minimal maintenance.

Applications in Automotive and Aerospace Industries

In the automotive sector, aluminum extrusions are used to manufacture lightweight components that improve fuel efficiency. From chassis to engine parts, aluminum plays a crucial role in modern vehicle design. Similarly, in the aerospace industry, aluminum extrusions are utilized for their strength and weight advantages, contributing to the overall performance of aircraft.

Role in Electronics and Consumer Products

Aluminum extrusions are also prevalent in the electronics industry, where they are used for heat sinks, enclosures, and structural supports. The excellent thermal conductivity of aluminum helps dissipate heat effectively, ensuring the longevity of electronic components. In consumer products, aluminum extrusions are used in everything from furniture to appliances, providing both functionality and aesthetic appeal.

Understanding the Aluminum Extrusion Process

The aluminum extrusion process involves several key steps:

1. Material Selection: The first step is selecting the appropriate aluminum alloy based on the project's requirements. Different alloys offer varying properties, such as strength, corrosion resistance, and machinability.

2. Die Design: A custom die is created to shape the aluminum into the desired profile. The die design is critical, as it determines the final shape and dimensions of the extrusion.

3. Heating: The aluminum billets are heated to a specific temperature to make them malleable. This heating process is essential for ensuring that the aluminum can be easily extruded through the die.

4. Extrusion: The heated aluminum is forced through the die using a hydraulic press. As the aluminum exits the die, it takes on the shape of the profile.

5. Cooling and Cutting: After extrusion, the profiles are cooled and cut to the required lengths. This step ensures that the extrusions maintain their shape and structural integrity.

6. Finishing: Finally, the extrusions may undergo various finishing processes, such as anodizing or powder coating, to enhance their appearance and protect against corrosion.

Choosing the Right Custom Aluminum Extrusions

When selecting custom aluminum extrusions for your project, consider the following factors:

Project Requirements

Begin by clearly defining the requirements of your project. Consider the intended use of the aluminum extrusions, the load they will bear, and any environmental factors that may affect their performance. Understanding these requirements will help you communicate effectively with suppliers and ensure that you receive the right profiles.

Design Considerations

Work closely with your design team to create detailed drawings and specifications for the aluminum extrusions. Consider factors such as dimensions, tolerances, and surface finishes. Providing clear and precise information will help manufacturers produce extrusions that meet your expectations.

Material Selection

Choose the appropriate aluminum alloy based on the specific needs of your project. Different alloys offer varying properties, such as strength, corrosion resistance, and thermal conductivity. Consult with suppliers to determine the best alloy for your application.

Supplier Capabilities

Research potential suppliers to ensure they have the capabilities to meet your project requirements. Look for manufacturers with experience in producing custom aluminum extrusions and a proven track record of quality and reliability. Request samples and references to evaluate their work.

Cost and Lead Time

Consider the cost and lead time associated with producing custom aluminum extrusions. While it may be tempting to choose the lowest-cost option, ensure that you are not compromising on quality. Discuss lead times with suppliers to ensure that they can meet your project deadlines.

Finding Reliable Aluminum Extrusion Suppliers

Tips for Identifying Reputable Suppliers

1. Research Online: Use online resources to find potential suppliers. Look for companies with a strong online presence and positive customer reviews.

2. Request Quotes: Contact multiple suppliers to request quotes for your project. Compare pricing, lead times, and capabilities.

3. Visit Facilities: If possible, visit the manufacturing facilities of potential suppliers. This will give you insight into their operations and quality control processes.

4. Ask for References: Request references from previous clients to gauge the supplier's reliability and quality of work.

5. Evaluate Customer Service: Assess the level of customer service provided by suppliers. A responsive and knowledgeable team can make a significant difference in your project experience.

Conclusion

Choosing the right custom aluminum extrusions for your project is a critical step that can significantly impact the success of your endeavor. By understanding the benefits of aluminum extrusions, the manufacturing process, and the factors to consider when selecting profiles, you can make informed decisions that align with your project requirements. Collaborating with experienced suppliers and providing clear specifications will ensure that you receive high-quality extrusions that meet your needs.

Related Questions

1. What are the advantages of using aluminum extrusions over other materials?

Aluminum extrusions offer several advantages, including lightweight properties, excellent strength-to-weight ratios, design flexibility, and corrosion resistance. These characteristics make aluminum a preferred choice for various applications across multiple industries.

2. How can I ensure the quality of custom aluminum extrusions?

To ensure quality, work with reputable suppliers, provide detailed specifications, and request samples before placing large orders. Additionally, consider suppliers that have quality control processes in place to monitor production.

3. What types of finishes are available for aluminum extrusions?

Common finishes for aluminum extrusions include anodizing, powder coating, and painting. Each finish offers different aesthetic and protective properties, allowing you to choose the best option for your project.

4. Can aluminum extrusions be recycled?

Yes, aluminum extrusions are highly recyclable. Recycling aluminum requires only a fraction of the energy needed to produce new aluminum, making it an environmentally friendly choice.

5. How do I determine the right aluminum alloy for my project?

Selecting the right aluminum alloy depends on your project's specific requirements, such as strength, corrosion resistance, and thermal conductivity. Consult with suppliers or materials engineers to identify the best alloy for your application.