Content Menu

● Understanding Aluminium Extrusion

>> Steps in the Aluminium Extrusion Production Process

● Advantages of Aluminium Extrusion

● Applications of Aluminium Extrusion in Manufacturing

● Impact on Manufacturing Industries

>> Enhanced Efficiency

>> Innovation in Design

>> Economic Benefits

● Challenges Faced by Aluminium Extrusion Manufacturers

● Future Trends in Aluminium Extrusion

● Conclusion

● FAQ

>> 1. What is the main advantage of using aluminium extrusions?

>> 2. How does the recycling process work for aluminium?

>> 3. What industries benefit most from aluminium extrusion?

>> 4. What challenges do manufacturers face in the aluminium extrusion industry?

>> 5. How does automation impact the aluminium extrusion process?

● Citations:

Aluminium extrusion is a vital manufacturing process that shapes aluminium into various profiles and components, significantly influencing multiple industries. This article explores the aluminium extrusion production process, its advantages, applications, and its transformative impact on manufacturing industries.

Understanding Aluminium Extrusion

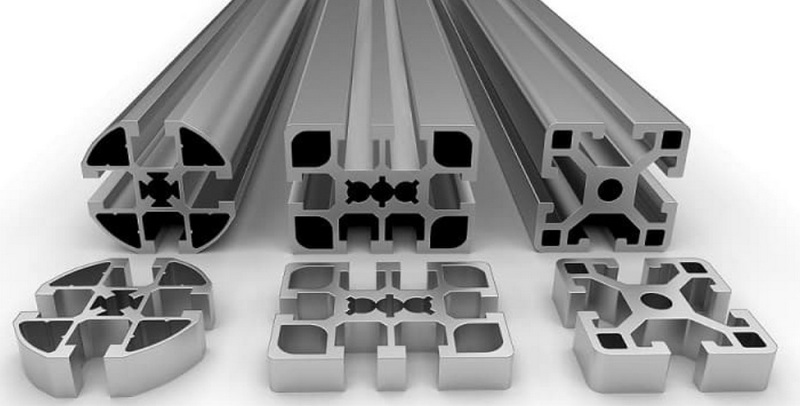

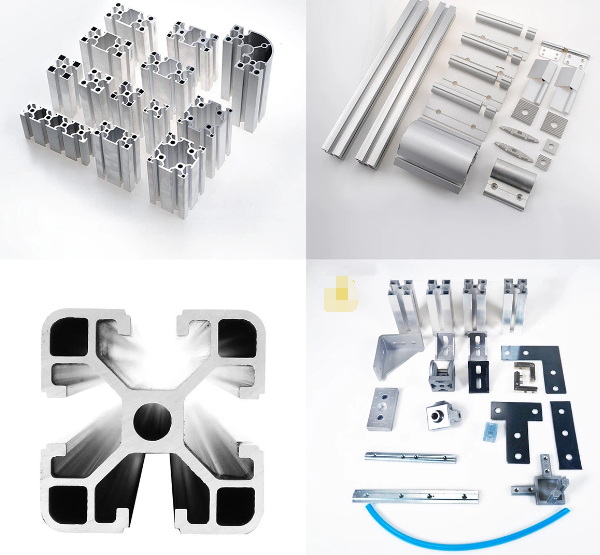

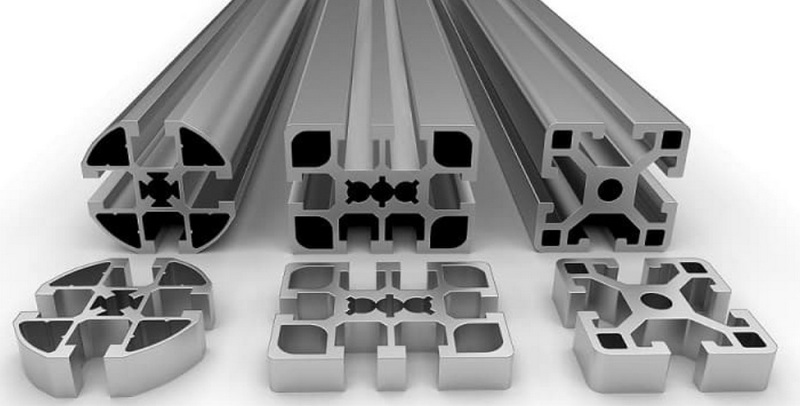

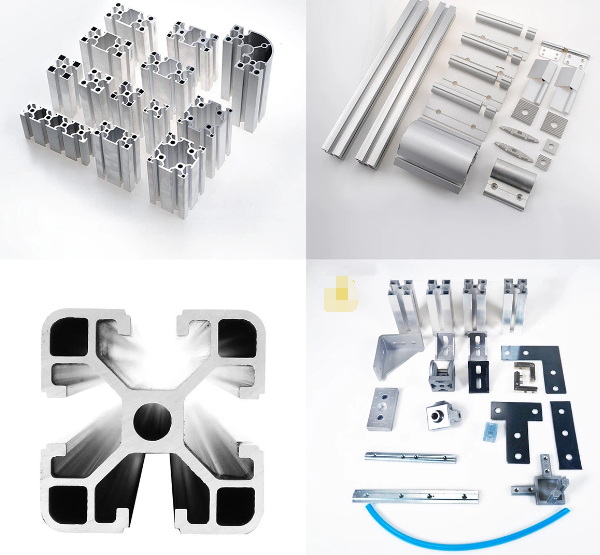

Aluminium extrusion involves forcing heated aluminium through a die to create specific cross-sectional shapes. The process begins with an aluminium billet, which is preheated to make it malleable. Once heated, the billet is placed in an extrusion press where it is subjected to high pressure, pushing it through the die to form the desired profile. The extruded material is then cooled, cut to length, and often undergoes further processing such as machining or finishing.

Steps in the Aluminium Extrusion Production Process

1. Preparation of the Die: The die is preheated to ensure optimal flow of the aluminium.

2. Heating the Billet: The aluminium billet is heated to around 450-500 degrees Celsius.

3. Extrusion: The heated billet is pushed through the die under high pressure.

4. Cooling: The extruded profile is cooled using air or water.

5. Cutting and Finishing: The extrusions are cut to specified lengths and may undergo additional finishing processes.

Advantages of Aluminium Extrusion

Aluminium extrusion offers numerous benefits that enhance its appeal in manufacturing:

- Lightweight and Durable: Aluminium's low density makes extruded products ideal for applications where weight reduction is crucial without compromising strength.

- Flexibility in Design: The extrusion process allows for complex shapes and designs that are difficult to achieve with other manufacturing methods.

- Cost-Effectiveness: The ability to produce intricate profiles without extensive machining reduces overall production costs.

- Sustainability: Aluminium is highly recyclable, and the extrusion process generates minimal waste, aligning with modern sustainability goals.

Applications of Aluminium Extrusion in Manufacturing

Aluminium extrusions are utilized across various sectors due to their versatility:

- Construction: Used in window frames, doors, and structural components due to their strength and resistance to corrosion.

- Automotive: Lightweight extrusions contribute to fuel efficiency while maintaining structural integrity in vehicles.

- Aerospace: Extruded components are essential for aircraft structures, offering high strength-to-weight ratios.

- Electronics: Used in heat sinks and enclosures due to excellent thermal conductivity properties.

Impact on Manufacturing Industries

The impact of aluminium extrusion on manufacturing industries can be summarized as follows:

Enhanced Efficiency

The lightweight nature of aluminium allows for faster assembly and transportation of products. This efficiency translates into reduced lead times and lower shipping costs.

Innovation in Design

The flexibility offered by aluminium extrusion enables designers to create innovative products that meet specific customer needs. This capability fosters creativity in product development across various sectors.

Economic Benefits

The aluminium industry supports a significant number of jobs and contributes substantially to the economy. In North America alone, over 660,000 workers are employed in this sector, generating approximately $170 billion in economic output annually[11].

Challenges Faced by Aluminium Extrusion Manufacturers

Despite its advantages, the aluminium extrusion industry faces several challenges:

- Raw Material Costs: Fluctuations in aluminium prices can impact production costs significantly[1].

- Energy Consumption: The extrusion process requires substantial energy input, prompting manufacturers to seek energy-efficient solutions[1].

- Quality Control: Maintaining consistent product quality is crucial; variations can lead to defects that affect customer satisfaction[1].

Future Trends in Aluminium Extrusion

The future of aluminium extrusion looks promising with emerging trends:

- Digitalization: Advanced technologies are being integrated into the extrusion process for better monitoring and quality assurance.

- Sustainability Initiatives: Manufacturers are increasingly adopting eco-friendly practices such as recycling scrap aluminium and utilizing renewable energy sources[1].

- Automation: Automation technologies are enhancing efficiency by reducing labor costs and minimizing errors during production[1].

Conclusion

Aluminium extrusion plays a pivotal role in modern manufacturing industries by providing lightweight, durable, and cost-effective solutions. Its flexibility in design fosters innovation while contributing significantly to economic growth. As manufacturers continue to embrace digitalization and sustainability initiatives, the future of aluminium extrusion appears bright.

FAQ

1. What is the main advantage of using aluminium extrusions?

Aluminium extrusions offer a lightweight yet strong solution suitable for various applications while allowing for complex designs at lower production costs.

2. How does the recycling process work for aluminium?

Aluminium can be recycled indefinitely without losing quality. The recycling process involves melting down scrap materials and reforming them into new products.

3. What industries benefit most from aluminium extrusion?

Industries such as construction, automotive, aerospace, and electronics benefit significantly from aluminium extrusions due to their lightweight properties and design flexibility.

4. What challenges do manufacturers face in the aluminium extrusion industry?

Manufacturers face challenges such as fluctuating raw material costs, energy consumption concerns, and maintaining consistent product quality.

5. How does automation impact the aluminium extrusion process?

Automation enhances efficiency by reducing labor costs, minimizing errors during production, and allowing for real-time monitoring of processes.

Citations:

[1] https://www.atieuno.com/2023/10/09/aluminium-extrusion-manufacturers/

[2] https://flowstore.com/understand-aluminium-extrusion-modern-manufacturing/

[3] https://www.youtube.com/watch?v=iiGlq7408ME

[4] https://www.youtube.com/watch?v=wD2sY6j6_oA

[5] https://starext.com/news/aluminum-extrusion-finishing-fabrication-frequently-asked-questions-faq

[6] https://aec.org/faqs

[7] https://www.zetwerk.com/resources/knowledge-base/aluminum-extrusions/top-applications-of-aluminum-extrusion-profiles-in-various-industries/

[8] https://aec.org/features-benefits

[9] https://www.gabrian.com/what-is-aluminum-extrusion-process/

[10] https://dajcor.com/learning-centre/content/2014/02/25/5-interesting-facts-about-aluminum-extrusion

[11] https://taberextrusions.com/taber-extrusions-social-study-aluminums-economic-impact/