Content Menu

● Introduction to Aluminum Extruders

>> Advantages of Aluminum Extruders

● Role of Steel Feeder Gear

● Installation of Upgraded Aluminum Extruder with Steel Feeder Gear

>> Installation Steps for Upgraded Aluminum Extruder

● Conclusion

● FAQ

>> 1. What are the primary benefits of using an upgraded aluminum extruder with steel feeder gear?

>> 2. How does the steel feeder gear improve filament feeding?

>> 3. What is the process for calibrating an upgraded aluminum extruder with steel feeder gear?

>> 4. Can an upgraded aluminum extruder with steel feeder gear be used in both Bowden and direct drive configurations?

>> 5. What materials are best suited for printing with an upgraded aluminum extruder with steel feeder gear?

● Citations:

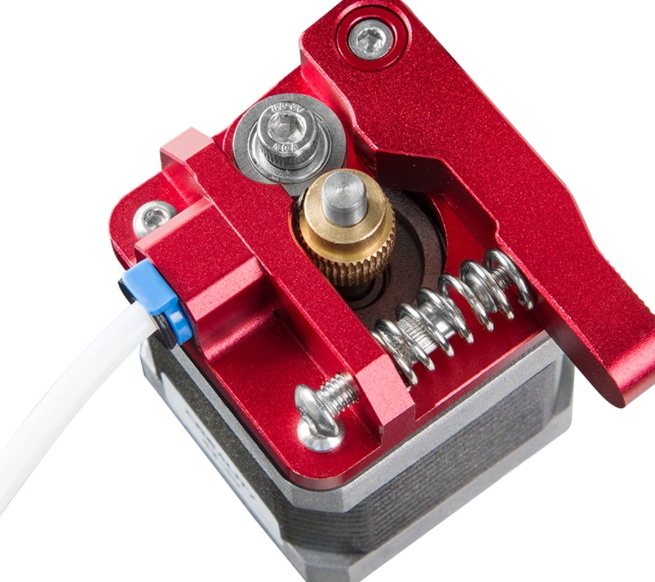

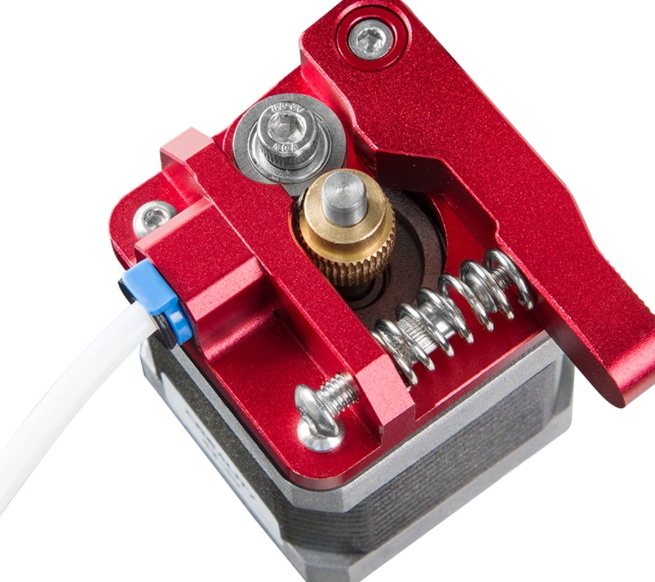

The integration of a steel feeder gear into an aluminum extruder represents a significant enhancement in 3D printing technology, particularly when it comes to improving print quality and durability. This article will delve into the specifics of how a steel feeder gear boosts the performance of an upgraded aluminum extruder with steel feeder gear, exploring its benefits, installation process, and calibration requirements.

Introduction to Aluminum Extruders

Aluminum extruders have become a popular choice for 3D printing due to their superior durability and consistency compared to traditional plastic extruders. The upgraded aluminum extruder with steel feeder gear offers enhanced filament feeding, reduced wear and tear, and improved temperature resistance, making it ideal for printing a wide range of materials, including flexible and abrasive filaments.

Advantages of Aluminum Extruders

1. Durability: Aluminum is more resistant to wear and tear than plastic, extending the lifespan of the extruder.

2. Consistent Filament Feeding: The rigidity of aluminum ensures consistent filament feeding, reducing the risk of slippage or jams.

3. Higher Temperature Resistance: Metal extruders can handle higher temperatures, allowing for the use of a broader range of filaments.

4. Better Grip: The dual gear mechanism, often featuring a steel feeder gear, provides a reliable and consistent filament feed.

Role of Steel Feeder Gear

The steel feeder gear plays a crucial role in enhancing the performance of the upgraded aluminum extruder with steel feeder gear. Here are some key benefits:

- Enhanced Grip: Steel gears offer a better grip on the filament, minimizing slippage and ensuring consistent feeding.

- Durability: Steel is more durable than plastic or aluminum gears, reducing wear and tear over time.

- Smooth Operation: The steel gear helps in maintaining smooth filament flow, which is critical for achieving high-quality prints.

Installation of Upgraded Aluminum Extruder with Steel Feeder Gear

Installing an upgraded aluminum extruder with steel feeder gear is relatively straightforward and can be completed in under an hour. Here's a step-by-step guide:

1. Preparation: Turn off and unplug your 3D printer. Remove any filament from the extruder.

2. Disassembly: Detach the Bowden tube from the stock extruder. Use an Allen wrench to remove the screws securing the stock extruder to the printer.

3. Component Removal: Carefully support the extruder motor as you remove the final screws.

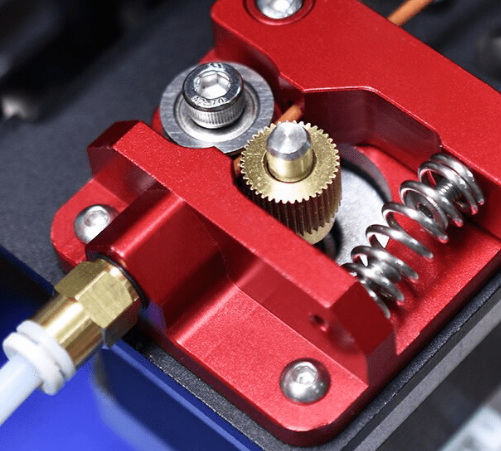

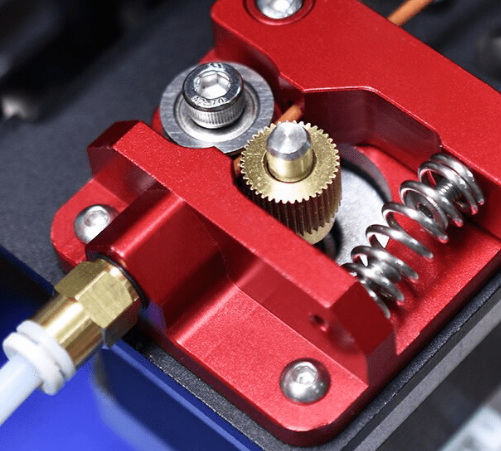

4. Gear Installation: Slide the new steel gear onto the motor shaft, aligning the grub screw with the flat side of the shaft.

5. Assembly: Attach the metal extruder housing using the provided screws. Ensure the motor cable is correctly oriented.

6. Lever Arm: Assemble the lever arm with the idler pulley and attach it to the housing, ensuring it moves freely.

7. Spring Installation: Position the spring and secure it with the retaining screw. The lever arm should spring back into place when pressed.

8. Re-attach the Bowden Tube: Depending on the design, the coupler may be built into the extruder housing or may be a separate piece that is screwed in. In either case, push the PTFE inward until it won't move and cannot be tugged back out.

9. Testing: Reconnect the wiring and power on the printer. Load filament and run a test print to ensure everything is functioning correctly.

10. Calibration: Calibrate the extruder by updating the printer's firmware settings to accommodate the new extruder specifications.

Installation Steps for Upgraded Aluminum Extruder

Calibrating the extruder after installing an upgraded aluminum extruder with steel feeder gear is essential for optimal performance. Here's how to do it:

1. Mark Filament: Measure and mark 120mm of filament from the extruder entrance.

2. Extrude Filament: Command the printer to extrude 100mm of filament.

3. Measure Remaining Filament: After extrusion, measure the remaining length of the marked filament.

4. Calculate New E-steps: Use the following formula to calculate the new E-steps value:

New E steps=Old E steps×(100mm/Actual Extrusion Length)

Where Actual Extrusion Length = 120mm - Remaining Length

5. Update Firmware: Update the E-steps value in your printer's firmware.

Conclusion

The upgraded aluminum extruder with steel feeder gear offers significant improvements in print quality and durability for 3D printing. By enhancing filament grip, reducing wear and tear, and allowing for higher temperature resistance, this setup is ideal for printing a variety of filaments, including flexible and abrasive materials. Proper installation and calibration are crucial to maximize the benefits of this upgrade.

FAQ

1. What are the primary benefits of using an upgraded aluminum extruder with steel feeder gear?

The primary benefits include enhanced durability, consistent filament feeding, improved print quality, and the ability to handle a wider range of filaments, including flexible and abrasive materials.

2. How does the steel feeder gear improve filament feeding?

The steel feeder gear provides a better grip on the filament, minimizing slippage and ensuring consistent feeding, which is crucial for achieving high-quality prints.

3. What is the process for calibrating an upgraded aluminum extruder with steel feeder gear?

Calibration involves measuring the actual extrusion length of filament, calculating new E-steps using a formula, and updating these values in the printer's firmware to ensure accurate filament extrusion.

4. Can an upgraded aluminum extruder with steel feeder gear be used in both Bowden and direct drive configurations?

Yes, this extruder can be used in both configurations. Direct drive setups are particularly beneficial for printing flexible filaments, as they reduce the risk of buckling or jamming.

5. What materials are best suited for printing with an upgraded aluminum extruder with steel feeder gear?

This setup is suitable for a wide range of materials, including PLA, ABS, PETG, TPU (flexible), carbon fiber infused, and nylon, offering excellent performance with both standard and more challenging filaments.

Citations:

[1] https://www.yjing-extrusion.com/is-the-upgraded-aluminum-extruder-v2-worth-the-investment-for-better-print-quality.html

[2] https://www.gabrian.com/what-is-aluminum-extrusion-process/

[3] https://patents.google.com/patent/WO2018035967A1/en

[4] https://www.aliexpress.com/i/1005005617004543.html

[5] https://www.youtube.com/watch?v=iiGlq7408ME

[6] https://pdf.directindustry.com/pdf/fong-kee-iron-works-co-ltd/catalog/76032-489093.html

[7] https://asia.store.bambulab.com/products/hardened-steel-extruder-gear-assembly

[8] https://www.linkedin.com/pulse/aluminum-extrusion-process-10-steps-video-clips-nomexfelt