Content Menu

● Understanding Aluminum Extrusion Frames

>> Benefits of Using Aluminum Extrusion Frames

● Components of a Vacuum Press System

● How to Hold Film on an Aluminum Extrusion Frame

>> 1. Using Gaskets

>> 2. Clamping Mechanisms

>> 3. Film Tensioning Techniques

>> 4. Vacuum Bagging

● Tips for Successful Vacuum Pressing

● Conclusion

● FAQ

>> 1. What type of film should I use for vacuum pressing?

>> 2. How do I know if my vacuum pump is powerful enough?

>> 3. Can I use any adhesive with my vacuum press?

>> 4. What maintenance does my aluminum extrusion frame require?

>> 5. Is it necessary to pre-stretch my film before applying it?

● Citations:

Vacuum pressing is a widely used technique in woodworking and various manufacturing processes, allowing for the efficient application of pressure to materials. One of the essential components of this process is the aluminum extrusion frame, which provides a sturdy structure for holding film and other materials during vacuum pressing. This article will explore the methods and techniques for effectively holding film on an aluminum extrusion frame for vacuum pressing, ensuring optimal results.

Understanding Aluminum Extrusion Frames

Aluminum extrusion frames are versatile structures made by forcing aluminum through a die to create specific shapes. These frames are lightweight, strong, and resistant to corrosion, making them ideal for use in vacuum pressing applications. The T-slot design of many aluminum extrusions allows for easy assembly and customization, accommodating various sizes and shapes of materials.

Benefits of Using Aluminum Extrusion Frames

- Strength and Durability: Aluminum is known for its high strength-to-weight ratio, making it suitable for supporting heavy materials under vacuum pressure.

- Corrosion Resistance: Aluminum does not rust, which is advantageous in environments where moisture may be present.

- Customizability: The T-slot design enables users to easily modify the frame to fit different projects.

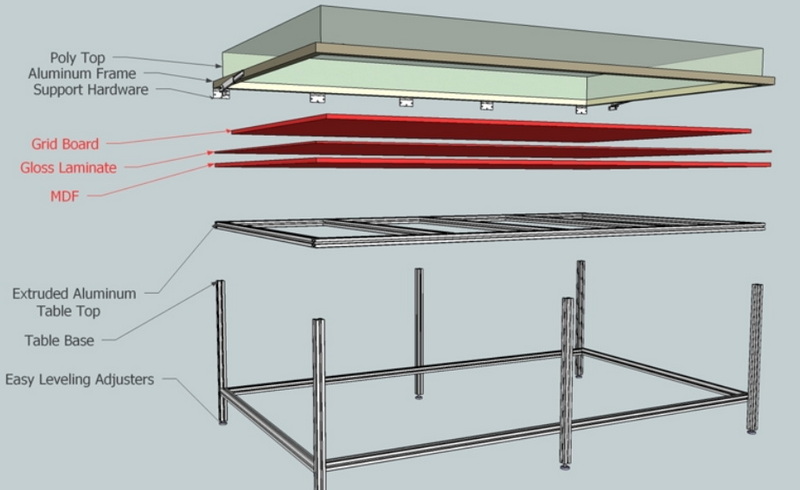

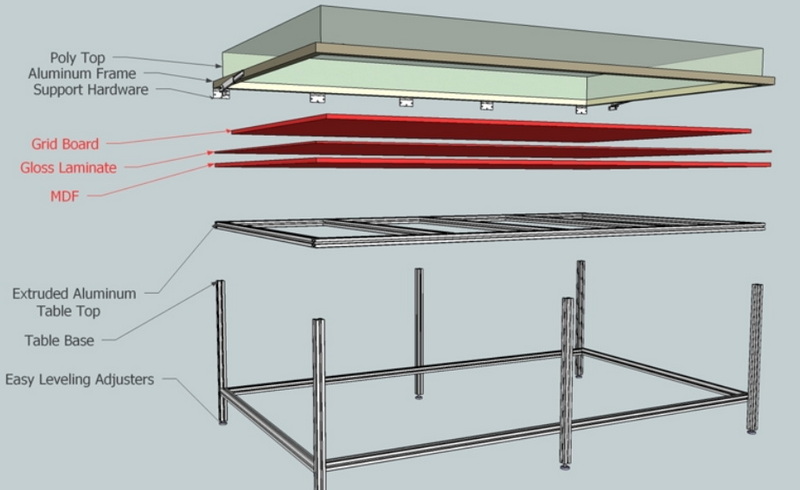

Components of a Vacuum Press System

A typical vacuum press system consists of several key components:

- Aluminum Extrusion Frame: The structural base that holds the film and materials.

- Vacuum Pump: This device removes air from the system, creating a vacuum that applies pressure to the materials.

- Silicone Rubber Membrane: This flexible material covers the workpiece, allowing it to conform to various shapes while maintaining a seal.

- Gaskets and Seals: These components ensure airtight connections between different parts of the system.

How to Hold Film on an Aluminum Extrusion Frame

Holding film securely on an aluminum extrusion frame is crucial for achieving even pressure during vacuum pressing. Here are several methods to effectively secure film:

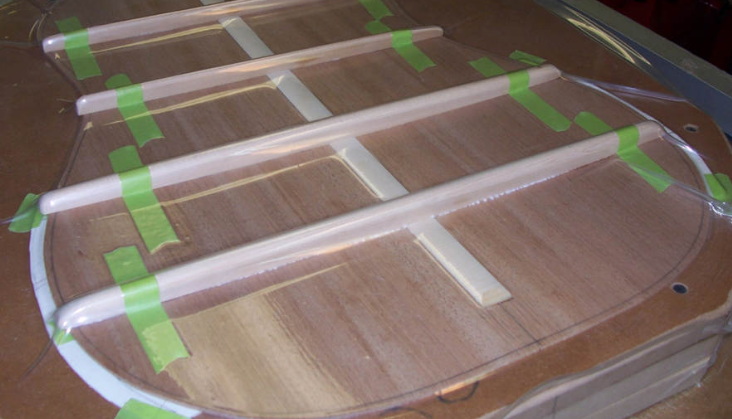

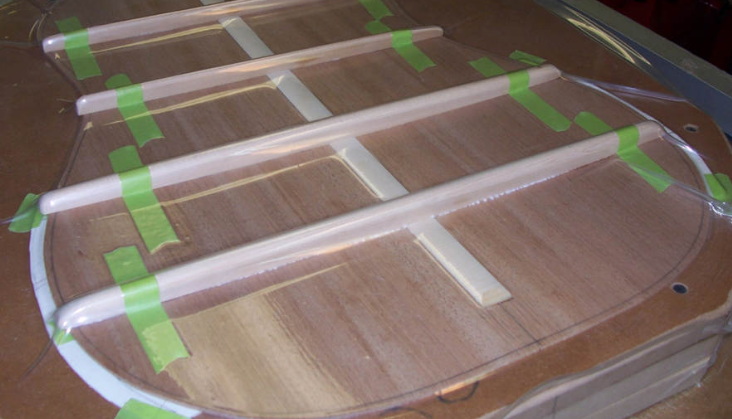

1. Using Gaskets

Gaskets made from materials like neoprene or EVA foam can be attached to the edges of the aluminum frame. These gaskets create a tight seal when the film is placed over them, preventing air leaks during the vacuum process.

- Installation Steps:

- Cut gaskets to fit the perimeter of the frame.

- Attach gaskets using adhesive or screws.

- Ensure that gaskets are clean and free from debris before placing film over them.

2. Clamping Mechanisms

Incorporating clamps into the design can provide additional security for holding film in place. Various types of clamps can be used, including:

- Spring Clamps: Quick and easy to use, these clamps apply constant pressure along the edges of the film.

- C-Clamps: For more substantial pressure, C-clamps can be employed at critical points along the frame.

- Toggle Clamps: These offer a strong hold without damaging the film surface.

3. Film Tensioning Techniques

To achieve optimal results, it's essential to maintain tension on the film as it is applied over the workpiece. Here are some techniques:

- Pre-stretching: Before securing the film, stretch it slightly to remove wrinkles and ensure it lies flat against the workpiece.

- Using Weights: Place weights around the edges of the film while securing it to help maintain tension.

4. Vacuum Bagging

Vacuum bags can also be used in conjunction with aluminum extrusion frames. This method involves placing both the workpiece and film inside a vacuum bag that is sealed around the edges.

- Steps for Vacuum Bagging:

- Place your workpiece on a flat surface.

- Cover it with film.

- Insert everything into a vacuum bag.

- Seal the bag according to manufacturer instructions.

- Connect your vacuum pump and evacuate air until desired pressure is reached.

Tips for Successful Vacuum Pressing

To ensure effective vacuum pressing with an aluminum extrusion frame, consider these tips:

- Maintain Clean Surfaces: Ensure that both the frame and film surfaces are clean before starting. Dust or debris can compromise seals.

- Check Seals Regularly: Inspect gaskets and seals frequently for wear or damage that could lead to air leaks.

- Use Proper Adhesives: When bonding materials, select adhesives designed for use with vacuum pressing to prevent bleed-through or failure under pressure.

Conclusion

Holding film securely on an aluminum extrusion frame during vacuum pressing is essential for achieving high-quality results in woodworking and manufacturing processes. By utilizing gaskets, clamps, tensioning techniques, and vacuum bagging methods, users can ensure that their materials are held firmly in place throughout the pressing process. With proper setup and maintenance, an aluminum extrusion frame can significantly enhance efficiency and effectiveness in various applications.

FAQ

1. What type of film should I use for vacuum pressing?

For best results, use films specifically designed for vacuum pressing applications, such as polyethylene or polyurethane films that offer good clarity and strength.

2. How do I know if my vacuum pump is powerful enough?

A good rule of thumb is to have a pump capable of achieving at least 20 inches of mercury (Hg) for effective vacuum pressing.

3. Can I use any adhesive with my vacuum press?

Not all adhesives are suitable; choose those specifically formulated for use with vacuum presses to avoid issues like bleed-through or inadequate bonding strength.

4. What maintenance does my aluminum extrusion frame require?

Regularly inspect seals and gaskets for wear or damage, clean surfaces before use, and ensure that all components are securely fastened.

5. Is it necessary to pre-stretch my film before applying it?

While not always necessary, pre-stretching your film can help eliminate wrinkles and ensure a tighter fit against your workpiece, leading to better results during pressing.

Citations:

[1] https://www.youtube.com/watch?v=9ynFpxokWlM

[2] https://hackaday.com/2020/08/13/under-pressure-how-aluminum-extrusions-are-made/

[3] http://www.vacuum-press.com/table.html

[4] https://veneersystems.com/product/flip-top-frame-49-inch-by-121-inch/

[5] https://www.youtube.com/watch?v=emaAg568qdo

[6] https://www.henryholsters.com/product/swiftpress/

[7] https://www.clampusystems.com/info-instructions/questions-answers/

[8] https://www.youtube.com/watch?v=LuqR3P6LJWM

[9] https://woodweb.com/knowledge_base/Frame_press__Troubleshooting_Flatness_Problems_wit.html

[10] https://vac-u-clamp.com/vacuum-presses/the-sp-series-vacuum-press/

[11] https://www.joewoodworker.com/veneering/vacuum-frame-press.htm

[12] https://cnc-clamping.com/vacuum-press/vacuum-press-4030

[13] https://www.alibaba.com/showroom/vacuum-printing-frame.html

[14] https://www.youtube.com/watch?v=emaAg568qdo

[15] https://www.youtube.com/watch?v=6DkTeIyAwZE

[16] https://www.wehomachinery.com/products/membrane-film-vacuum-press.html

[17] https://www.youtube.com/watch?v=8dNCQGarMxU

[18] https://qualityvak.com/frame.html

[19] https://yinmei.en.made-in-china.com/product/sjqEAfuFZkVg/China-Customized-Aluminum-Frame-Vacuum-Table-Honeycomb-Core-for-UV-Flatbed-Printer.html

[20] https://us.misumi-ec.com/vona2/mech/M1500000000/M1501000000/M1501200000/

[21] https://www.researchgate.net/figure/Different-stages-of-vacuum-press-compression-molding_tbl1_363357713

[22] https://www.easycomposites.co.uk/learning/hand-laminate-vacuum-bag-simple-part

[23] https://www.wurthbaermachinery.com/VacuPress-Flip-Top-Table-Kits

[24] https://www.dynisco.com/userfiles/files/27429_Legacy_Txt.pdf

[25] https://www.youtube.com/watch?v=bVb3BPQBGtA

[26] https://davelers.com/Workshop/Veneering/Presses/1731.html

[27] https://www.thegrumble.com/threads/homemade-vacuum-press.53004/

[28] https://www.henryholsters.com/product/swiftpress/

[29] https://www.youtube.com/watch?v=XqiroMdqZ0Y

[30] https://www.joewoodworker.com/veneering/visitorspress.htm

[31] https://qualityvak.com/structuralaluminum.html

[32] https://www.youtube.com/watch?v=SvCpem1abwU

[33] https://www.pinterest.com/ideas/veneer-vacuum-press/936655532422/

[34] https://www.joewoodworker.com/veneering/visitorspress2.htm

[35] https://www.woodshopnews.com/tools-machines/vacuum-pressing

[36] https://www.facebook.com/qualityvak/videos/vacuum-table-press-for-veneering-and-laminating/10155692921423527/

[37] https://www.woodmagazine.com/woodworking-how-to/veneer-inlay/vacuum-bag-veneering

[38] https://anver.com/vacuum-components/vacuum-cups/slsa-3-aluminum/

[39] https://www.cnczone.com/forums/diy-cnc-router-table-machines/6423-cnc.html

[40] https://us.misumi-ec.com/maker/misumi/mech/product/al/faq/

[41] https://qualityvak.com/faq.html

[42] https://www.joewoodworker.com/veneering/faq-veneering.htm

[43] https://aec.org/faqs

[44] https://www.practicalmachinist.com/forum/threads/vacuum-rated-aluminum.88506/

[45] https://www.joewoodworker.com/veneering/faq.htm

[46] https://starext.com/news/aluminum-extrusion-finishing-fabrication-frequently-asked-questions-faq

[47] https://sawmillcreek.org/showthread.php

[48] https://www.youtube.com/watch?v=LuqR3P6LJWM

[49] https://www.inglet.com/en/producto/cold-vacuum-press/