Content Menu

● Overview of Aluminum Extrusion

>> What is Aluminum Extrusion?

>> The Process of Aluminum Extrusion

● Aluminum Extruders in Portage MI

>> Erbsloeh Aluminum Solutions Inc.

● Comparison with Other Locations

● Market Dynamics

● Technological Innovations

● Applications Across Industries

● Environmental Considerations

● Conclusion

● FAQ

>> 1. What industries use aluminum extrusions?

>> 2. How does the aluminum extrusion process work?

>> 3. What are some advantages of using aluminum over other materials?

>> 4. How does Portage MI compare in terms of employment opportunities in aluminum extrusion?

>> 5. Are there any environmental considerations with aluminum extrusion?

● Citations:

Aluminum extrusion is a vital manufacturing process that shapes aluminum into various profiles for multiple applications, including construction, automotive, and consumer goods. Among the many locations in the United States, Portage, Michigan, stands out as a significant hub for aluminum extrusion, particularly through companies like Erbsloeh Aluminum Solutions, Inc. This article explores how aluminum extruders in Portage compare to those in other regions across the country, focusing on production capabilities, market presence, and technological advancements.

Overview of Aluminum Extrusion

What is Aluminum Extrusion?

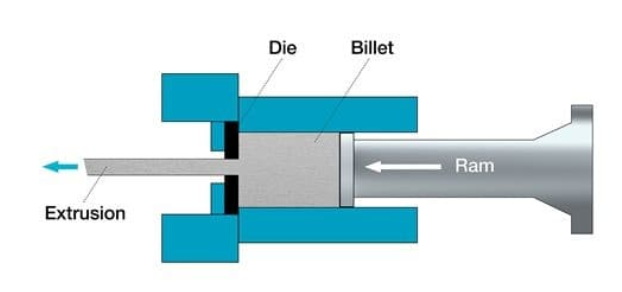

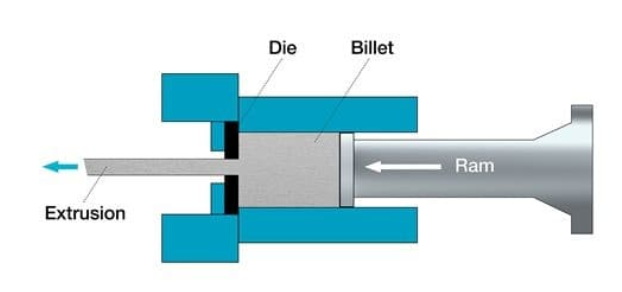

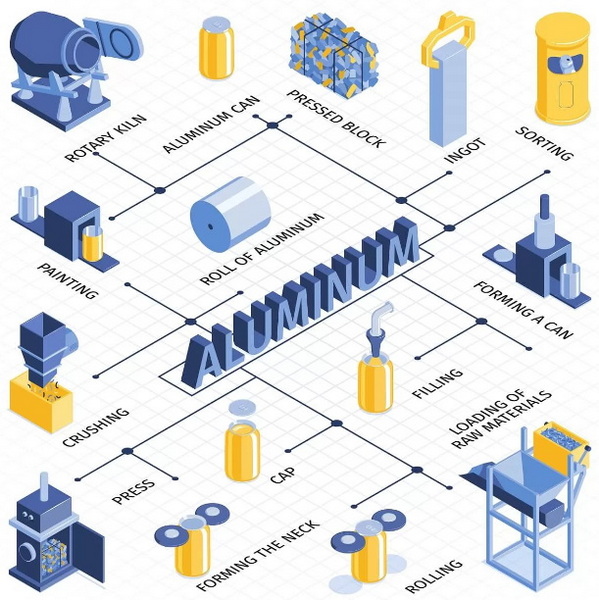

Aluminum extrusion involves forcing heated aluminum alloy through a die to create a specific cross-sectional profile. This process allows manufacturers to produce long lengths of aluminum with uniform shapes, which can be cut to size for various applications. The versatility and strength of extruded aluminum make it an essential material in many industries.

The Process of Aluminum Extrusion

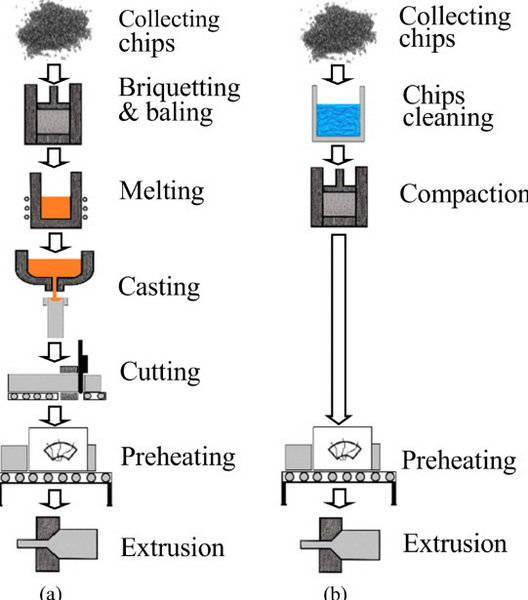

The extrusion process typically includes several key steps:

1. Preparation of the Die: The die is preheated to ensure optimal metal flow.

2. Heating the Billet: An aluminum billet is heated to a malleable state.

3. Extrusion: The heated billet is forced through the die under high pressure.

4. Cooling: The extruded profile is cooled, often through quenching methods.

5. Finishing: The extruded shapes may undergo additional processes like anodizing or machining.

For a visual representation of this process, you can refer to videos available online that demonstrate each step of aluminum extrusion.

Aluminum Extruders in Portage MI

Erbsloeh Aluminum Solutions Inc.

Located at 6565 S Sprinkle Road, Portage MI, Erbsloeh Aluminum Solutions is one of the prominent players in the aluminum extrusion industry in this region. The company operates three hydraulic extrusion lines within a 315,000 square-foot facility and employs around 500 people.

Erbsloeh specializes in producing extruded and surface-finished aluminum profiles for various applications, including:

- Furniture Industry: Manufacturing handles and moldings.

- Electronics: Components for high-end appliances and air conditioning technology.

- Industrial Applications: Cross sections for diverse industrial uses.

The company's commitment to quality and innovation has established it as a key employer in the Kalamazoo area and a significant contributor to the local economy.

Comparison with Other Locations

To understand how Portage's aluminum extruders stack up against those in other regions, we can look at some leading companies across the United States.

| Company Name | Location | Number of Employees | Specialization |

| Hydro Extrusion USA, LLC | Cressona, PA | 1,100 | Tubes and building systems |

| Western Extrusions Corp. | Carrollton, TX | 950 | Custom extrusions with cradle-to-recycle services |

| Crystal Finishing Systems, Inc. | Schofield, WI | 850 | Essential industry components during COVID-19 |

| Universal Alloy Corp. | Canton, GA | 650 | Aerospace industry products |

| Bonnell Aluminum | Newnan, GA | 500 | Quality flooring trims for buildings |

| Erbsloeh Aluminum Solutions | Portage, MI | 500 | Industrial applications across multiple sectors |

From this comparison table, it is evident that while Erbsloeh Aluminum Solutions has a solid workforce similar to Bonnell Aluminum and Tower Extrusions (both with 500 employees), companies like Hydro Extrusion USA lead significantly in terms of employment and production capacity.

Market Dynamics

Aluminum extrusion companies across the U.S. have adapted to various market conditions over recent years. For instance:

- Tariffs and Trade Policies: The introduction of tariffs on imported aluminum has benefited domestic manufacturers by leveling the playing field against cheaper foreign products.

- Technological Advancements: Companies are increasingly adopting robotics and automation to enhance productivity while addressing labor shortages caused by events like the COVID-19 pandemic.

- Regional Distribution: Approximately 38% of U.S. aluminum extruders are located in the Midwest, where Portage is situated. This regional concentration allows for better supply chain management and collaboration among manufacturers.

Technological Innovations

Portage's aluminum extruders are not only competitive due to their workforce size but also because of their commitment to technological advancements:

- Advanced Machinery: Companies like Erbsloeh utilize state-of-the-art extrusion presses and precision tooling that ensure high-quality production with tight tolerances.

- Diverse Capabilities: Many manufacturers offer additional services such as CNC machining, anodizing, and powder coating to enhance their product offerings beyond basic extrusion.

Recent advancements have also introduced new technologies into the aluminum extrusion process:

1. Artificial Intelligence (AI): AI algorithms analyze real-time data from machinery to optimize production processes and ensure quality control.

2. Robotics Automation: Robotics are being used for material handling and quality inspections to minimize human error and improve efficiency.

3. 3D Printing Integration: The combination of 3D printing with traditional extrusion methods allows for more complex designs that were previously difficult or impossible to achieve.

4. Nano-Coating Technologies: These ultra-thin coatings enhance durability by providing an extra layer of protection against corrosion and abrasion.

5. Smart Manufacturing Techniques: IoT technology enables real-time monitoring of production lines, leading to enhanced efficiency and predictive maintenance capabilities.

Applications Across Industries

Aluminum extrusions are utilized across various industries due to their lightweight yet strong characteristics:

- Electronics: Used for heat sinks that manage heat generated by electronic devices due to their excellent thermal conductivity.

- Automotive: Increasingly replacing steel in many car parts because of its lighter weight; used in housings and gear pumps among other applications.

- Aerospace: High-strength alloys are commonly employed in aircraft fuselages and wing structures due to their resistance to corrosion.

- Construction: Lightweight yet strong profiles are essential for modern architectural designs focusing on energy efficiency.

- Consumer Goods: From furniture frames to kitchen appliances, aluminum's versatility allows for innovative designs while maintaining durability.

Environmental Considerations

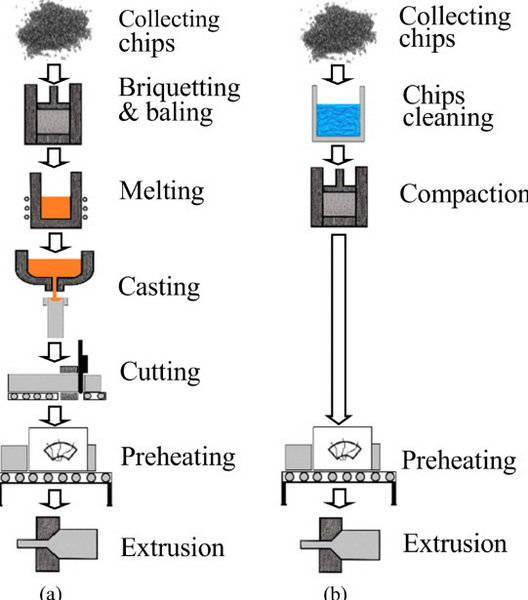

The aluminum extrusion industry is increasingly focusing on sustainability practices:

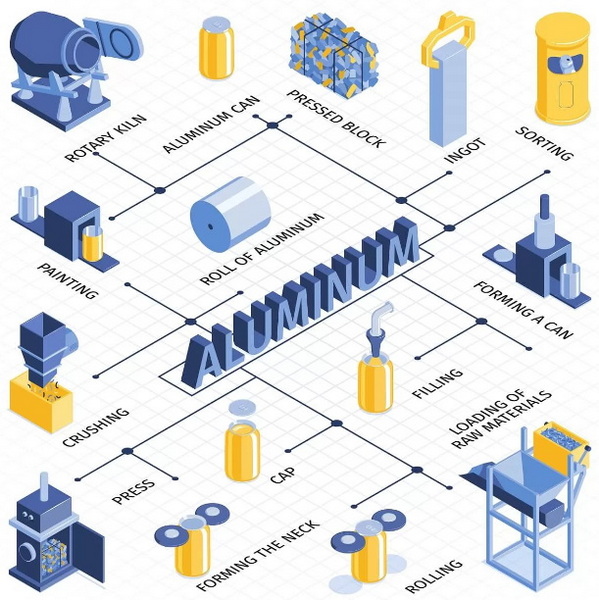

- Recycling Initiatives: Aluminum is 100% recyclable without losing its properties; many companies are implementing recycling programs that reduce waste and promote sustainability.

- Energy Efficiency Improvements: New technologies are being developed that reduce energy consumption during production processes while maintaining high-quality output.

- Carbon Footprint Reduction Strategies: Manufacturers are working towards reducing emissions throughout the entire production chain—from raw material extraction to end-of-life recycling.

Conclusion

In conclusion, while Portage MI houses significant players like Erbsloeh Aluminum Solutions with robust production capabilities and a skilled workforce, it faces competition from larger companies in other states that have greater employee numbers and specialized production focuses. The region's strategic advantages include its central location within the Midwest manufacturing hub and its access to advanced technologies that keep it competitive.

As industries continue to evolve with technological advancements and changing market dynamics, Portage's aluminum extruders are well-positioned to adapt and thrive alongside their counterparts across the nation.

FAQ

1. What industries use aluminum extrusions?

Aluminum extrusions are widely used in construction, automotive manufacturing, electronics production, furniture design, and consumer goods industries.

2. How does the aluminum extrusion process work?

The process involves heating an aluminum billet until malleable and then forcing it through a die under high pressure to create specific profiles.

3. What are some advantages of using aluminum over other materials?

Aluminum is lightweight yet strong, resistant to corrosion, easy to work with due to its malleability, and recyclable without losing its properties.

4. How does Portage MI compare in terms of employment opportunities in aluminum extrusion?

Portage MI has significant employment opportunities with companies like Erbsloeh Aluminum Solutions employing around 500 people; however, larger firms elsewhere may employ more.

5. Are there any environmental considerations with aluminum extrusion?

Yes, many companies are implementing sustainable practices such as recycling scrap aluminum and using energy-efficient machinery to reduce their environmental impact.

Citations:

[1] https://americandouglasmetals.com/2024/05/19/understanding-the-aluminum-extrusion-process/

[2] https://www.gabrian.com/aluminium-extrusions/industries/

[3] https://shop.machinemfg.com/understanding-the-aluminum-extrusion-process/

[4] https://www.explorium.ai/manufacturing/companies/wkw-extrusion-erbsloeh-aluminum-solutions

[5] https://www.wkw-group.com/en/subsidiaries/north-america/erbsloeh-aluminum-solutions-inc/company

[6] https://profileprecisionextrusions.com/the-evolution-of-aluminum-extrusions-emerging-trends-and-technologies/

[7] https://www.alcirclebiz.com/blogs/innovations-in-aluminium-extrusion-meeting-modern-industry-demands

[8] https://yamunaind.com/innovation-spotlight-recent-advancements-in-aluminium-extrusion-technology/

[9] https://proleantech.com/aluminum-extrusion-applications-across-industries/

[10] https://www.fortune-alu.com/info-detail/trends-shaping-the-future-of-aluminum-extrusion

[11] https://www.alcircle.com/news/tech-trends-driving-the-aluminium-extrusion-industry-111131

[12] https://americandouglasmetals.com/2023/12/20/global-aluminum-extrusion-market-2023-2030-growth-trends-key-players-and-industry-insights/

[13] https://www.richardsonmetals.com/innovations-in-aluminum-extrusion-pioneering-precision-and-quality/

[14] https://extal.com/en/the-evolution-of-aluminum-extrusion-techniques-with-extal/

[15] https://nationalindustries.world/2025/01/02/the-future-of-aluminum-how-extrusion-technology-is-transforming-industries/