Content Menu

● Introduction to MK8 Extruders

>> Advantages of Aluminum MK8 Extruders

● Delving Deeper into the Benefits

>> Enhanced Durability

>> Superior Filament Control

>> Expanded Material Compatibility

>> Unlocking Precision Printing

● Choosing the Right MK8 Aluminum Extruder

● Installation and Maintenance

>> Installation Steps

>> Maintenance Tips

● Conclusion

● Frequently Asked Questions

>> 1. What types of filaments can I use with an Aluminum MK8 extruder?

>> 2. Is it difficult to install an MK8 aluminum extruder?

>> 3. Will upgrading my extruder void my printer's warranty?

>> 4. How does an aluminum extruder improve print quality?

>> 5. Can I use an MK8 aluminum extruder on any 3D printer?

● Citations:

Upgrading your 3D printer with an aluminum MK8 extruder replacement can significantly enhance your printing experience. This article will delve into the benefits of making this upgrade, including improved durability, better filament control, and enhanced print quality. We will also explore the installation process and provide tips on selecting the right extruder for your needs.

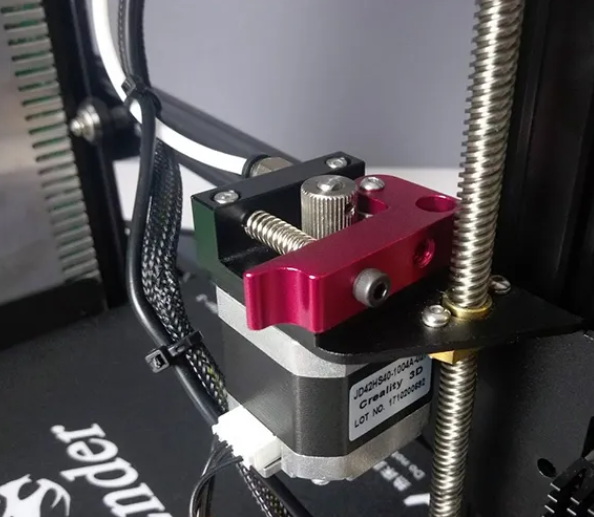

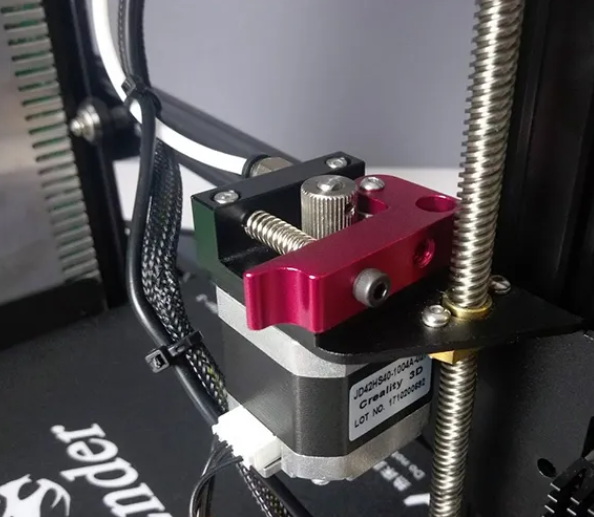

Introduction to MK8 Extruders

The MK8 extruder is a popular upgrade for many 3D printers, particularly those in the Creality series like the Ender 3 and CR-10. It is designed to replace stock plastic extruders, which often suffer from issues such as wear and tear, inconsistent extrusion, and limited temperature resistance.

Advantages of Aluminum MK8 Extruders

Aluminum MK8 extruders offer several advantages over their plastic counterparts:

- Durability: Aluminum is more robust and can withstand higher mechanical stress without cracking or warping, ensuring a longer lifespan for your extruder.

- Improved Filament Control: The design of aluminum extruders provides a better grip on the filament, reducing slippage and ensuring consistent extrusion.

- Higher Temperature Resistance: Aluminum can handle higher temperatures, making it suitable for printing with a wide range of filaments, including ABS and PETG.

- Precision Printing: Aluminum extruders contribute to better layer adhesion and reduced stringing, resulting in smoother surfaces and finer details in printed objects.

- Ease of Installation: Most MK8 aluminum extruders come as DIY kits that are easy to install, requiring minimal technical knowledge.

Delving Deeper into the Benefits

Enhanced Durability

Stock plastic extruders are prone to wear and tear due to the constant pressure and friction from the filament. Over time, this can lead to inconsistent extrusion and a decline in print quality. In contrast, aluminum extruders are built to last, withstanding significant mechanical stress without showing signs of wear.

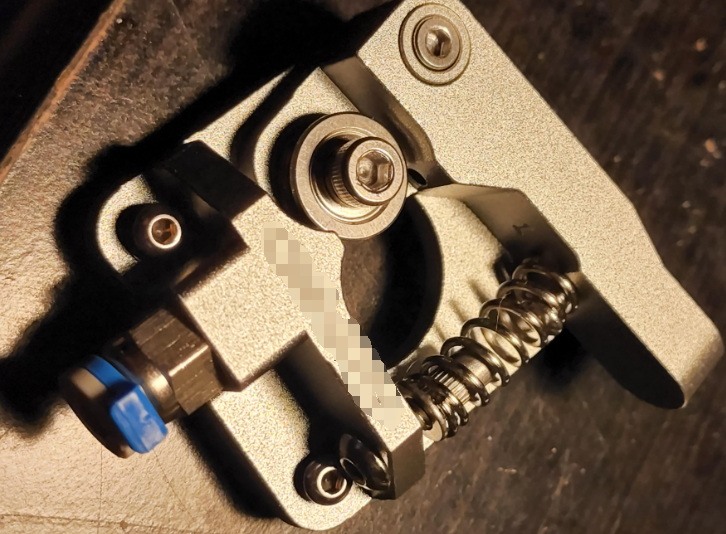

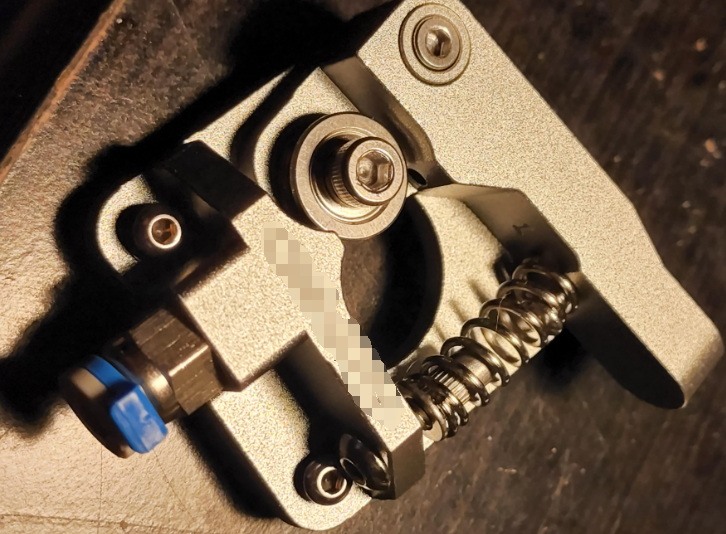

Superior Filament Control

One of the most common issues with stock extruders is their inability to maintain a consistent grip on the filament. This can result in slippage, under-extrusion, and inconsistent layer adhesion. The MK8 aluminum extruder is designed with a more aggressive grip that firmly holds the filament, providing better control during the printing process.

Expanded Material Compatibility

Stock extruders often struggle with high-temperature filaments like ABS and nylon. The plastic components can soften or deform under extreme heat, leading to extrusion problems and potentially damaging the extruder itself. Aluminum extruders excel in high-temperature environments due to their superior heat resistance.

| Filament Type | Stock Plastic Extruder | Aluminum MK8 Extruder |

| PLA | Compatible | Compatible |

| ABS | Limited | Compatible |

| PETG | Limited | Compatible |

| TPU | Difficult | Compatible |

Unlocking Precision Printing

Achieving high-quality prints requires precise control over the extrusion process. Inconsistent extrusion can lead to a variety of issues, such as stringing, blobs, and poor layer adhesion. The MK8 aluminum extruder offers superior precision compared to stock extruders, contributing to smoother layers and overall improved print quality.

Choosing the Right MK8 Aluminum Extruder

When selecting an MK8 aluminum extruder, consider the following factors:

- Compatibility: Ensure that the extruder is compatible with your 3D printer model. Check the product specifications or consult with the manufacturer to confirm compatibility.

- Material Quality: Look for extruders made from high-quality aluminum alloy for maximum durability and heat resistance.

- Kit Contents: Verify that the kit includes all necessary components for installation, such as screws, fittings, and a replacement Bowden tube if needed.

- Customer Reviews: Read reviews from other users to get an idea of the extruder's performance, ease of installation, and overall reliability.

Installation and Maintenance

Installation Steps

Upgrading to an MK8 aluminum extruder is relatively straightforward and can be done in a few steps:

1. Remove the Stock Extruder: Begin by unbolting the existing plastic extruder from your 3D printer. Make sure to keep any screws or components that may be reused.

2. Install the Aluminum Extruder: Align the new MK8 aluminum extruder with the mounting holes on your printer. Secure it using the screws provided in your kit.

3. Connect Filament Path: Ensure that the filament path is clear and properly aligned with the hot end. This may involve adjusting or replacing the Bowden tube if necessary.

4. Calibrate Your Printer: After installation, it's crucial to calibrate your printer settings to accommodate any changes in extrusion parameters due to the new extruder.

5. Test Printing: Finally, run a test print to ensure everything is functioning correctly and make any necessary adjustments.

Maintenance Tips

To keep your MK8 aluminum extruder performing at its best, follow these maintenance tips:

- Regular Cleaning: Periodically clean the extruder gear and filament path to remove any debris or accumulated filament dust.

- Lubrication: Apply a small amount of lubricant to the moving parts of the extruder, such as the idler pulley, to ensure smooth operation.

- Inspection: Regularly inspect the extruder for any signs of wear or damage. Replace any worn or damaged parts promptly to prevent further issues.

- Proper Storage: When not in use, store the extruder in a clean and dry environment to prevent corrosion or contamination.

Conclusion

Upgrading to an aluminum MK8 extruder is a significant step towards enhancing your 3D printing experience. With its improved durability, better filament control, and enhanced print quality, this upgrade is beneficial for both hobbyists and professionals. Whether you're looking to improve print consistency or expand your material options, an aluminum MK8 extruder is a worthwhile investment.

Frequently Asked Questions

1. What types of filaments can I use with an Aluminum MK8 extruder?

You can use a wide range of filaments with an aluminum MK8 extruder, including PLA, ABS, PETG, TPU (flexible), and specialty filaments that require higher temperatures[1][4].

2. Is it difficult to install an MK8 aluminum extruder?

Installing an MK8 aluminum extruder is relatively easy and can be done with basic tools. Most kits come with all necessary components and instructions for a straightforward installation process[1][4].

3. Will upgrading my extruder void my printer's warranty?

Upgrading your extruder may void your printer's warranty, depending on the manufacturer's policies. It's advisable to check with the manufacturer before making any modifications[1].

4. How does an aluminum extruder improve print quality?

An aluminum extruder improves print quality by providing consistent filament flow, better layer adhesion, and reduced stringing. This results in smoother surfaces and finer details in printed objects[1][8].

5. Can I use an MK8 aluminum extruder on any 3D printer?

While MK8 aluminum extruders are compatible with many popular 3D printers, it's essential to check compatibility with your specific printer model before purchasing[4].

Citations:

[1] https://www.yjing-extrusion.com/why-should-you-choose-an-mk8-extruder-aluminum-over-stock-extruders.html

[2] https://goindustrial.com/products/creality-mk8-black-aluminum-extruder

[3] https://www.youtube.com/watch?v=TPyTiZ6-_jM

[4] https://www.yjing-extrusion.com/is-the-aluminum-mk8-extruder-compatible-with-all-3d-printers.html

[5] https://www.creality.store/products/all-metal-extruder-aluminum-mk8-extruder-with-capricorn-tubing

[6] https://novo3d.in/mk8-extruder/

[7] https://electropeak.com/mk8-extruder-aluminum-block-kit-for-3d-printers

[8] https://www.yjing-extrusion.com/how-does-the-creality-mk8-aluminum-extruder-improve-filament-flow.html

[9] https://3dpart.se/en/products/mk8-extruder-alu-kitt-vanster

[10] https://www.yjing-extrusion.com/is-an-aluminum-mk8-extruder-upgrade-worth-it.html

[11] https://www.reddit.com/r/ender5plus/comments/n02dbn/reason_to_upgrade_to_an_all_metal_mk8_extruder/

[12] https://makersupplies.sg/products/upgraded-mk8-aluminium-extruder-feed-replacement-kit-for-creality-cr-ender

[13] https://www.aliexpress.com/item/32948241656.html

[14] https://www.aliexpress.com/item/1005004923874649.html

[15] https://www.ebay.com.au/itm/126115804391

[16] https://www.aliexpress.com/item/1005006200193071.html

[17] https://www.youtube.com/watch?v=hKqs-mR0urw

[18] https://www.aliexpress.com/item/1005006911732981.html