Content Menu

● Understanding Aluminum Extrusion

>> The Extrusion Process

● What Makes Miniature Aluminum Extrusion Presses Unique?

>> Key Features of Miniature Aluminum Extrusion Presses

>> Types of Miniature Aluminum Extrusion Presses

● Applications of Miniature Aluminum Extrusions

● Advantages of Using Miniature Aluminum Extrusions

● Challenges in Miniature Aluminum Extrusion

● Future Trends in Miniature Aluminum Extrusion

● Conclusion

● FAQ

>> 1. What is a miniature aluminum extrusion?

>> 2. How does an aluminum extrusion press work?

>> 3. What industries use miniature aluminum extrusions?

>> 4. What are the benefits of using aluminum for extrusions?

>> 5. Can miniature aluminum extrusions be customized?

In recent years, the demand for "miniature aluminum extrusions" has surged across various industries, including electronics, medical devices, and automotive manufacturing. A miniature aluminum extrusion press is a specialized machine designed to produce these small, intricate aluminum profiles with high precision. This article delves into the workings of a miniature aluminum extrusion press, its applications, and the technology behind it.

Understanding Aluminum Extrusion

Aluminum extrusion is a manufacturing process that involves shaping aluminum alloy by forcing it through a die with a specific cross-sectional profile. The process can create complex shapes that are lightweight yet strong, making aluminum an ideal material for many applications.

The Extrusion Process

1. Billet Preparation: The process begins with an aluminum billet, which is a solid block of aluminum alloy that is heated to a malleable state (approximately 800-900°F).

2. Extrusion: The heated billet is placed in the extrusion press. A ram pushes the aluminum through the die, shaping it as it exits.

3. Cooling: Once extruded, the profile is cooled rapidly in a water bath to set its shape.

4. Cutting and Finishing: The extruded profile is then cut to length and may undergo additional finishing processes such as anodizing or machining.

What Makes Miniature Aluminum Extrusion Presses Unique?

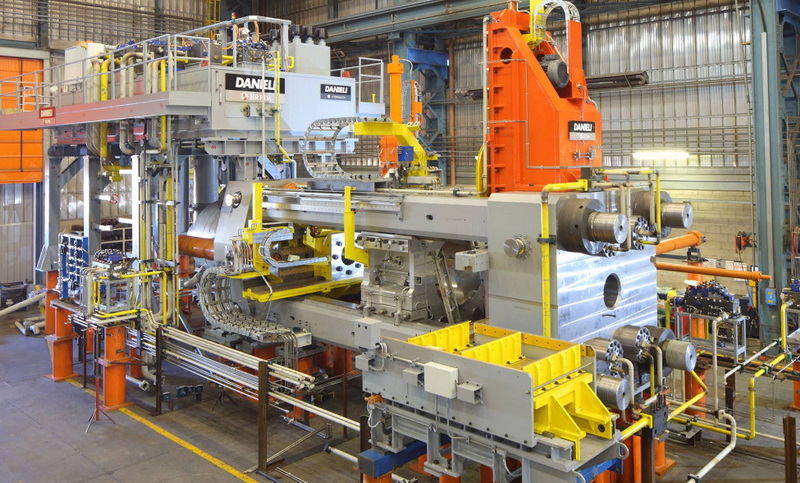

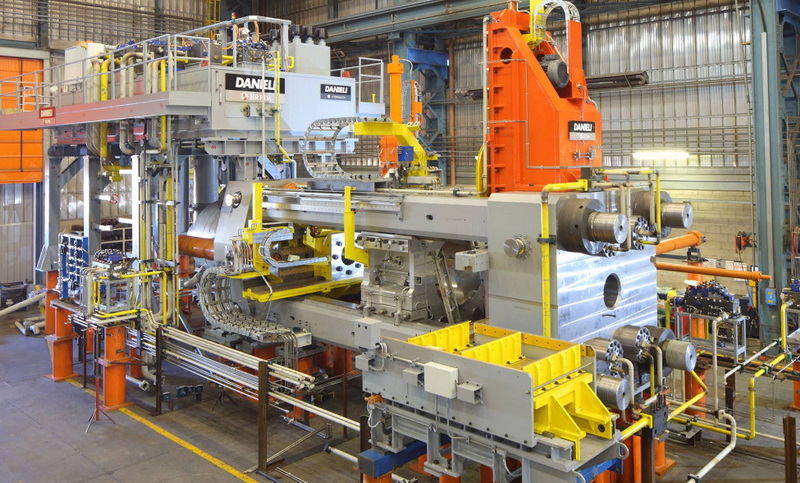

Miniature aluminum extrusion presses are specifically designed for producing small profiles that typically fit within a 5-inch diameter circle. These presses operate under different parameters than standard extrusion presses to accommodate the unique challenges associated with smaller profiles.

Key Features of Miniature Aluminum Extrusion Presses

- Precision Control: Miniature presses require precise control over temperature and pressure to ensure that the aluminum flows correctly through the die without defects.

- Specialized Dies: The dies used in miniature extrusion presses are often custom-made to achieve specific shapes and tolerances.

- Advanced Technology: Many modern presses utilize advanced hydraulic systems and automation for enhanced efficiency and reduced operational failures.

Types of Miniature Aluminum Extrusion Presses

1. Horizontal Presses: These are commonly used for small-scale production runs. The horizontal design allows for easy loading and unloading of billets.

2. Vertical Presses: Vertical presses are often used for higher production rates. They can accommodate larger dies and provide better control over the extrusion process.

3. Hydraulic Presses: Hydraulic systems provide consistent pressure during the extrusion process, which is crucial for producing high-quality miniature profiles.

4. Mechanical Presses: These presses use mechanical systems to generate force, which can be beneficial for certain applications requiring rapid cycle times.

Applications of Miniature Aluminum Extrusions

Miniature aluminum extrusions find applications in various sectors due to their lightweight and durable properties:

- Electronics: Used in heat sinks and structural components for devices like smartphones and laptops. The ability to dissipate heat efficiently makes these extrusions vital for maintaining device performance.

- Medical Devices: Employed in manufacturing components for life-saving equipment due to their precision and biocompatibility. For example, miniature extrusions are used in surgical instruments and diagnostic equipment.

- Automotive: Utilized in lightweight structural components that improve fuel efficiency. Miniature extrusions can be found in various parts of vehicles, contributing to overall performance and safety.

- Aerospace: The aerospace industry benefits from the high strength-to-weight ratio of aluminum extrusions, which are used in aircraft frames and components.

Advantages of Using Miniature Aluminum Extrusions

1. Lightweight: Aluminum's low density makes it ideal for applications where weight savings are critical.

2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, making it resistant to corrosion.

3. Design Flexibility: The extrusion process allows for complex shapes that can meet specific design requirements.

4. Cost-Effectiveness: While initial tooling costs may be higher, the efficiency of the extrusion process often leads to lower per-unit costs over time.

5. Sustainability: Aluminum is highly recyclable, making it an environmentally friendly choice for manufacturers looking to reduce their carbon footprint.

Challenges in Miniature Aluminum Extrusion

Despite its advantages, there are challenges associated with miniature aluminum extrusion:

1. Die Design Complexity: Creating dies for miniature profiles can be more complex than standard dies due to tighter tolerances and intricate shapes.

2. Material Flow Issues: Ensuring uniform material flow can be challenging when working with smaller profiles, as variations in temperature or pressure can lead to defects.

3. Production Speed: While miniature presses can produce high-quality parts, they may not match the production speed of larger presses used for standard-sized extrusions.

4. Maintenance Requirements: Maintaining precision equipment requires regular checks and maintenance schedules to avoid downtime.

Future Trends in Miniature Aluminum Extrusion

As technology continues to evolve, several trends are emerging in the field of miniature aluminum extrusion:

1. Increased Automation: Automation technologies such as robotics are being integrated into extrusion processes to improve efficiency and reduce labor costs.

2. Advanced Materials: Research into new aluminum alloys is ongoing, aiming to enhance properties such as strength, thermal conductivity, and corrosion resistance.

3. 3D Printing Integration: Combining traditional extrusion methods with additive manufacturing techniques may open new avenues for creating complex geometries that were previously impossible.

4. Sustainability Initiatives: Manufacturers are increasingly focusing on sustainable practices, including using recycled materials and reducing energy consumption during production.

5. Customization Capabilities: As demand grows for specialized components across industries, manufacturers are investing in technologies that allow for rapid prototyping and customization of dies and profiles.

Conclusion

Miniature aluminum extrusion presses play a crucial role in modern manufacturing by enabling the production of small, precise aluminum components that meet the demands of various industries. As technology advances, these presses will continue to evolve, offering even greater precision and efficiency while addressing challenges such as sustainability and customization needs.

FAQ

1. What is a miniature aluminum extrusion?

A miniature aluminum extrusion refers to small aluminum profiles produced through an extrusion process, typically fitting within a 5-inch diameter circle.

2. How does an aluminum extrusion press work?

An aluminum extrusion press works by heating an aluminum billet until it's malleable and then forcing it through a die using hydraulic pressure to create specific shapes.

3. What industries use miniature aluminum extrusions?

Industries such as electronics, medical devices, automotive, aerospace, and consumer goods utilize miniature aluminum extrusions for their lightweight and durable properties.

4. What are the benefits of using aluminum for extrusions?

Aluminum offers several advantages including lightweight construction, corrosion resistance, design flexibility, excellent strength-to-weight ratio, cost-effectiveness, and sustainability due to its recyclability.

5. Can miniature aluminum extrusions be customized?

Yes, miniature aluminum extrusions can be customized in terms of shape, size, alloy composition, surface finish, and other specifications to meet specific application requirements.