Content Menu

● Introduction to Extrusion Processes

>> Essential Components of Extrusion Machinery

● Industries Relying on Extrusion Processes

>> 1. Plastics Industry

>> 2. Metals Industry

>> 3. Food Industry

>> 4. Construction Sector

● Types of Extrusion Processes

● Advantages of Extrusion Processes

● Innovations in Extrusion Machinery

● Future Prospects

● Role of Automation and AI

● Integration of Industry 4.0 Technologies

● Emerging Materials and Applications

● Conclusion

● FAQ

>> 1. What are the primary components of an extrusion machine?

>> 2. Which industries rely heavily on extrusion processes?

>> 3. What are the types of extrusion processes?

>> 4. What are the advantages of using extrusion processes?

>> 5. How does extrusion contribute to sustainability?

● Citations:

Extrusion processes are fundamental in various industries, providing a versatile and efficient method for shaping materials into desired profiles. This article explores the reliance of different sectors on extrusion machinery and tooling, highlighting their applications, benefits, and future prospects.

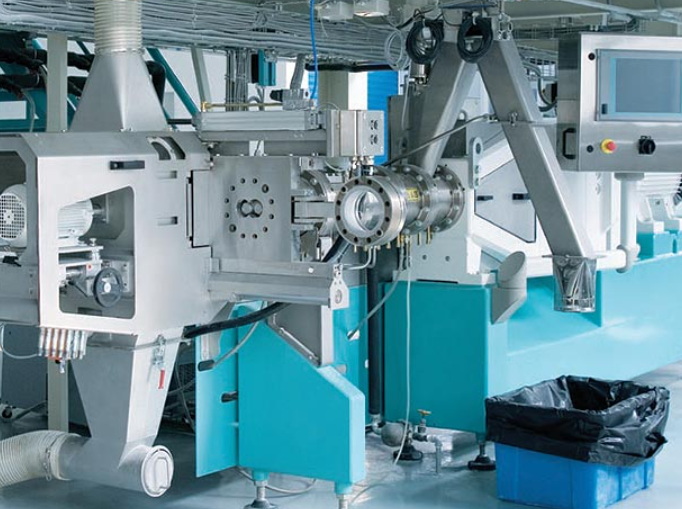

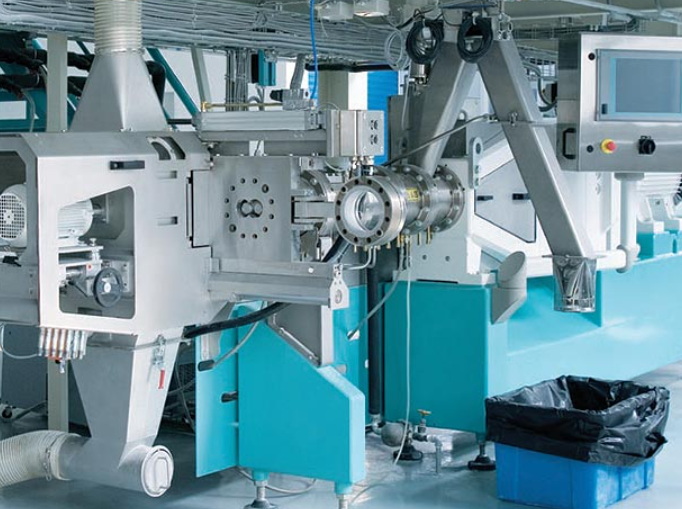

Introduction to Extrusion Processes

Extrusion involves forcing a material through a die to achieve a specific cross-sectional shape. This process is widely used across industries such as plastics, metals, food, and construction. The machinery involved includes extruders, dies, and cooling systems, which work together to produce continuous lengths of material with consistent properties.

Essential Components of Extrusion Machinery

1. Extruder: The core of the extrusion process, responsible for melting and transporting the material through the system.

2. Die: Shapes the molten material into the desired profile as it exits the machine.

3. Cooling System: Solidifies the extruded material, ensuring it retains its shape and properties.

Industries Relying on Extrusion Processes

1. Plastics Industry

Plastic extrusion is crucial for producing a wide range of products, including tubing, sheets, films, and profiles. These materials are used in various applications such as solar panels, automotive parts, appliances, construction materials, medical devices, and packaging solutions.

- Solar Industry: Extruded plastics are used for solar panel frames and encapsulation materials due to their lightweight and durable nature.

- Automotive Industry: Produces weather seals, gaskets, interior trim components, and vehicle tubing for fluid transfer systems.

- Appliance Industry: Utilizes extruded plastics for gaskets, seals, and handles, enhancing energy efficiency.

- Construction Industry: Provides weather-resistant and thermally efficient profiles for windows, doors, and architectural elements.

- Medical Industry: Manufactures tubing, catheters, and other medical device components using medical-grade plastics.

- Packaging Industry: Creates films, sheets, and other profiles for packaging materials with varying thicknesses and barrier properties.

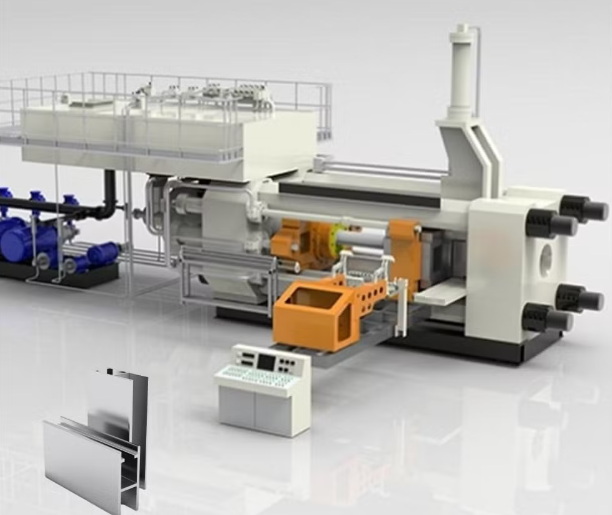

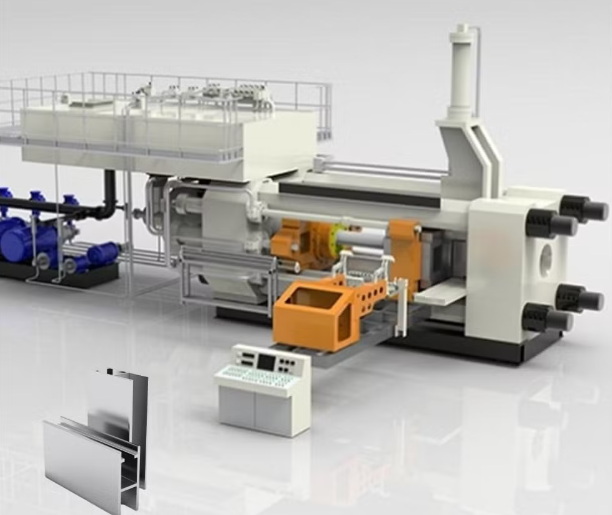

2. Metals Industry

Metal extrusion is used to create complex shapes from metals like aluminum, copper, and steel. This process is common in the automotive, aerospace, and construction sectors.

- Automotive Industry: Produces lightweight components such as transmission housings.

- Aerospace Industry: Utilizes magnesium alloys for lightweight components.

- Construction Industry: Manufactures aluminum window frames, roofing panels, and steel rods for building structures.

3. Food Industry

Food extrusion modifies the texture, shape, and nutritional content of food products. It is used to produce snacks, cereals, pasta, and pet foods.

4. Construction Sector

Extrusion is used to produce components like pipes, panels, and seals, allowing for complex shapes with high precision.

Types of Extrusion Processes

Extrusion processes vary based on material types and manufacturing goals:

- Direct Extrusion: Common in metal forming, where the material is pushed through the die in a continuous process.

- Indirect Extrusion: Used for more complex shapes, where the die moves with the ram.

- Cold Extrusion: Conducted at room temperature, ideal for materials requiring high strength or close tolerances.

- Hot Extrusion: Involves heating the material to make it more malleable, commonly used for metals and thermoplastics.

Advantages of Extrusion Processes

- Efficiency: Continuous production allows for high-volume manufacturing.

- Versatility: Can handle a wide range of materials and produce complex shapes.

- Cost-Effectiveness: Reduces waste and energy consumption compared to other manufacturing methods.

Innovations in Extrusion Machinery

Recent advancements in extrusion machinery focus on efficiency, precision, and sustainability. Innovations include:

- Differential Velocity Sideways Extrusion (DVSE): Enables curved metal profiles with fine grains and high strength, ideal for aerospace and automotive applications.

- Supercritical Fluid Extrusion (SCFX): Used in food processing to create unique textures at lower temperatures, preserving nutrients.

- 3D Printing Integration: Combines extrusion with 3D printing for customized, complex shapes in polymers and metals.

- Energy Efficiency and Sustainability: New extruders reduce energy use and incorporate renewable energy sources, supporting sustainable manufacturing.

Future Prospects

The demand for extrusion machinery is increasing due to its versatility and efficiency. The rise in sustainable practices, such as using recycled plastics, further boosts the market for extrusion equipment. Automation and AI are transforming the extrusion process by enabling real-time monitoring and adjustments, improving efficiency and reducing waste.

Role of Automation and AI

Automation and AI play a crucial role in modern extrusion machines. They handle tasks such as material transport and positioning with high precision, reducing errors and improving safety. AI algorithms can analyze production data to optimize process parameters, improve product quality, and predict potential defects.

Integration of Industry 4.0 Technologies

The integration of Industry 4.0 technologies, such as data analytics and digital twinning, enhances efficiency and predictive maintenance in extrusion processes. Digital twins allow for virtual testing and optimization of production lines before actual implementation, reducing downtime and improving overall performance.

Emerging Materials and Applications

There's an ongoing demand for new materials and applications in modern extrusion. From biodegradable plastics to high-performance composites, these materials offer unique properties and potential applications, driving the continuous evolution of extrusion technology.

Conclusion

Extrusion processes are indispensable in various industries, offering precision, efficiency, and versatility. The reliance on extrusion machinery and tooling will continue to grow as industries seek sustainable and cost-effective manufacturing solutions.

FAQ

1. What are the primary components of an extrusion machine?

- The primary components include the feeder, barrel and screw, and die. The feeder delivers raw material, the barrel and screw melt and transport the material, and the die shapes the final product.

2. Which industries rely heavily on extrusion processes?

- Industries such as plastics, metals, food, and construction rely heavily on extrusion processes for producing a wide range of products.

3. What are the types of extrusion processes?

- Types include direct, indirect, cold, and hot extrusion, each suited for different materials and applications.

4. What are the advantages of using extrusion processes?

- Advantages include high efficiency, versatility in handling various materials, and cost-effectiveness due to reduced waste and energy consumption.

5. How does extrusion contribute to sustainability?

- Extrusion contributes to sustainability by allowing the use of recycled materials, reducing waste, and promoting energy-efficient manufacturing practices.

Citations:

[1] https://jieyatwinscrew.com/blog/exploring-extrusion-equipment/

[2] https://uplastech.com/advancements-extrusion-machinery/

[3] https://www.tfgusa.com/understanding-extrusion-a-fundamental-manufacturing-process/

[4] https://kama-packaging.com/en/the-future-of-extrusion-technology-new-materials-and-technologies/

[5] https://www.jwellmachine.com/analysis-of-plastic-extrusion-technology/

[6] https://www.yjing-extrusion.com/what-are-the-latest-innovations-in-automatic-extrusion-machines.html

[7] https://www.clarkrandp.com/6-common-applications-of-plastic-extrusion/

[8] https://www.plasticsmachinerymanufacturing.com/extrusion/article/21161172/oems-forecast-high-tech-future-for-extrusion

[9] https://books.google.com/books/about/Extrusion.html?id=sPBTAAAAMAAJ

[10] https://www.yjing-extrusion.com/what-are-the-latest-trends-in-the-extrusion-machinery-market.html

[11] https://medcraveonline.com/MOJFPT/applications-of-food-extrusion-technology.html

[12] https://cbmplasticsusa.com/what-is-the-future-of-plastic-extrusion/

[13] https://www.lernermoldedplastics.com/the-comprehensive-guide-to-advanced-extrusion-techniques/

[14] https://www.globenewswire.com/news-release/2025/02/05/3021359/0/en/Plastic-Extrusion-Machine-Market-to-Grow-at-4-7-CAGR-During-2025-2035-Boosting-Global-Industry-to-USD-12-343-2-Million-by-2035-Future-Market-Insights-Inc.html

[15] https://paulmurphyplastics.com/industry-news-blog/extrusion-process-working-types-application-advantages-and-disadvantages/

[16] https://cmppin.com/blog/the-future-of-the-extrusion-blow-molding-machine/

[17] https://www.trelleborg.com/en/medical/tools-and-media/news/whitepaper-on-advanced-extrusion-techniques

[18] https://www.grandviewresearch.com/industry-analysis/extrusion-machinery-market-report

[19] https://daextrusion.com/applications/

[20] https://www.linkedin.com/pulse/future-aluminium-alloy-extrusion-industry-developments-challenges-5ppfe