Content Menu

● Understanding Aluminum Extrusion

● Key Benefits of Aluminum Extrusion Assembly

● Energy Efficiency

● Applications of Aluminum Extrusion Assembly

>> Case Study: Aerospace Applications

● The Manufacturing Process

>> Innovations in Extrusion Technology

● Challenges in Aluminum Extrusion Assembly

● Conclusion

● FAQ

>> 1. What industries benefit from aluminum extrusion assembly?

>> 2. How does aluminum compare to other metals in terms of weight?

>> 3. Is aluminum extrusion environmentally friendly?

>> 4. Can aluminum extrusions be customized?

>> 5. What are common applications of aluminum extrusions?

Aluminum extrusion assembly has gained significant traction across various industries due to its unique advantages. This article explores the key benefits of aluminum extrusion assembly, highlighting its applications, efficiency, and overall impact on manufacturing processes.

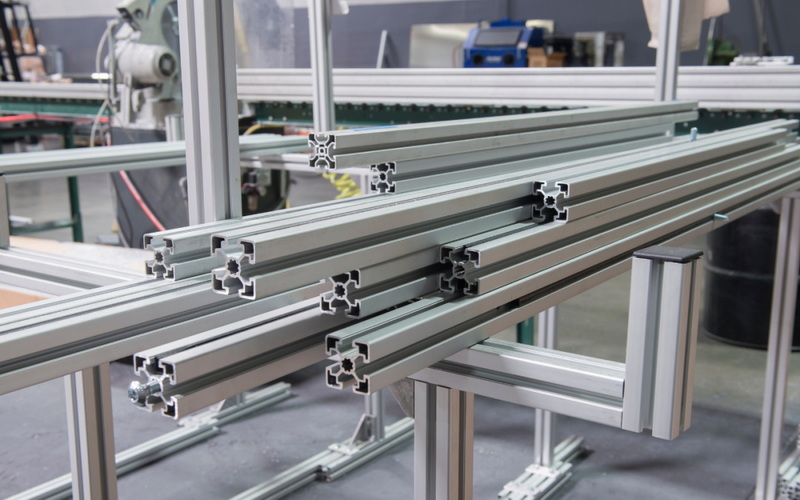

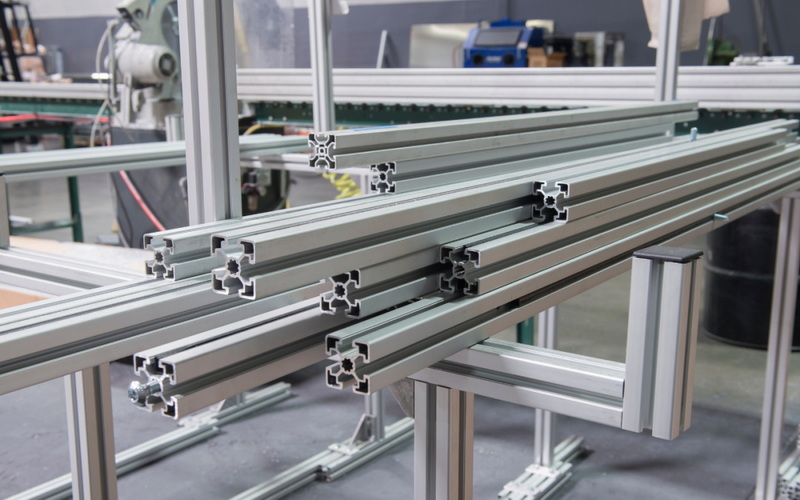

Understanding Aluminum Extrusion

Aluminum extrusion is a manufacturing process that involves shaping aluminum alloy into a desired cross-sectional profile. The process begins with heating an aluminum billet, which is then forced through a die to create a specific shape. This method allows for the production of complex profiles with high precision and minimal waste.

Key Benefits of Aluminum Extrusion Assembly

1. Versatility in Design

Aluminum extrusion offers unparalleled design flexibility. Manufacturers can create customized shapes tailored to specific applications, from structural components to intricate designs for consumer products. This versatility makes aluminum extrusion assembly suitable for various industries, including automotive, aerospace, construction, and consumer goods.

For instance, in the automotive industry, aluminum extrusions are used for components such as chassis frames and bumpers. These components benefit from the lightweight nature of aluminum while maintaining the necessary strength and safety standards. In consumer electronics, custom extrusions can be designed to house sensitive components while providing adequate ventilation.

2. Lightweight Yet Strong

One of the most significant benefits of aluminum extrusion assembly is the lightweight nature of aluminum compared to other metals like steel. Despite its light weight, aluminum exhibits excellent strength-to-weight ratios, making it ideal for applications where reducing weight is critical without compromising structural integrity.

This characteristic is particularly important in industries such as aerospace and automotive, where every ounce counts. For example, aircraft manufacturers are increasingly using aluminum extrusions to reduce overall weight, which leads to improved fuel efficiency and lower operational costs.

3. Corrosion Resistance

Aluminum naturally forms a protective oxide layer when exposed to air, which helps prevent corrosion. This property makes aluminum extrusions particularly suitable for outdoor applications or environments where moisture and chemicals are prevalent.

In construction, aluminum window frames and roofing systems benefit from this corrosion resistance, ensuring longevity and reducing maintenance costs over time. Similarly, in marine applications, aluminum extrusions are preferred for their ability to withstand harsh saltwater environments without deteriorating.

4. Cost-Effectiveness

The aluminum extrusion process is generally more cost-effective than other metal forming methods. The ability to produce complex shapes in large quantities reduces material waste and lowers production costs. Additionally, the lightweight nature of aluminum can lead to savings in shipping and handling costs.

Moreover, the durability of aluminum extrusions means that products have a longer lifespan, further enhancing their cost-effectiveness over time. This is particularly relevant in sectors like construction and infrastructure development, where long-term investments are crucial.

Energy Efficiency

The energy required for aluminum extrusion is significantly lower than that needed for other metal forming processes like casting or machining. This energy efficiency translates into lower operational costs and a reduced carbon footprint for manufacturers.

Furthermore, advancements in technology have made the extrusion process even more energy-efficient. For example, modern extruders utilize advanced heating methods that minimize energy consumption while maximizing output quality.

Applications of Aluminum Extrusion Assembly

Aluminum extrusion assembly finds applications in numerous sectors:

- Automotive Industry: Used for structural components such as chassis frames and heat exchangers.

- Aerospace: Employed in aircraft frames and components due to its strength and lightweight properties.

- Construction: Utilized in window frames, roofing systems, curtain walls, and architectural features.

- Consumer Products: Found in electronics casings, furniture components, sporting goods, and even packaging materials.

Case Study: Aerospace Applications

In the aerospace sector, companies like Boeing and Airbus have embraced aluminum extrusion assembly for various parts of their aircraft. For example:

- Wing Structures: Aluminum extrusions provide the necessary strength while minimizing weight.

- Fuselage Components: Custom profiles can be designed to fit specific aerodynamic requirements.

The use of aluminum not only enhances performance but also contributes to fuel efficiency—a critical factor in modern aviation.

The Manufacturing Process

The aluminum extrusion process consists of several steps:

1. Preparation of the Die: The extrusion die must be preheated to ensure optimal metal flow.

2. Heating the Billet: An aluminum billet is heated to make it malleable enough for extrusion.

3. Extrusion: The heated billet is pushed through the die under high pressure.

4. Cooling: The extruded profile is cooled using water or air.

5. Cutting and Finishing: The cooled extrusions are cut to length and may undergo additional finishing processes such as anodizing or powder coating to enhance surface properties.

Innovations in Extrusion Technology

Recent advancements in extrusion technology have further improved the efficiency and capabilities of the process:

- 3D Printing Integration: Some manufacturers are exploring hybrid processes that combine 3D printing with traditional extrusion methods to create complex geometries that were previously impossible.

- Automated Systems: Automation in handling and processing has reduced labor costs and increased production speeds without sacrificing quality.

These innovations not only streamline production but also open new avenues for design possibilities.

Challenges in Aluminum Extrusion Assembly

While there are numerous benefits associated with aluminum extrusion assembly, there are also challenges that manufacturers must navigate:

- Initial Tooling Costs: The upfront investment for custom dies can be significant; however, this cost is often offset by long-term savings through reduced waste and increased production efficiency.

- Material Limitations: Not all alloys are suitable for every application; selecting the right alloy is crucial for achieving desired mechanical properties.

Despite these challenges, many companies find that the advantages far outweigh the drawbacks when properly managed.

Conclusion

In conclusion, aluminum extrusion assembly offers numerous benefits that make it an attractive option for manufacturers across various industries. Its versatility in design, lightweight yet strong properties, corrosion resistance, cost-effectiveness, energy efficiency, and adaptability to modern technological advancements contribute to its growing popularity in contemporary manufacturing processes.

As industries continue to seek innovative solutions that balance performance with sustainability, aluminum extrusion assembly stands out as a key player in achieving these goals. With ongoing research and development efforts focused on enhancing this manufacturing method further, we can expect even broader applications and improvements in efficiency moving forward.

FAQ

1. What industries benefit from aluminum extrusion assembly?

Aluminum extrusion assembly benefits industries such as automotive, aerospace, construction, and consumer goods due to its versatility and strength.

2. How does aluminum compare to other metals in terms of weight?

Aluminum is significantly lighter than metals like steel while maintaining strong structural integrity; this makes it ideal for applications where weight reduction is essential.

3. Is aluminum extrusion environmentally friendly?

Yes! The aluminum extrusion process is energy-efficient and produces minimal waste compared to other metal forming methods; this contributes to a lower carbon footprint.

4. Can aluminum extrusions be customized?

Absolutely! One of the key advantages of aluminum extrusion assembly is the ability to create custom shapes tailored specifically to various applications.

5. What are common applications of aluminum extrusions?

Common applications include automotive parts (like chassis), aerospace components (such as wing structures), construction materials (like window frames), consumer products (like electronics casings), and packaging materials.