Content Menu

● Why Portugal Is a Strategic Location for Automatic Extrusion Line Manufacturing

● Leading Automatic Extrusion Line Manufacturers And Suppliers in Portugal

>> Exlabesa

>> STRUGAL

>> GAP Aluminium

>> Other Notable Names in Portugal's Aluminum Extrusion Landscape

● The Aluminum Extrusion Process: From Billet to Profile

● Technological Advancements and Industry 4.0 in Portugal

● Sustainability Leadership in Extrusion Line Manufacturing

● Market Trends and Future Outlook

● Conclusion

● Frequently Asked Questions

>> Q1: What aluminum alloys do Portuguese extrusion line manufacturers process?

>> Q2: How do suppliers ensure sustainability in their extrusion processes?

>> Q3: What is the typical production capacity of an extrusion facility in Portugal?

>> Q4: Do Portuguese manufacturers offer OEM and custom extrusion services?

>> Q5: Which industries primarily utilize aluminum extrusion lines from Portugal?

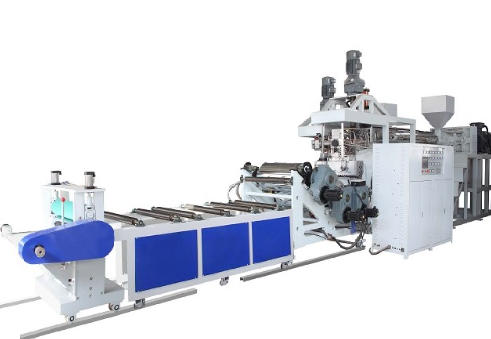

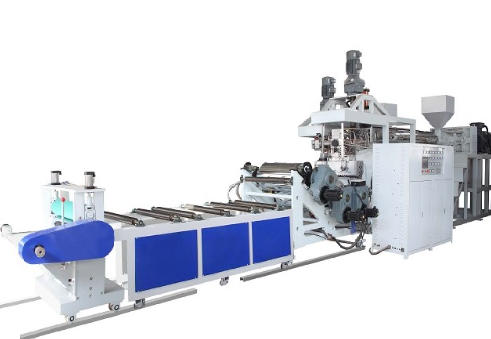

Portugal is rapidly emerging as one of Europe's leading hubs for Automatic Extrusion Line Manufacturers And Suppliers. With its strategic geographic location, highly skilled workforce, cutting-edge manufacturing infrastructure, and strong commitment to sustainability, Portuguese companies have attracted major international OEMs (Original Equipment Manufacturers), wholesalers, and producers seeking high-quality and cost-effective extrusion solutions. This comprehensive guide explores the top manufacturers and suppliers in Portugal, their technological strengths, operational capacities, certifications, and the future outlook for the Portuguese automatic extrusion line industry.

Why Portugal Is a Strategic Location for Automatic Extrusion Line Manufacturing

Portugal offers a unique combination of geographic, economic, and industrial advantages that make it an ideal location to set up extrusion line manufacturing operations:

- Geographic Location: Positioned strategically in Southern Europe, Portugal provides easy access to other European key markets such as Spain, France, Germany, and the UK. This facilitates efficient logistics with shorter lead times and favorable shipping conditions for exports.

- Industrial Expertise: Portugal has a solid history in the metallurgical and aluminum extrusion sectors. This experience is backed by a skilled and knowledgeable workforce that understands complex extrusion processes.

- Advanced Infrastructure: Modern manufacturing facilities in Portugal are equipped with the latest extrusion presses, automation technology, and finishing lines, enabling high-volume and flexible production.

- Commitment to Sustainability: Portuguese manufacturers prioritize environmental responsibility, achieving international certifications and adopting practices that emphasize recycled aluminum use, energy-efficient processes, and waste reduction.

- OEM-Friendly Market: Portugal's extrusion suppliers have developed capabilities to offer customized, value-added OEM services that meet the diverse requirements of construction, transportation, industrial machinery, renewable energy, and other industries.

Leading Automatic Extrusion Line Manufacturers And Suppliers in Portugal

Exlabesa

Exlabesa stands as one of Portugal's flagship companies in the automatic aluminum extrusion sector, operating a brand-new, state-of-the-art extrusion facility in João Rui Ferreira. The site serves as a vital component of the company's Southern Europe strategy.

- Facility and Capacity: The extrusion plant covers 86,000 square meters, with 10,000 square meters dedicated to covered production areas. Initially capable of producing 16,000 tonnes annually, there are plans to expand capacity to 45,000 tonnes per year.

- Machinery and Technology: Equipped with two massive 2,800-tonne presses, Exlabesa plans future acquisition of higher-capacity presses for enhanced operational flexibility and increased production of large, complex profiles.

- Alloy Range: The factory processes a full range of 6000 series aluminum alloys, including 6005, 6060, 6061, 6063, 6082, 6101, and 6106, catering to various strength and performance requirements.

- Product Range: Capable of extruding profiles up to 7.2 meters in length, with intricate cross-sectional designs and thickness variations based on OEM needs.

- Surface Treatment: The facility features on-site vertical powder coating lines that produce premium surface finishes, ensuring corrosion resistance and aesthetic appeal.

- Sustainability Efforts: Use of recycled aluminum billets and optimized energy consumption has enabled Exlabesa to achieve a carbon footprint as low as 2.95 kg CO₂ equivalent per kilogram of aluminum.

- Market Focus: Exlabesa supplies profiles extensively to sectors such as construction, transportation, infrastructure, renewable energy, and industrial machinery.

- Certifications and Compliance: Strict adherence to quality and environmental standards is maintained through ISO 9001, CE marking, Qualicoat, and Alu+C- certifications.

STRUGAL

STRUGAL is recognized as one of Europe's most technologically advanced extrusion companies and maintains robust operations within Portugal.

- Production Capacity: STRUGAL's annual production capacity reaches up to 42,000 tonnes.

- Equipment and Range: The company operates multiple press sizes ranging from 1,400 to 2,200 tonnes to ensure adaptability across a broad spectrum of extrusion profiles.

- Materials and Finishing: STRUGAL processes the entire suite of 6000 series alloys and implements heat treatments such as T4, T5, T6, and T66 to meet specific mechanical property requirements. Profile sizes range from 3 to 14 meters, thicknesses from 1 to 70 mm, and linear weights between 0.04 and 35 kg per meter.

- Certifications and Standards: STRUGAL rigorously complies with ISO 9001, EN 755-9, and EN 12020-2 standards.

- Clientele: The company serves a diverse client base, including architectural, industrial, and OEM customers requiring high-quality aluminum profiles.

GAP Aluminium

GAP Aluminium is a niche player specializing in repair, maintenance, and upgrade services to extrusion lines rather than production itself.

- Industry Expertise: With over 25 years of experience, GAP Aluminium specializes in servicing presses from manufacturers such as SMS, Turla, Tecalex, GIA, and Sutton.

- Range of Services: It provides mechanical repairs, hydraulic system maintenance, controlling and programming services, as well as furnace, lacquering, and anodizing line upgrades.

- Client Focus: Their customers primarily include OEMs and extrusion factories seeking tailored, high-efficiency retrofit and upgrade solutions with technical support to extend the lifespan and improve the performance of existing extrusion lines.

Other Notable Names in Portugal's Aluminum Extrusion Landscape

In addition to the leading companies above, Portugal boasts several other important players that contribute to the strong fabric of automatic extrusion line manufacturing and supply, including:

- Hydro Extrusion Avintes: A major aluminum extruder supplying both raw profiles and finished aluminum solutions.

- Navarra Group: Known for extruded aluminum profiles and comprehensive accessories.

- Extrusal S.A.: Specializing in sustainable, high-tech extrusion processes combined with advanced surface treatment options.

- Multiple smaller companies that offer flexible OEM-capable extrusion line components and services.

The Aluminum Extrusion Process: From Billet to Profile

Gaining an understanding of the automatic aluminum extrusion process is essential to appreciate the technological capabilities of Portugal's manufacturers and suppliers:

1. Die Preparation: Production begins with the engineering and precision machining of high-strength steel dies that define the shape of the final profile. These dies undergo preheating to temperatures between 450 and 500°C to ensure durability during the extrusion process.

2. Billet Preheating: Aluminum billets, typically cylindrical blocks of aluminum alloy, are preheated to approximately 400 to 500°C to render the metal malleable.

3. Extrusion: A powerful hydraulic ram, capable of exerting forces up to 15,000 tonnes, pushes the heated billet through the steel die. This action forces the aluminum to flow into the required profile shape as it exits the die continuously.

4. Cooling: The hot extruded profile is cooled either naturally through air-cooling or accelerated via quenching with water or other cooling media, helping improve its metallurgical properties.

5. Stretching and Cutting: The cooled profiles are then stretched to correct any distortion and cut to pre-agreed lengths using automated saws.

6. Aging: Artificial aging processes, involving controlled reheating of the profiles, are utilized to increase mechanical strength and hardness through precipitation hardening.

7. Surface Treatments: To enhance corrosion resistance and aesthetic quality, profiles undergo processes such as anodizing or powder coating—procedures that provide a durable finish for various applications.

Technological Advancements and Industry 4.0 in Portugal

Portuguese manufacturers are at the forefront of integrating modern technological advancements and Industry 4.0 principles into their extrusion processes to improve quality, efficiency, and sustainability:

- Automated Press Controls: Real-time monitoring systems track critical parameters such as pressure, temperature, and extrusion speed, enabling immediate adjustments to minimize defects and reduce waste.

- Energy Efficiency Innovations: Use of variable frequency drives (VFDs), heat recovery systems, and optimized press designs helps lower electricity consumption and carbon emissions.

- Advanced Alloys: Investments in metallurgical research allow the production of high-strength and specialty alloys tailored for demanding sectors like aerospace, automotive, and renewable energy.

- Surface Treatment Innovation: Vertical powder coating lines and advanced anodizing processes improve durability and broaden the aesthetic possibilities of extruded profiles.

- Smart Manufacturing and IoT: Incorporation of Internet of Things (IoT) sensors, predictive maintenance algorithms, and big data analytics enhances operational uptime, reduces maintenance costs, and improves overall line efficiency.

Sustainability Leadership in Extrusion Line Manufacturing

Sustainability remains a core pillar for Portuguese Automatic Extrusion Line Manufacturers And Suppliers, who have made significant progress by:

- Maximizing Recycled Aluminum Use: Extensive use of recycled aluminum billets greatly reduces primary aluminum production needs, drastically cutting greenhouse gas emissions.

- Waste Management Practices: Scraps and by-products generated during extrusion are carefully collected and recycled back into the production cycle, minimizing landfill waste.

- Renewable Energy Integration: Many manufacturers are increasingly powering their operations with renewable sources such as solar or wind energy.

- Environmental Certification and Reporting: Adopting internationally recognized standards like ISO 9001, Qualicoat, and Alu+C- provides customers with transparent evidence of production sustainability.

- Carbon Footprint Transparency: Leading companies actively measure and minimize their carbon footprints, providing documented data to OEMs concerned with green manufacturing requirements.

Market Trends and Future Outlook

The future of automatic extrusion line manufacturing in Portugal looks promising, with several key trends driving growth and innovation:

- Lightweighting Demand: The rising demand for lightweight materials in automotive and aerospace sectors favors aluminum extrusion as a key technology for producing strong, light components.

- Green Building and Sustainable Construction: Aluminum's recyclability and strength make it a preferred material for sustainable architecture, driving demand for advanced extrusion lines.

- Customization and OEM Capabilities: Increasingly complex customer requirements necessitate bespoke extrusion profiles and customer-specific engineering services.

- Process Innovations: Continuous improvements in extrusion speed, precision, and surface finish quality come from ongoing R&D in materials science and process engineering.

- Global Market Expansion: Portuguese manufacturers are leveraging their geographic position and technology sophistication to expand exports to emerging markets beyond Europe, including Africa, the Middle East, and South America.

Conclusion

Portugal has firmly positioned itself as a key player among Automatic Extrusion Line Manufacturers And Suppliers in Europe and globally. Through a combination of advanced technology, skilled workforce, OEM-friendly customization, and strong sustainability commitments, Portuguese companies like Exlabesa, STRUGAL, and others continue to meet and exceed the demands of diverse sectors — from construction and transportation to renewable energy and industrial machinery. With ongoing investments into Industry 4.0 integration, energy efficiency, and premium alloy production, the sector's growth trajectory looks robust and sustainable, making Portugal an attractive destination for international customers and partners seeking high-performance aluminum extrusion solutions.

Frequently Asked Questions

Q1: What aluminum alloys do Portuguese extrusion line manufacturers process?

A1: Portuguese manufacturers process the complete range of 6000 series aluminum alloys, including 6005, 6060, 6061, 6063, 6082, 6101, and 6106, allowing them to produce profiles suited for a variety of applications and mechanical requirements.

Q2: How do suppliers ensure sustainability in their extrusion processes?

A2: Sustainability is achieved by using recycled aluminum billets, implementing energy-efficient machinery and presses, applying rigorous waste recycling protocols, integrating renewable energy sources, and maintaining certifications such as ISO 9001, Qualicoat, and Alu+C- that verify environmental responsibility.

Q3: What is the typical production capacity of an extrusion facility in Portugal?

A3: Capacities vary by company, with leading facilities like Exlabesa producing initially 16,000 tonnes per year with plans to reach 45,000 tonnes, and STRUGAL operating at approximately 42,000 tonnes per year, accommodating diverse customer volume needs.

Q4: Do Portuguese manufacturers offer OEM and custom extrusion services?

A4: Yes, many Portuguese companies specialize in OEM services, offering bespoke profile design, custom alloy processing, and surface treatments tailored to the technical and volume requirements of their clients.

Q5: Which industries primarily utilize aluminum extrusion lines from Portugal?

A5: Key industries include construction, transportation (rail, automotive, aerospace), renewable energy (solar frame extrusion), infrastructure, and industrial machinery manufacturing.