Content Menu

● Understanding Aluminum Extruders

● Benefits of Using an Aluminum Extruder

● Compatibility Considerations

● Installation Process for Aluminum Extruders

● Common Issues and Solutions

● The Role of Aluminum in 3D Printer Design

● Future Trends in Aluminum Extrusion for 3D Printing

● Practical Applications of Aluminum Extruders

● Conclusion

● FAQ

>> 1. Can I use an aluminum extruder on any 3D printer?

>> 2. What are the advantages of upgrading to an aluminum extruder?

>> 3. Is installation difficult for an aluminum extruder?

>> 4. Will upgrading my extruder void my warranty?

>> 5. Can I use flexible filaments with an aluminum extruder?

● Citations:

3D printing has revolutionized the way we create and manufacture objects, enabling hobbyists and professionals alike to bring their ideas to life. One of the critical components in any 3D printer is the extruder, which is responsible for feeding filament into the hot end where it is melted and deposited onto the print bed. The choice of extruder can significantly impact print quality, consistency, and overall performance. Among the various types of extruders available, aluminum extruders have gained popularity due to their durability and efficiency. This article explores whether an aluminum extruder is compatible with all 3D printers, its benefits, installation considerations, and more.

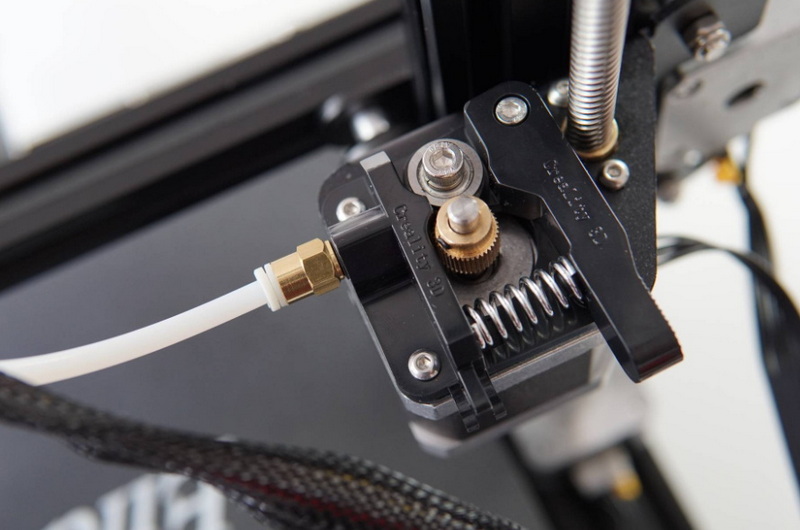

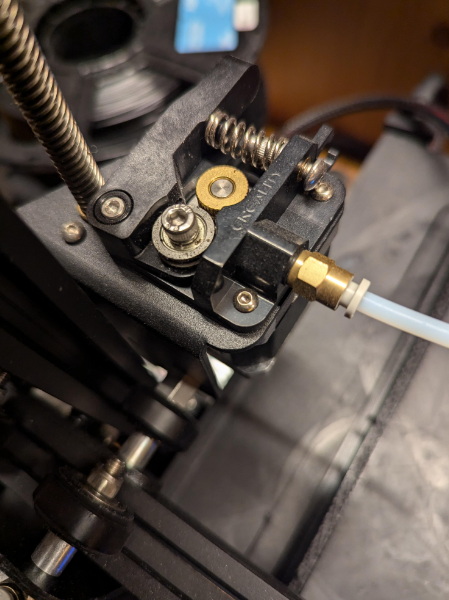

Understanding Aluminum Extruders

Aluminum extruders are designed to be robust and reliable, offering several advantages over their plastic counterparts. They are less prone to wear and tear, provide consistent filament feeding, and can better withstand high temperatures. However, compatibility with different 3D printers can vary based on several factors.

Benefits of Using an Aluminum Extruder

- Increased Durability: Aluminum is much more resistant to wear compared to plastic. This means that an aluminum extruder can endure the constant stress of filament feeding without degrading over time.

- Improved Consistency: The rigid construction of aluminum ensures more consistent filament feeding, which leads to better print quality with fewer imperfections.

- Better Heat Dissipation: Aluminum conducts heat more efficiently than plastic, reducing the risk of heat-related issues such as softening or clogging.

- Longer Lifespan: An aluminum extruder typically lasts longer than a plastic one due to its robust construction.

Compatibility Considerations

While aluminum extruders offer many advantages, they are not universally compatible with all 3D printers. Here are some factors to consider:

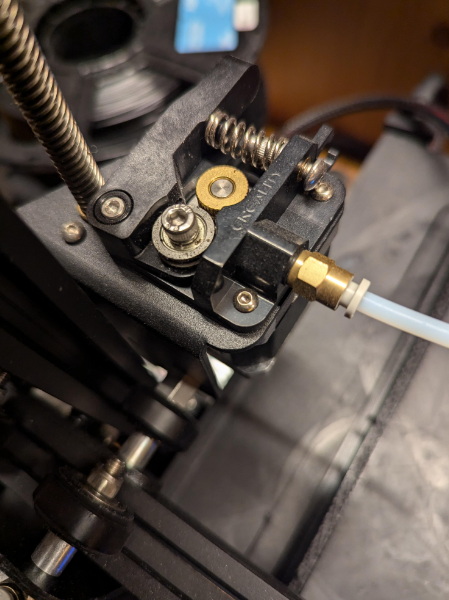

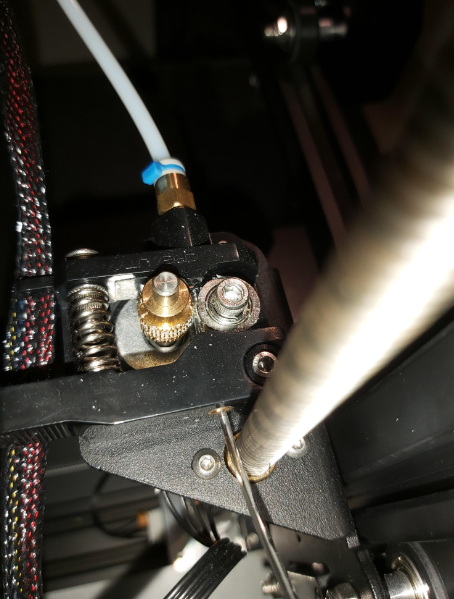

- Printer Model: Different printer models may have unique mounting systems or dimensions that require specific types of extruders. For example, the Creality Ender series has specific aluminum extruder kits designed for models like Ender 3, Ender 3 Pro, and Ender 5.

- Type of Extruder System: Some printers use a Bowden setup where the extruder is mounted away from the hot end. In contrast, others use a direct drive system where the extruder is mounted directly above the hot end. Ensure that the aluminum extruder you choose is compatible with your printer's system.

- Installation Complexity: Installing an aluminum extruder may require some technical skills. If you are not comfortable with disassembling and reassembling printer components, it may be best to seek assistance from someone experienced.

- Filament Type: Certain aluminum extruders are designed specifically for flexible filaments or high-temperature materials. If you plan on using these types of filaments, ensure that your chosen extruder is suitable.

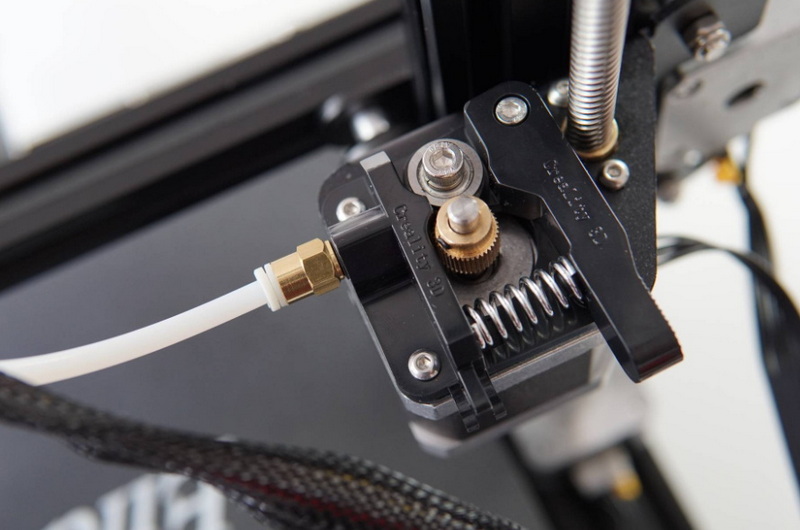

Installation Process for Aluminum Extruders

Upgrading to an aluminum extruder can significantly enhance your 3D printing experience. Here's a general overview of how to install one:

1. Gather Tools and Materials: You will need an aluminum extruder kit compatible with your printer model, hex wrenches (typically 2mm and 3mm), and possibly a screwdriver.

2. Remove the Old Extruder:

- Power off your printer and unplug it.

- Carefully detach the existing plastic extruder by unscrewing it from its mount.

- Disconnect any wiring associated with the old extruder.

3. Install the New Aluminum Extruder:

- Position the new aluminum extruder onto the mount.

- Secure it in place using screws provided in your kit.

- Reconnect any wiring as necessary, ensuring that connections are secure.

4. Calibrate Your Printer: After installation, recalibrate your printer settings to optimize performance with the new extruder.

5. Test Print: Conduct a test print to ensure that everything is functioning correctly and adjust settings as needed for optimal results.

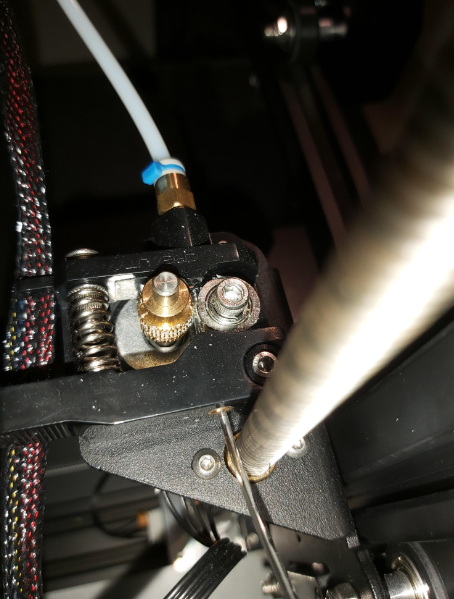

Common Issues and Solutions

While upgrading to an aluminum extruder can improve performance, users may encounter some common issues:

- Filament Slipping: If you notice that filament is slipping or not feeding correctly, check the tension on the extruder arm. Adjusting this tension can often resolve feeding issues.

- Clogs or Jams: If clogs occur frequently after upgrading, ensure that your filament path is clear and that you are using appropriate filament for your setup.

- Inconsistent Prints: If print quality does not improve as expected after upgrading, consider recalibrating your slicer settings or checking for other factors affecting print quality such as temperature settings or bed leveling.

The Role of Aluminum in 3D Printer Design

Aluminum extrusion plays a significant role in enhancing not just extruders but also other components of 3D printers. Many popular 3D printers utilize aluminum frames due to their rigidity and stability:

- Stability and Precision: A rigid frame constructed from aluminum minimizes vibrations during printing processes. This stability is crucial for achieving high-quality prints as it allows for consistent layer adhesion and accurate dimensional tolerances[1].

- Cost-effectiveness: The manufacturing process for aluminum components is efficient, making them a cost-effective choice for both manufacturers and hobbyists alike[1].

- Versatility: Aluminum can be used for various components beyond just frames; it can also be utilized in supports and even some print heads[1]. This versatility allows manufacturers to create complex designs that would be challenging with other materials.

Future Trends in Aluminum Extrusion for 3D Printing

As technology continues to advance, innovations in aluminum materials and extrusion techniques are expected to enhance 3D printing capabilities further:

- New Alloys Development: Research is ongoing to develop aluminum alloys that offer enhanced performance characteristics such as increased corrosion resistance and improved thermal conductivity[1]. These innovations could open new avenues for applications in industries like aerospace and automotive where material performance is critical[1].

- Integration of Additive Manufacturing Techniques: The integration of aluminum extrusion in additive manufacturing will likely grow as more manufacturers recognize its benefits. This trend will enable more efficient production processes and allow for creating even more complex geometries[1].

Practical Applications of Aluminum Extruders

Aluminum extruders are widely used across various applications due to their strength and reliability:

- Hobbyist Projects: Many DIY enthusiasts opt for aluminum extruders when building custom 3D printers or upgrading existing ones due to their ease of use and compatibility with various filament types[6].

- Prototyping: In professional settings, aluminum extruders are favored for prototyping because they provide consistent results across different materials[6]. This consistency helps engineers test designs effectively before moving into full-scale production.

- Production Runs: For small-scale production runs where quality control is paramount, aluminum extruders ensure that each piece meets stringent specifications without significant variations[6].

Conclusion

In summary, while aluminum extruders provide numerous benefits such as increased durability and improved print quality, they are not universally compatible with all 3D printers. It is essential to consider factors such as printer model, type of extrusion system, installation complexity, and filament type when selecting an aluminum extruder for your 3D printer. Proper installation and calibration can lead to significant enhancements in your printing experience.

FAQ

1. Can I use an aluminum extruder on any 3D printer?

No, compatibility depends on your specific printer model and its extrusion system (Bowden or direct drive).

2. What are the advantages of upgrading to an aluminum extruder?

Aluminum extruders offer increased durability, improved consistency in filament feeding, better heat dissipation, and a longer lifespan compared to plastic ones.

3. Is installation difficult for an aluminum extruder?

Installation requires some technical skills but is generally straightforward if you follow a guide or video tutorial specific to your printer model.

4. Will upgrading my extruder void my warranty?

Modifying your printer may affect its warranty; check with your manufacturer regarding their specific policies on upgrades.

5. Can I use flexible filaments with an aluminum extruder?

Yes, many aluminum extruders are designed to handle flexible filaments effectively; however, ensure compatibility before purchasing.

Citations:

[1] https://www.yjing-extrusion.com/what-are-the-benefits-of-using-aluminum-extrusion-in-3d-printing.html

[2] https://hackaday.com/2018/05/08/how-to-build-anything-out-of-aluminum-extrusion-and-3d-printed-brackets/

[3] https://www.youtube.com/watch?v=zJRxRVN3p3Y

[4] https://www.artillery3d.com/es/blogs/3d-printer-user-guide/common-issues-and-solutions-for-extruders-in-fdm-3d-printing

[5] https://www.3erp.com/blog/injection-molding-vs-extrusion-differences-and-comparison/

[6] https://www.yjing-extrusion.com/what-is-a-creality-aluminum-extruder-and-why-should-you-use-it.html

[7] https://www.reddit.com/r/3Dprinting/comments/16vzxk8/why_does_almost_every_diy_printer_use_aluminium/

[8] https://www.youtube.com/watch?v=OgI-rJljayY

[9] https://additive-x.com/blog/7-common-3d-printing-problems-with-solutions

[10] https://www.cnckitchen.com/blog/which-is-the-strongest-3d-printing-extruder

[11] https://jlcmc.com/blog/optimizing-aluminum-extrusion-frames-for-enhanced-3d-printing-accuracy

[12] https://www.robotshop.com/collections/aluminum-extrusions-3d-printers

[13] https://www.yjing-extrusion.com/how-to-build-a-custom-3d-printer-enclosure-with-aluminum-extrusion.html

[14] https://www.reddit.com/r/ender3v2/comments/nznbfr/th3d_aluminum_extruded_issues/

[15] https://www.worthyhardware.com/news/extrusion/plastic-extrusion/

[16] https://www.reddit.com/r/3Dprinting/comments/lbtobl/what_is_the_benefit_of_a_metal_extruder_for_an/

[17] https://www.aliexpress.com/w/wholesale-aluminum-extrusion-3d-printer.html

[18] https://www.youtube.com/watch?v=UtemZqFJ5rY

[19] https://reprap.org/forum/read.php

[20] https://www.3deo.co/featured/metal-3d-printing-processes-metal-extrusion-3d-printing/