Content Menu

● Introduction

● Benefits of Round Aluminum Extrusions

>> Lightweight and Durable Properties

>> Corrosion Resistance and Longevity

>> Versatility in Design and Application

● The Aluminum Extrusion Process

>> Overview of the Extrusion Process

>> Steps Involved in Creating Round Aluminum Profiles

>> Importance of Precision and Tolerances in Manufacturing

● Choosing Custom Aluminum Extrusions

>> Factors to Consider: Diameter, Wall Thickness, Alloy Composition

>> How to Align Extrusions with Project Requirements

>> Examples of Successful Custom Extrusion Projects

● Applications of Round Aluminum Extrusions

>> Common Industries Utilizing Round Extrusions

>> Case Studies of Innovative Uses in Real-World Applications

● Conclusion

● Related Questions

>> 1. What are the main advantages of using round aluminum extrusions?

>> 2. How does the aluminum extrusion process differ for round profiles compared to other shapes?

>> 3. What factors should be considered when selecting a round aluminum extrusion for a project?

>> 4. Can round aluminum extrusions be customized for specific applications?

>> 5. What industries commonly use round aluminum extrusions?

Introduction

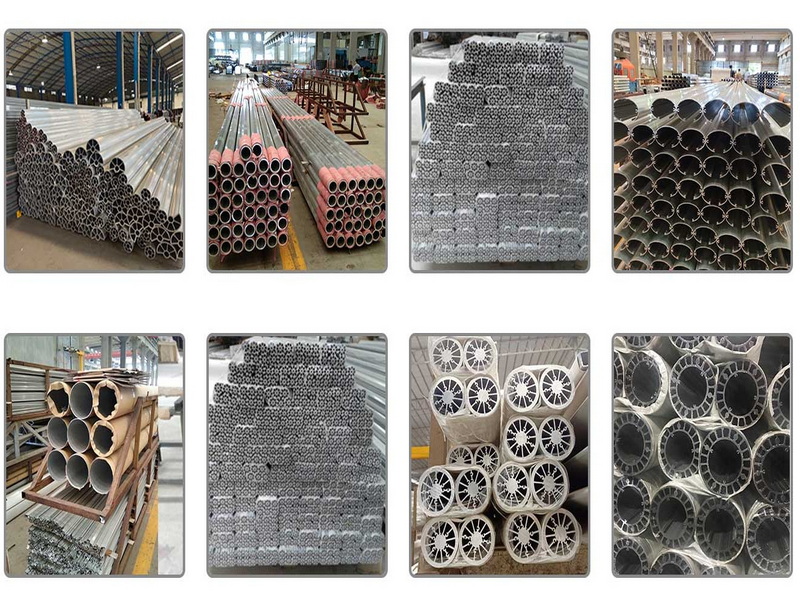

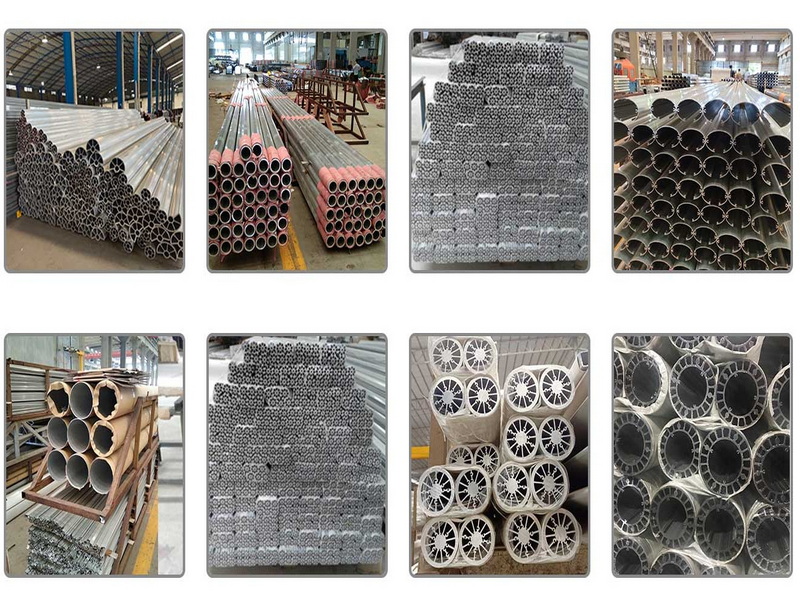

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into desired cross-sectional profiles. This technique is widely used in various industries due to its versatility, efficiency, and the unique properties of aluminum. Among the many shapes produced, round aluminum extrusions are particularly popular for their strength, lightweight nature, and aesthetic appeal. This article delves into the aluminum extrusion process specifically for round profiles, exploring its benefits, applications, and the intricacies involved in creating these essential components.

Benefits of Round Aluminum Extrusions

Round aluminum extrusions offer numerous advantages that make them a preferred choice in many applications.

Lightweight and Durable Properties

One of the most significant benefits of round aluminum extrusions is their lightweight nature. Aluminum is known for its low density, which allows for the production of strong yet lightweight components. This characteristic is particularly advantageous in industries such as aerospace and automotive, where reducing weight can lead to improved fuel efficiency and performance.

Corrosion Resistance and Longevity

Aluminum naturally forms a protective oxide layer when exposed to air, making it highly resistant to corrosion. This property ensures that round aluminum extrusions maintain their integrity and appearance over time, even in harsh environments. As a result, they are ideal for outdoor applications, such as architectural elements and structural components.

Versatility in Design and Application

Round aluminum extrusions can be customized to meet specific design requirements. They can be produced in various diameters, wall thicknesses, and lengths, allowing for a wide range of applications. Whether used in furniture, lighting fixtures, or industrial machinery, the versatility of round aluminum extrusions makes them an essential component in modern manufacturing.

The Aluminum Extrusion Process

The aluminum extrusion process involves several key steps that transform raw aluminum into finished round profiles. Understanding this process is crucial for appreciating the quality and precision of the final product.

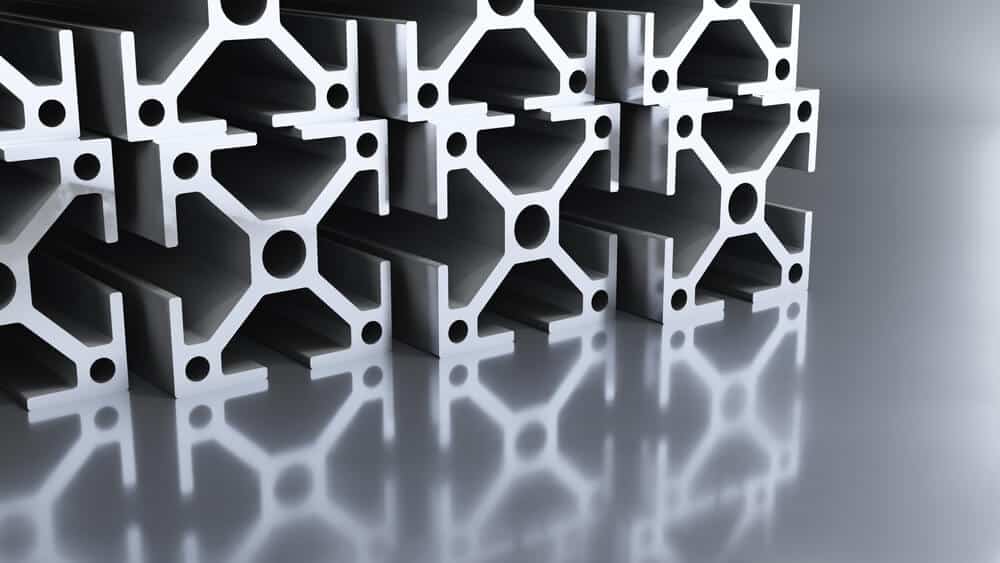

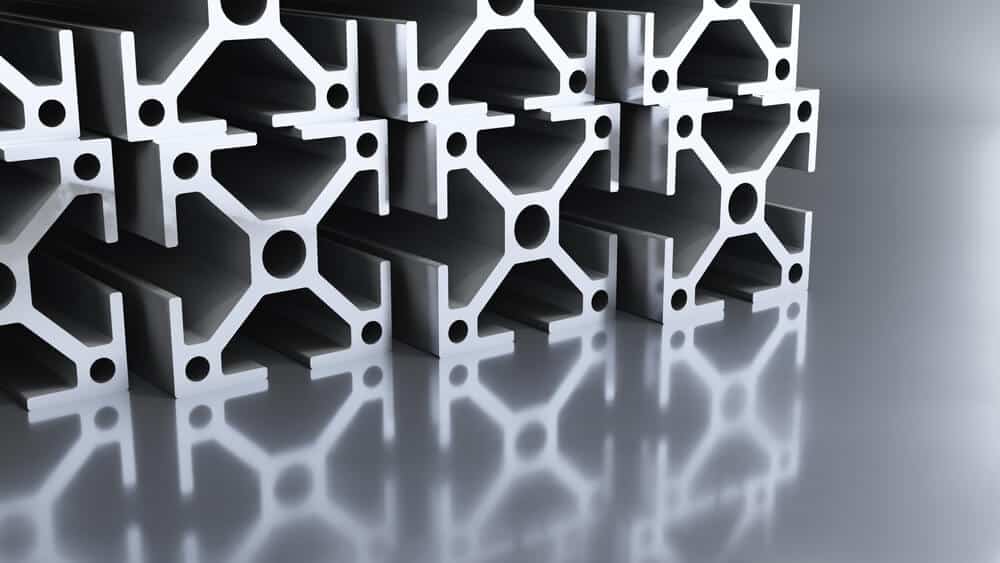

Overview of the Extrusion Process

The extrusion process begins with the selection of aluminum alloy, which is chosen based on the desired properties of the final product. Common alloys used for round aluminum extrusions include 6061 and 6063, known for their excellent mechanical properties and corrosion resistance.

Steps Involved in Creating Round Aluminum Profiles

1. Billet Preparation: The process starts with a cylindrical piece of aluminum known as a billet. The billet is heated to a specific temperature, typically between 400°F and 900°F, depending on the alloy being used. This heating process softens the aluminum, making it easier to shape.

2. Extrusion: Once the billet reaches the desired temperature, it is placed in an extrusion press. A ram pushes the heated billet through a die, which is a specially designed tool that shapes the aluminum into the desired round profile. The extrusion process can be done using either direct or indirect methods, with direct extrusion being the most common for round profiles.

3. Cooling: After the aluminum exits the die, it is rapidly cooled using air or water. This cooling process solidifies the aluminum and helps maintain the shape of the round profile.

4. Cutting and Finishing: Once cooled, the extruded aluminum is cut to the required lengths. Additional finishing processes, such as anodizing or powder coating, may be applied to enhance the appearance and corrosion resistance of the round aluminum extrusions.

Importance of Precision and Tolerances in Manufacturing

Precision is critical in the aluminum extrusion process, especially for round profiles. Manufacturers must adhere to strict tolerances to ensure that the final product meets the specifications required for its intended application. This precision is achieved through careful control of the extrusion parameters, including temperature, pressure, and die design.

Choosing Custom Aluminum Extrusions

When selecting round aluminum extrusions for a project, several factors must be considered to ensure the final product meets the specific requirements.

Factors to Consider: Diameter, Wall Thickness, Alloy Composition

1. Diameter: The diameter of the round aluminum extrusion is a critical factor that affects its strength and application. Larger diameters may be required for structural applications, while smaller diameters may be suitable for decorative elements.

2. Wall Thickness: The wall thickness of the extrusion also plays a significant role in its strength and weight. Thicker walls provide greater strength but may increase the overall weight of the component.

3. Alloy Composition: The choice of aluminum alloy impacts the mechanical properties of the extrusion. Different alloys offer varying levels of strength, corrosion resistance, and workability, making it essential to select the right alloy for the intended application.

How to Align Extrusions with Project Requirements

To ensure that round aluminum extrusions align with project requirements, it is essential to collaborate with experienced manufacturers who can provide guidance on design considerations and material selection. Customization options, such as specific lengths, finishes, and additional features, can also be discussed to meet unique project needs.

Examples of Successful Custom Extrusion Projects

Numerous industries have successfully utilized custom round aluminum extrusions in their projects. For instance, in the automotive industry, manufacturers have developed lightweight structural components that enhance vehicle performance while maintaining safety standards. In the architectural sector, round aluminum extrusions are often used in railings, window frames, and decorative elements, showcasing their versatility and aesthetic appeal.

Applications of Round Aluminum Extrusions

Round aluminum extrusions find applications across various industries due to their unique properties and versatility.

Common Industries Utilizing Round Extrusions

1. Aerospace: In the aerospace industry, round aluminum extrusions are used in aircraft frames, support structures, and fuel lines. Their lightweight nature contributes to improved fuel efficiency and performance.

2. Automotive: Round aluminum extrusions are commonly found in automotive components, such as chassis, suspension systems, and heat exchangers. Their strength and corrosion resistance make them ideal for demanding environments.

3. Construction: In construction, round aluminum extrusions are used in scaffolding, railings, and structural supports. Their durability and resistance to corrosion ensure long-lasting performance in outdoor applications.

4. Furniture: The furniture industry often employs round aluminum extrusions in the design of tables, chairs, and lighting fixtures. Their aesthetic appeal and lightweight nature make them popular choices for modern furniture designs.

5. Industrial Machinery: Round aluminum extrusions are utilized in various industrial machinery applications, including conveyor systems, frames, and supports. Their strength and versatility allow for efficient and reliable operation.

Case Studies of Innovative Uses in Real-World Applications

Several innovative projects have showcased the capabilities of round aluminum extrusions. For example, a leading automotive manufacturer developed a lightweight chassis using custom round aluminum extrusions, resulting in a significant reduction in vehicle weight and improved fuel efficiency. In another instance, an architectural firm designed a stunning outdoor pavilion using round aluminum extrusions, highlighting their aesthetic appeal and structural integrity.

Conclusion

The aluminum extrusion process for round profiles is a sophisticated and versatile manufacturing technique that offers numerous benefits across various industries. From lightweight and durable properties to corrosion resistance and design flexibility, round aluminum extrusions play a crucial role in modern manufacturing. Understanding the intricacies of the extrusion process, along with the factors to consider when selecting custom extrusions, empowers manufacturers and designers to create innovative solutions that meet the demands of their projects.

As industries continue to evolve, the demand for high-quality round aluminum extrusions will only increase. By leveraging the advantages of aluminum and the precision of the extrusion process, manufacturers can develop components that enhance performance, aesthetics, and sustainability.

Related Questions

1. What are the main advantages of using round aluminum extrusions?

Round aluminum extrusions offer lightweight, durable properties, corrosion resistance, and versatility in design, making them ideal for various applications.

2. How does the aluminum extrusion process differ for round profiles compared to other shapes?

The extrusion process for round profiles involves specific die designs and parameters to achieve the desired circular cross-section, while other shapes may require different tooling and techniques.

3. What factors should be considered when selecting a round aluminum extrusion for a project?

Key factors include diameter, wall thickness, alloy composition, and the specific requirements of the application.

4. Can round aluminum extrusions be customized for specific applications?

Yes, round aluminum extrusions can be customized in terms of size, length, finish, and additional features to meet unique project needs.

5. What industries commonly use round aluminum extrusions?

Round aluminum extrusions are widely used in aerospace, automotive, construction, furniture, and industrial machinery industries due to their unique properties and versatility.