Content Menu

● Introduction to Extrusion Machinery

>> Types of Extrusion Machinery

● Evaluating Used Extrusion Machinery

>> 1. Machine Specifications and Compatibility

>> 2. Condition and Age of the Machinery

>> 3. Maintenance and Support

>> 4. Energy Efficiency and Cost Savings

>> 5. Reputation of the Seller

● Quality Control in Extrusion Processes

>> In-line Quality Inspection Methods

>> Automation in Quality Assurance

● Buying Used Extrusion Machinery

>> 1. Define Your Requirements

>> 2. Set Your Budget

>> 3. Inspect the Machinery

>> 4. Work with a Professional

>> 5. Calculate Total Costs

● Common Defects in Extrusion Processes

>> Remedies for Defects

● Industry-Specific Requirements for Extrusion Machinery

>> Material Compatibility

>> Precision and Consistency

>> Energy Efficiency

>> Automation and Control

>> Compliance with Industry Standards

● Maintenance and Operational Considerations

>> Regular Cleaning

>> Routine Inspection

>> Proper Lubrication

>> Temperature Control

>> Training and Safety

>> Scheduled Downtime

● Conclusion

● FAQs

>> 1. What are the key factors to consider when buying used extrusion machinery?

>> 2. How do I inspect used extrusion machinery effectively?

>> 3. What role does automation play in quality assurance for extrusion processes?

>> 4. How important is energy efficiency in extrusion machinery?

>> 5. What are the benefits of purchasing used extrusion machinery?

● Citations:

Evaluating the quality of used extrusion machinery is a critical process that involves several key factors to ensure the equipment meets your production needs and provides a good return on investment. This article will guide you through the steps to assess used extrusion machinery effectively, including understanding the machinery's specifications, inspecting its condition, and considering maintenance and support options.

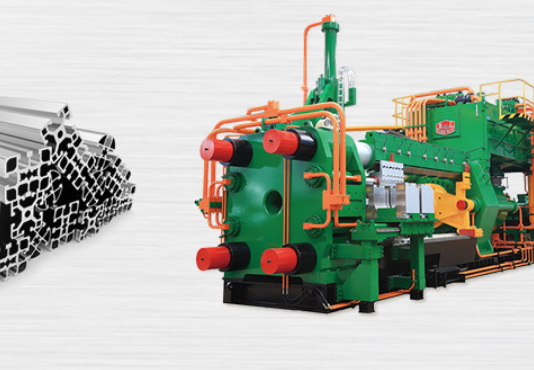

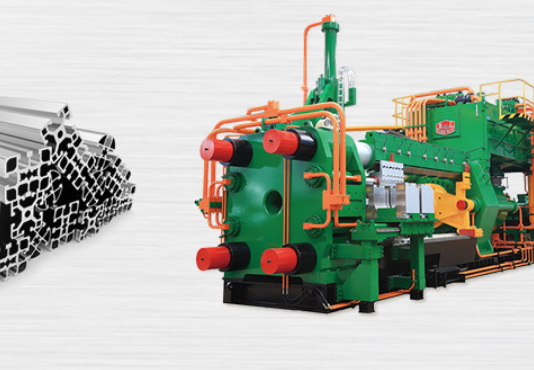

Introduction to Extrusion Machinery

Extrusion machinery is used in various industries, such as plastics, food, and pharmaceuticals, to create products by forcing material through a die to achieve a specific shape. The quality of the machinery directly impacts the quality and consistency of the final product.

Types of Extrusion Machinery

- Single Screw Extruders: These are the most common type, suitable for a wide range of materials.

- Twin Screw Extruders: Offer better mixing and are often used for more complex formulations.

- Profile Extruders: Specialized for creating specific profiles like pipes or window frames.

Evaluating Used Extrusion Machinery

When purchasing used extrusion machinery, several factors must be considered to ensure you are getting a reliable and efficient machine.

1. Machine Specifications and Compatibility

Ensure the machine is compatible with the material you plan to use. Different materials require different types of extrusion machines, considering factors such as melting point and viscosity. For instance, the type of plastic you plan to process determines the kind of extruder you should purchase. High throughput requirements may necessitate an extruder capable of processing large amounts of plastic in a short time[1].

2. Condition and Age of the Machinery

The age and condition of the machine are crucial. Check for signs of wear, maintenance records, and any repairs done. A well-maintained older machine can be more valuable than a newer one that has been neglected. Regular cleaning and inspection of machine parts like dies, screws, and barrels are essential to identify any wear and tear before they lead to significant damage[1].

3. Maintenance and Support

Consider the availability of spare parts and technical support. A reliable supply of spare parts and timely support can significantly reduce downtime and extend the machine's lifespan. Proper lubrication is critical to prevent friction between moving parts, reduce wear and tear, and extend the machine's lifespan[1].

4. Energy Efficiency and Cost Savings

Opt for energy-efficient models to reduce operating costs. Modern extruders often come with advanced control systems and optimized motor drives that can save energy without compromising productivity. Energy efficiency is a significant factor in reducing operating costs and environmental impact[1].

5. Reputation of the Seller

Work with reputable sellers who can provide detailed information about the machine's history and condition. This ensures you are buying from a trustworthy source. Reputable sellers often provide access to a wider range of options and can assist in the inspection process[4].

Quality Control in Extrusion Processes

Quality control is essential in extrusion processes to ensure the final products meet desired standards. This includes monitoring dimensional accuracy, surface finish, and mechanical properties.

In-line Quality Inspection Methods

- Visual Inspection Systems: Use advanced cameras to detect surface defects like cracks or irregularities.

- Ultrasonic Testing: Detects internal flaws or variations in material density.

- Laser Micrometers: Measure product dimensions with high accuracy to ensure they meet tight dimensional tolerances[2].

Automation in Quality Assurance

Automation involves integrating sensors, control systems, and robotic inspection to improve efficiency and accuracy. Automated systems can adjust process parameters in real-time based on sensor inputs, enhancing productivity and consistency[1].

Buying Used Extrusion Machinery

When purchasing used extrusion machinery, consider the following tips:

1. Define Your Requirements

Clearly understand the type of machinery you need and its specifications to optimize your production processes.

2. Set Your Budget

Consider not only the purchase price but also additional costs such as transportation and potential upgrades. The rule of thirds can be applied: one-third for the purchase price, one-third for repairs and upgrades, and one-third as savings compared to buying new[4].

3. Inspect the Machinery

Physically inspect the machine or request a professional evaluation to verify its condition. Check for missing parts, disconnected wires, and ensure all safety features are intact[3].

4. Work with a Professional

Engage with experts who can provide access to a wider range of options and assist in the inspection process.

5. Calculate Total Costs

Include costs for dismantling, transportation, installation, and any necessary upgrades in your budget.

Common Defects in Extrusion Processes

Defects in extrusion can arise from various factors, including improper system engineering, material selection, and processing issues. Common defects include rough surfaces, extruder surging, thickness variations, and uneven wall thickness[5].

Remedies for Defects

- Adjust Die Settings: Ensure proper alignment and uniform heating.

- Screen Raw Materials: Check for impurities and ensure proper mixing of resin and additives.

- Use Proper Temperature and Pressure Controls: Prevent overheating and over-pressurization[5].

Industry-Specific Requirements for Extrusion Machinery

Extrusion machinery must meet specific industry requirements to ensure optimal product quality, machine efficiency, and operational safety.

Material Compatibility

The machinery should be compatible with a variety of materials, from simple plastics like polyethylene to more complex compounds like PVC and ABS[1].

Precision and Consistency

Precise controls for pressure, speed, and temperature are crucial for maintaining output consistency and reducing material waste[1].

Energy Efficiency

High-performance, energy-efficient machines contribute to reduced operating costs and a lesser environmental impact[1].

Automation and Control

Modern extrusion equipment often integrates advanced automation and control systems for enhanced productivity and ease of operation[1].

Compliance with Industry Standards

Ensure the machinery complies with relevant manufacturing standards and safety regulations to ensure a safe working environment and quality assurance[1].

Maintenance and Operational Considerations

To ensure the longevity and optimal performance of extrusion machinery, regular maintenance routines and operational considerations are essential.

Regular Cleaning

Prevents clogging and ensures consistent output by removing residue accumulation[1].

Routine Inspection

Identify wear and tear or potential issues before they lead to significant machinery damage[1].

Proper Lubrication

Prevents friction between moving parts, reducing wear and tear and extending the machine's lifespan[1].

Temperature Control

Maintaining optimal temperature is essential for consistent product quality[1].

Training and Safety

Provide operators with proper training on machinery use and safety procedures to prevent accidents and mishandling[1].

Scheduled Downtime

Plan for comprehensive maintenance and potential repairs without affecting the production schedule[1].

Conclusion

Evaluating the quality of used extrusion machinery requires careful consideration of several factors, including machine specifications, condition, maintenance support, and energy efficiency. By following these guidelines and working with reputable sellers, you can ensure a successful purchase that meets your production needs and provides a good return on investment.

FAQs

1. What are the key factors to consider when buying used extrusion machinery?

When buying used extrusion machinery, consider the machine's age, condition, manufacturer reputation, and availability of spare parts. Also, ensure it meets your production needs and budget.

2. How do I inspect used extrusion machinery effectively?

Inspecting used machinery involves checking for signs of wear, reviewing maintenance records, and testing the machine if possible. Consider hiring a professional for a detailed evaluation.

3. What role does automation play in quality assurance for extrusion processes?

Automation in extrusion processes involves using sensors and control systems to monitor and adjust process parameters in real-time, improving efficiency and reducing human error.

4. How important is energy efficiency in extrusion machinery?

Energy efficiency is crucial as it reduces operating costs and aligns with sustainability goals. Modern extruders often feature advanced control systems and optimized motor drives to achieve this.

5. What are the benefits of purchasing used extrusion machinery?

Purchasing used extrusion machinery can be cost-effective, offers quicker availability compared to new machines, and can provide access to high-quality equipment from reputable brands.

Citations:

[1] https://jieyatwinscrew.com/blog/exploring-extrusion-equipment/

[2] https://www.la-plastic.com/post/what-is-the-quality-control-of-extrusion-process

[3] https://plastiwin.com/uncategorized/plastics-machinery-inspection-purchase-checklist/

[4] https://www.plasticstoday.com/extrusion-pipe-profile/extrusion-basics-how-much-do-you-love-me-evaluating-a-used-extrusion-line

[5] https://www.ijmerr.com/v3n3/ijmerr_v3n3_25.pdf

[6] https://www.machinerylubrication.com/Read/31915/machine-inspections

[7] https://drts.com/what-to-look-for-extruder-machine/

[8] https://satimaco.wixsite.com/satimaco/post/aluminum-extrusion-machine-maintenance-tips-for-peak-performance

[9] https://jieyatwinscrew.com/blog/the-ultimate-guide-to-plastic-extruder-machines/

[10] https://www.cowellextrusion.com/key-factors-influencing-pvc-compound-quality-in-extrusion/

[11] https://plasticextrusiontech.net/quality-control-and-testing-procedures-in-plastic-extrusions/

[12] https://cfaminternational.com/what-to-look-for-when-buying-an-extrusion-machine/

[13] https://www.wirecablemakingmachine.com/news/what-are-the-factors-that-affect-the-extrusion-quality-and-efficiency-of-cable-extrusion-machines.html

[14] https://www.cowinextrusion.com/tips-for-operating-and-debugging-the-extruder/

[15] https://www.cowinextrusion.com/all-about-plastic-extrusion-and-helpful-tips-for-buying-extruder-machinery/

[16] https://www.lesunscrew.com/the-main-factors-affecting-plasticizing-quality-of-extruder-screw.html

[17] https://jydjx.com/effective-maintenance-strategies-for-plastic-extrusion-machines/

[18] https://www.globalspec.com/learnmore/manufacturing_process_equipment/manufacturing_equipment_components/extrusion_machines

[19] https://www.linkedin.com/pulse/factors-affecting-extrusion-grace-gao

[20] https://www.yankangmachine.com/quality-of-the-extrusion-blow-molding-parison/