Content Menu

● Understanding Aluminum Extrusions

● Benefits of Custom Cut Aluminum Extrusions

>> Design Flexibility

>> Lightweight and Durable

>> Cost-Effectiveness

>> Aesthetic Appeal

>> Sustainability

● Applications of Custom Aluminum Extrusions

>> Automotive

>> Construction

>> Electronics

>> Furniture

● Enhancing Product Design with Custom Aluminum Extrusions

>> Innovative Shapes

>> Integration of Components

>> Improved Performance

>> Brand Identity

>> Collaboration with Designers

● Case Studies: Successful Implementations

>> Automotive Industry

>> Architectural Applications

>> Consumer Electronics

● Conclusion

● Frequently Asked Questions

>> 1. What are the main advantages of using custom aluminum extrusions?

>> 2. In which industries are custom aluminum extrusions commonly used?

>> 3. How do custom extrusions contribute to sustainability?

>> 4. Can custom aluminum extrusions be finished in different ways?

>> 5. How can collaboration with designers improve the extrusion process?

Understanding Aluminum Extrusions

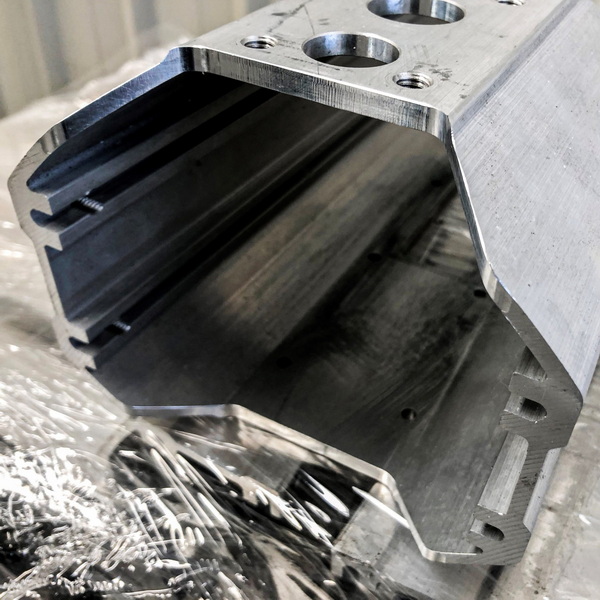

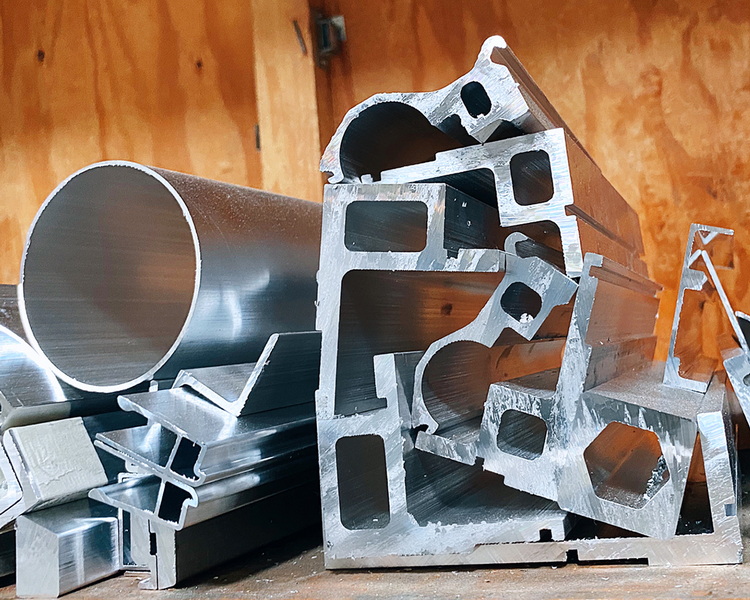

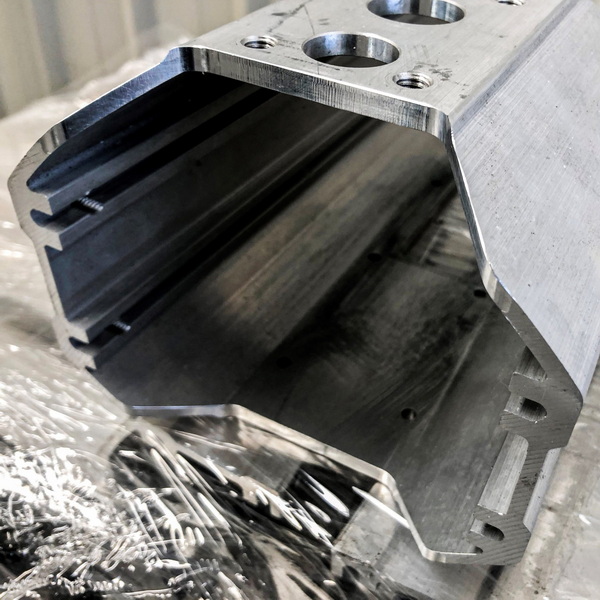

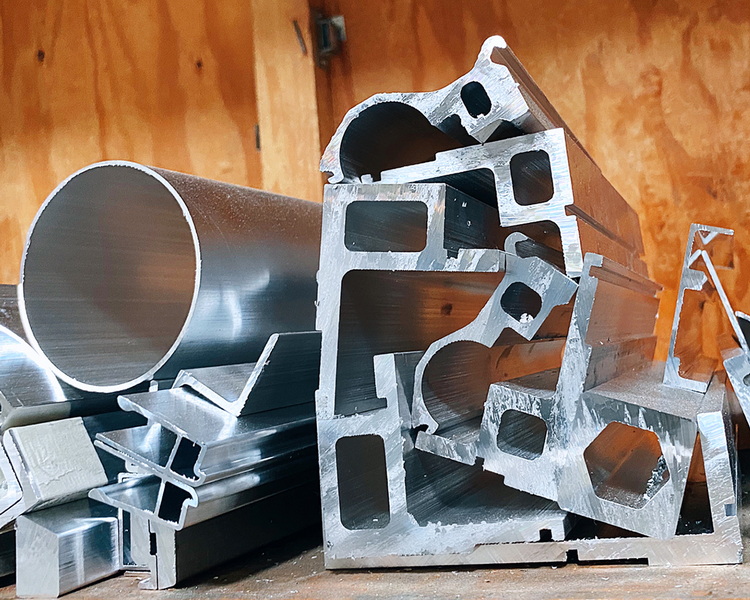

Aluminum extrusion is a process that involves shaping aluminum alloy into a desired cross-sectional profile. This is achieved by forcing the aluminum through a die, which gives it a specific shape. The resulting extrusions can be cut to length, allowing for customization in various applications. The process is not only efficient but also cost-effective, making it a popular choice for manufacturers.

Benefits of Custom Cut Aluminum Extrusions

Design Flexibility

One of the most significant advantages of custom aluminum extrusions is their design flexibility. Designers can create intricate shapes and profiles that meet specific functional and aesthetic requirements. This capability allows for innovative product development, enabling companies to stand out in competitive markets. For instance, a manufacturer can design a unique profile that integrates multiple functions, such as housing for electrical components and structural support, all in one piece.

Lightweight and Durable

Aluminum is known for its lightweight properties, which make it easier to handle and transport. Despite its lightness, aluminum is also incredibly strong and durable, making it suitable for a wide range of applications, from automotive parts to architectural elements. This combination of strength and weight is particularly beneficial in industries where performance and efficiency are critical.

Cost-Effectiveness

Custom aluminum extrusions can reduce manufacturing costs by minimizing waste and optimizing material usage. The ability to create complex shapes in a single extrusion reduces the need for additional components, streamlining the production process. Additionally, the long lifespan of aluminum products means that companies can save on replacement and maintenance costs over time.

Aesthetic Appeal

Aluminum extrusions can be finished in various ways, including anodizing, painting, and powder coating. These finishes not only enhance the appearance of the product but also provide additional protection against corrosion and wear. The ability to customize the finish allows manufacturers to align their products with brand identity and consumer preferences, making them more appealing in the marketplace.

Sustainability

Aluminum is a highly recyclable material, making it an environmentally friendly choice for manufacturers. Using custom extrusions can contribute to sustainability goals by reducing waste and promoting the use of recycled materials. Many companies are now prioritizing sustainable practices, and utilizing aluminum extrusions is a step towards achieving those objectives.

Applications of Custom Aluminum Extrusions

Custom aluminum extrusions are used in a wide array of industries, including:

Automotive

In the automotive industry, lightweight aluminum components improve fuel efficiency and performance. Custom extrusions can be used for various parts, including frames, body panels, and structural supports. The reduction in weight not only enhances vehicle performance but also contributes to lower emissions, aligning with global sustainability goals.

Construction

Custom extrusions are used in window frames, curtain walls, and structural supports in construction. The ability to create complex shapes allows architects and builders to design innovative structures that are both functional and visually appealing. Aluminum's resistance to corrosion makes it an ideal choice for outdoor applications, ensuring longevity and durability.

Electronics

In the electronics sector, heat sinks and enclosures made from aluminum extrusions help dissipate heat and protect sensitive components. Custom profiles can be designed to optimize airflow and cooling efficiency, which is crucial for maintaining the performance and reliability of electronic devices.

Furniture

Innovative designs in furniture can be achieved using custom aluminum profiles, enhancing both functionality and aesthetics. Aluminum's lightweight nature allows for easy mobility, making it a popular choice for modern furniture designs. Additionally, the ability to customize finishes means that furniture can be tailored to fit various interior styles.

Enhancing Product Design with Custom Aluminum Extrusions

Innovative Shapes

Custom extrusions allow designers to create unique shapes that can enhance the functionality of a product. For example, a custom profile can incorporate features such as channels for wiring or mounting points for accessories. This level of customization enables manufacturers to develop products that are not only functional but also tailored to specific user needs.

Integration of Components

By designing a single extrusion that incorporates multiple functions, manufacturers can simplify assembly and reduce the number of parts needed. This not only saves time but also reduces the potential for errors during assembly. For instance, a single aluminum extrusion can serve as both a structural support and a housing for electrical components, streamlining the manufacturing process.

Improved Performance

Custom extrusions can be designed to optimize performance characteristics, such as strength-to-weight ratios or thermal conductivity. This is particularly important in industries like aerospace and automotive, where performance is critical. By utilizing advanced design software, engineers can simulate and test various profiles to ensure optimal performance before production.

Brand Identity

Unique aluminum profiles can help establish a brand's identity. Custom designs can reflect a company's values and aesthetics, making products more recognizable and appealing to consumers. This branding aspect is crucial in competitive markets, where differentiation can lead to increased market share.

Collaboration with Designers

Working closely with designers during the extrusion process can lead to innovative solutions that meet specific design challenges. This collaboration can result in products that are not only functional but also visually striking. Manufacturers that foster strong relationships with designers often find that they can push the boundaries of what is possible with aluminum extrusions.

Case Studies: Successful Implementations

Automotive Industry

A leading automotive manufacturer utilized custom aluminum extrusions to create lightweight chassis components, resulting in a significant reduction in vehicle weight and improved fuel efficiency. This innovation not only enhanced the vehicle's performance but also contributed to the company's sustainability goals by lowering emissions.

Architectural Applications

An architectural firm designed a unique facade for a commercial building using custom aluminum extrusions, allowing for intricate patterns that enhanced the building's aesthetic appeal while providing structural support. The use of aluminum not only met the design requirements but also ensured durability and low maintenance.

Consumer Electronics

A tech company developed a new line of laptops with custom aluminum enclosures that provided durability and a sleek, modern look that appealed to consumers. The custom extrusions allowed for better heat dissipation, improving the overall performance of the devices.

Conclusion

Custom cut aluminum extrusions offer a multitude of benefits that can significantly enhance product design. Their versatility, lightweight nature, and aesthetic appeal make them an ideal choice for manufacturers across various industries. By leveraging the unique properties of aluminum extrusions, companies can innovate, reduce costs, and create products that stand out in the marketplace.

Frequently Asked Questions

1. What are the main advantages of using custom aluminum extrusions?

Custom aluminum extrusions provide design flexibility, lightweight durability, cost-effectiveness, aesthetic appeal, and sustainability.

2. In which industries are custom aluminum extrusions commonly used?

They are widely used in automotive, construction, electronics, and furniture industries.

3. How do custom extrusions contribute to sustainability?

Aluminum is highly recyclable, and using custom extrusions can reduce waste and promote the use of recycled materials.

4. Can custom aluminum extrusions be finished in different ways?

Yes, they can be anodized, painted, or powder-coated to enhance appearance and provide protection.

5. How can collaboration with designers improve the extrusion process?

Collaboration can lead to innovative solutions that address specific design challenges, resulting in functional and visually appealing products.