Content Menu

● Introduction

● Benefits of Refurbished Extrusion Machinery

● Key Factors to Consider When Buying Refurbished Extrusion Machinery

>> Machine Condition and Inspection

>> Screw Design and Barrel Specifications

>> Temperature Control Systems

>> Brand Reputation and Manufacturer Support

>> Energy Efficiency and Operational Costs

>> Control Systems and Automation

>> Spare Parts Availability and Maintenance

>> Safety and Regulatory Compliance

>> Documentation and Machine History

>> Seller Credibility and Warranty

● Comparing New vs. Refurbished Extrusion Machinery

● Common Mistakes to Avoid

● Where to Find Quality Refurbished Extrusion Machinery

● Conclusion

● FAQ

>> 1. What are the key factors to consider when buying refurbished extrusion machinery?

>> 2. How can I ensure the safety of refurbished extrusion machinery?

>> 3. What are the benefits of buying refurbished extrusion machinery?

>> 4. What common mistakes should I avoid when purchasing refurbished extrusion machinery?

>> 5. Where can I find quality refurbished extrusion machinery for sale?

● Citations:

Purchasing refurbished extrusion machinery is a strategic decision that can significantly impact the productivity, efficiency, and profitability of your manufacturing operations. While new extrusion equipment offers the latest technology and reliability, refurbished machinery provides a cost-effective alternative, often with shorter lead times and environmental benefits. However, the process of selecting the right refurbished extrusion machinery requires careful evaluation of technical, operational, and financial factors. This comprehensive guide explores what to look for when purchasing refurbished extrusion machinery, helping you make an informed investment that aligns with your production goals.

Introduction

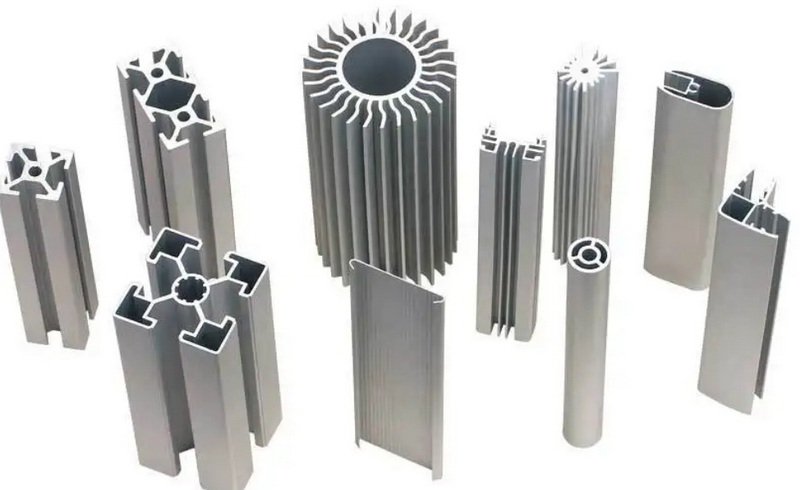

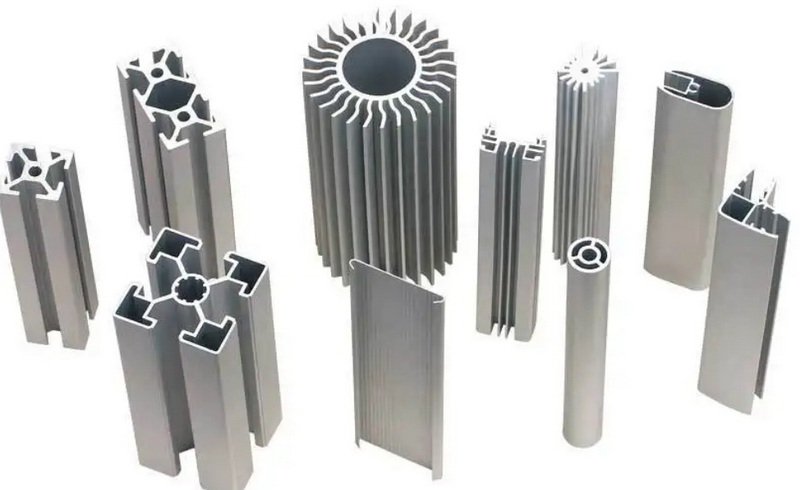

Extrusion machinery is the backbone of many manufacturing sectors, from plastics and rubber to food and pharmaceuticals. As capital equipment, extruders represent a significant investment. For many businesses, especially those seeking to optimize costs or expand capacity quickly, refurbished extrusion machinery offers a compelling alternative to new equipment. However, the used machinery market is diverse, and not all refurbished extruders are created equal. Understanding what to look for is essential to ensure your investment delivers value, reliability, and compliance.

Benefits of Refurbished Extrusion Machinery

Cost Savings

Refurbished extrusion machinery typically costs significantly less than new equipment, making it an attractive option for companies with budget constraints or those looking to maximize return on investment[5][2].

Environmental Sustainability

Reusing existing machinery reduces waste and minimizes the environmental impact associated with manufacturing new equipment[5].

Shorter Lead Times

Refurbished machines are often available for immediate purchase and installation, whereas new machines may have extended delivery times[2].

Proven Reliability

Well-maintained refurbished extrusion machinery can offer years of reliable service, especially when sourced from reputable dealers or directly from manufacturers' certified refurbishment programs[1][5].

Key Factors to Consider When Buying Refurbished Extrusion Machinery

Machine Condition and Inspection

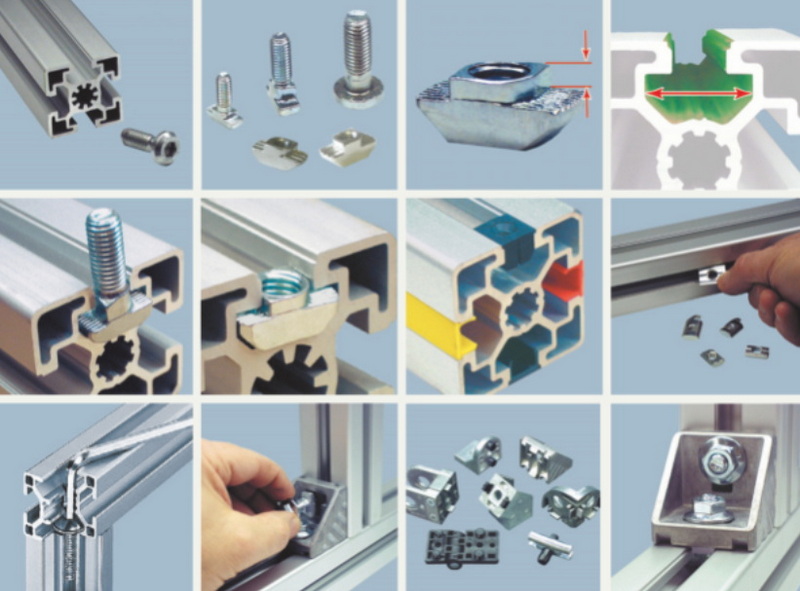

- Physical Inspection: Always physically inspect the machine before purchase. Look for signs of wear, rust, damage, or missing components. A thorough inspection can reveal issues that may not be evident in documentation or photos[3][5][7].

- Operating Hours: Check the number of hours the machine has operated. While high hours may indicate wear, a well-maintained machine can still offer good value[7].

- Maintenance Records: Review the machine's maintenance history to assess how well it has been cared for. Regular servicing and documented repairs are positive indicators[5][7].

- Testing: If possible, see the machine in operation or request a demonstration to verify its performance and output quality[3][6].

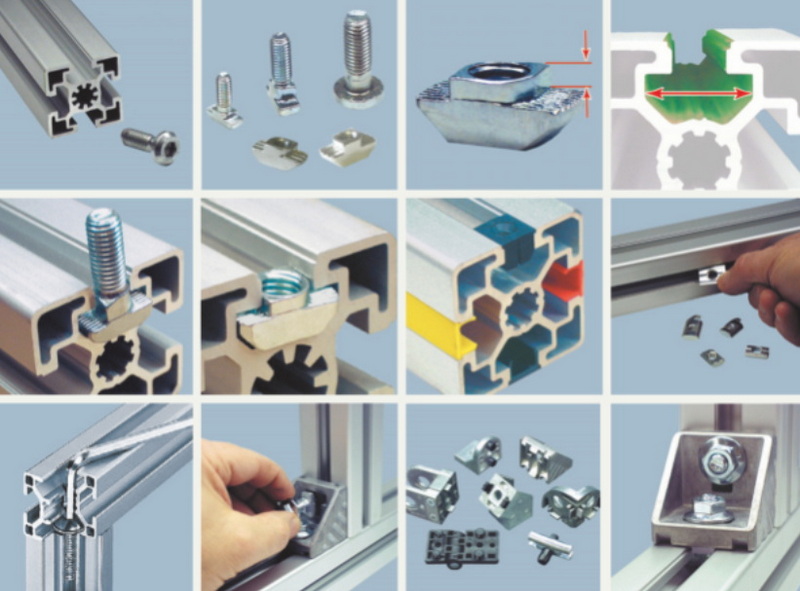

Screw Design and Barrel Specifications

- Screw Diameter and Length: These parameters directly affect throughput, mixing, and the types of products you can manufacture. Larger diameters generally allow for higher output, while the length-to-diameter (L/D) ratio influences residence time and mixing efficiency[4][5].

- Screw Condition: Inspect the screw for wear, corrosion, or damage. The screw is a critical component, and its condition affects product quality and machine efficiency[2][4].

- Barrel Condition: Check for scoring, wear, or deformation. The barrel's integrity is essential for consistent processing and temperature control[5].

Temperature Control Systems

- Heating and Cooling: Efficient temperature control is crucial for product quality and process stability. Assess the type, placement, and condition of heating elements and cooling systems[4][5].

- Accuracy: Refurbished machines may have less precise temperature control than new models. Verify that the system meets your process requirements[2].

Brand Reputation and Manufacturer Support

- Manufacturer Reputation: Established brands are more likely to offer reliable machines and better after-sales support. Research the manufacturer's history, customer reviews, and industry certifications[1][7].

- Spare Parts Availability: Ensure that spare parts are readily available, especially for older or less common models. This will reduce downtime and simplify maintenance[1][7].

Energy Efficiency and Operational Costs

- Power Consumption: Refurbished extrusion machinery may not be as energy-efficient as new models. Compare energy usage per kilogram of material processed and assess the impact on your operational costs[1][2].

- Maintenance Costs: Older machines may require more frequent maintenance and have higher associated costs. Factor this into your total cost of ownership calculations[2][5].

Control Systems and Automation

- Control Interface: Modern control systems offer better process management, monitoring, and automation. Check whether the refurbished machine has user-friendly controls and programmable settings[4].

- Upgradability: Assess whether the control system can be upgraded or integrated with your existing production line or factory automation systems[2].

Spare Parts Availability and Maintenance

- Parts Inventory: Confirm the availability and cost of spare parts. Some refurbished machines may use obsolete components, making replacements difficult or expensive[1][7].

- Service Support: Determine whether the seller or manufacturer offers maintenance services, technical support, or service agreements[1][5].

Safety and Regulatory Compliance

- Safety Standards: Ensure the machine complies with current safety regulations, such as CE Marking, NFPA 79, or other relevant standards for your industry and region[2][5].

- Inspection and Certification: Request third-party inspection reports or certifications that validate the machine's safety and operational integrity[2].

Documentation and Machine History

- Service Records: Review all available documentation, including service logs, repair records, and original manuals[5][7].

- Refurbishment Report: Request a detailed report outlining what components were replaced or upgraded during refurbishment[2].

Seller Credibility and Warranty

- Reputation: Work with reputable dealers or certified refurbishers. Request references and check their track record in the industry[3][5][7].

- Written Agreements: Ensure all terms, specifications, and warranties are clearly documented in writing before finalizing the purchase[3].

- Warranty: While refurbished extrusion machinery may have limited warranties compared to new equipment, some sellers offer short-term coverage on major components[2].

Comparing New vs. Refurbished Extrusion Machinery

| Factor |

New Extrusion Machinery |

Refurbished Extrusion Machinery |

| Initial Cost |

High ($450,000–$800,000) |

Lower ($180,000–$350,000)2 |

| Lead Time |

14–18 weeks |

6–8 weeks2 |

| Warranty |

3–5 years full coverage |

6–12 months limited2 |

| Energy Efficiency |

18–22 kWh/kg |

28–35 kWh/kg2 |

| Output Consistency |

±0.8% |

±2.5%2 |

| Uptime |

96.5% |

89.2%2 |

| Maintenance Cost (1–3 yrs) |

$8,000/year |

$18,000/year2 |

| Resale Value Retention |

45–50% |

15–20%2 |

While refurbished extrusion machinery offers significant savings and faster deployment, it may entail higher maintenance costs, lower energy efficiency, and shorter warranties. A thorough total cost of ownership (TCO) analysis is essential to determine the best option for your business[2].

Common Mistakes to Avoid

- Skipping Inspection: Never buy refurbished extrusion machinery without a thorough inspection or demonstration[3][5].

- Ignoring Machine History: Always review maintenance and refurbishment records to avoid hidden issues[5].

- Not Considering Operational Costs: Factor in energy consumption, maintenance, and spare parts availability when calculating total cost[2][5].

- Overlooking Safety Compliance: Ensure the machine meets current safety standards to avoid legal and operational risks[2][5].

- Failing to Verify Seller Credibility: Work only with reputable dealers or certified refurbishers, and get all agreements in writing[3][7].

Where to Find Quality Refurbished Extrusion Machinery

- Online Marketplaces: Platforms like Machineseeker, Used-Machines, and MachineryTrader offer extensive listings of refurbished extrusion machinery[5].

- Industry Auctions: Participate in auctions for potential deals on high-quality equipment[5].

- Reputable Dealers: Established machinery dealers often provide warranties, service agreements, and after-sales support[3][5].

- Trade Shows: Attend industry trade shows to inspect machines firsthand and network with sellers[5].

- Networking: Engage with industry forums, associations, and professionals for leads on available equipment[5].

Conclusion

Purchasing refurbished extrusion machinery can be a smart, cost-effective way to expand or update your production capabilities. However, it requires careful consideration of machine condition, technical specifications, operational costs, safety compliance, and seller reputation. By conducting thorough inspections, reviewing documentation, and working with reputable partners, you can mitigate risks and secure a machine that delivers reliable performance and value. Always balance the immediate savings against long-term operational costs and ensure the equipment aligns with your production requirements and safety standards.

FAQ

1. What are the key factors to consider when buying refurbished extrusion machinery?

Evaluate the machine's physical condition, screw and barrel specifications, temperature control systems, brand reputation, energy efficiency, control systems, spare parts availability, safety compliance, documentation, and the seller's credibility. Always inspect the machine and review maintenance records before purchase[5][4][7].

2. How can I ensure the safety of refurbished extrusion machinery?

Conduct a thorough inspection, verify compliance with current safety standards (such as CE Marking or NFPA 79), and request third-party inspection or certification reports. Ensure the machine has up-to-date safety features and that spare parts for critical safety components are available[2][5].

3. What are the benefits of buying refurbished extrusion machinery?

Refurbished extrusion machinery offers significant cost savings, environmental benefits through equipment reuse, and shorter lead times compared to new machines. When sourced from reputable dealers, refurbished machines can provide reliable performance and fast deployment[5][2].

4. What common mistakes should I avoid when purchasing refurbished extrusion machinery?

Avoid skipping inspections, neglecting to review maintenance and refurbishment records, underestimating operational costs, overlooking safety compliance, and failing to verify the seller's reputation. Always get all agreements and warranties in writing[3][5][7].

5. Where can I find quality refurbished extrusion machinery for sale?

Quality refurbished extrusion machinery can be found on online marketplaces (Machineseeker, Used-Machines), through industry auctions, reputable equipment dealers, trade shows, and by networking with industry professionals and associations[5].

Citations:

[1] https://www.linkedin.com/pulse/key-buying-pipe-extrusion-machinery-important-factors-nader-amin

[2] https://ptfe-machinery.com/new-vs-refurbished-ptfe-equipment-total-cost-of-ownership-analysis-expert-guide/

[3] https://www.plastimach.com/blog/778-tips-on-buying-a-used-machine

[4] https://surplusrecord.com/buying-guides/extruders/

[5] https://www.yjing-extrusion.com/is-it-safe-to-buy-used-extrusion-equipment-for-industrial-applications.html

[6] https://www.plasticstoday.com/extrusion-pipe-profile/tips-for-buying-a-new-or-not-so-new-extrusion-line

[7] https://presse.surplex.com/pressreleases/how-to-find-the-right-used-machine-what-to-consider-when-buying-3319879

[8] https://cfaminternational.com/what-to-look-for-when-buying-an-extrusion-machine/

[9] https://www.arlingtonmachinery.com/blog/p.220602001/top-5-questions-to-ask-when-purchasing-used-plastics-machinery/

[10] https://www.cowinextrusion.com/all-about-plastic-extrusion-and-helpful-tips-for-buying-extruder-machinery/

[11] https://jydjx.com/how-to-choose-a-extrusion-machine/

[12] https://extruderpress.com/faqs/

[13] https://www.leadertw.com/faq.htm

[14] https://www.packworld.com/trends/contract-packaging/article/13339553/10-questions-to-ask-when-purchasing-machinery

[15] https://www.won-plus.com/blog/extrusion-technology-related-questions-and-answers_b40

[16] https://www.linkedin.com/pulse/frequently-asked-questions-plastic-recycling

[17] https://plastiwin.com/uncategorized/how-to-buy-plastic-extrusion-equipment/

[18] https://www.triplepundit.com/story/2015/your-questions-about-refurbished-electronics-answered/31316

[19] https://www.seagateplastics.com/frequently-asked-questions/

[20] https://www.linkedin.com/pulse/part-4-haul-off-key-buying-pipe-extrusion-machinery-nader-amin

[21] https://www.ingrammicrolifecycle.com/blog/myths-of-buying-refurbished-technology

[22] https://www.plastar-machine.com/en/news/faq.html

[23] https://www.plasticstoday.com/extrusion-pipe-profile/tips-for-buying-a-new-or-not-so-new-extrusion-line

[24] https://www.polystarco.com/blog-detail/frequently-asked-questions-about-blown-film-machines/

[25] https://www.adremac.com/complete-guide-to-pipe-extrusion-machinery-equipment-and-advanced-cutting-solutions/